ASTM D3373-03(2007)e1

(Test Method)Standard Test Method for Vanadium in Water

Standard Test Method for Vanadium in Water

SIGNIFICANCE AND USE

Vanadium can be found in waste that result from chemical cleaning of components in which the metal is alloyed.

National Pollutant Discharge Elimination Systems permits or other standards, or both, require monitoring pollutants in waste discharged onto the water shed of, or into, navigable waters, and those disposed of in such a manner that eventual contamination of underground water could result.

This test method affords an accurate and sensitive means of determining compliance or noncompliance, or both, with those permits.

SCOPE

1.1 This test method covers the determination of dissolved and total recoverable vanadium in most waters and wastewater by graphite furnace atomic absorption spectrophotometry.

1.2 The optimum range of this test method is 10 to 200 μg/L of vanadium based on a 20-L sample size. Concentrations higher than 200 g/L may be determined by proper dilution of sample. A detection level as low as 4 μg/L of vanadium has been reported.

1.3 This test method has been used successfully with reagent water, lake water, tap water, river water, condensate from a medium Btu coal gasification process, and well water. It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability or regulatory limitations prior to use.

1.4 Former Test Method A (Catalytic) was discontinued. Refer to Appendix X1 for historical information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D3373 − 03(Reapproved 2007)

Standard Test Method for

Vanadium in Water

This standard is issued under the fixed designation D3373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Sections 7.5 and 13.5 were updated editorially in September 2007

1. Scope D1193 Specification for Reagent Water

D2777 Practice for Determination of Precision and Bias of

1.1 This test method covers the determination of dissolved

Applicable Test Methods of Committee D19 on Water

and total recoverable vanadium in most waters and wastewater

D3370 Practices for Sampling Water from Closed Conduits

by graphite furnace atomic absorption spectrophotometry.

D3919 Practice for Measuring Trace Elements in Water by

1.2 Theoptimumrangeofthistestmethodis10to200µg/L

Graphite Furnace Atomic Absorption Spectrophotometry

of vanadium based on a 20-µL sample size. Concentrations

D4841 Practice for Estimation of Holding Time for Water

higher than 200µ g/L may be determined by proper dilution of

Samples Containing Organic and Inorganic Constituents

sample. A detection level as low as 4 µg/L of vanadium has

D5810 Guide for Spiking into Aqueous Samples

been reported.

D5847 Practice for Writing Quality Control Specifications

1.3 This test method has been used successfully with

for Standard Test Methods for Water Analysis

reagent water, lake water, tap water, river water, condensate

from a medium Btu coal gasification process, and well water.

3. Terminology

It is the user’s responsibility to ensure the validity of this test

3.1 Definitions: For definitions of terms used in this test

method for waters of untested matrices.

method refer to Terminology D1129.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 total recoverable vanadium—dissolvedvanadiumplus

responsibility of the user of this standard to establish appro-

that solubilized by acid digestion of particulates and organics

priate safety and health practices and determine the applica-

in the sample.

bility or regulatory limitations prior to use.

1.5 Former Test Method A (Catalytic) was discontinued.

4. Summary of Test Method

Refer to Appendix X1 for historical information.

4.1 Vanadium is determined by an atomic absorption spec-

2. Referenced Documents

trophotometer utilizing a graphite furnace for sample atomiza-

2.1 ASTM Standards:

tion.

D1066 Practice for Sampling Steam

4.2 Asamplevolumeofseveralmicrolitres,dependingupon

D1129 Terminology Relating to Water

the concentration of the analyte, is transferred to a graphite

D1192 Guide for Equipment for Sampling Water and Steam

3 tube housed within an electrical furnace and the system is

in Closed Conduits (Withdrawn 2003)

heated in an inert or reducing atmosphere. The sample is

evaporated to dryness, charred (pyrolyzed or ashed) and

atomized.

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.05 on Inorganic Constituents

4.3 Groundstateatoms,producedinatomization,absorbthe

in Water.

light of their spectrum emanating from a source and passing

Current edition approved Aug. 1, 2007. Published September 2007. Originally

approved in 1975. Last previous edition approved in 2003 as D3373 – 03. DOI: through the sample vapor. The amount of light absorbed is

10.1520/D3373-03R07E01.

proportional to the concentration of the analyte in the sample.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.4 Since the graphite furnace uses the sample much more

Standards volume information, refer to the standard’s Document Summary page on

efficiently than does flame atomization, the detection of low

the ASTM website.

concentrations of the elements of interest in small volumes is

The last approved version of this historical standard is referenced on

www.astm.org. possible.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

´1

D3373 − 03 (2007)

4.5 Finally, the absorption signal produced during atomiza- where such specifications are available. Other grades may be

tion is recorded and compared to those of standards, taken used, provided it is first ascertained that the reagent is of

through the same process, by means of an analytical curve. sufficiently high purity to permit its use without lessening the

accuracy of the determination.

4.6 A general guide for graphite furnace applications is

given in Practice D3919. 8.2 Purity of Water—Unless otherwise indicated, references

towatershallbeunderstoodtomeanreagentwaterconforming

4.7 Dissolved vanadium is determined after filtration and

to Specification D1193, Type I. Other reagent water types may

addition of HNO toapHof ≤ 2.

be used provided it is first ascertained that the water is of

4.8 Total recoverable vanadium is determined following

sufficiently high purity to permit its use without adversely

acid digestion and filtration.

affecting the precision and bias of the test method.

8.3 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

5. Significance and Use

(HNO ).

5.1 Vanadium can be found in waste that result from

8.4 Vanadium Solution, Stock (1.0 mL = 100 µg vanadium).

chemicalcleaningofcomponentsinwhichthemetalisalloyed.

Dissolve 0.2296 g of ammonium metavanadate (NH VO)in

4 3

5.2 National Pollutant Discharge Elimination Systems per-

water and dilute to 1000 mL.

mits or other standards, or both, require monitoring pollutants

8.5 Vanadium Solution, Intermediate (1.0 mL = 1.0 µg va-

in waste discharged onto the water shed of, or into, navigable

nadium) —Dilute 5 mL of vanadium stock solution to 500 mL

waters, and those disposed of in such a manner that eventual

with water.

contamination of underground water could result.

8.6 Vanadium Solution, Standard (1.0 mL = 0.100 µg

5.3 Thistestmethodaffordsanaccurateandsensitivemeans

vanadium)—Dilute10.0mLofvanadiumintermediatesolution

of determining compliance or noncompliance, or both, with

to 100 mL with water.

those permits.

8.7 Nitrogen Gas—standard, welders grade, commercially

6. Interferences

available.

6.1 For a complete discussion on general interferences with

NOTE 2—It is probable that argon or some other inert gas can be used

furnace procedures, the analyst is referred to Practice D3919.

in place of nitrogen. It is the analyst’s responsibility to verify suitability.

7. Apparatus

9. Sampling

7.1 Atomic Absorption Spectrophotometer , for use at 318.4

9.1 Collect the sample in accordance with Practice D1066,

nm with background correction.

Specification D1192, and Practices D3370, as applicable. The

holding time for the sample may be calculated in accordance

NOTE 1—The manufacturer’s instructions should be followed for all

with Practice D4841.

instrumental parameters.

7.2 Vanadium Hollow Cathode Lamp.

9.2 Preserve samples with nitric acid (HNO , sp gr 1.42) to

a pH of 2 or less immediately at the time of collection,

7.3 Graphite Furnace capable of reaching temperature suf-

normally about 2 mL/L. If only dissolved vanadium is to be

ficient to atomize the element of interest.

determined, filter the sample through a 0.45-µm (No. 325)

7.4 Graphite Tubes, pyrolytically coated, compatible with

membrane filter before acidification.

furnace device are recommended.

7.5 Pipettes, microlitre with disposable tips, ranging in size

10. Standardization

from 1 to 100 µL.

10.1 Initially, set the instrument in accordance with the

7.6 Strip Chart Recorder—A recorder is strongly recom-

manufacturer’s specifications. Follow the general instructions

mended.Thetracingscanbeusedaspermanentrecordsandare as provided in Practice D3919.

of diagnostic value in the identification and analysis of

instrument problems (such as drift, incomplete atomization, 11. Procedure

change in sensitivity, etc.). A fast response recorder (0.2 s or

11.1 Clean all glassware to be used for preparation of

less for full-scale deflection) is recommended to ensure accu-

standard solutions or in the digestion step, or both, by rinsing

racy. Electronic peak-measuring devices have also been found

first with HNO (1 + 1) and then with water. Alternatively,

useful.

soaking the glassware overnight in HNO (1 + 1) is useful for

7.7 Automatic Sampling Accessory is recommended, if low levels.

available.

8. Reagents and Materials

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

8.1 Purity of Reagents—Reagent grade chemicals shall be

listed by the American Chemical Society, see Annual Standards for Laboratory

used in all tests. Unless otherwise indicated, it is intended that

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

all reagents shall conform to the specifications of Committee

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

on Analytical Reagents of the American Chemical Society, MD.

´1

D3373 − 03 (2007)

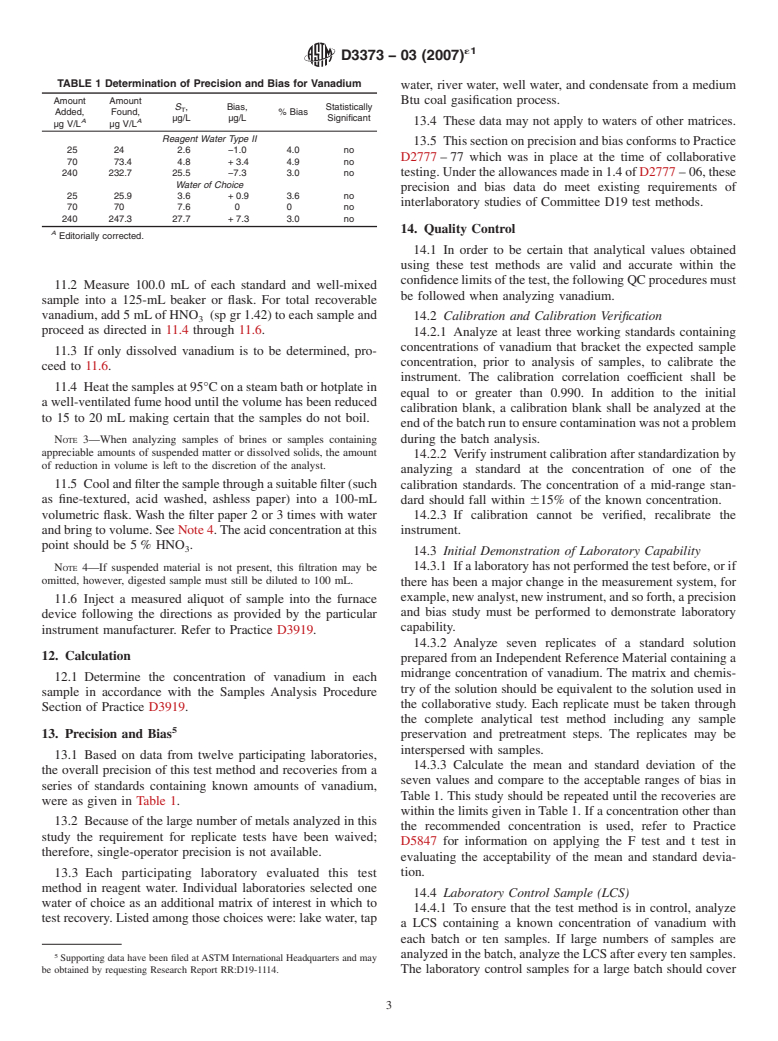

TABLE 1 Determination of Precision and Bias for Vanadium

water, river water, well water, and condensate from a medium

Amount Amount Btu coal gasification process.

S , Bias, Statistically

T

Added, Found, % Bias

µg/L µg/L Significant

A A

13.4 These data may not apply to waters of other matrices.

µg V/L µg V/L

Reagent Water Type II

13.5 ThissectiononprecisionandbiasconformstoPractice

25 24 2.6 −1.0 4.0 no

D2777 – 77 which was in place at the time of collaborative

70 73.4 4.8 + 3.4 4.9 no

240 232.7 25.5 −7.3 3.0 no testing.Undertheallowancesmadein1.4ofD2777 – 06,these

Water of Choice

precision and bias data do meet existing requirements of

25 25.9 3.6 + 0.9 3.6 no

interlaboratory studies of Committee D19 test methods.

70 70 7.6 0 0 no

240 247.3 27.7 + 7.3 3.0 no

14. Quality Control

A

Editorially corrected.

14.1 In order to be certain that analytical values obtained

using these test methods are valid and accurate within the

confidencelimitsofthetest,thefollowingQCproceduresmust

11.2 Measure 100.0 mL of each standard and well-mixed

be followed when analyzing vanadium.

sample into a 125-mL beaker or flask. For total recoverable

vanadium, add 5 mLof HNO (sp gr 1.42) to each sample and

14.2 Calibration and Calibration Verification

proceed as d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.