ASTM D7046-11

(Guide)Standard Guide for Use of the Metal Detection Method for Subsurface Exploration (Withdrawn 2020)

Standard Guide for Use of the Metal Detection Method for Subsurface Exploration (Withdrawn 2020)

SIGNIFICANCE AND USE

Concepts:

This guide summarizes the equipment, field procedures, and interpretation methods for using the metal detection method for locating subsurface metallic objects. Personnel requirements are as discussed in Practice D3740.

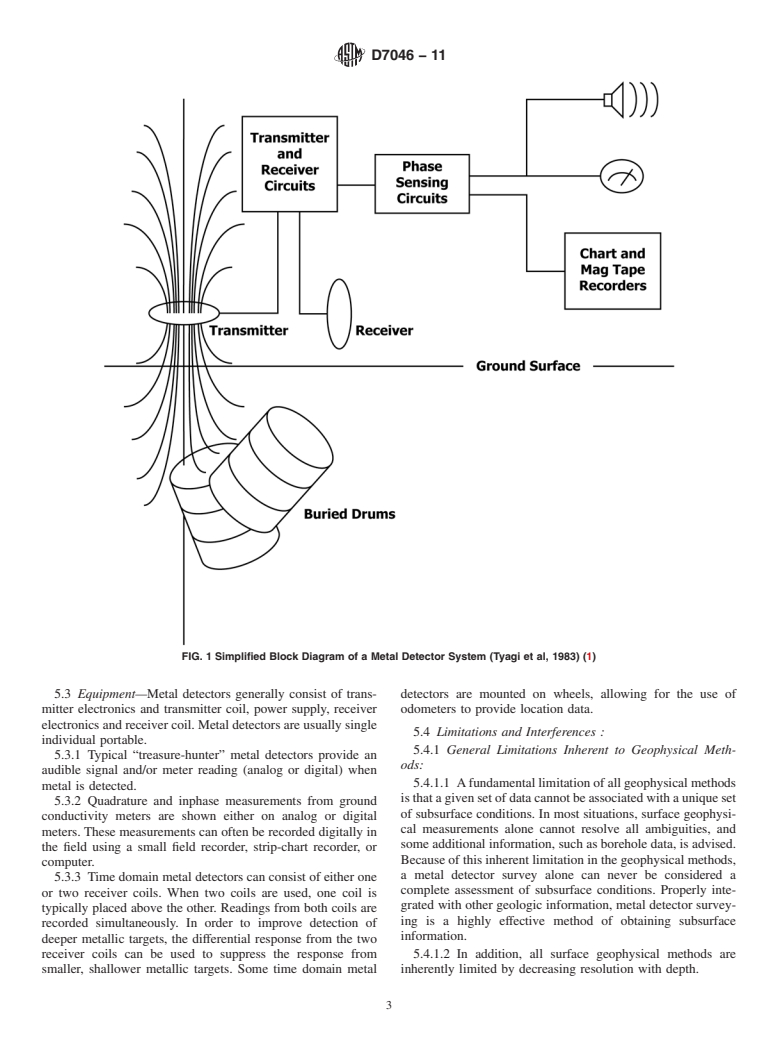

Method—Metal detectors are electromagnetic instruments that work on the principle of induction, using typically two coils (antennas); a transmitter and a receiver. Both coils are fixed in respect to each other and are used near the surface of the earth. Either an alternating or a pulsed voltage is applied to the transmitter coil causing electrical eddy currents to be induced in the earth. The electrical currents flowing in the earth are proportional to electrical conductivity of the medium. Theses currents generate eddy currents in buried metallic objects that is detected and measured by the receiver (Fig. 1).

Parameter Measured and Representative Values:

Frequency Domain Metal Detectors:

Frequency domain metal detectors apply an alternating current having a fixed frequency and amplitude to the transmit coil which generates a time-varying magnetic field around the coil. This field induces eddy currents in nearby metallic objects that in turn generate time-varying magnetic fields of their own. These eddy-fields induce a voltage in the receiver coil. The presence of metal causes small changes in the phase and amplitude of the receiver voltage. Most metal detectors amplify the differences in the receiver coil voltage caused by nearby metal and generate an audible sound or meter (analog or digital) reading.

Ground conductivity meters (frequency domain metal detectors) measure the two-components of the secondary magnetic field simultaneously. The first is the quadrature-phase component which indicates soil electrical conductivity and is measured in millisiemens per meter (mS/m). The second is the inphase component, which is related to the subsurface magnetic susceptibility and is measured in parts per thousand (ppt) (that is...

SCOPE

1.1 Purpose and Application—This guide summarizes the equipment, field procedures, and interpretation methods for the assessment of subsurface materials using the metal detection method. Metal detectors respond to the presence of both ferrous and nonferrous metals by inducing eddy currents in conductive objects. Metal detectors are either frequency domain (continuous frequency or wave) or time domain (pulsed) systems. A wide range of metal detectors is commonly available.

1.1.1 Metal detectors can detect any kind of metallic material, including both ferrous metals such as iron and steel, and non-ferrous metals such as aluminum and copper. In contrast, magnetometers only detect ferrous metals.

1.1.2 Metal detector measurements can be used to detect the presence of buried metal trash, drums (Tyagi et al, 1983) (1) and tanks, abandoned wells (Guide D6285); to trace buried utilities; and to delineate the boundaries of landfill metal and trench metal. They are also used to detect metal based unexploded ordnance (UXO).

1.2 Limitations:

1.2.1 This guide provides an overview of the metal detection method. This guide does not provide or address the details of the theory, field procedures, or interpretation of the data. References are included for that purpose and are considered an essential part of this guide. It is recommended that the user of this guide be familiar with the references cited and with the ASTM standards D420, D653, D5088, D5608, D5730, D5753, D6235, D6429, and D6431.

1.2.2 This guide is limited to metal detection measurements made on land. The metal detection method can be adapted for a number of special uses on land, water, airborne and ice.

1.2.3 The approaches suggested in this guide for the metal detection method are commonly used, widely accepted, and proven. However, other approaches or modifications to the metal detection method that are technically sound may be substituted.

1.2.4 This gui...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7046 − 11

Standard Guide for

Use of the Metal Detection Method for Subsurface

1

Exploration

This standard is issued under the fixed designation D7046; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* proven. However, other approaches or modifications to the

metal detection method that are technically sound may be

1.1 Purpose and Application—This guide summarizes the

substituted.

equipment, field procedures, and interpretation methods for the

1.2.4 This guide offers an organized collection of informa-

assessment of subsurface materials using the metal detection

tion or a series of options and does not recommend a specific

method. Metal detectors respond to the presence of both

course of action. This document cannot replace education or

ferrous and nonferrous metals by inducing eddy currents in

experience and should be used in conjunction with professional

conductive objects. Metal detectors are either frequency do-

judgment. Not all aspects of this guide may be applicable in all

main (continuous frequency or wave) or time domain (pulsed)

circumstances. This ASTM standard is not intended to repre-

systems. A wide range of metal detectors is commonly avail-

sent or replace the standard of care by which the adequacy of

able.

a given professional service must be judged, nor should this

1.1.1 Metal detectors can detect any kind of metallic

document be applied without consideration of a project’s many

material, including both ferrous metals such as iron and steel,

unique aspects. The word “Standard” in the title of this

and non-ferrous metals such as aluminum and copper. In

document means only that the document has been approved

contrast, magnetometers only detect ferrous metals.

through the ASTM consensus process.

1.1.2 Metaldetectormeasurementscanbeusedtodetectthe

2

1.3 The values stated in SI units are regarded as standard.

presence of buried metal trash, drums (Tyagi et al, 1983) (1)

and tanks, abandoned wells (Guide D6285); to trace buried The values given in parentheses are inch-pound units, which

are provided for information only and are not considered

utilities; and to delineate the boundaries of landfill metal and

trench metal. They are also used to detect metal based standard.

unexploded ordnance (UXO).

1.4 Precautions:

1.4.1 It is the responsibility of the user of this guide to

1.2 Limitations:

follow any precautions in the equipment manufacturer’s rec-

1.2.1 This guide provides an overview of the metal detec-

ommendations and to establish appropriate health and safety

tion method.This guide does not provide or address the details

practices.

of the theory, field procedures, or interpretation of the data.

1.4.2 If the method is used at sites with hazardous materials,

References are included for that purpose and are considered an

operations, or equipment, it is the responsibility of the user of

essential part of this guide. It is recommended that the user of

this guide to establish appropriate safety and health practices

this guide be familiar with the references cited and with the

and to determine the applicability of any regulations prior to

ASTM standards D420, D653, D5088, D5608, D5730, D5753,

use.

D6235, D6429, and D6431.

1.4.3 This standard does not purport to address all of the

1.2.2 This guide is limited to metal detection measurements

safety concerns, if any, associated with its use. It is the

made on land. The metal detection method can be adapted for

responsibility of the user of this standard to establish appro-

a number of special uses on land, water, airborne and ice.

priate safety and health practices and determine the applica-

1.2.3 The approaches suggested in this guide for the metal

bility of regulatory requirements prior to use.

detection method are commonly used, widely accepted, and

2. Referenced Documents

3

2.1 ASTM Standards:

1

ThisguideisunderthejurisdictionofASTMCommitteeD18onSoilandRock

and is the direct responsibility of Subcommittee D18.01 on Surface and Subsurface

Characterization.

3

Current edition approved May 1, 2011. Published June 2011. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 2004 as D7046–04. DOI: 10.1520/D7046-11. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.