ASTM C1579-06(2012)

(Test Method)Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert)

Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert)

SIGNIFICANCE AND USE

4.1 The test method is intended to evaluate the effects of evaporation, settlement, and early autogenous shrinkage on the plastic shrinkage cracking performance of fiber reinforced concrete up to and for some hours beyond the time of final setting (See Terminology C125).

4.2 The measured values obtained from this test may be used to compare the performance of concretes with different mixture proportions, concretes with and without fibers, concretes containing various amounts of different types of fibers, and concretes containing various amounts and types of admixtures. For meaningful comparisons, the evaporative conditions during test shall be sufficient to produce an average crack width of at least 0.5 mm in the control specimens (2, 5) (See Note 2). In addition, the evaporation rate from a free surface of water shall be within ± 5 % for each test.Note 2—To achieve evaporation rates that result in a crack of at least 0.5 mm in the control specimens, it may be necessary to use an evaporation rate higher than that discussed in Note 1.

4.3 This method attempts to control atmospheric variables to quantify the relative performance of a given fresh concrete mixture. Since many other variables such as cement fineness, aggregate gradation, aggregate volume, mixing procedures, slump, air content, concrete temperature and surface finish can also influence potential cracking, attention shall be paid to keep these as consistent as possible from mixture to mixture.

SCOPE

1.1 This test method compares the surface cracking of fiber reinforced concrete panels with the surface cracking of control concrete panels subjected to prescribed conditions of restraint and moisture loss that are severe enough to produce cracking before final setting of the concrete.

1.2 This test method can be used to compare the plastic shrinkage cracking behavior of different concrete mixtures containing fiber reinforcement.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. ( Warning— fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)2

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1579 − 06(Reapproved 2012)

Standard Test Method for

Evaluating Plastic Shrinkage Cracking of Restrained Fiber

Reinforced Concrete (Using a Steel Form Insert)

This standard is issued under the fixed designation C1579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for Test Methods for Construction Materials

C995 Test Method for Time of Flow of Fiber-Reinforced

1.1 This test method compares the surface cracking of fiber

Concrete Through Inverted Slump Cone (Withdrawn

reinforced concrete panels with the surface cracking of control

2009)

concrete panels subjected to prescribed conditions of restraint

and moisture loss that are severe enough to produce cracking

3. Summary of Test Method

before final setting of the concrete.

3.1 Panels of control concrete and fiber reinforced concrete

1.2 This test method can be used to compare the plastic

are prepared in a prescribed manner and are exposed to

shrinkage cracking behavior of different concrete mixtures

controlled drying conditions after finishing. The drying condi-

containing fiber reinforcement.

tions (See Note 1) are intended to be severe enough to induce

1.3 The values stated in SI units are to be regarded as

plastic shrinkage cracking in test panels made of control

standard. No other units of measurement are included in this

concrete. The evaporation rate from a free water surface is

standard.

monitored by pans placed next to the panels in the environ-

mental chamber.

1.4 This standard does not purport to address all of the

NOTE 1—An important parameter in this method is the rate of

safety concerns, if any, associated with its use. It is the

evaporative water loss, which is controlled by the atmospheric conditions

responsibility of the user of this standard to establish appro-

surrounding the test specimens. Since the concrete specimens will not

priate safety and health practices and determine the applica-

always have the same rate of water evaporation as the pan of water (due

bility of regulatory limitations prior to use. (Warning— fresh

to evaporative and bleeding effects), the rate of evaporation of 1.0 kg/m ·h

hydraulic cementitious mixtures are caustic and may cause from the pan of water represents the minimum evaporation rate that must

be attained for this test (1). The moisture loss from the concrete test

chemical burns to skin and tissue upon prolonged exposure.)

panels can also be monitored and reported, however, the rate of evapora-

tion from the free surface of the water in the pan is the parameter that

2. Referenced Documents

should be used to quantify the drying environment.

2.1 ASTM Standards:

3.2 The test is terminated at the time of final setting of the

C125 Terminology Relating to Concrete and Concrete Ag-

concrete determined in accordance with Test Method C403/

gregates

C403M. At 24 h from initial mixing, the average crack width

C143/C143M Test Method for Slump of Hydraulic-Cement

is determined.

Concrete

3.3 A cracking reduction ratio (CRR) is computed from the

C192/C192M Practice for Making and Curing Concrete Test

average crack width for the fiber-reinforced concrete panels

Specimens in the Laboratory

and the average crack width for the control concrete panels.

C403/C403M Test Method for Time of Setting of Concrete

Mixtures by Penetration Resistance

4. Significance and Use

C670 Practice for Preparing Precision and Bias Statements

4.1 The test method is intended to evaluate the effects of

evaporation, settlement, and early autogenous shrinkage on the

This test method is under the jurisdiction of ASTM Committee C09 on

plastic shrinkage cracking performance of fiber reinforced

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

concrete up to and for some hours beyond the time of final

C09.42 on Fiber-Reinforced Concrete.

Current edition approved April 1, 2012. Published October 2012. DOI: 10.1520/

setting (See Terminology C125).

C1579-06R12.

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

Annual Book of ASTM Standards, Vol. 04.02.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1579 − 06 (2012)

4.2 The measured values obtained from this test may be alsoinfluencepotentialcracking,attentionshallbepaidtokeep

used to compare the performance of concretes with different these as consistent as possible from mixture to mixture.

mixture proportions, concretes with and without fibers, con-

5. Apparatus

cretes containing various amounts of different types of fibers,

5.1 Molds:

and concretes containing various amounts and types of admix-

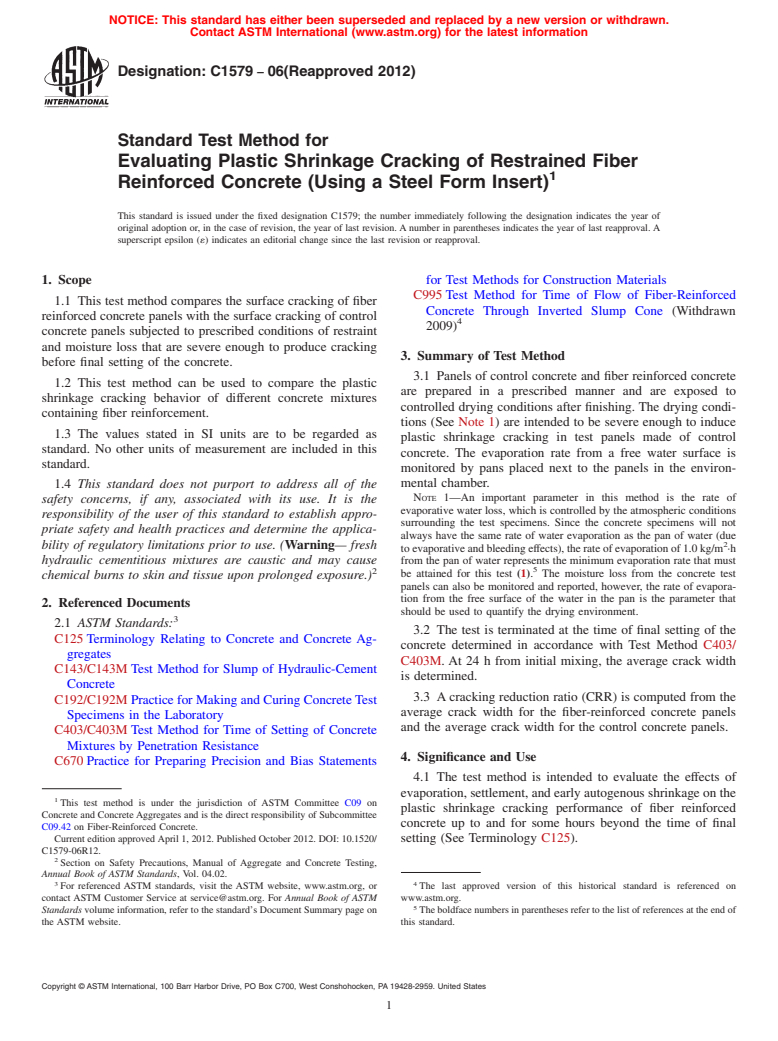

5.1.1 For maximum coarse aggregate size equal to or less

tures. For meaningful comparisons, the evaporative conditions

than 19 mm, use a mold with a depth of 100 65mmand

duringtestshallbesufficienttoproduceanaveragecrackwidth

rectangulardimensionsof355 610mmby560 615mm(See

of at least 0.5 mm in the control specimens (2, 5) (See Note 2).

Fig. 1). The mold can be fabricated from metal, plastic, or

In addition, the evaporation rate from a free surface of water

plywood.

shall be within 6 5 % for each test.

NOTE 2—To achieve evaporation rates that result in a crack of at least

NOTE 3—If plywood is used for molds, the plywood should have low

0.5 mm in the control specimens, it may be necessary to use an

moisture absorption. The mold should be constructed to be lightweight

evaporation rate higher than that discussed in Note 1.

and stiff. The molds, when properly constructed, should last for approxi-

mately 50 uses.

4.3 This method attempts to control atmospheric variables

to quantify the relative performance of a given fresh concrete 5.1.2 This test method is designed for aggregate less than or

mixture. Since many other variables such as cement fineness,

equal to 19 mm. For coarse aggregate greater than 19 mm, the

aggregate gradation, aggregate volume, mixing procedures, depth of the mold shall be at least 65 mm plus at least 2 times

slump, air content, concrete temperature and surface finish can

the maximum coarse aggregate size.

FIG. 1 Specimen and Stress Riser Geometry (4, 5)

C1579 − 06 (2012)

5.2 Stress Riser and Internal Restraints—The internal re- 5.9 Scale—If the rate of moisture loss from test panels is

straints and stress riser shall be bent from one piece of sheet required by the specifier of tests, weigh test panels with a scale

metal, as illustrated in Fig. 1, or made from a solid piece of having a capacity of at least 100 kg and accurate to within

steel. The sheet metal shall have a thickness of 1.2 6 0.05 mm 0.1 % of the test load. Weigh the evaporation rate monitoring

(18 gauge) (See Fig. 1 and Ref 2). Two 32 6 1 mm high pans with a balance or scale having a capacity of at least 3 kg

restraints are placed 90 6 2 mm inward from each end of the and accurate to within 5 g.

mold. The central stress riser is 64 6 2 mm high and serves as

5.10 Crack Measurement Tool—Optical hand-held

an initiation point for cracking. This sheet metal stress riser

microscope,crackcomparator,orimageanalysissystemcanbe

with internal restraints shall fit at the bottom of the mold.

used. The measurement tool should be capable of measuring

5.2.1 Use form release oil to coat the metal insert and mold

crack width to at least the nearest 0.05 mm. If an automated

sides to reduce bond with concrete. The insert and mold are

image analysis system is used, it should be demonstrated to

considered to be properly oiled when the entire surface is

provideanaccuratemeasurement.Todemonstratetheaccuracy

coated and excess oil has been removed with a clean, dry rag.

of the measurement, the system shall be used to measure a 0.5

5.3 VariableSpeedFan(s)—Thefan(s)usedshallbecapable mm notch that is machined into a piece of steel and the

reported notch width shall be within 6 0.05 mm of the

of achieving a wind speed of more than 4.7 m/s over the entire

machined width.

test panel surface area.

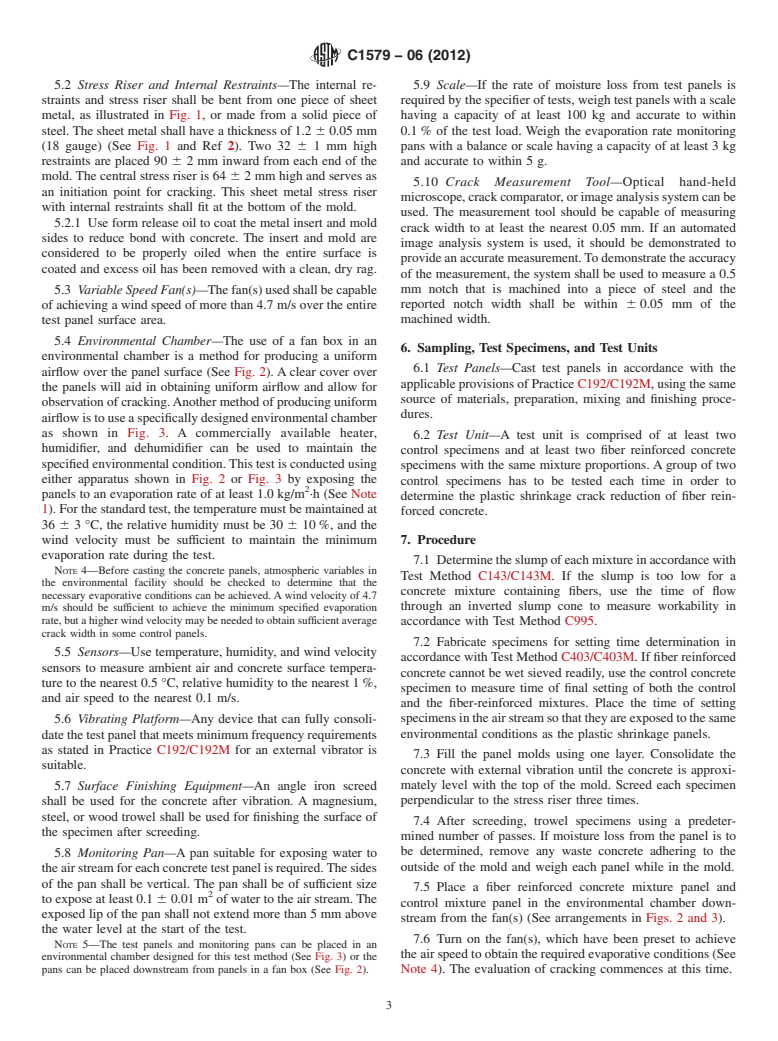

5.4 Environmental Chamber—The use of a fan box in an

6. Sampling, Test Specimens, and Test Units

environmental chamber is a method for producing a uniform

6.1 Test Panels—Cast test panels in accordance with the

airflow over the panel surface (See Fig. 2). A clear cover over

applicable provisions of Practice C192/C192M, using the same

the panels will aid in obtaining uniform airflow and allow for

source of materials, preparation, mixing and finishing proce-

observation of cracking.Another method of producing uniform

dures.

airflowistouseaspecificallydesignedenvironmentalchamber

as shown in Fig. 3. A commercially available heater,

6.2 Test Unit—A test unit is comprised of at least two

humidifier, and dehumidifier can be used to maintain the

control specimens and at least two fiber reinforced concrete

specified environmental condition.This test is conducted using

specimens with the same mixture proportions. A group of two

either apparatus shown in Fig. 2 or Fig. 3 by exposing the

control specimens has to be tested each time in order to

panels to an evaporation rate of at least 1.0 kg/m ·h (See Note

determine the plastic shrinkage crack reduction of fiber rein-

1). For the standard test, the temperature must be maintained at

forced concrete.

36 6 3 °C, the relative humidity must be 30 6 10 %, and the

wind velocity must be sufficient to maintain the minimum 7. Procedure

evaporation rate during the test.

7.1 Determinetheslumpofeachmixtureinaccordancewith

NOTE 4—Before casting the concrete panels, atmospheric variables in

Test Method C143/C143M. If the slump is too low for a

the environmental facility should be checked to determine that the

concrete mixture containing fibers, use the time of flow

necessary evaporative conditions can be achieved.Awind velocity of 4.7

through an inverted slump cone to measure workability in

m/s should be sufficient to achieve the minimum specified evaporation

rate, but a higher wind velocity may be needed to obtain sufficient average

accordance with Test Method C995.

crack width in some control panels.

7.2 Fabricate specimens for setting time determination in

5.5 Sensors—Use temperature, humidity, and wind velocity

accordance with Test Method C403/C403M. If fiber reinforced

sensors to measure ambient air and concrete surface tempera-

concrete cannot be wet sieved readily, use the control concrete

ture to the nearest 0.5 °C, relative humidity to the nearest 1 %,

specimen to measure time of final setting of both the control

and air speed to the nearest 0.1 m/s.

and the fiber-reinforced mixtures. Place the time of setting

specimensintheairstreamsothattheyareexposedtothesame

5.6 Vibrating Platform—Any device that can fully consoli-

environmental conditions as the plastic shrinkage panels.

datethetestpanelthatmeetsminimumfrequencyrequirements

as stated in Practice C192/C192M for an external vibrator is

7.3 Fill the panel molds using one layer. Consolidate the

suitable.

concrete with external vibration until the concrete is approxi-

mately level with the top of the mold. Screed each specimen

5.7 Surface Finishing Equipment—An angle iron screed

perpendicular to the stress riser three times.

shall be used for the concrete after vibration. A magnesium,

steel, or wood trowel shall be used for finishing the surface of

7.4 After screeding, trowel specimens using a predeter-

the specimen after screeding.

mined number of passes. If moisture loss from the panel is to

be determined, remove any waste concrete adhering to the

5.8 Monitoring Pan—A pan suitable for exposing water to

outside of the mold and weigh each panel while in the mold.

theairstreamforeachconcretetestpanelisrequired.Thesides

of the pan shall be vertical. The pan shall be of sufficient size

7.5 Place a fiber reinforced concrete mixture panel and

to expose at least 0.1 6 0.01 m of water to the air stream. The

control mixture panel in the environmental chamber down-

exposed lip of the pan shall not extend more than 5 mm above

stream from the fan(s) (See arrangements in Figs. 2 and 3).

the water level at the start of the test.

7.6 Turn on the fan(s), which have been preset to achieve

NOTE 5—The test panels and monitoring pans can be placed in an

the air speed to obtain the required evaporative conditions (See

environmental chamber designed for this test method (See Fig. 3) or the

pans can be placed downstream from panels in a fan box (See Fig. 2). Note 4). The evaluation of cracking commences at this time.

C1579 − 06 (2012)

FIG. 2 Example of Fan Box to Maintain Environmental Conditions (2) (Not to Scale)

C1579 − 06 (2012)

FIG. 3 Example of Chamber to Maintain Environmental Conditions (4)

7.7 At the start of the test and at 30-min intervals, record air weighings by the surface area of the water in the weighing pan

temperature, relative humidity, and air flow speed at a location and the time interval between successive weighings (See Note

100 6 5 mm above each panel surface. If required by the 6). The test is not valid if the average evaporation rate is less

specifier of tests, record the time at which cracking is first than 1.0 kg/m ·h.

observed for each panel surface. Perform penetration tests at NOTE 6—Adjustments to wind velocity should be made if necessary to

maintain the evaporation rate at the required level. It is suggested that the

regular time intervals according to Test Method C403/C403M.

monitoring pans be placed on scales in the air stream for continuous

Continue recording the environmental variables until the time

monitoring without periodic removal during testing. If this is not possible,

of final setting.

the monitoring pan should be removed from the air stream, weighed, and

returned to the air stream within 15 seconds.

7.8 The evaporation rate is determined by initially weighing

the full monitoring pans at the start of the test and at 30-min 7.9 After final setting occurs (use the later of the measured

intervals thereafter (3). Record the mass loss to the nearest 5 g time of setting in the two speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.