ASTM D7340-07(2023)

(Practice)Standard Practice for Thermal Conductivity of Leather

Standard Practice for Thermal Conductivity of Leather

SIGNIFICANCE AND USE

5.1 Part of the function of a shoe is to assist the foot in maintaining body temperature and to guard against large heat changes. The insulating property of a material used in shoe construction is dependent on porosity or the amount of air spaces present. A good insulating material has a low thermal conductivity value, k. The thermal conductivity value increases with an increase in moisture content since the k value for water is high, 0.0014 cal/s cm · °C (0.59 W/m·K).

SCOPE

1.1 This practice is intended to determine the thermal conductivity of a sheet material. This practice is not limited to leather, but may be used for any poorly conductive material such as rubber, textile and cork associated with the construction of shoes.

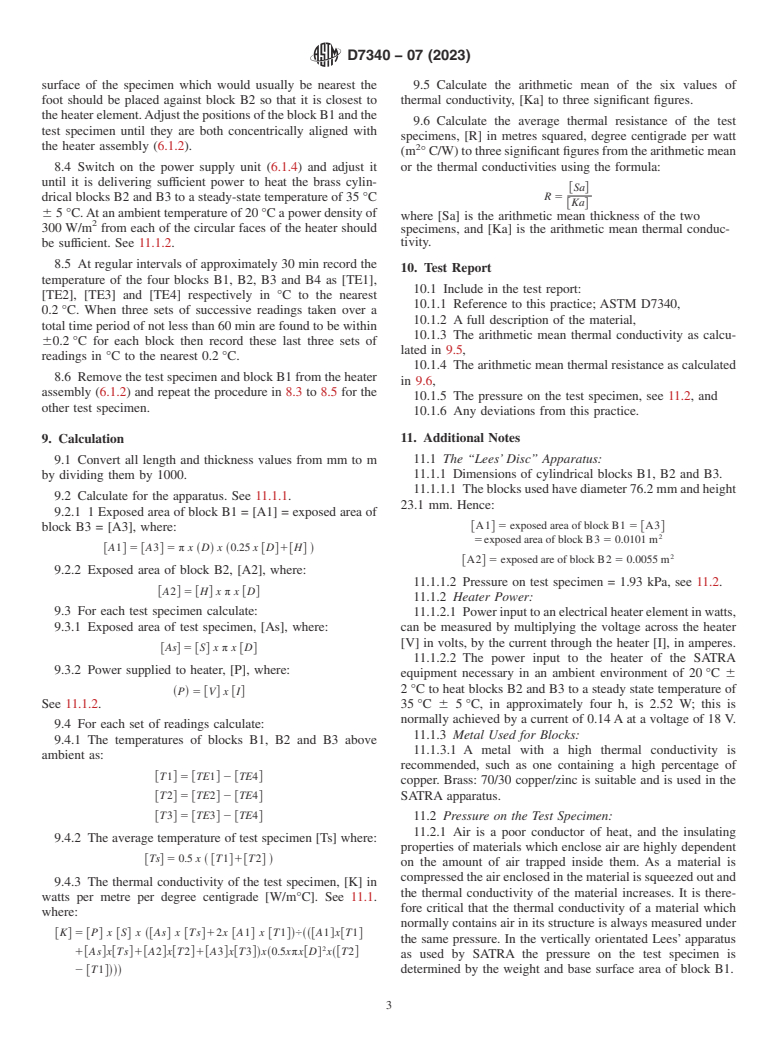

1.2 A constant heat source is sandwiched between two identical metal cylinders which are mounted with their axes vertical. A test specimen is placed on the top surface of the upper cylinder and a third identical metal cylinder is placed on top of the test specimen so that all the cylinders and the test specimen are concentrically aligned (see Fig. 1). The heat source is switched on and the temperatures of the three blocks allowed to reach equilibrium. The thermal conductivity of the test specimen is then determined from the steady-state temperatures of the three blocks, the exposed surface areas of the blocks and test specimen and the thickness of the test specimen.

FIG. 1 SATRA Lees' Disc Thermal Conductivity Apparatus

1.3 This practice does not apply to wet blue.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7340 − 07 (Reapproved 2023)

Standard Practice for

Thermal Conductivity of Leather

This standard is issued under the fixed designation D7340; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1610 Practice for Conditioning Leather and Leather Prod-

ucts for Testing

1.1 This practice is intended to determine the thermal

D1813 Test Method for Measuring Thickness of Leather

conductivity of a sheet material. This practice is not limited to

Test Specimens

leather, but may be used for any poorly conductive material

2.2 Other Standard:

such as rubber, textile and cork associated with the construc-

SATRA TM 146 Thermal Conductivity

tion of shoes.

1.2 A constant heat source is sandwiched between two 3. Terminology

identical metal cylinders which are mounted with their axes

3.1 Definitions:

vertical. A test specimen is placed on the top surface of the

3.2 thermal conductivity, n—the quantity of heat conducted

upper cylinder and a third identical metal cylinder is placed on

per unit time through unit area of a slab of unit thickness

top of the test specimen so that all the cylinders and the test

having unit temperature difference between its faces.

specimen are concentrically aligned (see Fig. 1). The heat

source is switched on and the temperatures of the three blocks

4. Summary of Practice

allowed to reach equilibrium. The thermal conductivity of the

4.1 A conditioned specimen of leather (see Practice D1610)

test specimen is then determined from the steady-state tem-

is placed between two plates at different temperatures. The

peratures of the three blocks, the exposed surface areas of the

upper plate is at a constant temperature while the temperature

blocks and test specimen and the thickness of the test speci-

of the lower plate is slowly changing. The temperature differ-

men.

ence is measured by thermocouples. The rate of flow of heat

1.3 This practice does not apply to wet blue.

through the specimen is proportional to the area and the

1.4 This standard does not purport to address all of the temperature difference of the faces of the specimen, and

inversely proportional to the thickness. Assuming no heat loss,

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- the amount of heat flowing through the specimen per unit time

priate safety, health, and environmental practices and deter- is equal to the amount of heat received by the lower plate

mine the applicability of regulatory limitations prior to use. (copper block receiver) per unit time.

1.5 This international standard was developed in accor-

5. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5.1 Part of the function of a shoe is to assist the foot in

Development of International Standards, Guides and Recom- maintaining body temperature and to guard against large heat

mendations issued by the World Trade Organization Technical changes. The insulating property of a material used in shoe

Barriers to Trade (TBT) Committee. construction is dependent on porosity or the amount of air

spaces present. A good insulating material has a low thermal

2. Referenced Documents conductivity value, k. The thermal conductivity value increases

2 with an increase in moisture content since the k value for water

2.1 ASTM Standards:

is high, 0.0014 cal/s cm · °C (0.59 W/m·K).

6. Apparatus and Materials

This practice is under the jurisdiction of ASTM Committee D31 on Leather and

6.1 A “Lees’ disc” apparatus, see Fig. 1, consisting of:

is the direct responsibility of Subcommittee D31.03 on Footwear.

6.1.1 A metal, see 11.1.2, cylindrical block, which will

Current edition approved Dec. 1, 2023. Published January 2024. Originally

ɛ1

subsequently be referred to as block B1, with:

approved in 2007. Last previous edition approved in 2018 as D7340 – 07 (2018) .

DOI: 10.1520/D7340-23.

6.1.1.1 A diameter of (D), in millimetres, which is known to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

an accuracy of 0.2 mm (see 11.1.1).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.1.2 A height of (H), in millimetres, which is known to an

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. accuracy of 0.2 mm (see 11.2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7340 − 07 (2023)

FIG. 1 SATRA Lees’ Disc Thermal Conductivity Apparatus

6.1.1.3 A small hole of diameter 2 mm 6 1 mm drilled 6.1.7 A device capable of measuring and displaying the

radially to its center. temperatures of the thermocouples in the four brass cylindrical

6.1.1.4 A type K thermocouple inserted into the hole until blocks to an accuracy of 60.2 °C.

its junction is at the bottom of the hole.

6.2 A circular press knife of diameter (D) 6 0.5 mm.

6.1.1.5 The remaining volume of the hole filled with a high

6.3 A dial thickness gauge which applies a pressure of

thermal conductivity compound with a thermal conductivity of

13.86 oz 6 0.35 oz (393 g 6 10 g) on the test specimen and is

better than 0.8 W/(m°C), for example a metal oxide filled paste

capable of measuring to an accuracy of 0.01 mm. This is

of the type used between high power semiconductor electronic

identical to the gauge used in Test Method D1813.

devices and heat sinks.

6.1.2 A circular electrical heater element which:

7. Preparation of Test Specimens

6.1.2.1 Has a diameter of (D) 6 0.5 mm.

7.1 Place the uncut sheet material in a standard controlled

6.1.2.2 Is capable of dissipating a minimum power density

environment of 20 6 2 °C ⁄65 6 2% relative humidity or 23 6

of 400 W/m from each of its circular faces. See 11.1.1.

2 °C ⁄50 6 2% relative humidity or for a minimum of 48 h.

6.1.2.3 Has a cylindrical metal block, see 11.1.3, with

Include details of the conditions used in the test report.

thermocouple as block B1 (6.1.1), of diameter (D) 6 0.5 mm

and of height (H) 6 0.2 mm bonded to its top and bottom faces

7.2 Use the press knife (6.2) to cut two circular test

with a high thermal conductivity adhesive compound. These

specimens of diameter (D) 6 0.5 mm.

two blocks will subsequently be referred to as B2 and B3.

(Warning—Do not attempt to separate these blocks from the

8. Procedure

heater element.)

8.1 Use the thickness gauge (6.3) to measure the thickness

6.1.3 A fourth metal cylindrical block fitted with a thermo-

(S) at the center of each test specimen and record these two

couple as (6.1.1) of diameter (D) 6 0.5 mm and of thickness

values in millimetres to the nearest 0.05 mm.

8 mm 6 2 mm. This is for measuring the ambient temperature

8.2 Ensure that the heater assembly (6.1.2) is mounted

of the surrounding atmosphere and will subsequently be

vertically so that block B2 is above block B3 (see Fig. 1). It

referred to as block B4.

should also be situated in a temperature-controlled environ-

6.1.4 A power supply unit connected to the heater element

ment of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.