ASTM C578-14a

(Specification)Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation

Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation

ABSTRACT

This specification covers the standards for the types, physical properties and dimensions of cellular polystyrene boards with or without facings or coatings made by molding (EPS) or extrusion (XPS) of expandable polystyrene proposed for use as thermal insulation. This specification, however, does not cover laminated products manufactured with any type of rigid board facer including fiberboard, perlite board, gypsum board, or oriented strand board. All thermal insulation shall be of uniform density and shall contain sufficient flame retardants to meet the oxygen index of requirements. They shall also meet the physical requirements such as thermal resistance, compressive resistance, flexural strength, water vapor permeance, water absorption, dimensional stability, and oxygen index specified herein.

SCOPE

1.1 This specification2 covers the types, physical properties, and dimensions of cellular polystyrene boards with or without facings or coatings made by molding (EPS) or extrusion (XPS) of expandable polystyrene. Products manufactured to this specification are intended for use as thermal insulation for temperatures from -65 to +165°F (-53.9 to +73.9°C). This specification does not apply to laminated products manufactured with any type of rigid board facer including fiberboard, perlite board, gypsum board, or oriented strand board.

1.1.1 For Type XIII only, this specification covers the physical properties, and dimensions of cellular polystyrene intended for use as thermal insulation for temperatures from −297 to +165°F (−183 to +73.9°C).

1.2 Consult the manufacturer for specific recommendations and properties in cryogenic conditions.

1.2.1 This specification does not cover cryogenic properties except for the k-factors for Type XIII in Appendix X1. For Type XIII in specific cryogenic applications, the manufacturer and purchaser shall agree upon the actual temperature limits and physical property requirements in addition to the k-factors in Appendix X1.

1.3 The use of thermal insulation materials covered by this specification may be regulated by building codes that address fire performance. For some end uses, specifiers should also address the effect of moisture and wind pressure resistance. Guidelines regarding these end use considerations are included in Appendix X1.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C578 −14a

StandardSpecification for

Rigid, Cellular Polystyrene Thermal Insulation

This standard is issued under the fixed designation C578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope conversions to SI units that are provided for information only

and are not considered standard.

1.1 Thisspecification coversthetypes,physicalproperties,

1.5 This standard does not purport to address all of the

and dimensions of cellular polystyrene boards with or without

safety concerns, if any, associated with its use. It is the

facingsorcoatingsmadebymolding(EPS)orextrusion(XPS)

responsibility of the user of this standard to establish appro-

of expandable polystyrene. Products manufactured to this

priate safety and health practices and determine the applica-

specification are intended for use as thermal insulation for

bility of regulatory limitations prior to use.

temperatures from -65 to +165°F (-53.9 to +73.9°C). This

specification does not apply to laminated products manufac-

2. Referenced Documents

tured with any type of rigid board facer including fiberboard,

2.1 ASTM Standards:

perlite board, gypsum board, or oriented strand board.

C165TestMethodforMeasuringCompressivePropertiesof

1.1.1 For Type XIII only, this specification covers the

Thermal Insulations

physical properties, and dimensions of cellular polystyrene

C168Terminology Relating to Thermal Insulation

intended for use as thermal insulation for temperatures from

C177Test Method for Steady-State Heat Flux Measure-

−297 to +165°F (−183 to +73.9°C).

ments and Thermal Transmission Properties by Means of

1.2 Consult the manufacturer for specific recommendations

the Guarded-Hot-Plate Apparatus

and properties in cryogenic conditions.

C203Test Methods for Breaking Load and Flexural Proper-

1.2.1 This specification does not cover cryogenic properties

ties of Block-Type Thermal Insulation

except for the k-factors for Type XIII in Appendix X1. For

C272Test Method for Water Absorption of Core Materials

Type XIII in specific cryogenic applications, the manufacturer

for Structural Sandwich Constructions

and purchaser shall agree upon the actual temperature limits

C303Test Method for Dimensions and Density of Pre-

and physical property requirements in addition to the k-factors

formed Block and Board–Type Thermal Insulation

in Appendix X1.

C335Test Method for Steady-State HeatTransfer Properties

of Pipe Insulation

1.3 The use of thermal insulation materials covered by this

C390Practice for Sampling and Acceptance of Thermal

specification may be regulated by building codes that address

Insulation Lots

fire performance. For some end uses, specifiers should also

C518Test Method for Steady-State Thermal Transmission

address the effect of moisture and wind pressure resistance.

Properties by Means of the Heat Flow Meter Apparatus

Guidelinesregardingtheseenduseconsiderationsareincluded

C550Test Method for Measuring Trueness and Squareness

in Appendix X1.

of Rigid Block and Board Thermal Insulation

1.4 The values stated in inch-pound units are to be regarded

C870Practice for Conditioning of Thermal Insulating Ma-

as standard. The values given in parentheses are mathematical

terials

C1045Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

This specification is under the jurisdiction of ASTM Committee C16 on

C1058Practice for Selecting Temperatures for Evaluating

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

and Reporting Thermal Properties of Thermal Insulation

Organic and Nonhomogeneous Inorganic Thermal Insulations.

C1114Test Method for Steady-State Thermal Transmission

Current edition approved Oct. 15, 2014. Published November 2014. Originally

approved in 1965. Last previous edition approved in 2014 as C578–14. DOI: Properties by Means of the Thin-Heater Apparatus

10.1520/C0578-14A.

ThisspecificationissimilartoISO4898-1984,“CellularPlastics–Specification

for Rigid Cellular Materials Used in the Thermal Insulation of Buildings,” in title For referenced ASTM standards, visit the ASTM website, www.astm.org, or

only. The scope and technical content are significantly different. contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

ISO standards are available fromAmerican National Standards Institute (ANSI), Standards volume information, refer to the standard’s Document Summary page on

25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C578−14a

C1303Test Method for Predicting Long-Term Thermal Re- 5. Ordering Information

sistance of Closed-Cell Foam Insulation

5.1 Acquisition documents shall specify the following:

C1363Test Method for Thermal Performance of Building

5.1.1 Title, number, and year of this specification,

Materials and Envelope Assemblies by Means of a Hot

5.1.2 Type (see Table 1),

Box Apparatus

5.1.3 R-value or thickness required (see Tables 1 and 2),

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

5.1.3.1 Thermal Resistance/Thickness Relationship—The

tics

thermal resistance (R -value) and the thermal resistivity (R-

D1621Test Method for Compressive Properties of Rigid

value/inch) of RCPS thermal insulation may vary with thick-

Cellular Plastics

ness. Therefore, when ordering, specify the R-value or the

D1622Test Method for Apparent Density of Rigid Cellular

thickness, or both. For additional information, see Practice

Plastics

C1045.

D2126Test Method for Response of Rigid Cellular Plastics

5.1.4 Density, if other than specified in Table 1,

to Thermal and Humid Aging

5.1.5 Tolerance, if other than specified (see 8.2),

D2863Test Method for Measuring the Minimum Oxygen

5.1.6 Length and width required (see Table 2 and 8.1),

Concentration to Support Candle-Like Combustion of

5.1.7 If other than straight edges are required (see 8.3),

Plastics (Oxygen Index)

5.1.8 If either ship-lap or tongue-and-groove edges are

E84Test Method for Surface Burning Characteristics of

required (see 8.6),

Building Materials

5.1.9 Tapered Insulation—special ordering information. In

E96/E96MTest Methods for Water Vapor Transmission of

additiontootherapplicablerequirementsinSection5(Note1),

Materials

acquisition documents for tapered RCPS thermal insulation

E176Terminology of Fire Standards

shall specify the following:

2.2 CAN/ULC Standard

5.1.9.1 Minimum starting thickness,

CAN/ULC S770Standard Test Method for the Determina-

5.1.9.2 Slope, in./ft (mm/m),

tion of Long-Term Thermal Resistance of Closed-Cell

5.1.9.3 Average R-value,

Thermal Insulating Foams

5.1.9.4 Minimum thickness,

5.1.9.5 Shop Drawings—The tapered insulation supplier

3. Terminology

shall provide shop drawings to illustrate installation patterns

3.1 Definitions:

and dimensions for each tapered module,

3.1.1 Terms used in this specification are defined in Termi-

5.1.10 Sampling, if different (see 10.1),

nology C168.

5.1.11 If a certificate of compliance is required (see 14.1),

3.1.2 Terms used in this specification that relate to fire

and

standards are defined in Terminology E176.

5.1.12 If marking is other than specified (see 15.1).

3.2 Definitions of Terms Specific to This Standard:

NOTE1—Physicalpropertiesoftaperedinsulationshouldbedetermined

3.2.1 EPS—letter designation for the molded expanded

on blocks of RCPS thermal insulation before the insulation is tapered.

polystyrene thermal insulation classified by this specification.

It is defined as cellular plastic product manufactured from 5.1.13 Type XIII—Special ordering information. In addition

pre-expanded polystyrene beads subsequently molded into to other applicable requirements in Section 5, acquisition

desired shapes and sizes resulting in a product which is rigid documents for Type XIII thermal insulation shall specify if

with closed cellular structure.

presence of surface skins is required.

3.2.2 RCPS—letter designations for the rigid cellular poly-

6. Materials and Manufacture

styrene thermal insulation classified by this specification that

identifies the product as rigid cellular polystyrene.

6.1 RCPS thermal insulation shall be formed by the expan-

sionofpolystyreneresinbeadsorgranulesinaclosedmold,or

3.2.3 PS—usedinthisspecificationtorepresentpolystyrene

by the expansion of polystyrene base resin in an extrusion

in accordance with Terminology D1600.

process. RCPS thermal insulation shall be of uniform density

3.2.4 XPS—letter designation for the extruded expanded

and have essentially closed cells.All RCPS thermal insulation

polystyrene thermal insulation classified by this specification.

shall contain sufficient flame retardants to meet the oxygen

It is defined as cellular plastic product manufactured in a one

index requirements of Table 1.

stage process by extrusion and expansion of the base polymer

in the presence of blowing agent(s) resulting in a product

7. Physical Requirements

which is rigid with closed cellular structure.

7.1 Inspection Requirements:

4. Classification

7.1.1 The physical requirements listed in this section are

4.1 This specification covers types of RCPS thermal insu- defined as inspection requirements (refer to Practice C390).

lations currently commercially available as described by the 7.1.2 AlldimensionalrequirementsaredescribedinSection

physical property requirements in Table 1. 8.

7.1.3 Allworkmanship,finish,andappearancerequirements

are described in Section 9.

Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas,

WA 98607-8542, http://www.ul.com. 7.1.4 Density shall be in accordance with Table 1.

C578−14a

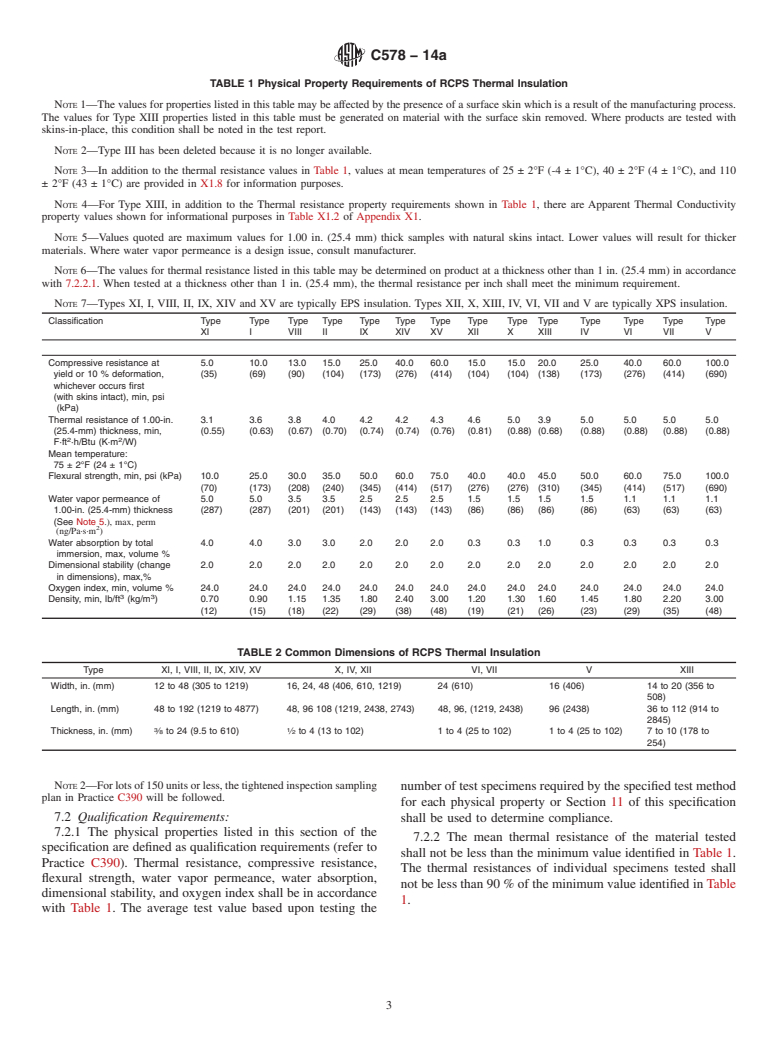

TABLE 1 Physical Property Requirements of RCPS Thermal Insulation

NOTE 1—The values for properties listed in this table may be affected by the presence of a surface skin which is a result of the manufacturing process.

The values for Type XIII properties listed in this table must be generated on material with the surface skin removed. Where products are tested with

skins-in-place, this condition shall be noted in the test report.

NOTE 2—Type III has been deleted because it is no longer available.

NOTE 3—In addition to the thermal resistance values in Table 1, values at mean temperatures of 25 ± 2°F (-4 ± 1°C), 40 ± 2°F (4 ± 1°C), and 110

± 2°F (43 ± 1°C) are provided in X1.8 for information purposes.

NOTE 4—For Type XIII, in addition to the Thermal resistance property requirements shown in Table 1, there are Apparent Thermal Conductivity

property values shown for informational purposes in Table X1.2 of Appendix X1.

NOTE 5—Values quoted are maximum values for 1.00 in. (25.4 mm) thick samples with natural skins intact. Lower values will result for thicker

materials. Where water vapor permeance is a design issue, consult manufacturer.

NOTE 6—The values for thermal resistance listed in this table may be determined on product at a thickness other than 1 in. (25.4 mm) in accordance

with 7.2.2.1. When tested at a thickness other than 1 in. (25.4 mm), the thermal resistance per inch shall meet the minimum requirement.

NOTE 7—Types XI, I, VIII, II, IX, XIV and XV are typically EPS insulation. Types XII, X, XIII, IV, VI, VII and V are typically XPS insulation.

Classification Type Type Type Type Type Type Type Type Type Type Type Type Type Type

XI I VIII II IX XIV XV XII X XIII IV VI VII V

Compressive resistance at 5.0 10.0 13.0 15.0 25.0 40.0 60.0 15.0 15.0 20.0 25.0 40.0 60.0 100.0

yield or 10 % deformation, (35) (69) (90) (104) (173) (276) (414) (104) (104) (138) (173) (276) (414) (690)

whichever occurs first

(with skins intact), min, psi

(kPa)

Thermal resistance of 1.00-in. 3.1 3.6 3.8 4.0 4.2 4.2 4.3 4.6 5.0 3.9 5.0 5.0 5.0 5.0

(25.4-mm) thickness, min, (0.55) (0.63) (0.67) (0.70) (0.74) (0.74) (0.76) (0.81) (0.88) (0.68) (0.88) (0.88) (0.88) (0.88)

2 2

F·ft ·h/Btu (K·m /W)

Mean temperature:

75 ± 2°F (24 ± 1°C)

Flexural strength, min, psi (kPa) 10.0 25.0 30.0 35.0 50.0 60.0 75.0 40.0 40.0 45.0 50.0 60.0 75.0 100.0

(70) (173) (208) (240) (345) (414) (517) (276) (276) (310) (345) (414) (517) (690)

Water vapor permeance of 5.0 5.0 3.5 3.5 2.5 2.5 2.5 1.5 1.5 1.5 1.5 1.1 1.1 1.1

1.00-in. (25.4-mm) thickness (287) (287) (201) (201) (143) (143) (143) (86) (86) (86) (86) (63) (63) (63)

(See Note 5.), max, perm

(ng/Pa·s·m )

Water absorption by total 4.0 4.0 3.0 3.0 2.0 2.0 2.0 0.3 0.3 1.0 0.3 0.3 0.3 0.3

immersion, max, volume %

Dimensional stability (change 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

in dimensions), max,%

Oxygen index, min, volume % 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0

3 3

Density, min, lb/ft (kg/m ) 0.70 0.90 1.15 1.35 1.80 2.40 3.00 1.20 1.30 1.60 1.45 1.80 2.20 3.00

(12) (15) (18) (22) (29) (38) (48) (19) (21) (26) (23) (29) (35) (48)

TABLE 2 Common Dimensions of RCPS Thermal Insulation

Type XI, I, VIII, II, IX, XIV, XV X, IV, XII VI, VII V XIII

Width, in. (mm) 12 to 48 (305 to 1219) 16, 24, 48 (406, 610, 1219) 24 (610) 16 (406) 14 to 20 (356 to

508)

Length, in. (mm) 48 to 192 (1219 to 4877) 48, 96 108 (1219, 2438, 2743) 48, 96, (1219, 2438) 96 (2438) 36 to 112 (914 to

2845)

3 1

Thickness, in. (mm) ⁄8 to 24 (9.5 to 610) ⁄2 to 4 (13 to 102) 1 to 4 (25 to 102) 1 to 4 (25 to 102) 7 to 10 (178 to

254)

NOTE2—Forlotsof150unitsorless,thetightenedinspectionsampling

numberoftestspecimensrequiredbythespecifiedtestmethod

plan in Practice C390 will be followed.

for each physical property or Section 11 of this specification

7.2 Qualification Requirements:

shall be used to determine compliance.

7.2.1 The physical properties listed in this section of the

7.2.2 The mean thermal resistance of the material tested

specification are defined as qualification requirements (refer to

shall not be less than the minimum value identified in Table 1.

Practice C390). Thermal resistance, compressive resistance,

The thermal resistances of individual specimens tested shall

flexural strength, water vapor permeance, water absorption,

notbelessthan90%oftheminimumvalueidentifiedinTable

dimensional stability, and oxygen index shall be in accordance

1.

with Table 1. The average test value based upon testing the

C578−14a

7.2.2.1 Test 1 in. (25.4 mm) thick specimens for determi- 8.6 Ship-Lap and Tongue-and-Groove Edges—When

nation of compliance with thermal resistance, compressive specified, RCPS thermal insulation shall be fur

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C578 − 14 C578 − 14a

Standard Specification for

Rigid, Cellular Polystyrene Thermal Insulation

This standard is issued under the fixed designation C578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers the types, physical properties, and dimensions of cellular polystyrene boards with or without

facings or coatings made by molding (EPS) or extrusion (XPS) of expandable polystyrene. Products manufactured to this

specification are intended for use as thermal insulation for temperatures from -65 to +165°F (-53.9 to +73.9°C). This specification

does not apply to laminated products manufactured with any type of rigid board facer including fiberboard, perlite board, gypsum

board, or oriented strand board.

1.1.1 For Type XIII only, this specification covers the physical properties, and dimensions of cellular polystyrene intended for

use as thermal insulation for temperatures from −297 to +165°F (−183 to +73.9°C).

1.2 Consult the manufacturer for specific recommendations and properties in cryogenic conditions.

1.2.1 This specification does not cover cryogenic properties except for the k-factors for Type XIII in Appendix X1. For Type

XIII in specific cryogenic applications, the manufacturer and purchaser shall agree upon the actual temperature limits and physical

property requirements in addition to the k-factors in Appendix X1.

1.3 The use of thermal insulation materials covered by this specification may be regulated by building codes that address fire

performance. For some end uses, specifiers should also address the effect of moisture and wind pressure resistance. Guidelines

regarding these end use considerations are included in Appendix X1.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C203 Test Methods for Breaking Load and Flexural Properties of Block-Type Thermal Insulation

C272 Test Method for Water Absorption of Core Materials for Structural Sandwich Constructions

C303 Test Method for Dimensions and Density of Preformed Block and Board–Type Thermal Insulation

C335 Test Method for Steady-State Heat Transfer Properties of Pipe Insulation

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on Organic and

Nonhomogeneous Inorganic Thermal Insulations.

Current edition approved Jan. 1, 2014Oct. 15, 2014. Published March 2014November 2014. Originally approved in 1965. Last previous edition approved in 20132014

as C578 – 13.C578 – 14. DOI: 10.1520/C0578-14.10.1520/C0578-14A.

This specification is similar to ISO 4898-1984, “Cellular Plastics–Specification for Rigid Cellular Materials Used in the Thermal Insulation of Buildings,” in title only.

The scope and technical content are significantly different.

ISO standards are available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C578 − 14a

C550 Test Method for Measuring Trueness and Squareness of Rigid Block and Board Thermal Insulation

C870 Practice for Conditioning of Thermal Insulating Materials

C1045 Practice for Calculating Thermal Transmission Properties Under Steady-State Conditions

C1058 Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

C1114 Test Method for Steady-State Thermal Transmission Properties by Means of the Thin-Heater Apparatus

C1303 Test Method for Predicting Long-Term Thermal Resistance of Closed-Cell Foam Insulation

C1363 Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1621 Test Method for Compressive Properties of Rigid Cellular Plastics

D1622 Test Method for Apparent Density of Rigid Cellular Plastics

D2126 Test Method for Response of Rigid Cellular Plastics to Thermal and Humid Aging

D2863 Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics

(Oxygen Index)

E84 Test Method for Surface Burning Characteristics of Building Materials

E96/E96M Test Methods for Water Vapor Transmission of Materials

E176 Terminology of Fire Standards

2.2 CAN/ULC Standard

CAN/ULC S770 Standard Test Method for the Determination of Long-Term Thermal Resistance of Closed-Cell Thermal

Insulating Foams

3. Terminology

3.1 Definitions:

3.1.1 Terms used in this specification are defined in Terminology C168.

3.1.2 Terms used in this specification that relate to fire standards are defined in Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 EPS—letter designation for the molded expanded polystyrene thermal insulation classified by this specification. It is

defined as cellular plastic product manufactured from pre-expanded polystyrene beads subsequently molded into desired shapes

and sizes resulting in a product which is rigid with closed cellular structure.

3.2.2 RCPS—letter designations for the rigid cellular polystyrene thermal insulation classified by this specification that identifies

the product as rigid cellular polystyrene.

3.2.3 PS—used in this specification to represent polystyrene in accordance with Terminology D1600.

3.2.4 XPS—letter designation for the extruded expanded polystyrene thermal insulation classified by this specification. It is

defined as cellular plastic product manufactured in a one stage process by extrusion and expansion of the base polymer in the

presence of blowing agent(s) resulting in a product which is rigid with closed cellular structure.

4. Classification

4.1 This specification covers types of RCPS thermal insulations currently commercially available as described by the physical

property requirements in Table 1.

5. Ordering Information

5.1 Acquisition documents shall specify the following:

5.1.1 Title, number, and year of this specification,

5.1.2 Type (see Table 1),

5.1.3 R-value or thickness required (see Tables 1 and 2),

5.1.3.1 Thermal Resistance/Thickness Relationship—The thermal resistance (R -value) and the thermal resistivity (R-value/

inch) of RCPS thermal insulation may vary with thickness. Therefore, when ordering, specify the R-value or the thickness, or both.

For additional information, see Practice C1045.

5.1.4 Density, if other than specified in Table 1,

5.1.5 Tolerance, if other than specified (see 8.2),

5.1.6 Length and width required (see Table 2 and 8.1),

5.1.7 If other than straight edges are required (see 8.3),

5.1.8 If either ship-lap or tongue-and-groove edges are required (see 8.6),

5.1.9 Tapered Insulation—special ordering information. In addition to other applicable requirements in Section 5 (Note 1),

acquisition documents for tapered RCPS thermal insulation shall specify the following:

5.1.9.1 Minimum starting thickness,

Available from Underwriters Laboratories (UL), 2600 N.W. Lake Rd., Camas, WA 98607-8542, http://www.ul.com.

C578 − 14a

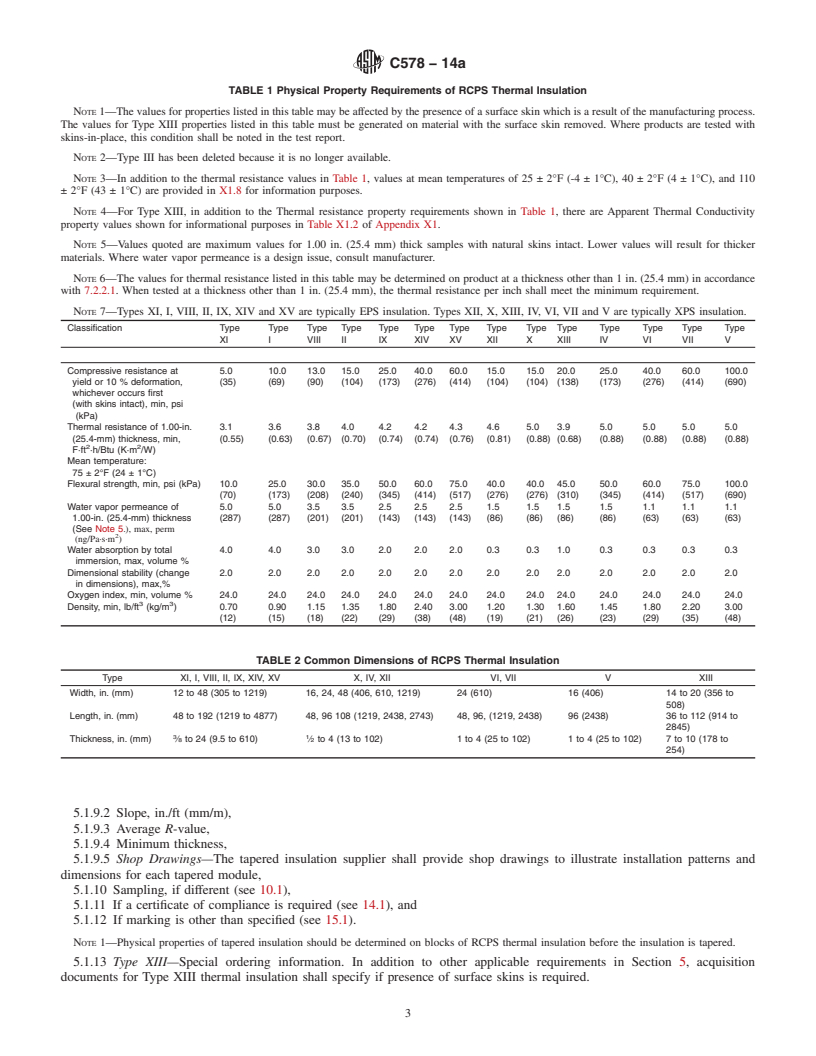

TABLE 1 Physical Property Requirements of RCPS Thermal Insulation

NOTE 1—The values for properties listed in this table may be affected by the presence of a surface skin which is a result of the manufacturing process.

The values for Type XIII properties listed in this table must be generated on material with the surface skin removed. Where products are tested with

skins-in-place, this condition shall be noted in the test report.

NOTE 2—Type III has been deleted because it is no longer available.

NOTE 3—In addition to the thermal resistance values in Table 1, values at mean temperatures of 25 ± 2°F (-4 ± 1°C), 40 ± 2°F (4 ± 1°C), and 110

± 2°F (43 ± 1°C) are provided in X1.8 for information purposes.

NOTE 4—For Type XIII, in addition to the Thermal resistance property requirements shown in Table 1, there are Apparent Thermal Conductivity

property values shown for informational purposes in Table X1.2 of Appendix X1.

NOTE 5—Values quoted are maximum values for 1.00 in. (25.4 mm) thick samples with natural skins intact. Lower values will result for thicker

materials. Where water vapor permeance is a design issue, consult manufacturer.

NOTE 6—The values for thermal resistance listed in this table may be determined on product at a thickness other than 1 in. (25.4 mm) in accordance

with 7.2.2.1. When tested at a thickness other than 1 in. (25.4 mm), the thermal resistance per inch shall meet the minimum requirement.

NOTE 7—Types XI, I, VIII, II, IX, XIV and XV are typically EPS insulation. Types XII, X, XIII, IV, VI, VII and V are typically XPS insulation.

Classification Type Type Type Type Type Type Type Type Type Type Type Type Type Type

XI I VIII II IX XIV XV XII X XIII IV VI VII V

Compressive resistance at 5.0 10.0 13.0 15.0 25.0 40.0 60.0 15.0 15.0 20.0 25.0 40.0 60.0 100.0

yield or 10 % deformation, (35) (69) (90) (104) (173) (276) (414) (104) (104) (138) (173) (276) (414) (690)

whichever occurs first

(with skins intact), min, psi

(kPa)

Thermal resistance of 1.00-in. 3.1 3.6 3.8 4.0 4.2 4.2 4.3 4.6 5.0 3.9 5.0 5.0 5.0 5.0

(25.4-mm) thickness, min, (0.55) (0.63) (0.67) (0.70) (0.74) (0.74) (0.76) (0.81) (0.88) (0.68) (0.88) (0.88) (0.88) (0.88)

2 2

F·ft ·h/Btu (K·m /W)

Mean temperature:

75 ± 2°F (24 ± 1°C)

Flexural strength, min, psi (kPa) 10.0 25.0 30.0 35.0 50.0 60.0 75.0 40.0 40.0 45.0 50.0 60.0 75.0 100.0

(70) (173) (208) (240) (345) (414) (517) (276) (276) (310) (345) (414) (517) (690)

Water vapor permeance of 5.0 5.0 3.5 3.5 2.5 2.5 2.5 1.5 1.5 1.5 1.5 1.1 1.1 1.1

1.00-in. (25.4-mm) thickness (287) (287) (201) (201) (143) (143) (143) (86) (86) (86) (86) (63) (63) (63)

(See Note 5.), max, perm

(ng/Pa·s·m )

Water absorption by total 4.0 4.0 3.0 3.0 2.0 2.0 2.0 0.3 0.3 1.0 0.3 0.3 0.3 0.3

immersion, max, volume %

Dimensional stability (change 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

in dimensions), max,%

Oxygen index, min, volume % 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0 24.0

3 3

Density, min, lb/ft (kg/m ) 0.70 0.90 1.15 1.35 1.80 2.40 3.00 1.20 1.30 1.60 1.45 1.80 2.20 3.00

(12) (15) (18) (22) (29) (38) (48) (19) (21) (26) (23) (29) (35) (48)

TABLE 2 Common Dimensions of RCPS Thermal Insulation

Type XI, I, VIII, II, IX, XIV, XV X, IV, XII VI, VII V XIII

Width, in. (mm) 12 to 48 (305 to 1219) 16, 24, 48 (406, 610, 1219) 24 (610) 16 (406) 14 to 20 (356 to

508)

Length, in. (mm) 48 to 192 (1219 to 4877) 48, 96 108 (1219, 2438, 2743) 48, 96, (1219, 2438) 96 (2438) 36 to 112 (914 to

2845)

3 1

Thickness, in. (mm) ⁄8 to 24 (9.5 to 610) ⁄2 to 4 (13 to 102) 1 to 4 (25 to 102) 1 to 4 (25 to 102) 7 to 10 (178 to

254)

5.1.9.2 Slope, in./ft (mm/m),

5.1.9.3 Average R-value,

5.1.9.4 Minimum thickness,

5.1.9.5 Shop Drawings—The tapered insulation supplier shall provide shop drawings to illustrate installation patterns and

dimensions for each tapered module,

5.1.10 Sampling, if different (see 10.1),

5.1.11 If a certificate of compliance is required (see 14.1), and

5.1.12 If marking is other than specified (see 15.1).

NOTE 1—Physical properties of tapered insulation should be determined on blocks of RCPS thermal insulation before the insulation is tapered.

5.1.13 Type XIII—Special ordering information. In addition to other applicable requirements in Section 5, acquisition

documents for Type XIII thermal insulation shall specify if presence of surface skins is required.

C578 − 14a

6. Materials and Manufacture

6.1 RCPS thermal insulation shall be formed by the expansion of polystyrene resin beads or granules in a closed mold, or by

the expansion of polystyrene base resin in an extrusion process. RCPS thermal insulation shall be of uniform density and have

essentially closed cells. All RCPS thermal insulation shall contain sufficient flame retardants to meet the oxygen index

requirements of Table 1.

7. Physical Requirements

7.1 Inspection Requirements:

7.1.1 The physical requirements listed in this section are defined as inspection requirements (refer to Practice C390).

7.1.2 All dimensional requirements are described in Section 8.

7.1.3 All workmanship, finish, and appearance requirements are described in Section 9.

7.1.4 Density shall be in accordance with Table 1.

NOTE 2—For lots of 150 units or less, the tightened inspection sampling plan in Practice C390 will be followed.

7.2 Qualification Requirements:

7.2.1 The physical properties listed in this section of the specification are defined as qualification requirements (refer to Practice

C390). Thermal resistance, compressive resistance, flexural strength, water vapor permeance, water absorption, dimensional

stability, and oxygen index shall be in accordance with Table 1. The average test value based upon testing the number of test

specimens required by the specified test method for each physical property or Section 11 of this specification shall be used to

det

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.