ASTM D1335-17

(Test Method)Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings

Standard Test Method for Tuft Bind of Pile Yarn Floor Coverings

SIGNIFICANCE AND USE

5.1 Test Method D1335 for tuft bind of pile yarn floor coverings is being used for acceptance testing of commercial shipments. Comparative tests as directed in 5.1.1 may be advisable.

5.1.1 In case of a dispute arising from differences in reported test results using this test method, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended from the investigation of bias. As a minimum, the two parties should take a group of test samples that are homogeneous as possible and are from a lot of material of the type in question. The test samples should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using appropriate statistical analysis, and a probability level chosen by the two parties before testing begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

5.2 The satisfactory performance of a pile yarn floor covering depends to a considerable extent on the maintenance of its original appearance. In a cut pile yarn floor covering an inadequate tuft bind may result in complete loss of pile in areas exposed to severe wear. In a looped pile yarn floor covering with inadequate tuft bind the pile loops may be pulled out to form unsightly long loops which may be hazardous.

SCOPE

1.1 This test method covers the measurement of force required to pull or break a tuft from a pile floor covering sample.

1.2 This test method is applicable to both cut and loop pile yarn floor covering.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1335 −17

Standard Test Method for

1

Tuft Bind of Pile Yarn Floor Coverings

This standard is issued under the fixed designation D1335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 This test method covers the measurement of force 3.1 For all terminology related to Pile Floor Coverings,

required to pull or break a tuft from a pile floor covering D13.21, refer to Terminology D5684.

sample. 3.1.1 The following terms are relevant to this standard:

carpet, constant-rate-of-extension, cut pile yarn floor covering,

1.2 This test method is applicable to both cut and loop pile

finished, finished pile yarn floor covering, floor covering, loop

yarn floor covering.

pile yarn floor covering, pile, pile yarn floor covering, textile

1.3 The values stated in inch-pound units are to be regarded

floor covering, tuft, tuft bind, tuft leg, tufted fabric.

as standard. The values given in parentheses are mathematical

3.2 For all other terminology related to textiles see Termi-

conversions to SI units that are provided for information only

nology D123.

and are not considered standard.

1.4 This standard does not purport to address all of the 4. Summary of Method

safety concerns, if any, associated with its use. It is the

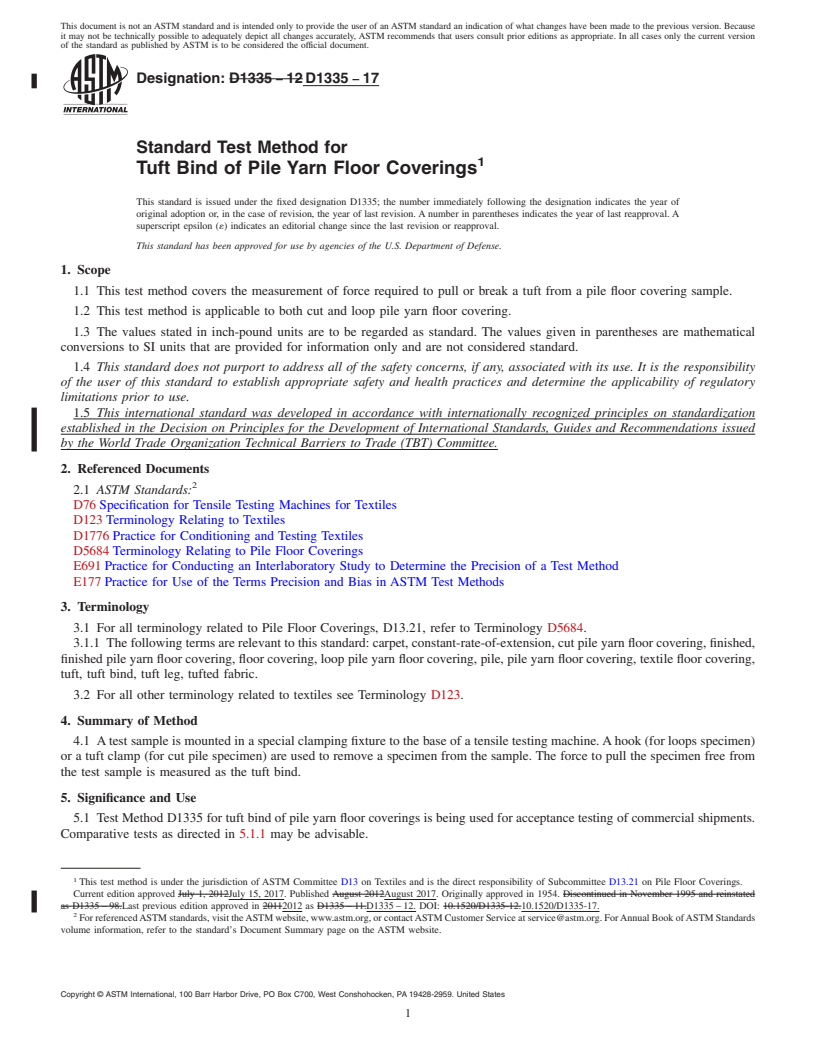

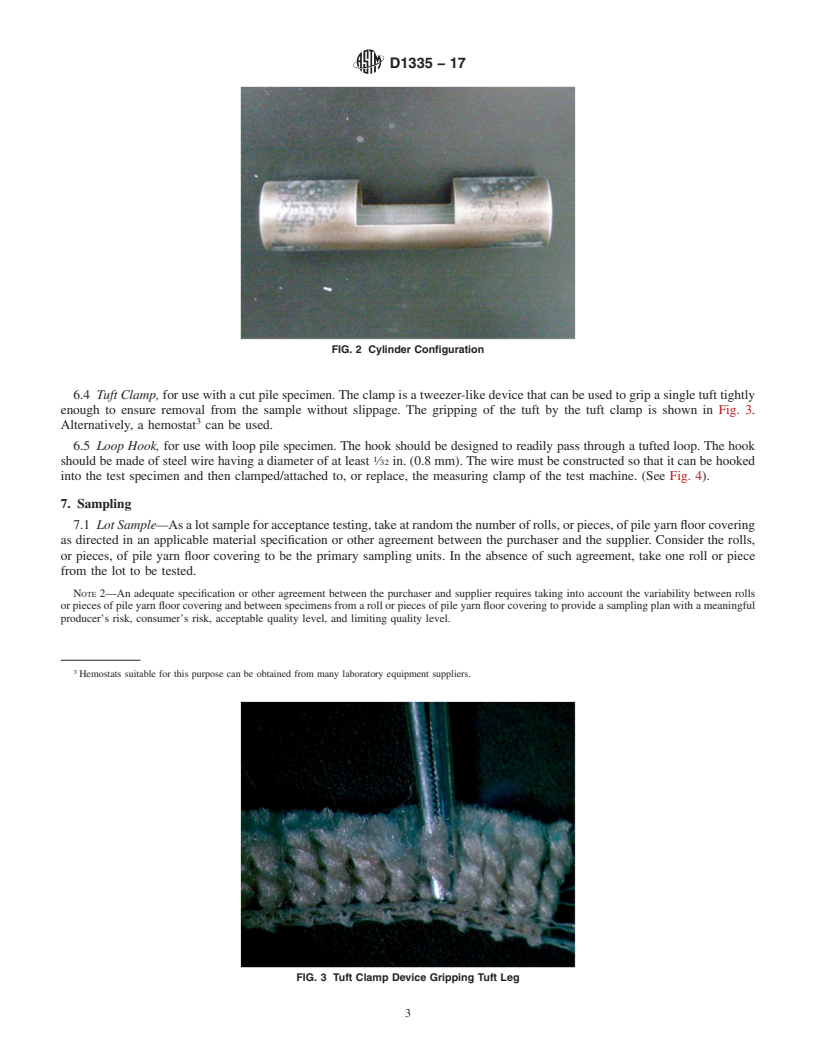

4.1 Atest sample is mounted in a special clamping fixture to

responsibility of the user of this standard to establish appro-

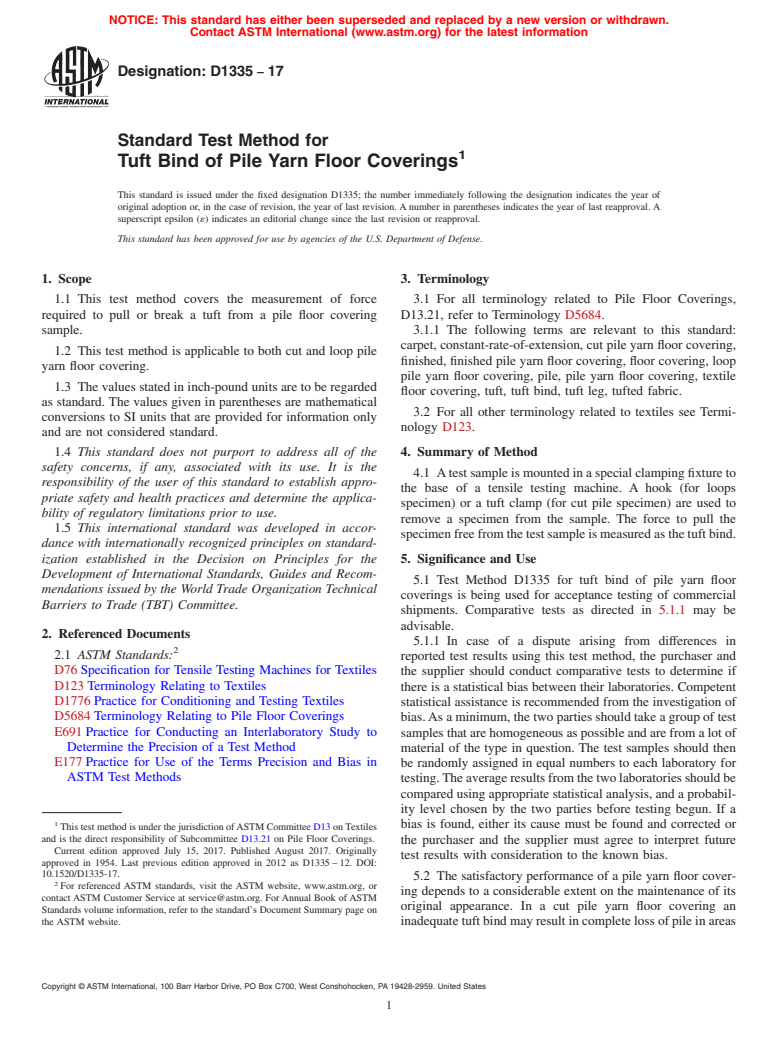

the base of a tensile testing machine. A hook (for loops

priate safety and health practices and determine the applica-

specimen) or a tuft clamp (for cut pile specimen) are used to

bility of regulatory limitations prior to use.

remove a specimen from the sample. The force to pull the

1.5 This international standard was developed in accor-

specimenfreefromthetestsampleismeasuredasthetuftbind.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5. Significance and Use

Development of International Standards, Guides and Recom-

5.1 Test Method D1335 for tuft bind of pile yarn floor

mendations issued by the World Trade Organization Technical

coverings is being used for acceptance testing of commercial

Barriers to Trade (TBT) Committee.

shipments. Comparative tests as directed in 5.1.1 may be

advisable.

2. Referenced Documents

5.1.1 In case of a dispute arising from differences in

2

2.1 ASTM Standards:

reported test results using this test method, the purchaser and

D76 Specification for Tensile Testing Machines for Textiles

the supplier should conduct comparative tests to determine if

D123 Terminology Relating to Textiles

there is a statistical bias between their laboratories. Competent

D1776 Practice for Conditioning and Testing Textiles

statistical assistance is recommended from the investigation of

D5684 Terminology Relating to Pile Floor Coverings

bias.As a minimum, the two parties should take a group of test

E691 Practice for Conducting an Interlaboratory Study to

samples that are homogeneous as possible and are from a lot of

Determine the Precision of a Test Method

material of the type in question. The test samples should then

E177 Practice for Use of the Terms Precision and Bias in

be randomly assigned in equal numbers to each laboratory for

ASTM Test Methods

testing.Theaverageresultsfromthetwolaboratoriesshouldbe

compared using appropriate statistical analysis, and a probabil-

ity level chosen by the two parties before testing begun. If a

1

bias is found, either its cause must be found and corrected or

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

the purchaser and the supplier must agree to interpret future

Current edition approved July 15, 2017. Published August 2017. Originally

test results with consideration to the known bias.

approved in 1954. Last previous edition approved in 2012 as D1335 – 12. DOI:

10.1520/D1335-17.

5.2 The satisfactory performance of a pile yarn floor cover-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ing depends to a considerable extent on the maintenance of its

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

original appearance. In a cut pile yarn floor covering an

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. inadequate tuft bind may result in complete loss of pile in areas

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, P

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1335 − 12 D1335 − 17

Standard Test Method for

1

Tuft Bind of Pile Yarn Floor Coverings

This standard is issued under the fixed designation D1335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the measurement of force required to pull or break a tuft from a pile floor covering sample.

1.2 This test method is applicable to both cut and loop pile yarn floor covering.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D5684 Terminology Relating to Pile Floor Coverings

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

3. Terminology

3.1 For all terminology related to Pile Floor Coverings, D13.21, refer to Terminology D5684.

3.1.1 The following terms are relevant to this standard: carpet, constant-rate-of-extension, cut pile yarn floor covering, finished,

finished pile yarn floor covering, floor covering, loop pile yarn floor covering, pile, pile yarn floor covering, textile floor covering,

tuft, tuft bind, tuft leg, tufted fabric.

3.2 For all other terminology related to textiles see Terminology D123.

4. Summary of Method

4.1 A test sample is mounted in a special clamping fixture to the base of a tensile testing machine. A hook (for loops specimen)

or a tuft clamp (for cut pile specimen) are used to remove a specimen from the sample. The force to pull the specimen free from

the test sample is measured as the tuft bind.

5. Significance and Use

5.1 Test Method D1335 for tuft bind of pile yarn floor coverings is being used for acceptance testing of commercial shipments.

Comparative tests as directed in 5.1.1 may be advisable.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

Current edition approved July 1, 2012July 15, 2017. Published August 2012August 2017. Originally approved in 1954. Discontinued in November 1995 and reinstated

as D1335 – 98.Last previous edition approved in 20112012 as D1335 – 11.D1335 – 12. DOI: 10.1520/D1335-12.10.1520/D1335-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1335 − 17

5.1.1 In case of a dispute arising from differences in reported test results using this test method, the purchaser and the supplier

should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical

assistance is recommended from the investigation of bias. As a minimum, the two parties should take a group of test samples that

are homogeneous as possible and are from a lot of material of the type in question. The test samples should then be randomly

assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using

appropriate statist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.