ASTM D5635/D5635M-18(2022)

(Test Method)Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens

Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens

SIGNIFICANCE AND USE

5.1 An important factor affecting the performance of membrane roofing systems is their ability to resist dynamic puncture impacts. This test method provides a means to assess dynamic puncture resistance.

5.2 This test method can be used to compare the dynamic puncture resistance of a single type of membrane as a function of a variety of insulation substrates or, conversely, to compare the resistance of a number of membrane specimens set on a single type of insulation.

5.3 The effect of temperature on puncture resistance can be studied by conducting the test under controlled conditions using such equipment as an environmental chamber, oven, or freezer.

5.4 The test method can be useful in developing performance criteria for membrane roofing systems.

5.5 The test method can be useful in developing classifications of dynamic puncture resistance of membrane roofing systems.

5.6 While it is considered that the results obtained by this laboratory test can afford a measure of the dynamic puncture resistance of membrane roofing systems in the field (provided that service loads and temperature conditions are known), no direct correlation has yet been established.

5.7 This test method can be useful for evaluating the dynamic puncture resistance of membranes used in vegetative roof systems.

SCOPE

1.1 This test method covers the evaluation of the dynamic puncture energy that roofing membrane specimens can withstand, without allowing the passage of water, when subjected to impact from a rigid object having a sharp edge.

1.2 This laboratory test can be conducted at any desired temperature using membrane specimens manufactured in a factory or prepared in a laboratory.

1.3 Roof membrane specimens to which the test method is applicable include bituminous built-up, polymer-modified bitumens, vulcanized rubbers, non-vulcanized polymeric, and thermoplastic materials.

1.3.1 The applicability of this test method to these membrane specimens includes their use in vegetative roof systems.

1.4 This test method is not applicable to aggregate-surfaced membrane specimens; however, it is applicable to specimens having factory-applied granules.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5635/D5635M −18 (Reapproved 2022)

Standard Test Method for

Dynamic Puncture Resistance of Roofing Membrane

Specimens

This standard is issued under the fixed designation D5635/D5635M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the evaluation of the dynamic 2.1 ASTM Standards:

puncture energy that roofing membrane specimens can C578 Specification for Rigid, Cellular Polystyrene Thermal

withstand, without allowing the passage of water, when sub- Insulation

jected to impact from a rigid object having a sharp edge. D1079 Terminology Relating to Roofing and Waterproofing

1.2 This laboratory test can be conducted at any desired

3. Terminology

temperature using membrane specimens manufactured in a

factory or prepared in a laboratory. 3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer

1.3 Roof membrane specimens to which the test method is

to Terminology D1079.

applicable include bituminous built-up, polymer-modified

bitumens, vulcanized rubbers, non-vulcanized polymeric, and

4. Summary of Test Method

thermoplastic materials.

4.1 The roofing membrane test specimen, set on a thermal

1.3.1 The applicability of this test method to these mem-

brane specimens includes their use in vegetative roof systems. insulation substrate, is subjected to a predetermined dynamic

impact energy created by a rigid falling puncture head. The

1.4 This test method is not applicable to aggregate-surfaced

head falls through a quarter-circle trajectory from a vertical

membrane specimens; however, it is applicable to specimens

position to horizontal position under gravitational acceleration.

having factory-applied granules.

4.2 The predetermined dynamic puncture energy is selected

1.5 The values stated in either SI units or inch-pound units

as follows:

are to be regarded separately as standard. The values stated in

4.2.1 In accordance with a performance requirement given

each system may not be exact equivalents; therefore, each

in a standard specification in which this test method is cited, or

system shall be used independently of the other. Combining

4.2.2 Through agreement between the party requesting the

values from the two systems may result in nonconformance

test and the testing laboratory.

with the standard.

4.3 Puncture of the test specimen is assessed by visual

1.6 This standard does not purport to address all of the

examination and, if necessary, verified by conducting a water-

safety concerns, if any, associated with its use. It is the

tightness test.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

5. Significance and Use

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

5.1 An important factor affecting the performance of mem-

dance with internationally recognized principles on standard- braneroofingsystemsistheirabilitytoresistdynamicpuncture

ization established in the Decision on Principles for the

impacts. This test method provides a means to assess dynamic

Development of International Standards, Guides and Recom- puncture resistance.

mendations issued by the World Trade Organization Technical

5.2 This test method can be used to compare the dynamic

Barriers to Trade (TBT) Committee.

puncture resistance of a single type of membrane as a function

of a variety of insulation substrates or, conversely, to compare

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

and Waterproofing and is the direct responsibility of Subcommittee D08.20 on

Roofing Membrane Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2022. Published November 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 2018 as D5635/D5635M – 18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5635_D5635M-18R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5635/D5635M − 18 (2022)

the resistance of a number of membrane specimens set on a 0.5 kg [1.1 lb] increments. The mass of the puncture head shall

single type of insulation. be within 60.5 % of that selected.

5.3 The effect of temperature on puncture resistance can be

NOTE 1—It is suggested that the puncture head be fabricated from 1018

studied by conducting the test under controlled conditions mild steel to minimize risk of damage during its use. No matter the metal

from which the puncture head is made, users of the test device should

using such equipment as an environmental chamber, oven, or

periodically examine the puncture head to check that damage has not

freezer.

occurred during use.

5.4 The test method can be useful in developing perfor-

6.1.3 Acounterweight, equivalent to the mass of the falling

mance criteria for membrane roofing systems.

arm, is placed on the arm on the side of the axis of rotation

5.5 The test method can be useful in developing classifica-

opposite to that holding the puncture head. The presence of the

tions of dynamic puncture resistance of membrane roofing

counterweight eliminates the need to include the mass of the

systems.

arm in the determination of the puncture energy.Alternatively,

if a counterweight is not used, then the mass of the arm shall

5.6 While it is considered that the results obtained by this

be included in the determination of the impact energy.

laboratory test can afford a measure of the dynamic puncture

6.1.4 The device shall incorporate a mechanism that allows

resistance of membrane roofing systems in the field (provided

the puncture head to be kept stationary in an upright position,

that service loads and temperature conditions are known), no

forming an angle from the vertical not exceeding 5°. This

direct correlation has yet been established.

mechanism shall allow release of the arm so that it falls freely

5.7 This test method can be useful for evaluating the

without any additional motion imposed.

dynamic puncture resistance of membranes used in vegetative

roof systems. NOTE 2—Avacuum release mechanism has been found suitable for this

purpose.

6. Apparatus

6.1.5 The base of the device, supporting the arm and

6.1 Dynamic Puncture Device—The dynamic puncture de-

puncture head, is placed on a horizontal surface that is

vice consists primarily of a heavy base, a falling arm, and

sufficiently stable. This surface shall not shake, vibrate, or

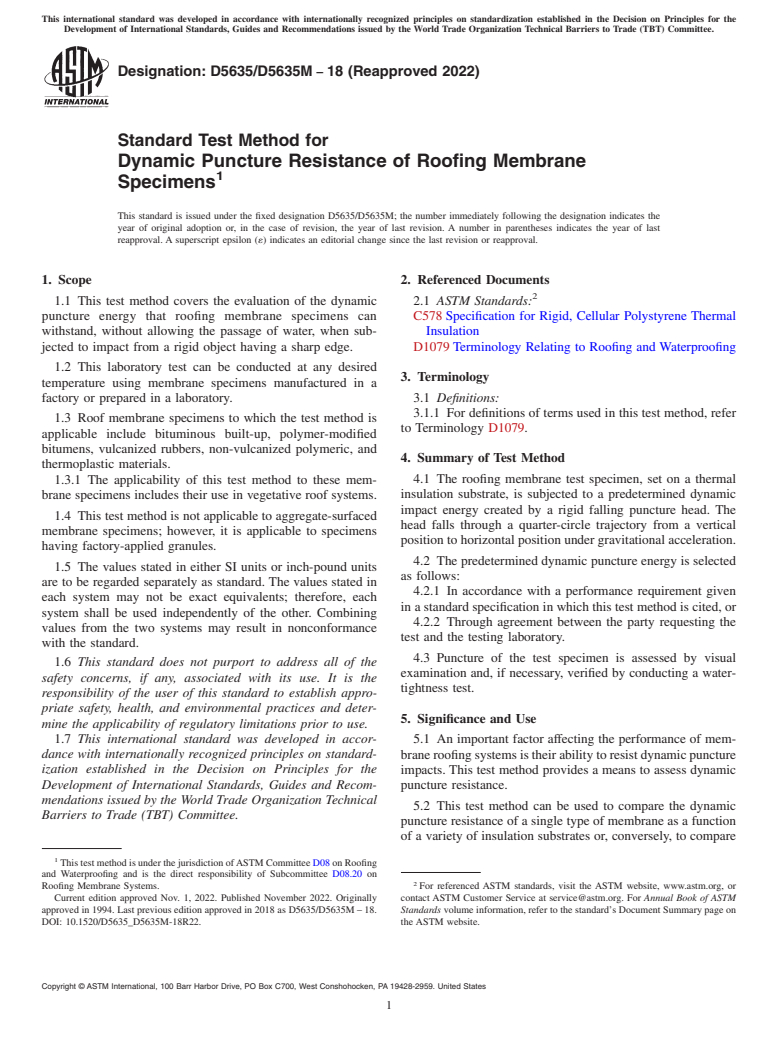

puncture head (see Fig. 1).

otherwisemovewhenthetestisconductedatmaximumimpact

6.1.1 The falling arm is attached to the base so that it can

energy. The arm and puncture head of the dynamic puncture

rotate freely (for example, using ball bearings) from a vertical

device shall be horizontal when the puncture head contacts the

to horizontal position.The length of the arm is sufficiently long

horizontalsurfaceofthetestspecimen(seeFig.1).Heavyrigid

so that the puncture head can be secured to it at a distance that

shims having length and width dimensions larger than those of

is 0.51 m [1.67 ft] 60.5 % from the point of rotation at the

the test specimen and substrate may be used.

base.

6.2 Specimen Frame—A frame, having minimum exterior

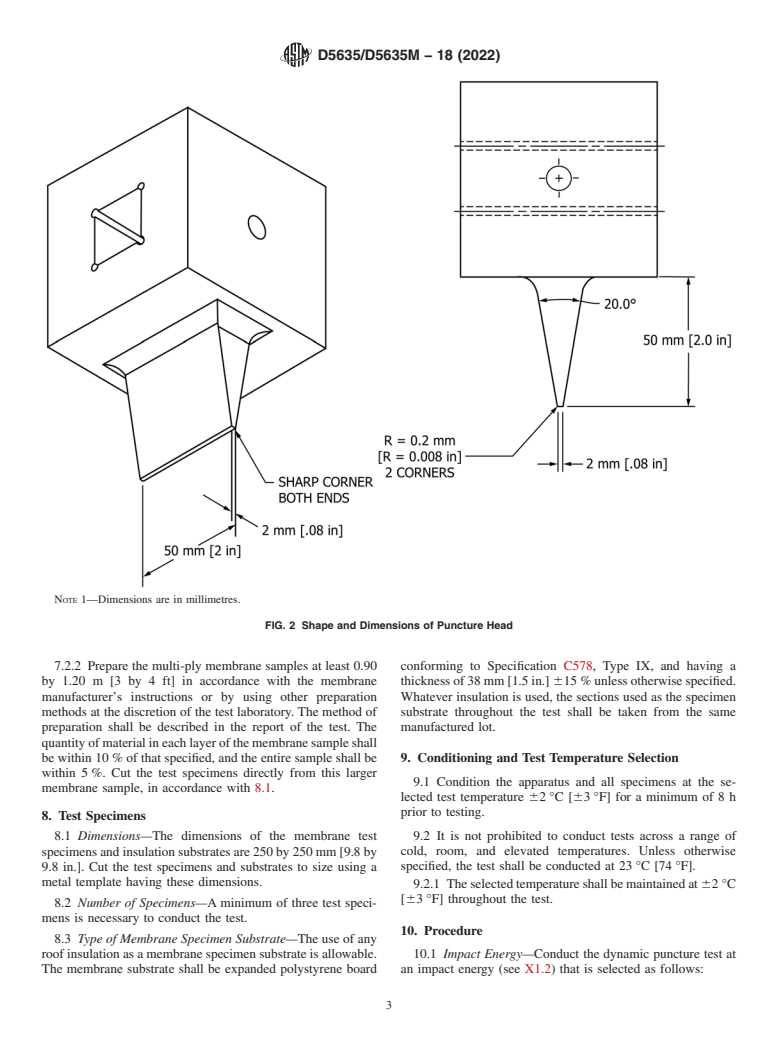

6.1.2 The shape and dimensions of a typical puncture head

and interior dimensions of 250 by 250 mm [9.8 by 9.8 in.] and

are given in Fig. 2. When mounted on the arm, the face of the

200 by 200 mm [7.9 by 7.9 in.], respectively, and a minimum

puncture head is parallel to axis of rotation. Several heads of

massof2.5kg[5.5lb]isusedtoholdthetestspecimeninplace

different masses may be needed. Alternatively, a means for

on the insulation substrate during the test. Adhere medium

adding weights to a given puncture head to increase its mass

abrasive, 60 grit sandpaper to the bottom surface of the

can be used. The head and additional weights shall constitute a

specimen frame.

continuous series of masses from 1 to 10 kg [2.2 to 22 lb] in

NOTE 3—The bottom surface of the frame is that surface which sets on

the specimen. The use of sandpaper assists in securing the specimen

during test. Double-sided adhesive tape has been found suitable for

adhering the sandpaper to metal frames. The sandpaper is replaced with

new pieces when it no longer assists in securing the specimen during test.

6.2.1 It is not prohibited to use clamping for holding the test

specimen in place on the insulation substrate and for inhibiting

the test specimen from slipping under the specimen frame

during impact (Note 4).

NOTE4—Nonreinforcedrubbermembranematerialshavebeenfoundto

be prone to such slipping when clamping is not used.

7. Sampling and Sample Preparation

7.1 Single-Ply Samples—Cut the test specimens directly

from the sheet membrane material in accordance with 8.1.

7.2 Multi-Ply Samples Prepared in the Laboratory:

7.2.1 Condition all components at 23 6 2 °C [74 6 3 °F]

and 50 6 5 % relative humidity for 24 6 0.25 h prior to

FIG. 1 Schematic of the Dynamic Puncture Device constructing the membrane sample.

D5635/D5635M − 18 (2022)

NOTE 1—Dimensions are in millimetres.

FIG. 2 Shape and Dimensions of Puncture Head

7.2.2 Prepare the multi-ply membrane samples at least 0.90 conforming to Specification C578, Type IX, and having a

by 1.20 m [3 by 4 ft] in accordance with the membrane thicknessof38mm[1.5in.] 615 %unlessotherwisespecified.

manufacturer’s instructions or by using other preparation Whatever insulation is used, the sections used as the specimen

methods at the discretion of the test laboratory. The method of substrate throughout the test shall be taken from the same

preparation shall be described in the report of the test. The manufactured lot.

quantityofmaterialineachlayerofthemembranesampleshall

be within 10 % of that specified, and the entire sample shall be

9. Conditioning and Test Temperature Selection

within 5 %. Cut the test specimens directly from this larger

9.1 Condition the apparatus and all specimens at the se-

membrane sample, in accordance with 8.1.

lected test temperature 62°C[63 °F] for a minimum of 8 h

prior to testing.

8. Test Specimens

8.1 Dimensions—The dimensions of the membrane test 9.2 It is not prohibited to conduct tests across a range of

cold, room, and elevated temperatures. Unless otherwise

specimens and insulation substrates are 250 by 250 mm [9.8 by

9.8 in.]. Cut the test specimens and substrates to size using a specified, the test shall be conducted at 23 °C [74 °F].

metal template having these dimensions.

9.2.1 Theselectedtemperatureshallbemaintainedat 62°C

[63 °F] throughout the test.

8.2 Number of Specimens—A minimum of three test speci-

mens is necessary to conduct the test.

10. Procedure

8.3 Type of Membrane Specimen Substrate—The use of any

roof insulation as a membrane specimen substrate is allowable. 10.1 Impact Energy—Conduct the dynamic puncture test at

The membrane substrate shall be expanded polystyrene board an impact energy (see X1.2) that is selected as follows:

D5635/D5635M − 18 (2022)

metal plate. The size of the metal plate is at least that of the specimen. A

10.1.1 In accordance with a performance requirement given

15 kV charge is applied across the specimen at the location of the applied

in a standard specification in which this test method is cited, or

puncture force by passing the pointed electrode over the impacted area

10.1.2 Through agreement between the party requesting the

while in contact with the specimen surface. If sparks are observed,

test and the testing laboratory.

puncture has occurred.

NOTE 5—If there is interest to conduct the test at the maximum impact 10.3 Test Results—Consider the results as follows:

energy at which specimen failure (that is, puncture) is expected to occur,

10.3.1 If none of the three specimens punctured at the

this maximum energy, if unknown, can be estimated using the screening

selected impact energy, report that the specimens passed the

procedure described in Appendix X1.

test.

10.2 Dynamic Puncture Testing:

10.3.2 If one or more of the three specimens punctured at

10.2.1 Conduct the test on three new membrane specimens

the selected impact energy, report that the specimens failed the

and insulation substrates at the selected impact energy.

test.

10.2.2 Secure the membrane specimen on the insulation

11. Report

using the specimen frame.

10.2.3 Position the membrane-insulation assembly under 11.1 Report, as a minimum, the following information:

the falling arm of the dynamic puncture device so that the 11.1.1 Completeidentificationoftheroofmembranesample

puncture head is set on the center of the surface of the including type, source, manufacturer, and method of prepara-

specimen.Align the arm and puncture head horizontally to the tion if made in the laboratory.

specimen surface. The direction of the test specimen (that is,

11.1.2 Complete identification of the insulation substrate

longitudinal or transverse) shall be perpendicular to the direc- including type, source, manufacturer, density, and thickness.

tion of the puncture head.

11.1.3 Impact energy at which the test was conducted.

10.2.4 Raise the arm and puncture head to the vertical 11.1.3.1 If the impact energy was selected in accordance

position and allow it to fall freely onto the specimen surface. with a performance requirement in a standard specification,

Then visually examine the specimen to determine whether report the designation of the standard specification.

puncture has occurred. 11.1.4 The temperature of the test.

11.1.5 A description of the watertightness test, if used.

10.2.4.1 If it cannot be determined visually that the speci-

men has or has not been punctured, apply a suitable water- 11.1.6 The test result; that is, whether the specimens passed

or failed at the selected impact energy.

tightness test. One example of a suitable test is the use of water

pressure of 5000 Pa [0.73 lbf/in. ] applied for 15 min to the 11.1.7 A description of the type, number, and locations of

clamps, if any, used in securing the test specimen to the

surface of the membrane specimen that was subjected to the

impact (Note 6). Another exam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.