ASTM E1673-96(2006)

(Test Method)Standard Test Method for Percent Suspensibility

Standard Test Method for Percent Suspensibility

SIGNIFICANCE AND USE

This test method is designed specifically for dry formulations, but need not be restricted to these materials.

Either option of this test method (see Section 8) may be used to determine the percent suspensibility.

This test method may not be applicable to all dry formulations such as those containing either liquids or ingredients that rise to the top upon separation.

This test method may not be applicable to formulations containing ingredients that decompose under the test conditions.

This test method may not give reproducible results if flocculation occurs.

This test method should be run in duplicate.

Products containing water soluble or volatile components may result in errors.

SCOPE

1.1 This test method is used to determine the percent suspensibility of dry pesticide formulations.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1673 − 96(Reapproved 2006)

Standard Test Method for

Percent Suspensibility

This standard is issued under the fixed designation E1673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.4 This test method may not be applicable to formulations

containing ingredients that decompose under the test condi-

1.1 This test method is used to determine the percent

tions.

suspensibility of dry pesticide formulations.

4.5 This test method may not give reproducible results if

1.2 This standard does not purport to address all of the

flocculation occurs.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.6 This test method should be run in duplicate.

priate safety and health practices and determine the applica-

4.7 Products containing water soluble or volatile compo-

bility of regulatory limitations prior to use. For specific

nents may result in errors.

precautionary statements see Section 7.

2. Referenced Documents 5. Apparatus

2.1 ASTM Standards: 5.1 Balance, top loading, with an accuracy of 60.01g or

D1126Test Method for Hardness in Water

better.

D1193Specification for Reagent Water

5.2 Beaker, 100 mL.

3. Summary of Test Method

5.3 Mixing Cylinder, stoppered, 250 mL, flat bottom, KI-

MAX series 20039 or equivalent.

3.1 Aknownquantityofdrypesticideisslurriedinto50mL

of test water in a 100-mL beaker. The slurry is quantitatively

5.4 Timer, adjustable, with an accuracy of 6 min.

transferred to a 250-mL mixing cylinder using additional test

5.5 Magnetic Stirrer, 120 to 1200 rpm, or equivalent.

water to rinse the beaker. The 250-mL mixing cylinder is then

filled to volume with test water. The mixing cylinder is

5.6 Stir Bar, magnetic 1 in. in length and ⁄8 in. in diameter

stoppered and inverted 15 complete cycles. The mixing cylin- (2.5 cm×1 cm).

derisallowedtostandfor30min.After30minthetop225mL

5.7 Weighing Dish,aluminum(57×18mm)orpetridish,or

isdrawnoffandtheremainingsuspensionisdried.Theresidue

equivalent.

weight will determine the percent suspensibility.

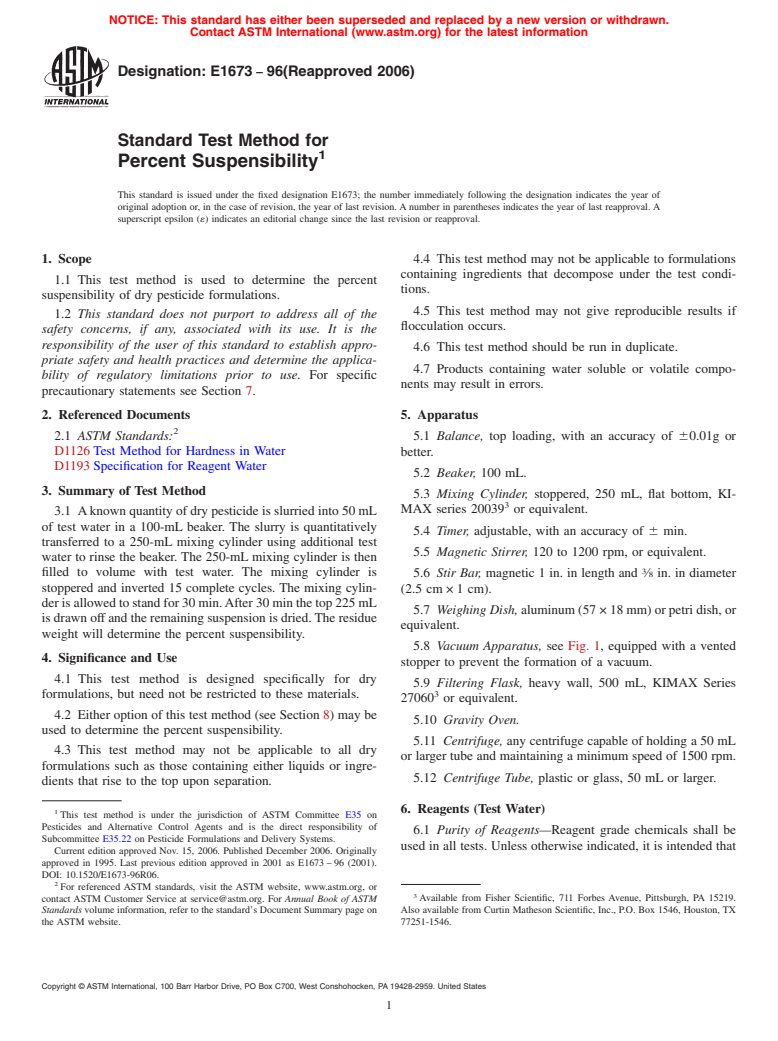

5.8 Vacuum Apparatus, see Fig. 1, equipped with a vented

4. Significance and Use

stopper to prevent the formation of a vacuum.

4.1 This test method is designed specifically for dry

5.9 Filtering Flask, heavy wall, 500 mL, KIMAX Series

formulations, but need not be restricted to these materials.

27060 or equivalent.

4.2 Either option of this test method (see Section 8) may be

5.10 Gravity Oven.

used to determine the percent suspensibility.

5.11 Centrifuge, any centrifuge capable of holding a 50 mL

4.3 This test method may not be applicable to all dry

or larger tube and maintaining a minimum speed of 1500 rpm.

formulations such as those containing either liquids or ingre-

5.12 Centrifuge Tube, plastic or glass, 50 mL or larger.

dients that rise to the top upon separation.

6. Reagents (Test Water)

This test method is under the jurisdiction of ASTM Committee E35 on

Pesticides and Alternative Control Agents and is the direct responsibility of

6.1 Purity of Reagents—Reagent grade chemicals shall be

Subcommittee E35.22 on Pesticide Formulations and Delivery Systems.

used in all tests. Unless otherwise indicated, it is intended that

Current edition approved Nov. 15, 2006. Published December 2006. Originally

approved in 1995. Last previous edition approved in 2001 as E1673–96 (2001).

DOI: 10.1520/E1673-96R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Fisher Scientific, 711 Forbes Avenue, Pittsburgh, PA 15219.

Standards volume information, refer to the standard’s Document Summary page on Also available from Curtin Matheson Scientific, Inc., P.O. Box 1546, Houston, TX

the ASTM website. 77251-1546.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1673 − 96 (2006)

6.3.1 Soft Water—Equivalenttoatotalhardnessof34.2ppm

as calcium carbonate (CaCO ). Transfer 2.50 mL of synthetic

hard water stock by pipet to a 1000-mL volumetric flask and

dilute to volume with water at 20°C. Mix solution thoroughly.

NOTE 2—It is recommended that total hardness be checked in accor-

dance with Test Method MT-73, CIPAC 1, EDTA titration. An alternate

method is provided in Test Method D1126 where the value is represented

as CaCO . A value within 6 % of the nominal hardness value is

acceptable.

6.3.2 Hard Water—Equivalent to a total hardness of 342

ppm as calcium carbonate (CaCO ). Transfer 25 mL of

synthetic hard water stock by buret to a 1000-mL volumetric

flaskanddilutetovolumewithwaterat20°C.Mixthissolution

thoroughly (see Note 2).

6.3.3 Extra-Hard Water—Equivalent to a total hardness of

1000 ppm as calcium carbonate (CaCO ).Transfer 73.1 mLof

synthetic hard water stock by buret to a 1000-mL volumetric

flaskanddilutetovolumewithwaterat20°C.Mixthissolution

thoroughly (see Note 2).

6.3.4 Other Test Waters—Other synthetic waters can be

prepared by using the following calculation:

DesiredWaterHardness413.6805 (1)

[millilitresofsynthetichardwaterstockat 207Ctobe

dilutedvolumetricallyto1000mLwithwaterat207C]

6.4 Other Carriers—Carriers other than water may be used

when appropriate.

7. Safety Precautions

FIG. 1 Vacuum Apparatus 7.1 Before testing, read the precautionary statements on the

product label or the Material Safety Data Sheet (MSDS), or

both. Take proper precautions to prevent skin contact and

inhalation of the fines or vapors, or both. Take care to prevent

all reagents shall conform to the specifications of the Commit-

contamination of the surrounding area. Always wear the

tee onAnalytical Reagents of theAmerican Chemical Society

appropriatesafetyequipmentand,whereindicated,wearrespi-

where such specifications are available.

ratory devices approved by the National Institute of Occupa-

6.2 Purity of Water—Unless otherwise indicated, reference tionalSafetyandHealth(NIOSH)fortheproductbeingtested.

towatershallbeunderstoodtomeanreagentwater,TypeIV,as

8. Procedure

defined by Specification D1193.

8.1 Option A (Evaporation):

NOTE 1—Type IV grade reagent water may be prepared by distillation,

8.1.1 Each sample should be run in duplicate.

ion exchange, reverse osmosis, electrodialysis, or a combination thereof.

8.1.2 Weigh a 4-g sample into a weighing dish. Record the

6.3 Synthetic Hard Water Stock—Transfer 12.14 g of anhy-

sample weight (W ) to an accuracy of 60.10g.

drou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.