ASTM D5162-00

(Practice)Standard Practice for Discontinuity (Holiday) Testing of Nonconductive Protective Coating on Metallic Substrates

Standard Practice for Discontinuity (Holiday) Testing of Nonconductive Protective Coating on Metallic Substrates

SCOPE

1.1 This practice covers procedures for determining discontinuities using two types of test equipment:

1.1.1 Test Method A--Low Voltage Wet Sponge, and

1.1.2 Test Method B--High Voltage Spark Testers.

1.2 This practice addresses metallic substrates. For concrete surfaces, refer to Practice D4787.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses immediately following inch-pound units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5162 – 00

Standard Practice for

Discontinuity (Holiday) Testing of Nonconductive Protective

Coating on Metallic Substrates

This standard is issued under the fixed designation D 5162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope both. The degree of coating continuity required is dictated by

service conditions. Discontinuities in a coating are frequently

1.1 This practice covers procedures for determining discon-

very minute and not readily visible. This practice provides a

tinuities using two types of test equipment:

procedure for electrical detection of minute discontinuities in

1.1.1 Test Method A—Low Voltage Wet Sponge, and

nonconductive coating systems.

1.1.2 Test Method B—High Voltage Spark Testers.

4.2 Electrical testing to determine the presence and number

1.2 This practice addresses metallic substrates. For concrete

of discontinuities in a coating film is performed on a noncon-

surfaces, refer to Practice D 4787.

ductive coating applied to a conductive surface. The allowable

1.3 This standard does not purport to address all of the

number of discontinuities should be determined prior to

safety concerns, if any, associated with its use. It is the

conducting this test since the acceptable quantity of disconti-

responsibility of the user of this standard to establish appro-

nuities will vary depending on coating film thickness, design,

priate safety and health practices and determine the applica-

and service conditions.

bility of regulatory limitations prior to use.

4.3 The low voltage wet sponge test equipment is generally

2. Referenced Documents used for determining the existence of discontinuities in coating

films having a total thickness of 20 mils (0.5 mm) or less. High

2.1 ASTM Standards:

voltage spark test equipment is generally used for determining

D 4787 Practice for Continuity Verification of Liquid or

the existences of discontinuities in coating films having a total

Sheet Linings Applied to Concrete Substrates

thickness of greater than 20 mils (0.5 mm).

3. Terminology

4.4 Coatings that are applied at a thickness of less than 20

mils (0.5 mm) may be susceptible to damage if tested with high

3.1 Definitions of Terms Specific to This Standard:

voltage spark testing equipment. Consult the coating manufac-

3.1.1 discontinuity, as used in this standard— a void, crack,

turer for proper test equipment and inspection voltages.

thin spot, foreign inclusion, or contamination in the coating

4.5 To prevent damage to a coating film when using high

film that significantly lowers the dielectric strength of the

voltage test instrumentation, total film thickness and dielectric

coating film. May also be identified as a holiday or pinhole.

strength in a coating system shall be considered in selecting the

3.1.2 holiday, as used in this standard—a term that identi-

appropriate voltage for detection of discontinuities. Atmo-

fies a discontinuity.

spheric conditions shall also be considered since the voltage

3.1.3 holiday detector, as used in this standard— a device

required for the spark to gap a given distance in air varies with

that locates discontinuities in a nonconductive coating film

the conductivity of the air at the time the test is conducted.

applied to a conductive surface.

Suggested starting voltages are provided in Table 1.

3.1.4 pinhole, as used in this standard—a film defect

4.6 The coating manufacturer shall be consulted to obtain

characterized by small porelike flaws in the coating which,

the following information, which would affect the accuracy of

when extended entirely through the film, will appear as a

this test to determine discontinuities:

discontinuity. A pinhole in the finish coat may not appear as a

4.6.1 Establish the length of time required to adequately dry

discontinuity.

or cure the applied coating film prior to testing. Solvents

4. Significance and Use

retained in an uncured coating film may form an electrically

conductive path through the film to the substrate.

4.1 A coating is applied to a metallic substrate to prevent

4.6.2 Determine whether the coating contains electrically

corrosion, reduce abrasion or reduce product contamination, or

conductive fillers or pigments that may affect the normal

dielectric properties.

This practice is under the jurisdiction of ASTM Committee D-33 on Protective

4.7 This practice is intended for use with new linings

Coating and Lining Work for Power Generation Facilities and is the direct

applied to metal substrates. Its use on a lining previously

responsibility of Subcommittee D33.04 on Inspection.

Current edition approved May 10, 2000. Published July 2000. Originally

exposed to an immersion condition could result in damaging

published as D 5162–91. Last previous edition D 5162–91.

the lining or producing erroneous detection of discontinuities

Annual Book of ASTM Standards, Vol 06.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5162

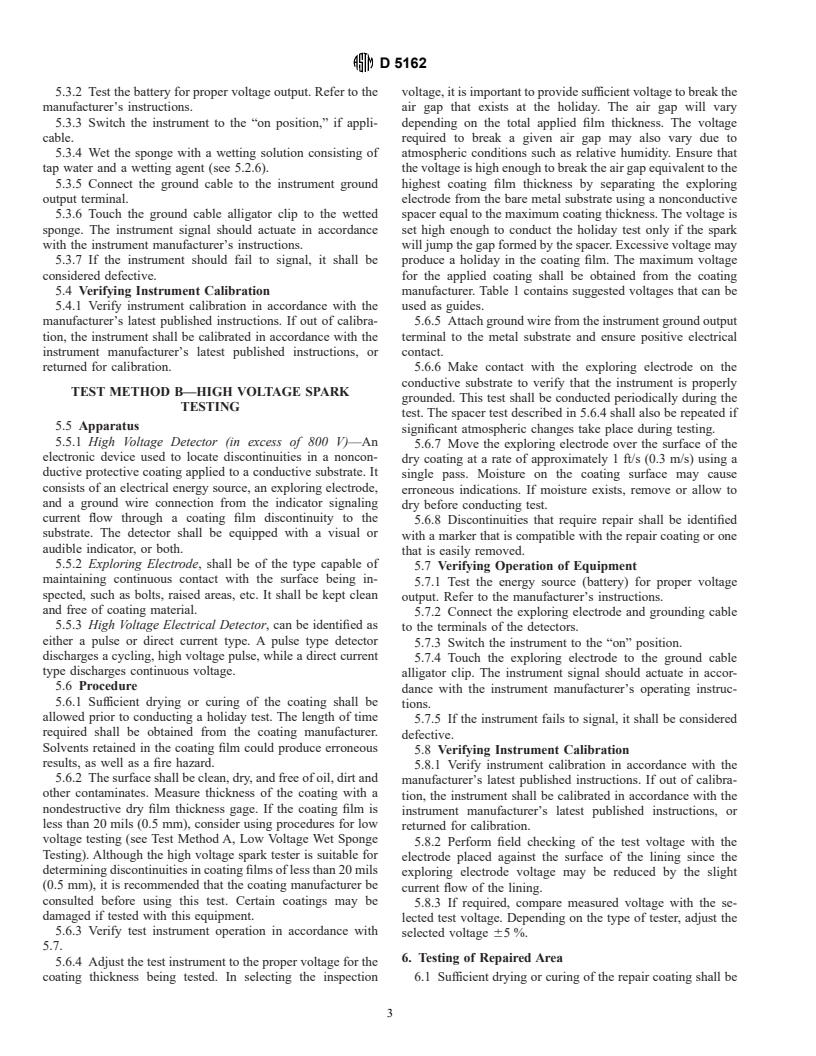

TABLE 1 Suggested Voltages for High Voltage Spark Testing

5.2 Procedure

Total Dry Film Thickness

5.2.1 Sufficient drying or curing of the coating shall be

Suggested Inspection, V

allowed prior to conducting a test. The length of time required

mils mm

shall be obtained from the coating manufacturer. Solvents

8–12 0.20–0.31 1 500

13–18 0.32–0.46 2 000 retained in the coating film could produce erroneous indicators.

19–30 0.47–0.77 2 500

5.2.2 The surface shall be clean, dry, and free of oil, dirt and

31–40 0.78–1.03 4 000

other contaminates. Measure the film thickness of the coating

41–60 1.04–1.54 5 000

61–80 1.55–2.04 7 500

with a nondestructive dry film thickness gage. If the coating

81–100 2.05–2.55 10 000

film exceeds 20 mils (0.5 mm), use the procedures for high

101–125 2.56–3.19 12 000

voltage spark testing described in Test Method B, High Voltage

126–160 3.20–4.07 15 000

161–200 4.08–5.09 20 000

Spark Testing.

201–250 5.10–6.35 25 000

5.2.3 Test the instrument for sensitivity in accordance with

5.3.

5.2.4 Attach the ground wire from the instrument ground

due to permeation or moisture absorption of the lining.

output terminal to the metallic substrate and ensure positive

Deposits may also be present on the surface causing telegraph-

electrical contact.

ing. The use of a high voltage tester on a previously exposed

5.2.5 Attach the exploring sponge lead to the other output

lining has to be carefully considered because of possible spark

terminal.

through which could damage an othewise sound lining. A low

5.2.6 Wet the sponge with a solution consisting of tap water

voltage tester can be used without damaging the lining but may

and a low sudsing wetting agent, combined at a ratio of not

also produce erroneous results.

more than ⁄2 fluid oz of wetting agent to 1 gal water. An

example of a low sudsing wetting agent is one used in

5. Test Methods

photographic development. The sponge shall be wetted suffi-

ciently to barely avoid dripping of the solution while the

TEST METHOD A—LOW VOLTAGE WET SPONGE

sponge is moved over the coating. The wetting agent residue

TESTING

must be removed prior to executing repairs.

5.1 Apparatus

5.2.7 Sodium chloride (salt) shall not be added to the

5.1.1 Low Voltage Holiday Detector—an electronic device

wetting solution because of the potential erroneous indications

powered by a self-contained battery with voltages ranging from

of discontinuities. The salt, after drying on the coated surface,

5 to 90 V dc, depending on the equipment manufacturer’s

may form a continuous path of conductivity. It will also

circuit design. It is used to locate discontinuities in a noncon-

interfere with intercoat adhesion of additional coats.

ductive coating applied to a conductive substrate. Operation

5.2.8 Contact a bare spot on the conductive substrate with

includes the use of an open-cell sponge electrode wetted with

the wetted sponge to verify that the instrument is properly

a solution for exploring the coating surface, a ground connec-

grounded. This procedure shall be repeated periodically during

tion, and an audible or visual indicator, or both, for signaling a

the test.

point of coating discontinuity.

5.2.9 Move the sponge over the surface of the coating at a

5.1.2 Low Voltage Wet Sponge Tester— a sensitivity device

moderate rate approximately 1 ft/s (0.3 m/s), using a double

with the operating voltage being of little importance other than

pass over each area. Apply sufficient pressure to maintain a wet

being part of the particular electronic circuit design.

surface. If a discontinuity is detected, turn the sponge on end to

5.1.3 Wet Sponge Type Instruments—a number of commer-

determine the exact location of the discontinuity.

cially available, industry-accepted, instruments are available.

5.2.10 Discontinuities that require repair shall be identified

The following electronic principle describes two types of

with a marker that is compatible with the repair coating or one

devices generally used; others may be available but are not

that is easily removed.

described in this practice.

5.2.11 To pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.