ASTM A709/A709M-00

(Specification)Standard Specification for Carbon and High-Strength Low-Alloy Structural Steel Shapes, Plates, and Bars and Quenched-and-Tempered Alloy Structural Steel Plates for Bridges

Standard Specification for Carbon and High-Strength Low-Alloy Structural Steel Shapes, Plates, and Bars and Quenched-and-Tempered Alloy Structural Steel Plates for Bridges

SCOPE

1.1 This specification covers carbon and high-strength low-alloy steel structural shapes, plates, and bars and quenched and tempered alloy steel for structural plates intended for use in bridges. Seven grades are available in four yield strength levels as follows: Grade U.S. [SI] Yield Strength, ksi: [MPa] 36 [250] 36 [250] 50 [345] 50 [345] 50S[345W] 50 [345] HPS 50W [HPS 345W]50 [345] HPS 70W [HPS 485W]70 [485] 100 [690] 100 [690] 100W [690W] 100 [690]

1.1.1 Grades 36 [250], 50 [345], 50S [345W], 100 [690], and 100W [690W] are also included in Specifications A 36/A 36M, A 572/A 572M, A 992/A 992M, A 588/A 588M, and A 514/A 514M, respectively. When the supplementary requirements of this specification are specified, they exceed the requirements of Specifications A 36/A 36M, A 572/A 572M, A 992/A 992M, A 588/A 588M, and A 514/A 514M.

1.1.2 Grades 50W [345W], HPS 50W [HPS 345], HPS 70W [HPS 485W], and 100W [690W] have enhanced atmospheric corrosion resistance (see 11.1.2). Product availability is shown in .

1.2 Grade HPS 70W [HPS 485W], 100 [690], or 100W [690W] shall not be substituted for Grades 36 [250], 50 [345], 50S [345S], 50W [345W], or HPS 50W [HPS 345W]. Grade 50W [345W], or HPS 50W [HPS 345W] shall not be substituted for Grades 36 [250], 50 [345] or 50S [345S] without agreement between the purchaser and the supplier.

1.3 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A 6/A 6M for information on weldability.

1.4 Supplementary requirements are available but shall apply only when specified by the purchaser at the time of ordering.

1.5 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.6 For structural products cut from coiled product, the additional requirements, including additional testing requirements and the reporting of additional test results, of Specification A 6/A 6M apply.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 709/A 709M – 00

Standard Specification for

Carbon and High-Strength Low-Alloy Structural Steel

Shapes, Plates, and Bars and Quenched-and-Tempered

Alloy Structural Steel Plates for Bridges

This standard is issued under the fixed designation A 709/A 709M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Supplementary requirements are available but shall

apply only when specified by the purchaser at the time of

1.1 This specification covers carbon and high-strength low-

ordering.

alloy steel structural shapes, plates, and bars and quenched and

1.5 The values stated in either inch-pound units or SI units

tempered alloy steel for structural plates intended for use in

are to be regarded as standard. Within the text, the SI units are

bridges. Six grades are available in four yield strength levels as

shown in brackets. The values stated in each system are not

follows:

exact equivalents; therefore, each system must be used inde-

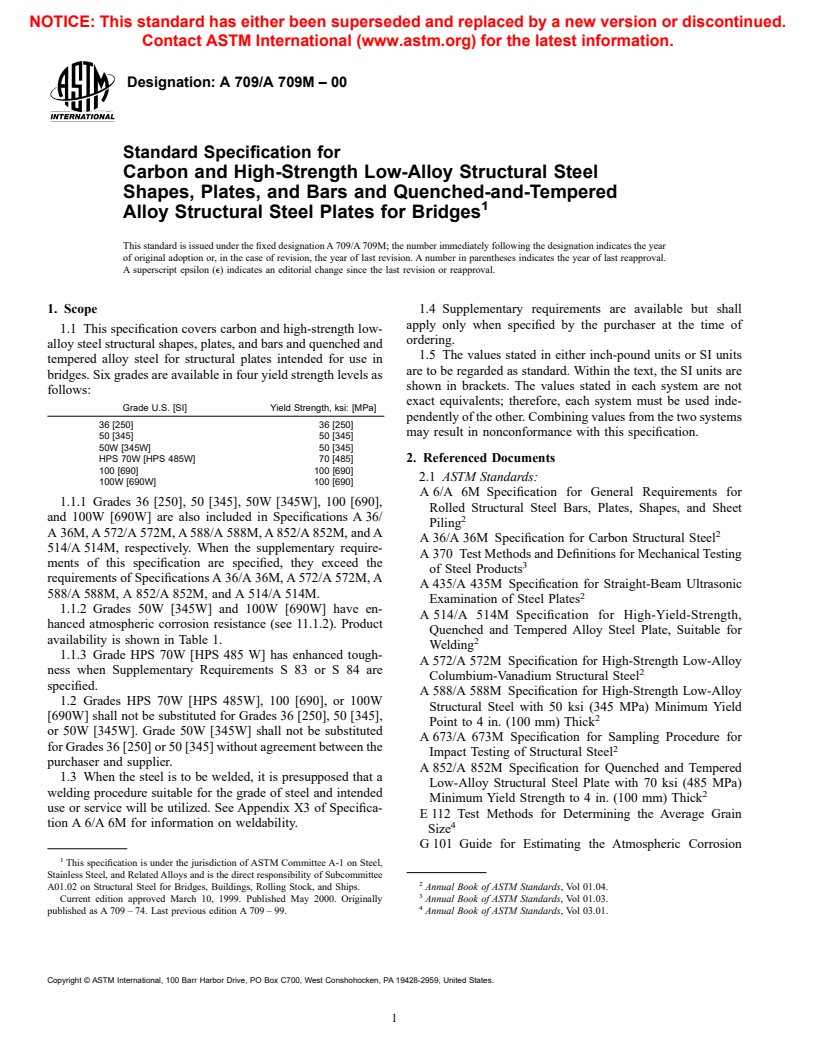

Grade U.S. [SI] Yield Strength, ksi: [MPa]

pendently of the other. Combining values from the two systems

36 [250] 36 [250]

may result in nonconformance with this specification.

50 [345] 50 [345]

50W [345W] 50 [345]

HPS 70W [HPS 485W] 70 [485] 2. Referenced Documents

100 [690] 100 [690]

2.1 ASTM Standards:

100W [690W] 100 [690]

A 6/A 6M Specification for General Requirements for

1.1.1 Grades 36 [250], 50 [345], 50W [345W], 100 [690],

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

and 100W [690W] are also included in Specifications A 36/

Piling

A 36M, A 572/A 572M, A 588/A 588M, A 852/A 852M, and A 2

A 36/A 36M Specification for Carbon Structural Steel

514/A 514M, respectively. When the supplementary require-

A 370 Test Methods and Definitions for Mechanical Testing

ments of this specification are specified, they exceed the 3

of Steel Products

requirements of Specifications A 36/A 36M, A 572/A 572M, A

A 435/A 435M Specification for Straight-Beam Ultrasonic

588/A 588M, A 852/A 852M, and A 514/A 514M. 2

Examination of Steel Plates

1.1.2 Grades 50W [345W] and 100W [690W] have en-

A 514/A 514M Specification for High-Yield-Strength,

hanced atmospheric corrosion resistance (see 11.1.2). Product

Quenched and Tempered Alloy Steel Plate, Suitable for

availability is shown in Table 1.

Welding

1.1.3 Grade HPS 70W [HPS 485 W] has enhanced tough-

A 572/A 572M Specification for High-Strength Low-Alloy

ness when Supplementary Requirements S 83 or S 84 are

Columbium-Vanadium Structural Steel

specified.

A 588/A 588M Specification for High-Strength Low-Alloy

1.2 Grades HPS 70W [HPS 485W], 100 [690], or 100W

Structural Steel with 50 ksi (345 MPa) Minimum Yield

[690W] shall not be substituted for Grades 36 [250], 50 [345], 2

Point to 4 in. (100 mm) Thick

or 50W [345W]. Grade 50W [345W] shall not be substituted

A 673/A 673M Specification for Sampling Procedure for

for Grades 36 [250] or 50 [345] without agreement between the 2

Impact Testing of Structural Steel

purchaser and supplier.

A 852/A 852M Specification for Quenched and Tempered

1.3 When the steel is to be welded, it is presupposed that a

Low-Alloy Structural Steel Plate with 70 ksi (485 MPa)

welding procedure suitable for the grade of steel and intended

Minimum Yield Strength to 4 in. (100 mm) Thick

use or service will be utilized. See Appendix X3 of Specifica-

E 112 Test Methods for Determining the Average Grain

tion A 6/A 6M for information on weldability.

Size

G 101 Guide for Estimating the Atmospheric Corrosion

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships. Annual Book of ASTM Standards, Vol 01.04.

Current edition approved March 10, 1999. Published May 2000. Originally Annual Book of ASTM Standards, Vol 01.03.

published as A 709 – 74. Last previous edition A 709 – 99. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 709/A 709M

A

TABLE 1 Tensile and Hardness Requirements

NOTE 1— Where “. . .” appears in this table, there is no requirement.

Minimum Elongation, %

Yield Point

Reduc- Brinell

EC E

or Yield Tensile Plates and Bars Shapes

Plate Thickness, Structural Shapes tion of Hard-

B

Grade Strength, Strength,

C,D

in. [mm] Groups 8 in. 2 in. 8 in. 2 in. Area ness

min, ksi ksi [MPa]

min, % Number

or 200 or 50 or 200 or 50

[MPa]

mm mm mm mm

F G

36 [250] to 4 [100], incl to 426 lb/ft (634 kg/m) 36 [250] 58–80 [400–550] 20 23 20 21 .

G

over 426 lb/ft (634 kg/m) 36 [250] 58 min [400] . . 20 19 .

F G

50 [345] to 4 [100], incl all 50 [345] 65 min [450] 18 21 18 21 .

H G

50W [345W] to 4 [100], incl all 50 [345] 70 min [485] 18 21 18 21 .

I B G

HPS 70W [HPS to 4 [100], incl 70 [485] 85–110 [585–760] . . . 19 . . . . . . . . .

485 W]

I B J K L G

100 [690] and to21 2 [65], 100 [690] 110–130 [760–895] . 18 . . 40 –50 235–293

/

100W [690W] incl

I B J K LG

100 [690] and over 2 1 2to4 90 [620] 100–130 [690–895] . 16 . . 40 –50

/

100W [690 W] [65

to 100]

A

See specimen orientation and preparation subsection in the Tension Tests section of Specification A 6/A 6 M.

B

Measured at 0.2 % offset or 0.5 % extension under load as described in Section 13 of Test Methods A 370.

C

Elongation and reduction of area not required to be determined for floor plates.

D

For plates wider than 24 in. [600 mm], the reduction of area requirement, where applicable, is reduced by five percentage points.

E

For plates wider than 24 in. [600 mm], the elongation requirement is reduced two percentage points. See elongation requirement adjustments in the Tension Tests

section of Specification A 6/A 6M.

F

Elongation in 2 in. or 50 mm: 19 % for shapes over 426 lb/ft [634 kg/m].

G

Brinell requirements apply only to material ⁄8 in. [10 mm] and thinner for Grades 100 and 100W.

H

For wide flange shapes over 426 lb/ft [634 kg/m], elongation in 2 in. of 18 % minimum applies.

I

The grade is not described for this product.

J

When measured on the Fig. 3 (Test Methods A 370) 1 ⁄2–in. [40–mm] wide specimen the elongation is determined in a 2–in. or 50–mm gage length which includes the

fracture and shows the greatest elongation.

K

When measured on the Fig. 3 (Test Methods A 370) 1 ⁄2-in. [40-mm] wide specimen.

L

When measured on the Fig. 4 (Test Methods A 370) ⁄2–in. [12.5–mm] round specimen.

Resistance of Low-Alloy Steels conform to the tensile and hardness requirements of Table 1 by

heating to not less than 1650°F [900°C], quenching in water or

3. General Requirements for Delivery

oil, and tempering at not less than 1100°F [593°C] for Grades

3.1 Material furnished under this specification shall con-

70W [485W] and HPS 70W [HPS 485 W] and not less than

form to the requirements of the current edition of Specification 1150°F [620°C] for Grades 100 [690] and 100W [690W]. The

A 6/A 6M, for the ordered material, unless a conflict exists in

heat-treating temperatures shall be reported on the test certifi-

which case this specification shall prevail. cates.

4. Manufacture 6. Chemical Requirements

6.1 The heat analysis shall conform to the requirements of

4.1 The steel shall be made by one of the following

processes: open-hearth, basic-oxygen, or electric-furnace. Ad- the specified grade in Tables 2-7.

6.2 The steel shall conform on product analysis to the

ditional refining in the ladle, by electroslag remelting (ESR) or

requirements prescribed in Tables 2-7, subject to the product

vacuum-arc remelting (VAR) is permitted.

analysis tolerances in Specification A 6/A 6M, except as speci-

4.2 Grades 36 [250] and 50 [345] steel shall be made of

fied in 6.3.

other than rimmed or capped steel.

6.3 Product analysis is not applicable for bar size shapes and

4.3 Grades 50W [345W] and HPS 70W [HPS 485 W] shall

for flat bars ⁄2 in. [12.5 mm] and under in thickness.

be made to a killed fine grain practice.

4.4 Grade HPS 70W [HPS 485 W] shall be made using a

7. Tensile Requirements

low-hydrogen practice, such as vacuum degassing or con-

7.1 The material as represented by test specimens, except as

trolled soaking and/or cooling of ingots, slabs, or plates, or

specified in 7.2, shall conform to the requirements for tensile

combination thereof.

properties prescribed in Table 1.

4.5 Grades 100 [690] and 100W [690W] steel shall be killed

2 2

7.2 For Grade 36 [250] shapes less than 1 in. [645 mm ]in

and shall conform to the fine austenitic grain size requirement

cross section and bars, other than flats, less than ⁄2 in. [12.5

of Specification A 6/A 6M.

mm] in thickness or diameter need not be subjected to tension

5. Heat Treatment

tests by the manufacturer.

5.1 Grades HPS 70W [HPS 485 W], 100 [690], and 100W

8. Brinell Hardness Requirements for Grades 100 [690]

[690W] steel shall be heat treated by the manufacturer to

and 100W [690W]

8.1 For plates ⁄8in. [10 mm] and under in thickness, a

Annual Book of ASTM Standards, Vol 03.02. Brinell hardness test may be used instead of tension testing

A 709/A 709M

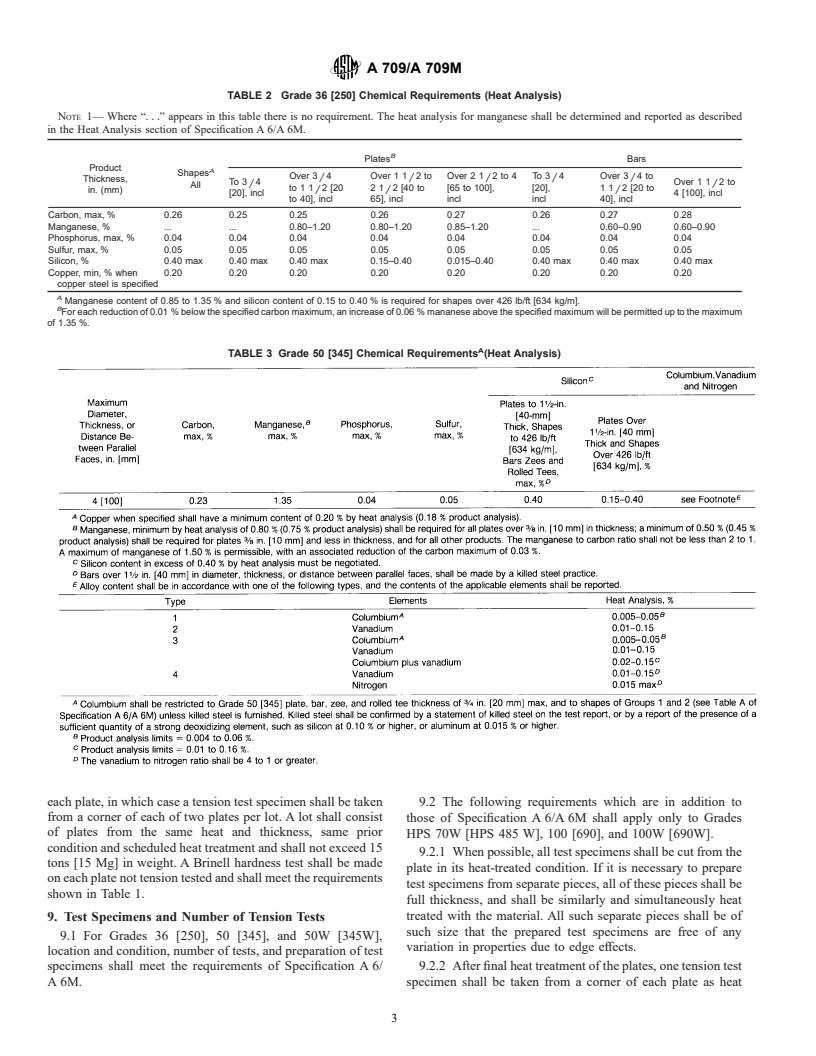

TABLE 2 Grade 36 [250] Chemical Requirements (Heat Analysis)

NOTE 1— Where “. . .” appears in this table there is no requirement. The heat analysis for manganese shall be determined and reported as described

in the Heat Analysis section of Specification A 6/A 6M.

B

Plates Bars

Product

A

Shapes

Over 3 4 Over 1 1 2to Over 2 1 2to4 To 3 4 Over 3 4to

Thickness, / / / / /

To 3 4 Over 1 1 2to

All / /

to11 2 [20 21 2 [40 to [65 to 100], [20], 11 2 [20 to

in. (mm)

/ / /

[20], incl 4 [100], incl

to 40], incl 65], incl incl incl 40], incl

Carbon, max, % 0.26 0.25 0.25 0.26 0.27 0.26 0.27 0.28

Manganese, % . . 0.80–1.20 0.80–1.20 0.85–1.20 . 0.60–0.90 0.60–0.90

Phosphorus, max, % 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04

Sulfur, max, % 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05

Silicon, % 0.40 max 0.40 max 0.40 max 0.15–0.40 0.015–0.40 0.40 max 0.40 max 0.40 max

Copper, min, % when 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20

copper steel is specified

A

Manganese content of 0.85 to 1.35 % and silicon content of 0.15 to 0.40 % is required for shapes over 426 lb/ft [634 kg/m].

B

For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % mananese above the specified maximum will be permitted up to the maximum

of 1.35 %.

A

TABLE 3 Grade 50 [345] Chemical Requirements (Heat Analysis)

each plate, in which case a tension test specimen shall be taken 9.2 The following requirements which are in addition to

from a corner of each of two plates per lot. A lot shall consist

those of Specification A 6/A 6M shall apply only to Grades

of plates from the same heat and thickness, same prior

HPS 70W [HPS 485 W], 100 [690], and 100W [690W].

condition and scheduled heat treatment and shall not exceed 15

9.2.1 When possible, all test specimens shall be cut from the

tons [15 Mg] in weight. A Brinell hardness test shall be made

plate in its heat-treated condition. If it is necessary to prepare

on each plate not tension tested and shall meet the requirements

test specimens from separate pieces, all of these pieces shall be

shown in Table 1.

full thickness, and shall be similarly and simultaneously heat

treated with the material. All such separate pieces shall be of

9. Test Specimens and Number of Tension Tests

such size that the prepared test specimens are free of any

9.1 For Grades 36 [250], 50 [345], and 50W [345W],

variation in properties due to edge effects.

location and condition, number of tests, and preparation of test

specimens shall meet the requirements of Specification A 6/ 9.2.2 After final heat treatment of the plates, one tension test

A 6M. specimen shall be taken from a corner of each plate as heat

A 709/A 709M

TABLE 4 Grade 50W [345 W] Chemical Requirements (Heat

requirements, at the manufacturer’s option, may be subjected

Analysis)

to tension testing and shall be accepted if the results conform

to the requirements of Table 1.

NOTE 1—Types A, B, and C are equivalent to Specification A 588/

A 588M Grades A, B, and C, respectively. 10.3 The manufacturer may reheat treat Grades HPS 70W

[HPS 485 W], 100 [690], and 100W [690W] plates that fail to

A

Composition, %

meet the mechanical property requirements of this specifica-

Element

Type A Type B Type C

tion. All mechanical property tests shall be repeated when the

material is resubmitted for inspection.

Carbon 0.19 max 0.20 max 0.15 max

Manganese 0.80–1.25 0.75–1.35 0.80–1.35

11. Atmospheric Corrosion Resistance

Phosphorus 0.04 max 0.04 max 0.04 max

Sulfur 0.05 max 0.05 max 0.05 max

11.1 Steels meeting this specification provide two levels of

Silicon 0.30–0.65 0.15–0.50 0.15–0.40

atmospheric corrosion resistance:

Nickel 0.40 max 0.50 max 0.25–0.50

Chromium 0.40–0.65 0.40–0.70 0.30–0.50

11.1.1 Steel grades without suffix provide a level of atmo-

Copper 0.25–0.40 0.20–0.40 0.20–0.50

spheric corrosion resistance typical of carbon or alloy steel

Vanadium 0.02–0.10 0.01–0.10 0.01–0.10

without copper.

A

Weldability data for these types have been qualified by FHWA for use in bridge

11.1.2 To comply with Specification A 709, steel grade 50W

construction.

[345W], and HPS 70W [HPS 485W] shall have an atmospheric

corrosion resistance index of 6.0 or higher, calculated from the

TABLE 5 Grade 70W [485 W] Chemical Requirements (Heat

heat analysis in accordance with Guide G 101 (see Note 2).

Analysis)

When properly exposed to the atmosphere, these steels can be

Element Composition, % used bare (unpainted) for many applications. Steel grade 100W

provides an improved level of atmospheric corrosion resistance

Carbon 0.19 max

Manganese 0.80–1.35

over alloy steel without copper.

Phosphorus 0.035 max

Sulfur 0.04 max

NOTE 2—For methods of estimating the atmospheric corrosion resis-

Silicon 0.20–0.65

tance of low-alloy steels, see Guide G 101.

Copper 0.20–0.40

The user is cautioned that the Guide G 101 predictive equation for

Nickel 0.50 max

calculation of an atmospheric corrosion resistance index has only been

Chromium 0.40–0.70

verified for the composition limits stated in that guide.

Vanadium 0.02–0.10

12. Marking

12.1 In addition to the marking requirements of Specifica-

treated (except as specified in 8.1).

tion A 6/A 6M, material identification shall also include the

NOTE 1—The term “plate” identifies the “plate as heat treated.”

composition type for Grades 50W [345W], 100 [690] and

100W [

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.