ASTM D924-08

(Test Method)Standard Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical Insulating Liquids

Standard Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical Insulating Liquids

SIGNIFICANCE AND USE

Dissipation Factor (or Power Factor)—This is a measure of the dielectric losses in an electrical insulating liquid when used in an alternating electric field and of the energy dissipated as heat. A low dissipation factor or power factor indicates low ac dielectric losses. Dissipation factor or power factor may be useful as a means of quality control, and as an indication of changes in quality resulting from contamination and deterioration in service or as a result of handling.

The loss characteristic is commonly measured in terms of dissipation factor (tangent of the loss angle) or of power factor (sine of the loss angle) and may be expressed as a decimal value or as a percentage. For decimal values up to 0.05, dissipation factor and power factor values are equal to each other within about one part in one thousand. In general, since the dissipation factor or power factor of insulating oils in good condition have decimal values below 0.005, the two measurements (terms) may be considered interchangeable.

The exact relationship between dissipation factor (D) and power factor (PF) is given by the following equations:

The reported value of D or PF may be expressed as a decimal value or as a percentage. For example:

Relative Permittivity (Dielectric Constant)—Insulating liquids are used in general either to insulate components of an electrical network from each other and from ground, alone or in combination with solid insulating materials, or to function as the dielectric of a capacitor. For the first use, a low value of relative permittivity is often desirable in order to have the capacitance be as small as possible, consistent with acceptable chemical and heat transfer properties. However, an intermediate value of relative permittivity may sometimes be advantageous in achieving a better voltage distribution of a-c electric fields between the liquid and solid insulating materials with which the liquid may be in series. When used as the dielectric in ...

SCOPE

1.1 This test method describes testing of new electrical insulating liquids as well as liquids in service or subsequent to service in cables, transformers, oil circuit breakers, and other electrical apparatus.

1.2 This test method provides a procedure for making referee tests at a commercial frequency of between 45 and 65 Hz.

1.3 Where it is desired to make routine determinations requiring less accuracy, certain modifications to this test method are permitted as described in Sections 16 to 24.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. Specific warnings are given in 11.3.3.

1.5 Mercury has been designated by the EPA and many state agencies as a hazardous material that can cause nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and the EPA's website: http://www.epa.gov/mercury/faq.htm for additional information. Users should be aware that selling mercury and/or mercury containing products into your state may be prohibited by state law.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D924 − 08

StandardTest Method for

Dissipation Factor (or Power Factor) and Relative

Permittivity (Dielectric Constant) of Electrical Insulating

1

Liquids

This standard is issued under the fixed designation D924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 This test method describes testing of new electrical 2.1 ASTM Standards:

insulating liquids as well as liquids in service or subsequent to D150 Test Methods forAC Loss Characteristics and Permit-

service in cables, transformers, oil circuit breakers, and other tivity (Dielectric Constant) of Solid Electrical Insulation

electrical apparatus. D923 Practices for Sampling Electrical Insulating Liquids

D2864 Terminology Relating to Electrical Insulating Liq-

1.2 This test method provides a procedure for making

uids and Gases

referee tests at a commercial frequency of between 45 and 65

D2865 Practice for Calibration of Standards and Equipment

Hz.

for Electrical Insulating Materials Testing

1.3 Where it is desired to make routine determinations

E691 Practice for Conducting an Interlaboratory Study to

requiring less accuracy, certain modifications to this test

Determine the Precision of a Test Method

method are permitted as described in Sections 16 to 24.

2.2 IEEE Standard:

1.4 This standard does not purport to address all of the

Standard 4 IEEE Standard Techniques for High-Voltage

3

safety concerns, if any, associated with its use. It is the Testing

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and to determine the

applicability of regulatory limitations prior to use. Specific

3.1 Definitions—Definitions of terms used in this test

warnings are given in 11.3.3.

method are given in Terminology D2864. Also refer to Test

1.5 Mercury has been designated by the EPA and many state

Methods D150 for detailed discussion of terms.D150

agencies as a hazardous material that can cause nervous

4. Significance and Use

system, kidney and liver damage. Mercury, or its vapor, may be

hazardous to health and corrosive to materials. Caution should

4.1 Dissipation Factor (or Power Factor)—This is a mea-

be taken when handling mercury and mercury containing

sure of the dielectric losses in an electrical insulating liquid

products. See the applicable product Material Safety Data

when used in an alternating electric field and of the energy

Sheet (MSDS) for details and the EPA’s website: http://

dissipated as heat. A low dissipation factor or power factor

www.epa.gov/mercury/faq.htm for additional information. Us-

indicates low ac dielectric losses. Dissipation factor or power

ers should be aware that selling mercury and/or mercury

factor may be useful as a means of quality control, and as an

containing products into your state may be prohibited by state

indication of changes in quality resulting from contamination

law.

and deterioration in service or as a result of handling.

1 2

This test method is under the jurisdiction of ASTM Committee D27 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mittee D27.05 on Electrical Test. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2008. Published December 2008. Originally the ASTM website.

3

approved in 1947 as D924 – 47 T. Last previous edition approved in 2004 as Available from Institute of Electrical and Electronic Engineers, 445 Hoes Lane,

D924 – 04. DOI: 10.1520/D0924-08. Piscataway, NJ 08854.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

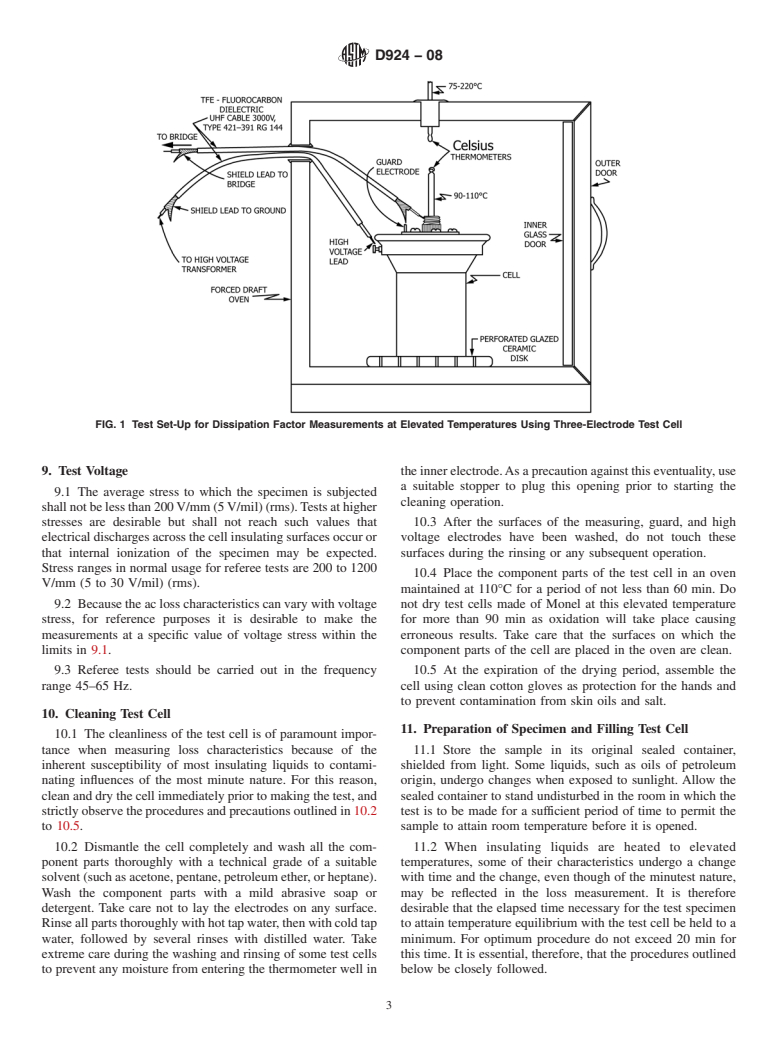

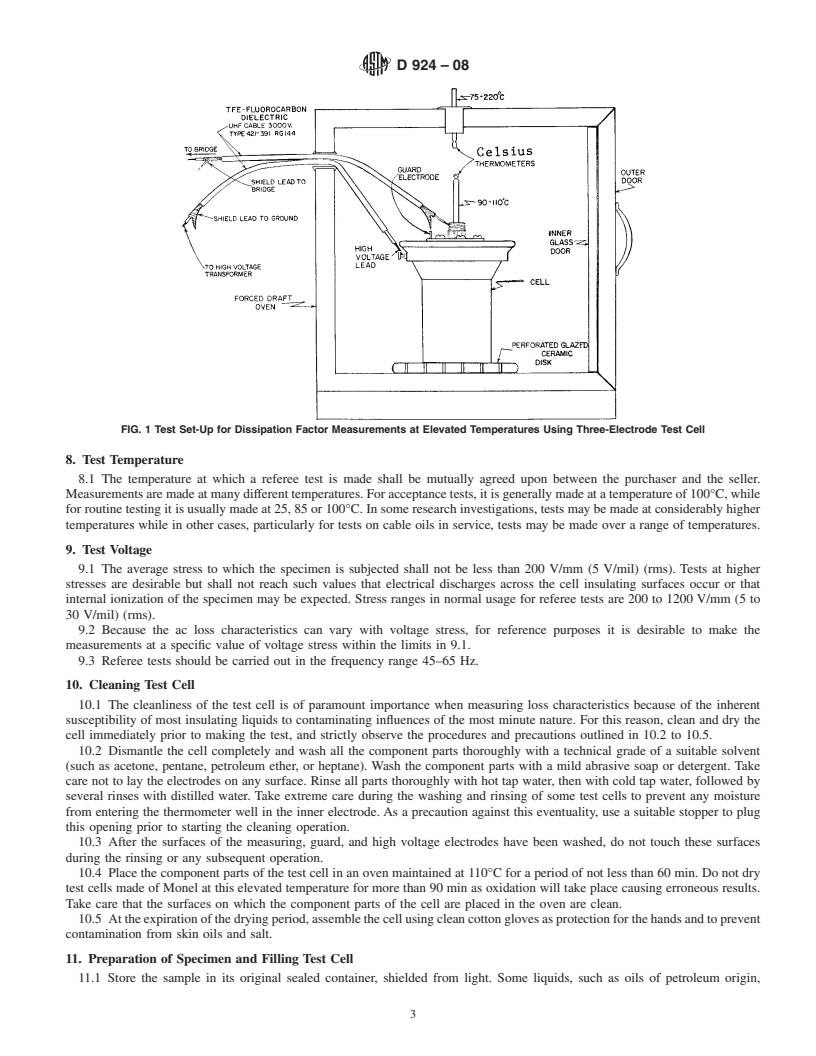

D924 − 08

4.1.1 The loss characteristic is commonly measured in PROCEDURE FOR MAKING REFEREE TESTS

terms of dissipation factor (tangent of the loss angle) or of

6. Apparatus

power factor (sine of the loss angle) and may be expressed as

a decimal value or as a percentage. For decimal values up to

6.1 Measuring equipment used in these procedures shall be

0.05, dissipation factor and power factor values are equal to

in accordance with Test Methods D150.

each other within about one part in one thousand. In general,

6.2 Use only a three-terminal cell for these tests.

since the dissipation factor or power factor of insulating oils in

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 924–04 Designation:D 924–08

Standard Test Method for

Dissipation Factor (or Power Factor) and Relative

Permittivity (Dielectric Constant) of Electrical Insulating

1

Liquids

This standard is issued under the fixed designation D 924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method describes testing of new electrical insulating liquids as well as liquids in service or subsequent to service

in cables, transformers, oil circuit breakers, and other electrical apparatus.

1.2 This test method provides a procedure for making referee tests at a commercial frequency of between 45 and 65 Hz.

1.3 Where it is desired to make routine determinations requiring less accuracy, certain modifications to this test method are

permitted as described in Sections 16 to 24.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use. Specific warnings are given in 11.3.3.

1.5 Mercury has been designated by the EPA and many state agencies as a hazardous material that can cause nervous system,

kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken

when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for

details and the EPA’s website: http://www.epa.gov/mercury/faq.htm for additional information. Users should be aware that selling

mercury and/or mercury containing products into your state may be prohibited by state law.

2. Referenced Documents

2

2.1 ASTM Standards:

D 150 Test Methods forAC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulating Materials

D 923 Practices for Sampling Electrical Insulating Liquids

D 2864 Terminology Relating to Electrical Insulating Liquids and Gases

D 2865 Practice for Calibration of Standards and Equipment for Electrical Insulating Materials Testing

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 IEEE Standard:

3

Standard 4 IEEE Standard Techniques for High-Voltage Testing

3. Terminology

3.1 Definitions—Definitions of terms used in this test method are given in Terminology D 2864.Also refer to Test Methods D

150 for detailed discussion of terms.

4. Significance and Use

4.1 DissipationFactor(orPowerFactor)—Thisisameasureofthedielectriclossesinanelectricalinsulatingliquidwhenused

in an alternating electric field and of the energy dissipated as heat. A low dissipation factor or power factor indicates low ac

dielectric losses. Dissipation factor or power factor may be useful as a means of quality control, and as an indication of changes

in quality resulting from contamination and deterioration in service or as a result of handling.

4.1.1 The loss characteristic is commonly measured in terms of dissipation factor (tangent of the loss angle) or of power factor

1

This test method is under the jurisdiction ofASTM Committee D27 on Electrical Insulating Liquids and Gases and is the direct responsibility of Subcommittee D27.05

on Electrical Tests.Test.

Current edition approved Oct.Nov. 1, 2004.2008. Published October 2004.December 2008. Originally approved in 1947 as D 924 – 47 T. Last previous edition approved

in 20032004 as D924–03a. D 924 – 04.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Institute of Electrical and Electronic Engineers, 445 Hoes Lane, Piscataway, NJ 08854.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D924–08

(sine of the loss angle) and may be expressed as a decimal value or as a percentage. For decimal values up to 0.05, dissipation

factorandpowerfactorvaluesareequaltoeachotherwithinaboutonepartinonethousand.Ingeneral,sincethed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.