ASTM F1551-09(2017)

(Test Method)Standard Test Methods for Comprehensive Characterization of Synthetic Turf Playing Surfaces and Materials

Standard Test Methods for Comprehensive Characterization of Synthetic Turf Playing Surfaces and Materials

SIGNIFICANCE AND USE

5.1 These test methods constitute a standard for obtaining data in research and development, quality control, acceptance and rejection under specifications, and for special purposes.

5.2 The data obtained from use of these test methods are applicable to the system and its components under conditions of the particular test procedures and are not necessarily the same as the data that might be obtained in other environments or use conditions.

5.3 The selection of test methods or tests should be limited to those appropriate to the system or material(s) being evaluated.

SCOPE

1.1 These test methods establish a recommended list from which suitable test methods shall be selected for the identification of physical property characteristics and comparison of the performance properties of synthetic turf systems or components for athletic and recreational uses, or both.

1.2 Some of the test procedures are suitable only for the laboratory characterization of either components or the complete system; others are suitable for tests on installed sports fields; and some tests may be applied in both the laboratory and the field.

1.3 The test procedures included in these test methods apply as a group to the description of synthetic turf playing surfaces.

1.4 Some of the test procedures are specific for components of the synthetic turf system, and others apply to the complete synthetic turf playing surface.

1.5 Reference to the methods for testing the synthetic turf playing surface and its components contained herein should state specifically the particular test or tests desired and not necessarily refer to these test methods as a whole.

1.6 This is a physical property characterization standard, and it shall not be construed as a safety standard.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1551 − 09 (Reapproved 2017) An American National Standard

Standard Test Methods for

Comprehensive Characterization of Synthetic Turf Playing

Surfaces and Materials

This standard is issued under the fixed designation F1551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 These test methods establish a recommended list from

which suitable test methods shall be selected for the identifi-

2. Referenced Documents

cation of physical property characteristics and comparison of

2.1 ASTM Standards:

the performance properties of synthetic turf systems or com-

2.1.1 Pile Fiber:

ponents for athletic and recreational uses, or both.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 Some of the test procedures are suitable only for the

tive Density) of Plastics by Displacement

laboratory characterization of either components or the com-

D1577 Test Methods for Linear Density of Textile Fibers

plete system; others are suitable for tests on installed sports

D1907 Test Method for Linear Density of Yarn (Yarn Num-

fields;andsometestsmaybeappliedinboththelaboratoryand

ber) by the Skein Method

the field.

D2256 Test Method for Tensile Properties of Yarns by the

1.3 Thetestproceduresincludedinthesetestmethodsapply

Single-Strand Method

as a group to the description of synthetic turf playing surfaces.

D3218 Specification for Polyolefin Monofilaments

D7138 Test Method to Determine Melting Temperature of

1.4 Some of the test procedures are specific for components

Synthetic Fibers

of the synthetic turf system, and others apply to the complete

2.1.2 Fabric:

synthetic turf playing surface.

D1335 Test Method for Tuft Bind of Pile Yarn Floor

1.5 Reference to the methods for testing the synthetic turf

Coverings

playing surface and its components contained herein should

D1776 Practice for Conditioning and Testing Textiles

state specifically the particular test or tests desired and not

D2859 Test Method for Ignition Characteristics of Finished

necessarily refer to these test methods as a whole.

Textile Floor Covering Materials

1.6 This is a physical property characterization standard,

D4158 Guide for Abrasion Resistance of Textile Fabrics

and it shall not be construed as a safety standard.

(Uniform Abrasion)

D5034 TestMethodforBreakingStrengthandElongationof

1.7 The values stated in SI units are to be regarded as the

Textile Fabrics (Grab Test)

standard. The values given in parentheses are for information

D5251 Practice for the Operation of the Tetrapod Walker

only.

Drum Tester (Withdrawn 2014)

1.8 This standard does not purport to address all of the

D5793 Test Method for Binding Sites per Unit Length or

safety concerns, if any, associated with its use. It is the

Width of Pile Yarn Floor Coverings

responsibility of the user of this standard to establish appro-

D5823 Test Method for Tuft Height of Pile Floor Coverings

priate safety, health, and environmental practices and deter-

D5848 Test Method for Mass Per Unit Area of Pile Yarn

mine the applicability of regulatory limitations prior to use.

Floor Coverings

1.9 This international standard was developed in accor-

E648 Test Method for Critical Radiant Flux of Floor-

dance with internationally recognized principles on standard-

Covering Systems Using a Radiant Heat Energy Source

ization established in the Decision on Principles for the

F1015 Test Method for Relative Abrasiveness of Synthetic

Development of International Standards, Guides and Recom-

1 2

These test methods are under the jurisdiction of ASTM Committee F08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Sports Equipment, Playing Surfaces, and Facilities and are the direct responsibility contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of Subcommittee F08.65 on Artificial Turf Surfaces and Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2017. Published December 2017. Originally the ASTM website.

approved in 1994. Last previous edition approved in 2009 as F1551 – 09. DOI: The last approved version of this historical standard is referenced on

10.1520/F1551-09R17. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1551 − 09 (2017)

Turf Playing Surfaces prEN 15301-1 Surfaces for Sports Areas- Part 1. Determi-

2.1.3 Shock Absorbing Cushion Underlayment: nation of Rotational Resistance

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods forVulcanized Rubber andThermoplas-

3. Terminology

tic Elastomers—Tension

3.1 Definitions—Terms are as defined in the referenced

D624 Test Method for Tear Strength of Conventional Vul-

ASTM procedures comprising these test methods.

canized Rubber and Thermoplastic Elastomers

3.2 Definitions of Terms Specific to This Standard:

D1667 Specification for Flexible Cellular Materials—Poly

3.2.1 fabric construction—the method of assembly of pile

(Vinyl Chloride) Foam (Closed-Cell)

ribbon and backing yarns that produces the fabric, usually

D1876 Test Method for Peel Resistance of Adhesives (T-

tufting, knitting, or weaving.

Peel Test)

D2126 Test Method for Response of Rigid Cellular Plastics

3.2.2 infilled turf system—field system having a long pile

to Thermal and Humid Aging

height and either one or more substances in the face of the

D3574 Test Methods for Flexible Cellular Materials—Slab,

fabric to provide the desired playing properties. Infill sub-

Bonded, and Molded Urethane Foams

stances can be either sand, rubber or other substances or a

D3575 Test Methods for Flexible Cellular Materials Made

combination of items.

From Olefin Polymers

3.2.3 lengthwise direction, n—in textiles, the direction in a

D3936 Test Method for Resistance to Delamination of the

machine-made fabric parallel to the direction of movement the

Secondary Backing of Pile Yarn Floor Covering

fabric followed in the manufacturing machine.

F355 TestMethodforImpactAttenuationofPlayingSurface

Systems, Other Protective Sport Systems, and Materials

3.2.4 matting—the extent of change of the apparent syn-

Used for Athletics, Recreation and Play

thetic turf pile thickness from the original value due to

2.1.4 Turf Systems:

permanent compression of the pile from sports use.

D1667 Specification for Flexible Cellular Materials—Poly

3.2.5 pile, n—for pile fiber turf surfacing, surface texture

(Vinyl Chloride) Foam (Closed-Cell)

composed of many individual thin strands or groups of strands

F355 TestMethodforImpactAttenuationofPlayingSurface

bound to a backing fabric in a repetitive array.

Systems, Other Protective Sport Systems, and Materials

Used for Athletics, Recreation and Play

3.2.6 pile lay—the direction in which most of the pile fibers

F1015 Test Method for Relative Abrasiveness of Synthetic

lean in the original, uncrushed fabric.

Turf Playing Surfaces

3.2.7 secondary backing—a material adhered to the backing

F1936 Specification for Impact Attenuation of Turf Playing

side of a pile turf fabric.

Systems as Measured in the Field

F2117 Test Method for Vertical Rebound Characteristics of 3.2.8 sports shoe traction—ameasureofthestaticorsliding

Sports Surface/Ball Systems; Acoustical Measurement

coefficient of friction between a weighted sports shoe and the

F2333 Test Method for Traction Characteristics of the Ath-

turf pile surface, horizontal motion.

letic Shoe-Sports Surface Interface

3.2.9 synthetic turf field system—composite of synthetic

2.1.4 Infill Materials:

contact surface material, any fill material used in the contact

D5644 Test Methods for Rubber Compounding Materials—

surface, energy absorbing material, fabric layers, adhesives, if

Determination of Particle Size Distribution of Recycled

any, and other constructed layers (as applicable to the indi-

Vulcanizate Particulate Rubber

vidual system construction).

F1632 Test Method for Particle Size Analysis and Sand

Shape Grading of Golf Course Putting Green and Sports

3.2.10 synthetic turf system components—the separate com-

Field Rootzone Mixes

ponentssuchasturffabric,shock-absorbingpad,andadhesives

that comprise the synthetic turf playing surface when as-

2.2 Other Standards:

sembled; the subcomponents such as pile yarns and backing

AT-030 Sports Shoe Traction

yarns that comprise the turf fabric.

NOTE 1—AstroTurf® Industries internal test procedure is suitable as a

3.2.11 texture—the detailed configuration of loops, cut pile

basis for new ASTM test methods.

ends, and individual fibers in the pile layer.

DIN 18-035 Part 6—Water Permeability of Synthetic Turf

3.2.11.1 Discussion—Texture is the detailed appearance of

Systems and Permeable Bases

the pile that changes by matting, crushing, flattening, fuzzing,

EN12234 SurfacesforSportsAreas–DeterminationofBall

untwisting, etc. during exposure to service. The texture should

Roll

be distinguished from the construction, that is, the specifica-

EN 12616 Surfaces for Sports Areas – Determination of

tions of kinds of yarns, yarn sizes, and the mode of combina-

Infiltration Rate

tion.

EN 14808 Surfaces for Sports Areas- Determination of

Force Reduction 3.2.12 water permeability—the rate at which water of a

specified head flows vertically through synthetic turf or other

EN 14809 Surfaces for Sports Areas – Determination of

Vertical Deformation components of the system.

F1551 − 09 (2017)

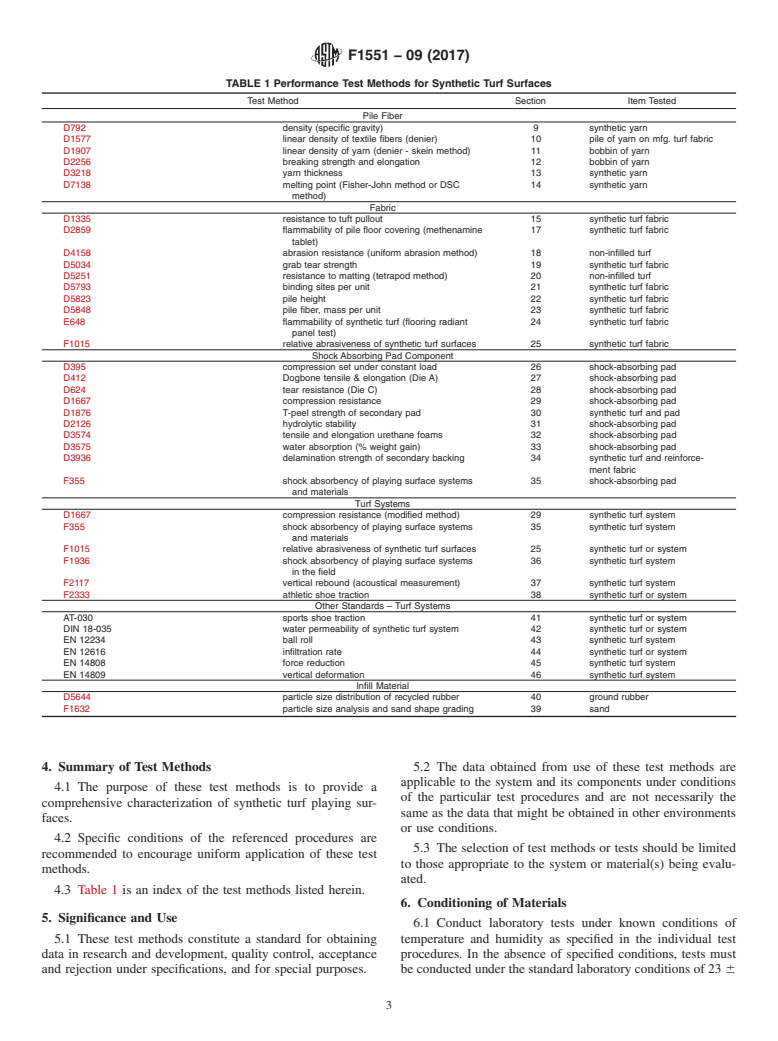

TABLE 1 Performance Test Methods for Synthetic Turf Surfaces

Test Method Section Item Tested

Pile Fiber

D792 density (specific gravity) 9 synthetic yarn

D1577 linear density of textile fibers (denier) 10 pile of yarn on mfg. turf fabric

D1907 linear density of yarn (denier - skein method) 11 bobbin of yarn

D2256 breaking strength and elongation 12 bobbin of yarn

D3218 yarn thickness 13 synthetic yarn

D7138 melting point (Fisher-John method or DSC 14 synthetic yarn

method)

Fabric

D1335 resistance to tuft pullout 15 synthetic turf fabric

D2859 flammability of pile floor covering (methenamine 17 synthetic turf fabric

tablet)

D4158 abrasion resistance (uniform abrasion method) 18 non-infilled turf

D5034 grab tear strength 19 synthetic turf fabric

D5251 resistance to matting (tetrapod method) 20 non-infilled turf

D5793 binding sites per unit 21 synthetic turf fabric

D5823 pile height 22 synthetic turf fabric

D5848 pile fiber, mass per unit 23 synthetic turf fabric

E648 flammability of synthetic turf (flooring radiant 24 synthetic turf fabric

panel test)

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf fabric

Shock Absorbing Pad Component

D395 compression set under constant load 26 shock-absorbing pad

D412 Dogbone tensile & elongation (Die A) 27 shock-absorbing pad

D624 tear resistance (Die C) 28 shock-absorbing pad

D1667 compression resistance 29 shock-absorbing pad

D1876 T-peel strength of secondary pad 30 synthetic turf and pad

D2126 hydrolytic stability 31 shock-absorbing pad

D3574 tensile and elongation urethane foams 32 shock-absorbing pad

D3575 water absorption (% weight gain) 33 shock-absorbing pad

D3936 delamination strength of secondary backing 34 synthetic turf and reinforce-

ment fabric

F355 shock absorbency of playing surface systems 35 shock-absorbing pad

and materials

Turf Systems

D1667 compression resistance (modified method) 29 synthetic turf system

F355 shock absorbency of playing surface systems 35 synthetic turf system

and materials

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf or system

F1936 shock absorbency of playing surface systems 36 synthetic turf system

in the field

F2117 vertical rebound (acoustical measurement) 37 synthetic turf system

F2333 athletic shoe traction 38 synthetic turf or system

Other Standards – Turf Systems

AT-030 sports shoe traction 41 synthetic turf or system

DIN 18-035 water permeability of synthetic turf system 42 synthetic turf or system

EN 12234 ball roll 43 synthetic turf system

EN 12616 infiltration rate 44 synthetic turf or system

EN 14808 force reduction 45 synthetic turf system

EN 14809 vertical deformation 46 synthetic turf system

Infill Material

D5644 particle size distribution of recycled rubber 40 ground rubber

F1632 particle size analysis and sand shape grading 39 sand

4. Summary of Test Methods 5.2 The data obtained from use of these test methods are

applicable to the system and its components under conditions

4.1 The purpose of these test methods is to provide a

of the particular test procedures and are not necessarily the

comprehensive characterization of synthetic turf playing sur-

same as the data that might be obtained in other environments

faces.

or use conditions.

4.2 Specific conditions of the referenced procedures are

5.3 The selection of test methods or tests should be limited

recommended to encourage uniform application of these test

to those appropriate to the system or material(s) being evalu-

methods.

ated.

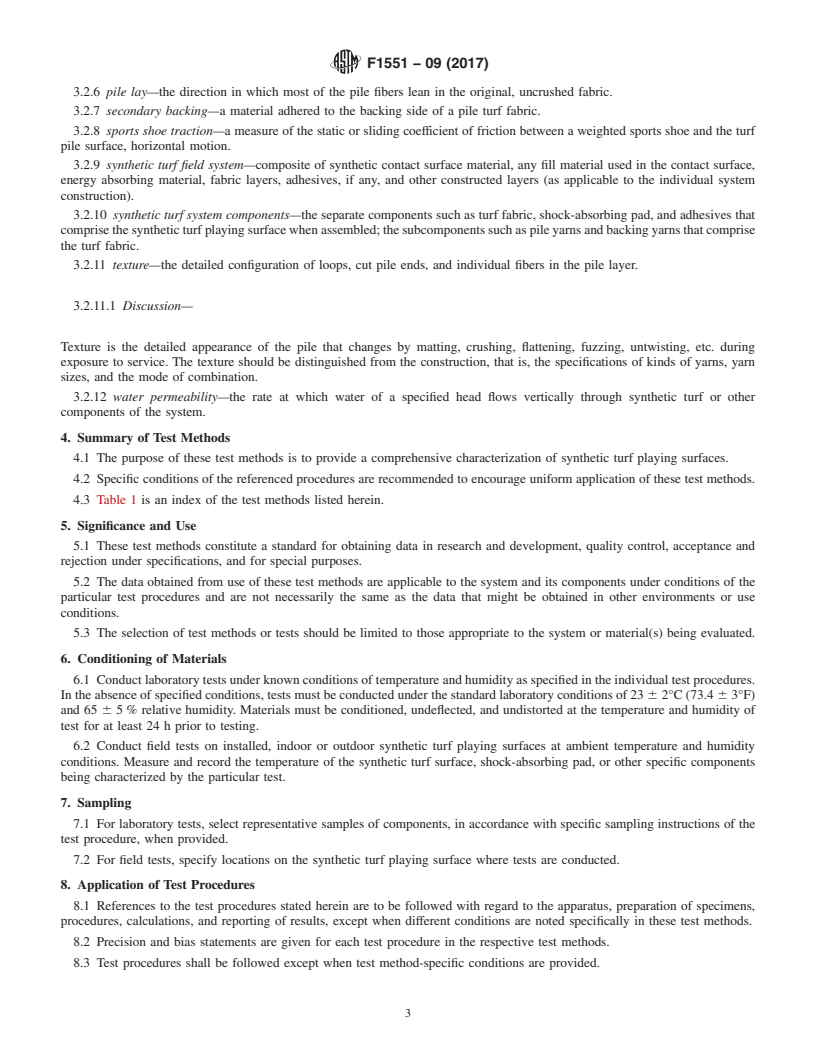

4.3 Table 1 is an index of the test methods listed herein.

6. Conditioning of Materials

5. Significance and Use

6.1 Conduct laboratory tests under known conditions of

5.1 These test methods constitute a standard for obtaining temperature and humidity as specified in the individual test

data in research and development, quality control, acceptance procedures. In the absence of specified conditions, tests must

and rejection under specifications, and for special purposes. be conducted under the standard laboratory conditions of 23 6

F1551 − 09 (2017)

2°C (73.4 6 3°F) and 65 6 5 % relative humidity. Materials 11.2 Test Method Specific Conditions:

must be conditioned, undeflected, and undistorted at the 11.2.1 Specified lengths of yarn are wound on reels as

temperature and humidity of test for at least 24 h prior to skeins, and weighed.

testing. 11.2.2 Nine meters is recommended length weighed in

grams times 1000 for denier, grams per 9000 meters.

6.2 Conduct field tests on installed, indoor or outdoor

synthetic turf playing surfaces at ambient temperature and

12. Test Method D2256, Tensile Properties of Yarns by

humidity conditions. Measure and record the temperature of

the Single Strand Method

the synthetic turf surface, shock-absorbing pad, or other

12.1 Scope:

specific components being characterized by the particular

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1551 − 09 (Reapproved 2017) An American National Standard

Standard Test Methods for

Comprehensive Characterization of Synthetic Turf Playing

Surfaces and Materials

This standard is issued under the fixed designation F1551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 These test methods establish a recommended list from

which suitable test methods shall be selected for the identifi-

2. Referenced Documents

cation of physical property characteristics and comparison of

2.1 ASTM Standards:

the performance properties of synthetic turf systems or com-

2.1.1 Pile Fiber:

ponents for athletic and recreational uses, or both.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 Some of the test procedures are suitable only for the

tive Density) of Plastics by Displacement

laboratory characterization of either components or the com-

D1577 Test Methods for Linear Density of Textile Fibers

plete system; others are suitable for tests on installed sports

D1907 Test Method for Linear Density of Yarn (Yarn Num-

fields; and some tests may be applied in both the laboratory and

ber) by the Skein Method

the field.

D2256 Test Method for Tensile Properties of Yarns by the

1.3 The test procedures included in these test methods apply

Single-Strand Method

as a group to the description of synthetic turf playing surfaces.

D3218 Specification for Polyolefin Monofilaments

D7138 Test Method to Determine Melting Temperature of

1.4 Some of the test procedures are specific for components

Synthetic Fibers

of the synthetic turf system, and others apply to the complete

2.1.2 Fabric:

synthetic turf playing surface.

D1335 Test Method for Tuft Bind of Pile Yarn Floor

1.5 Reference to the methods for testing the synthetic turf

Coverings

playing surface and its components contained herein should

D1776 Practice for Conditioning and Testing Textiles

state specifically the particular test or tests desired and not

D2859 Test Method for Ignition Characteristics of Finished

necessarily refer to these test methods as a whole.

Textile Floor Covering Materials

1.6 This is a physical property characterization standard,

D4158 Guide for Abrasion Resistance of Textile Fabrics

and it shall not be construed as a safety standard.

(Uniform Abrasion)

D5034 Test Method for Breaking Strength and Elongation of

1.7 The values stated in SI units are to be regarded as the

Textile Fabrics (Grab Test)

standard. The values given in parentheses are for information

D5251 Practice for the Operation of the Tetrapod Walker

only.

Drum Tester (Withdrawn 2014)

1.8 This standard does not purport to address all of the

D5793 Test Method for Binding Sites per Unit Length or

safety concerns, if any, associated with its use. It is the

Width of Pile Yarn Floor Coverings

responsibility of the user of this standard to establish appro-

D5823 Test Method for Tuft Height of Pile Floor Coverings

priate safety, health, and environmental practices and deter-

D5848 Test Method for Mass Per Unit Area of Pile Yarn

mine the applicability of regulatory limitations prior to use.

Floor Coverings

1.9 This international standard was developed in accor-

E648 Test Method for Critical Radiant Flux of Floor-

dance with internationally recognized principles on standard-

Covering Systems Using a Radiant Heat Energy Source

ization established in the Decision on Principles for the

F1015 Test Method for Relative Abrasiveness of Synthetic

Development of International Standards, Guides and Recom-

1 2

These test methods are under the jurisdiction of ASTM Committee F08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Sports Equipment, Playing Surfaces, and Facilities and are the direct responsibility contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of Subcommittee F08.65 on Artificial Turf Surfaces and Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2017. Published December 2017. Originally the ASTM website.

approved in 1994. Last previous edition approved in 2009 as F1551 – 09. DOI: The last approved version of this historical standard is referenced on

10.1520/F1551-09R17. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1551 − 09 (2017)

Turf Playing Surfaces prEN 15301-1 Surfaces for Sports Areas- Part 1. Determi-

2.1.3 Shock Absorbing Cushion Underlayment:

nation of Rotational Resistance

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplas-

3. Terminology

tic Elastomers—Tension

3.1 Definitions—Terms are as defined in the referenced

D624 Test Method for Tear Strength of Conventional Vul-

ASTM procedures comprising these test methods.

canized Rubber and Thermoplastic Elastomers

3.2 Definitions of Terms Specific to This Standard:

D1667 Specification for Flexible Cellular Materials—Poly

3.2.1 fabric construction—the method of assembly of pile

(Vinyl Chloride) Foam (Closed-Cell)

ribbon and backing yarns that produces the fabric, usually

D1876 Test Method for Peel Resistance of Adhesives (T-

tufting, knitting, or weaving.

Peel Test)

D2126 Test Method for Response of Rigid Cellular Plastics

3.2.2 infilled turf system—field system having a long pile

to Thermal and Humid Aging

height and either one or more substances in the face of the

D3574 Test Methods for Flexible Cellular Materials—Slab,

fabric to provide the desired playing properties. Infill sub-

Bonded, and Molded Urethane Foams

stances can be either sand, rubber or other substances or a

D3575 Test Methods for Flexible Cellular Materials Made

combination of items.

From Olefin Polymers

3.2.3 lengthwise direction, n—in textiles, the direction in a

D3936 Test Method for Resistance to Delamination of the

machine-made fabric parallel to the direction of movement the

Secondary Backing of Pile Yarn Floor Covering

fabric followed in the manufacturing machine.

F355 Test Method for Impact Attenuation of Playing Surface

Systems, Other Protective Sport Systems, and Materials

3.2.4 matting—the extent of change of the apparent syn-

Used for Athletics, Recreation and Play

thetic turf pile thickness from the original value due to

2.1.4 Turf Systems:

permanent compression of the pile from sports use.

D1667 Specification for Flexible Cellular Materials—Poly

3.2.5 pile, n—for pile fiber turf surfacing, surface texture

(Vinyl Chloride) Foam (Closed-Cell)

composed of many individual thin strands or groups of strands

F355 Test Method for Impact Attenuation of Playing Surface

bound to a backing fabric in a repetitive array.

Systems, Other Protective Sport Systems, and Materials

Used for Athletics, Recreation and Play

3.2.6 pile lay—the direction in which most of the pile fibers

F1015 Test Method for Relative Abrasiveness of Synthetic

lean in the original, uncrushed fabric.

Turf Playing Surfaces

3.2.7 secondary backing—a material adhered to the backing

F1936 Specification for Impact Attenuation of Turf Playing

side of a pile turf fabric.

Systems as Measured in the Field

F2117 Test Method for Vertical Rebound Characteristics of

3.2.8 sports shoe traction—a measure of the static or sliding

Sports Surface/Ball Systems; Acoustical Measurement

coefficient of friction between a weighted sports shoe and the

F2333 Test Method for Traction Characteristics of the Ath-

turf pile surface, horizontal motion.

letic Shoe-Sports Surface Interface

3.2.9 synthetic turf field system—composite of synthetic

2.1.4 Infill Materials:

contact surface material, any fill material used in the contact

D5644 Test Methods for Rubber Compounding Materials—

surface, energy absorbing material, fabric layers, adhesives, if

Determination of Particle Size Distribution of Recycled

any, and other constructed layers (as applicable to the indi-

Vulcanizate Particulate Rubber

vidual system construction).

F1632 Test Method for Particle Size Analysis and Sand

Shape Grading of Golf Course Putting Green and Sports

3.2.10 synthetic turf system components—the separate com-

Field Rootzone Mixes

ponents such as turf fabric, shock-absorbing pad, and adhesives

that comprise the synthetic turf playing surface when as-

2.2 Other Standards:

sembled; the subcomponents such as pile yarns and backing

AT-030 Sports Shoe Traction

yarns that comprise the turf fabric.

NOTE 1—AstroTurf® Industries internal test procedure is suitable as a

3.2.11 texture—the detailed configuration of loops, cut pile

basis for new ASTM test methods.

ends, and individual fibers in the pile layer.

DIN 18-035 Part 6—Water Permeability of Synthetic Turf

3.2.11.1 Discussion—Texture is the detailed appearance of

Systems and Permeable Bases

the pile that changes by matting, crushing, flattening, fuzzing,

EN 12234 Surfaces for Sports Areas – Determination of Ball

untwisting, etc. during exposure to service. The texture should

Roll

be distinguished from the construction, that is, the specifica-

EN 12616 Surfaces for Sports Areas – Determination of

tions of kinds of yarns, yarn sizes, and the mode of combina-

Infiltration Rate

tion.

EN 14808 Surfaces for Sports Areas- Determination of

3.2.12 water permeability—the rate at which water of a

Force Reduction

EN 14809 Surfaces for Sports Areas – Determination of specified head flows vertically through synthetic turf or other

Vertical Deformation components of the system.

F1551 − 09 (2017)

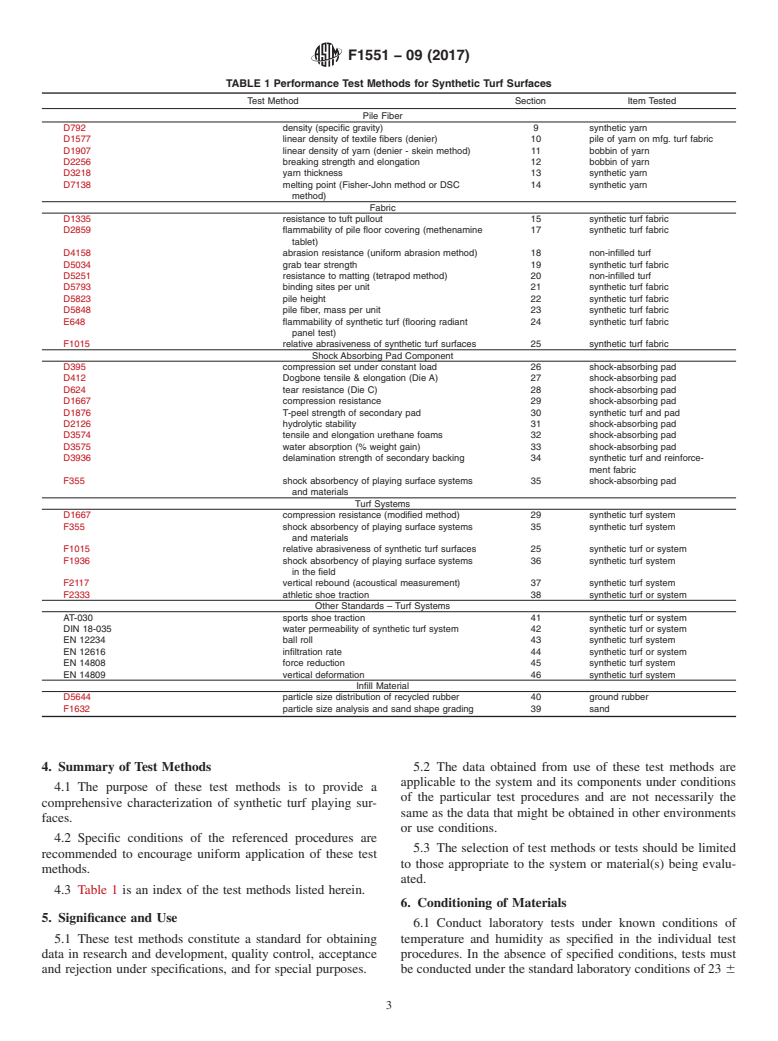

TABLE 1 Performance Test Methods for Synthetic Turf Surfaces

Test Method Section Item Tested

Pile Fiber

D792 density (specific gravity) 9 synthetic yarn

D1577 linear density of textile fibers (denier) 10 pile of yarn on mfg. turf fabric

D1907 linear density of yarn (denier - skein method) 11 bobbin of yarn

D2256 breaking strength and elongation 12 bobbin of yarn

D3218 yarn thickness 13 synthetic yarn

D7138 melting point (Fisher-John method or DSC 14 synthetic yarn

method)

Fabric

D1335 resistance to tuft pullout 15 synthetic turf fabric

D2859 flammability of pile floor covering (methenamine 17 synthetic turf fabric

tablet)

D4158 abrasion resistance (uniform abrasion method) 18 non-infilled turf

D5034 grab tear strength 19 synthetic turf fabric

D5251 resistance to matting (tetrapod method) 20 non-infilled turf

D5793 binding sites per unit 21 synthetic turf fabric

D5823 pile height 22 synthetic turf fabric

D5848 pile fiber, mass per unit 23 synthetic turf fabric

E648 flammability of synthetic turf (flooring radiant 24 synthetic turf fabric

panel test)

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf fabric

Shock Absorbing Pad Component

D395 compression set under constant load 26 shock-absorbing pad

D412 Dogbone tensile & elongation (Die A) 27 shock-absorbing pad

D624 tear resistance (Die C) 28 shock-absorbing pad

D1667 compression resistance 29 shock-absorbing pad

D1876 T-peel strength of secondary pad 30 synthetic turf and pad

D2126 hydrolytic stability 31 shock-absorbing pad

D3574 tensile and elongation urethane foams 32 shock-absorbing pad

D3575 water absorption (% weight gain) 33 shock-absorbing pad

D3936 delamination strength of secondary backing 34 synthetic turf and reinforce-

ment fabric

F355 shock absorbency of playing surface systems 35 shock-absorbing pad

and materials

Turf Systems

D1667 compression resistance (modified method) 29 synthetic turf system

F355 shock absorbency of playing surface systems 35 synthetic turf system

and materials

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf or system

F1936 shock absorbency of playing surface systems 36 synthetic turf system

in the field

F2117 vertical rebound (acoustical measurement) 37 synthetic turf system

F2333 athletic shoe traction 38 synthetic turf or system

Other Standards – Turf Systems

AT-030 sports shoe traction 41 synthetic turf or system

DIN 18-035 water permeability of synthetic turf system 42 synthetic turf or system

EN 12234 ball roll 43 synthetic turf system

EN 12616 infiltration rate 44 synthetic turf or system

EN 14808 force reduction 45 synthetic turf system

EN 14809 vertical deformation 46 synthetic turf system

Infill Material

D5644 particle size distribution of recycled rubber 40 ground rubber

F1632 particle size analysis and sand shape grading 39 sand

4. Summary of Test Methods 5.2 The data obtained from use of these test methods are

applicable to the system and its components under conditions

4.1 The purpose of these test methods is to provide a

of the particular test procedures and are not necessarily the

comprehensive characterization of synthetic turf playing sur-

same as the data that might be obtained in other environments

faces.

or use conditions.

4.2 Specific conditions of the referenced procedures are

5.3 The selection of test methods or tests should be limited

recommended to encourage uniform application of these test

to those appropriate to the system or material(s) being evalu-

methods.

ated.

4.3 Table 1 is an index of the test methods listed herein.

6. Conditioning of Materials

5. Significance and Use

6.1 Conduct laboratory tests under known conditions of

5.1 These test methods constitute a standard for obtaining temperature and humidity as specified in the individual test

data in research and development, quality control, acceptance procedures. In the absence of specified conditions, tests must

and rejection under specifications, and for special purposes. be conducted under the standard laboratory conditions of 23 6

F1551 − 09 (2017)

2°C (73.4 6 3°F) and 65 6 5 % relative humidity. Materials 11.2 Test Method Specific Conditions:

must be conditioned, undeflected, and undistorted at the 11.2.1 Specified lengths of yarn are wound on reels as

temperature and humidity of test for at least 24 h prior to skeins, and weighed.

testing. 11.2.2 Nine meters is recommended length weighed in

grams times 1000 for denier, grams per 9000 meters.

6.2 Conduct field tests on installed, indoor or outdoor

synthetic turf playing surfaces at ambient temperature and

12. Test Method D2256, Tensile Properties of Yarns by

humidity conditions. Measure and record the temperature of

the Single Strand Method

the synthetic turf surface, shock-absorbing pad, or other

12.1 Scope:

specific components being characterized by the particular test.

12.1.1 This test procedure des

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1551 − 09 F1551 − 09 (Reapproved 2017) An American National Standard

Standard Test Methods for

Comprehensive Characterization of Synthetic Turf Playing

Surfaces and Materials

This standard is issued under the fixed designation F1551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods establish a recommended list from which suitable test methods shall be selected for the identification

of physical property characteristics and comparison of the performance properties of synthetic turf systems or components for

athletic and recreational uses, or both.

1.2 Some of the test procedures are suitable only for the laboratory characterization of either components or the complete

system; others are suitable for tests on installed sports fields; and some tests may be applied in both the laboratory and the field.

1.3 The test procedures included in these test methods apply as a group to the description of synthetic turf playing surfaces.

1.4 Some of the test procedures are specific for components of the synthetic turf system, and others apply to the complete

synthetic turf playing surface.

1.5 Reference to the methods for testing the synthetic turf playing surface and its components contained herein should state

specifically the particular test or tests desired and not necessarily refer to these test methods as a whole.

1.6 This is a physical property characterization standard, and it shall not be construed as a safety standard.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

2.1.1 Pile Fiber:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D1577 Test Methods for Linear Density of Textile Fibers

D1907 Test Method for Linear Density of Yarn (Yarn Number) by the Skein Method

D2256 Test Method for Tensile Properties of Yarns by the Single-Strand Method

D3218 Specification for Polyolefin Monofilaments

D7138 Test Method to Determine Melting Temperature of Synthetic Fibers

2.1.2 Fabric:

D1335 Test Method for Tuft Bind of Pile Yarn Floor Coverings

D1776 Practice for Conditioning and Testing Textiles

D2859 Test Method for Ignition Characteristics of Finished Textile Floor Covering Materials

D4158 Guide for Abrasion Resistance of Textile Fabrics (Uniform Abrasion)

D5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

These test methods are under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and are the direct responsibility of

Subcommittee F08.65 on Artificial Turf Surfaces and Systems.

Current edition approved July 1, 2009Dec. 1, 2017. Published August 2009December 2017. Originally approved in 1994. Last previous edition approved in 20032009 as

F1551 – 03.F1551 – 09. DOI: 10.1520/F1551-09.10.1520/F1551-09R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1551 − 09 (2017)

D5251 Practice for the Operation of the Tetrapod Walker Drum Tester (Withdrawn 2014)

D5793 Test Method for Binding Sites per Unit Length or Width of Pile Yarn Floor Coverings

D5823 Test Method for Tuft Height of Pile Floor Coverings

D5848 Test Method for Mass Per Unit Area of Pile Yarn Floor Coverings

E648 Test Method for Critical Radiant Flux of Floor-Covering Systems Using a Radiant Heat Energy Source

F1015 Test Method for Relative Abrasiveness of Synthetic Turf Playing Surfaces

2.1.3 Shock Absorbing Cushion Underlayment:

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D1667 Specification for Flexible Cellular Materials—Poly (Vinyl Chloride) Foam (Closed-Cell)

D1876 Test Method for Peel Resistance of Adhesives (T-Peel Test)

D2126 Test Method for Response of Rigid Cellular Plastics to Thermal and Humid Aging

D3574 Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams

D3575 Test Methods for Flexible Cellular Materials Made From Olefin Polymers

D3936 Test Method for Resistance to Delamination of the Secondary Backing of Pile Yarn Floor Covering

F355 Test Method for Impact Attenuation of Playing Surface Systems, Other Protective Sport Systems, and Materials Used for

Athletics, Recreation and Play

2.1.4 Turf Systems:

D1667 Specification for Flexible Cellular Materials—Poly (Vinyl Chloride) Foam (Closed-Cell)

F355 Test Method for Impact Attenuation of Playing Surface Systems, Other Protective Sport Systems, and Materials Used for

Athletics, Recreation and Play

F1015 Test Method for Relative Abrasiveness of Synthetic Turf Playing Surfaces

F1936 Specification for Impact Attenuation of Turf Playing Systems as Measured in the Field

F2117 Test Method for Vertical Rebound Characteristics of Sports Surface/Ball Systems; Acoustical Measurement

F2333 Test Method for Traction Characteristics of the Athletic Shoe-Sports Surface Interface

2.1.4 Infill Materials:

D5644 Test Methods for Rubber Compounding Materials—Determination of Particle Size Distribution of Recycled Vulcanizate

Particulate Rubber

F1632 Test Method for Particle Size Analysis and Sand Shape Grading of Golf Course Putting Green and Sports Field Rootzone

Mixes

2.2 Other Standards:

AT-030 Sports Shoe Traction

NOTE 1—AstroTurf® Industries internal test procedure is suitable as a basis for new ASTM test methods.

DIN 18-035 Part 6—Water Permeability of Synthetic Turf Systems and Permeable Bases

EN 12234 Surfaces for Sports Areas – Determination of Ball Roll

EN 12616 Surfaces for Sports Areas – Determination of Infiltration Rate

EN 14808 Surfaces for Sports Areas- Determination of Force Reduction

EN 14809 Surfaces for Sports Areas – Determination of Vertical Deformation

prEN 15301-1 Surfaces for Sports Areas- Part 1. Determination of Rotational Resistance

3. Terminology

3.1 Definitions—Terms are as defined in the referenced ASTM procedures comprising these test methods.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 fabric construction—the method of assembly of pile ribbon and backing yarns that produces the fabric, usually tufting,

knitting, or weaving.

3.2.2 infilled turf system—field system having a long pile height and either one or more substances in the face of the fabric to

provide the desired playing properties. Infill substances can be either sand, rubber or other substances or a combination of items.

3.2.3 lengthwise direction, n—in textiles, the direction in a machine-made fabric parallel to the direction of movement the fabric

followed in the manufacturing machine.

3.2.4 matting—the extent of change of the apparent synthetic turf pile thickness from the original value due to permanent

compression of the pile from sports use.

3.2.5 pile, n—for pile fiber turf surfacing, surface texture composed of many individual thin strands or groups of strands bound

to a backing fabric in a repetitive array.

The last approved version of this historical standard is referenced on www.astm.org.

F1551 − 09 (2017)

3.2.6 pile lay—the direction in which most of the pile fibers lean in the original, uncrushed fabric.

3.2.7 secondary backing—a material adhered to the backing side of a pile turf fabric.

3.2.8 sports shoe traction—a measure of the static or sliding coefficient of friction between a weighted sports shoe and the turf

pile surface, horizontal motion.

3.2.9 synthetic turf field system—composite of synthetic contact surface material, any fill material used in the contact surface,

energy absorbing material, fabric layers, adhesives, if any, and other constructed layers (as applicable to the individual system

construction).

3.2.10 synthetic turf system components—the separate components such as turf fabric, shock-absorbing pad, and adhesives that

comprise the synthetic turf playing surface when assembled; the subcomponents such as pile yarns and backing yarns that comprise

the turf fabric.

3.2.11 texture—the detailed configuration of loops, cut pile ends, and individual fibers in the pile layer.

3.2.11.1 Discussion—

Texture is the detailed appearance of the pile that changes by matting, crushing, flattening, fuzzing, untwisting, etc. during

exposure to service. The texture should be distinguished from the construction, that is, the specifications of kinds of yarns, yarn

sizes, and the mode of combination.

3.2.12 water permeability—the rate at which water of a specified head flows vertically through synthetic turf or other

components of the system.

4. Summary of Test Methods

4.1 The purpose of these test methods is to provide a comprehensive characterization of synthetic turf playing surfaces.

4.2 Specific conditions of the referenced procedures are recommended to encourage uniform application of these test methods.

4.3 Table 1 is an index of the test methods listed herein.

5. Significance and Use

5.1 These test methods constitute a standard for obtaining data in research and development, quality control, acceptance and

rejection under specifications, and for special purposes.

5.2 The data obtained from use of these test methods are applicable to the system and its components under conditions of the

particular test procedures and are not necessarily the same as the data that might be obtained in other environments or use

conditions.

5.3 The selection of test methods or tests should be limited to those appropriate to the system or material(s) being evaluated.

6. Conditioning of Materials

6.1 Conduct laboratory tests under known conditions of temperature and humidity as specified in the individual test procedures.

In the absence of specified conditions, tests must be conducted under the standard laboratory conditions of 23 6 2°C (73.4 6 3°F)

and 65 6 5 % relative humidity. Materials must be conditioned, undeflected, and undistorted at the temperature and humidity of

test for at least 24 h prior to testing.

6.2 Conduct field tests on installed, indoor or outdoor synthetic turf playing surfaces at ambient temperature and humidity

conditions. Measure and record the temperature of the synthetic turf surface, shock-absorbing pad, or other specific components

being characterized by the particular test.

7. Sampling

7.1 For laboratory tests, select representative samples of components, in accordance with specific sampling instructions of the

test procedure, when provided.

7.2 For field tests, specify locations on the synthetic turf playing surface where tests are conducted.

8. Application of Test Procedures

8.1 References to the test procedures stated herein are to be followed with regard to the apparatus, preparation of specimens,

procedures, calculations, and reporting of results, except when different conditions are noted specifically in these test methods.

8.2 Precision and bias statements are given for each test procedure in the respective test methods.

8.3 Test procedures shall be followed except when test method-specific conditions are provided.

F1551 − 09 (2017)

TABLE 1 Performance Test Methods for Synthetic Turf Surfaces

Test Method Section Item Tested

Pile Fiber

D792 density (specific gravity) 9 synthetic yarn

D1577 linear density of textile fibers (denier) 10 pile of yarn on mfg. turf fabric

D1907 linear density of yarn (denier - skein method) 11 bobbin of yarn

D2256 breaking strength and elongation 12 bobbin of yarn

D3218 yarn thickness 13 synthetic yarn

D7138 melting point (Fisher-John method or DSC 14 synthetic yarn

method)

Fabric

D1335 resistance to tuft pullout 15 synthetic turf fabric

D2859 flammability of pile floor covering (methenamine 17 synthetic turf fabric

tablet)

D4158 abrasion resistance (uniform abrasion method) 18 non-infilled turf

D5034 grab tear strength 19 synthetic turf fabric

D5251 resistance to matting (tetrapod method) 20 non-infilled turf

D5793 binding sites per unit 21 synthetic turf fabric

D5823 pile height 22 synthetic turf fabric

D5848 pile fiber, mass per unit 23 synthetic turf fabric

E648 flammability of synthetic turf (flooring radiant 24 synthetic turf fabric

panel test)

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf fabric

Shock Absorbing Pad Component

D395 compression set under constant load 26 shock-absorbing pad

D412 Dogbone tensile & elongation (Die A) 27 shock-absorbing pad

D624 tear resistance (Die C) 28 shock-absorbing pad

D1667 compression resistance 29 shock-absorbing pad

D1876 T-peel strength of secondary pad 30 synthetic turf and pad

D2126 hydrolytic stability 31 shock-absorbing pad

D3574 tensile and elongation urethane foams 32 shock-absorbing pad

D3575 water absorption (% weight gain) 33 shock-absorbing pad

D3936 delamination strength of secondary backing 34 synthetic turf and reinforce-

ment fabric

F355 shock absorbency of playing surface systems 35 shock-absorbing pad

and materials

Turf Systems

D1667 compression resistance (modified method) 29 synthetic turf system

F355 shock absorbency of playing surface systems 35 synthetic turf system

and materials

F1015 relative abrasiveness of synthetic turf surfaces 25 synthetic turf or system

F1936 shock absorbency of playing surface systems 36 synthe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.