ASTM E2730-10(2015)e2

(Practice)Standard Practice for Calibration and Use of Thermocouple Reference Junction Probes in Evaluation of Electronic Reference Junction Compensation Circuits

Standard Practice for Calibration and Use of Thermocouple Reference Junction Probes in Evaluation of Electronic Reference Junction Compensation Circuits

SIGNIFICANCE AND USE

5.1 Many electronic instruments that are designed to be used with thermocouples use some method of reference junction compensation. In many industrial applications it may be impractical to use a physical ice bath as a temperature reference in a thermocouple circuit. The instrument must therefore be able to measure the temperature at the point of electrical connection of the thermocouple and either add or subtract voltage to give a corrected equivalent of what that thermocouple would indicate had there physically been 0°C reference junctions present in the circuit. There are two types of instruments that generally apply these techniques: electronic thermometer readouts that use a thermocouple as the sensor, and calibrators designed to calibrate these digital thermometer readouts. Additionally, the probe and circuit described in this guide can be used with a voltmeter to emulate a thermometer or a voltage source to calibrate temperature-indicating instrumentation. In all cases the probe must be calibrated if traceability or an uncertainty analysis, or both, is required.

SCOPE

1.1 This guide covers methods of calibration and use of thermocouple reference junction probes (cold junction compensation probes) in the evaluation of electronic reference junction compensation circuits. Their use with instruments that measure only voltage is also covered.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation: E2730 − 10 (Reapproved 2015) An American National Standard

Standard Practice for

Calibration and Use of Thermocouple Reference Junction

Probes in Evaluation of Electronic Reference Junction

Compensation Circuits

This standard is issued under the fixed designation E2730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Note 12 was moved to a new location below Table 2 in November 2015.

1. Scope E563 Practice for Preparation and Use of an Ice-Point Bath

as a Reference Temperature

1.1 This guide covers methods of calibration and use of

E1129/E1129M Specification for Thermocouple Connectors

thermocouple reference junction probes (cold junction com-

E1684 Specification for Miniature Thermocouple Connec-

pensation probes) in the evaluation of electronic reference

tors

junction compensation circuits.Their use with instruments that

E1750 Guide for Use of Water Triple Point Cells

measure only voltage is also covered.

E2623 Practice for Reporting Thermometer Calibrations

1.2 The values stated in SI units are to be regarded as the

2.2 Other References:

standard. The values given in parentheses are for information

NIST Monograph 175 Temperature-Electromotive Force

only.

Reference Functions and Tables for the Letter-Designated

1.3 This standard does not purport to address all of the

Thermocouple Types Based on the ITS-90

safety concerns, if any, associated with its use. It is the

ASTM MNL12 Manual On The Use Of Thermocouples In

responsibility of the user of this standard to establish appro-

Temperature Measurement

priate safety and health practices and determine the applica-

BIPM JCGM 100:2008 Evaluation of Measurement Data—

bility of regulatory limitations prior to use.

Guide to the Expression of Uncertainty in Measurement

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1 Definitions—The definitions given inTerminology E344

mendations issued by the World Trade Organization Technical

shall apply to this guide.

Barriers to Trade (TBT) Committee.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2.1 correction, n—an offset value added to the result of a

measurement to obtain a correct result.

2.1 ASTM Standards:

E220 Test Method for Calibration of Thermocouples By

NOTE 1—This definition is from Test Method E220.

Comparison Techniques

3.2.2 referencejunctioncompensation,n—theelectricalcor-

E230 Specification for Temperature-Electromotive Force

rection of the indication of a thermocouple such that the

(emf) Tables for Standardized Thermocouples

corrected indication is equivalent to the emf or temperature the

E344 Terminology Relating to Thermometry and Hydrom-

instrument would indicate if the reference junctions were

etry

physically maintained at 0°C.

3.2.3 reference junction probe, n—a probe constructed from

ThispracticeisunderthejurisdictionofASTMCommitteeE20onTemperature

thermocouple materials and high purity copper wire for the

Measurement and is the direct responsibility of Subcommittee E20.14 on Thermo-

couples - Testing. purposeofservingasthereferencejunctionforathermocouple

Current edition approved June 15, 2015. Published June 2015. Originally

assembly. Reference junction probes may be constructed as

approved in 2010. Last previous edition approved in 2010 as E2730 – 10.

part of the measuring probe or they can be manufactured

DOI:10.1520/E2730-10R15E02.

separately and later attached to thermocouple sensors via plugs

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

or other connection types.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.2.4 UUT, n—Unit Under Test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

E2730 − 10 (2015)

4. Summary of Guide 6. Reagents

4.1 Calibration of a Reference Junction Probe (RJP) con- 6.1 Laboratory or commercially produced distilled water is

sists of establishing the emf error in the RJP relative to the

required to create an accurate ice bath. Clean tap water can be

applicable thermocouple reference function by placing the used in cases where high accuracy is not a requirement; in this

measuring junction and the reference junctions at known case the temperature of the bath should be measured directly.

temperatures while measuring the voltage with a digital volt-

Chlorine, fluorine, and other chemicals such as dissolved salts

meter (DVM) or potentiometer. Three methods are described inthewateroricewilldepresstheicepointandtheamountcan

for establishing the two known temperatures and thus the

be significant in some measurements. See Practice E563 for

temperature difference. For the temperature measurement,

further guidance.

manydevicessuchasStandardPlatinumResistanceThermom-

eters (SPRTs), Platinum Resistance Thermometers (PRTs),

7. Procedure

thermistors, or thermocouples, and a variety of readout instru-

7.1 Calibration of RJP (Methods A, B, or C).

ments are suitable, depending on the required accuracy. The

7.1.1 Reference Point Temperature Source:

measured voltage at the copper leads indicates the emf asso-

ciated with the temperature difference of the references. Error 7.1.1.1 Method A: Ice Bath Method—Prepare the reference

point temperature source using an ice-point bath in accordance

is determined by comparing the observed emf to the calculated

with Practice E563. Refer to Fig. 1.

emf for the known temperature difference. The emf error is

then applied as a correction. The corrected emf can then be

NOTE 5—Be careful to closely follow the guidelines in Practice E563

converted to temperature.

forestablishingandmaintaininganIcePointReferenceassignificanterror

can occur over time without proper maintenance.

NOTE 2—In particular, cold work should be avoided in the sections of

copper and thermocouple wire that pass from the top of the ice bath to

7.1.1.2 Method B: Triple Point of Water (TPW) Cell

ambient temperature continuing on to the terminal connection. Careful

Method—Prepare the reference point temperature source using

design of the RJP, with supporting sleeve and strain relief, can minimize

a triple point of water cell in accordance with Guide E1750.

cold work in these sections.

Refer to Fig. 2.

4.2 Use of the calibrated RJP consists of applying the

NOTE6—BecarefultocloselyfollowtheguidelinesinGuideE1750for

corrections obtained during calibration appropriately for the

establishing and maintaining a TPW cell as significant error can occur

mode of use. Three modes of use with corresponding applica-

over time without proper maintenance.

tion equations are described.

7.1.1.3 Method C: Variable Temperature Source Method—

NOTE3—Homogeneityisassumedinboththethermocoupleandcopper

Prepare the reference point temperature source using a variable

wires. Care should be taken to minimize the stress induced over time and

temperature source (calibration bath or dryblock calibrator) set

during use on both sets of wire. Cold work in particular should be avoided

to 0.0°C and verify using a reference thermometer. Refer to

in the sections of the copper and thermocouple wire from a distance 5 cm

(2 in.) below the top of the ice/water mixture to a distance 5 cm (2 in.) Fig. 3.

above the top of the ice-point bath.

7.1.2 Prepare the room temperature source using a variable

NOTE 4—Proper operation of the measuring instruments is not de-

temperature source (calibration bath or dry-block calibrator)

scribed in this guide. To ensure correct results, the operator must

set to 25°C and verify using a reference thermometer. The

understand and apply proper technique in the use of all measuring

instruments involved. temperature of 25ºC is nominal; in actual testing the tempera-

tureofthebathshouldbesetascloseaspossibletotheambient

5. Significance and Use room temperature. Throughout this procedure 25ºC will be

used to designate the ambient temperature. There are many

5.1 Many electronic instruments that are designed to be

cases where the terminal ends may be at a temperature higher

used with thermocouples use some method of reference junc-

than ambient temperature. Connections inside an instrument or

tion compensation. In many industrial applications it may be

control box can reach temperatures of 40°C or higher.The RJP

impractical to use a physical ice bath as a temperature

can be calibrated at multiple temperatures and the resulting

reference in a thermocouple circuit. The instrument must

RJP correction can be modeled as a first- or second-order

therefore be able to measure the temperature at the point of

polynomial correction versus RJP temperature.

electrical connection of the thermocouple and either add or

7.1.3 Weld, solder, or braze the thermocouple wire ends of

subtract voltage to give a corrected equivalent of what that

the RJP together to create a thermocouple measuring junction

thermocouple would indicate had there physically been 0°C

and then insert it into a protective sheath. Twisting or crimping

reference junctions present in the circuit. There are two types

the wires is acceptable if a reliable electrical connection can be

of instruments that generally apply these techniques: electronic

achieved. The measuring junction should be electrically iso-

thermometer readouts that use a thermocouple as the sensor,

lated from the sheath. All fluxes or chemicals that may have

and calibrators designed to calibrate these digital thermometer

been used should be thoroughly removed.

readouts. Additionally, the probe and circuit described in this

7.1.4 Place the measuring junction and protective sheath in

guide can be used with a voltmeter to emulate a thermometer

or a voltage source to calibrate temperature-indicating instru- the temperature source that has been stabilized at 25ºC nomi-

mentation. In all cases the probe must be calibrated if trace- nal. Place the reference junction probe in the reference point

ability or an uncertainty analysis, or both, is required. temperature source. Both the sheath and probe should be

´2

E2730 − 10 (2015)

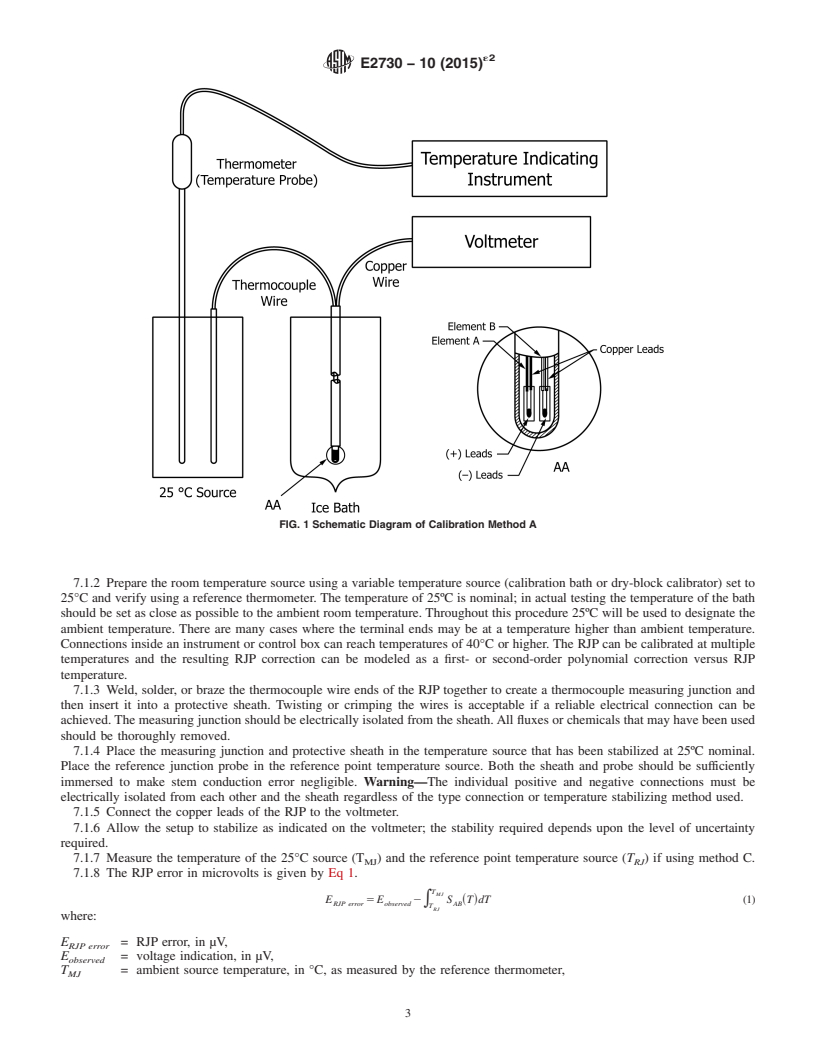

FIG. 1 Schematic Diagram of Calibration Method A

NOTE 8—The values given are taken from NIST Monograph 175.

sufficiently immersed to make stem conduction error negli-

gible. Warning—Theindividualpositiveandnegativeconnec-

7.1.9 The RJP error in microvolts is algebraically approxi-

tions must be electrically isolated from each other and the

mated using Eq 2 for method A.

sheath regardless of the type connection or temperature stabi-

E 5 E 2 E (2)

RJP error observed expected

lizing method used.

where:

7.1.5 Connect the copper leads of the RJP to the voltmeter.

7.1.6 Allow the setup to stabilize as indicated on the E = RJP error, in µV,

RJP error

voltmeter; the stability required depends upon the level of E = voltmeter indication, in µV, and

observed

E = thermocouple voltage, in µV, at the ambient

uncertainty required.

expected

source temperature, as computed by the refer-

7.1.7 Measure the temperature of the 25°C source (T ) and

MJ

ence function or interpolated from the thermo-

thereferencepointtemperaturesource(T )ifusingmethodC.

RJ

couple table.

7.1.8 The RJP error in microvolts is given by Eq 1.

T

MJ 7.1.10 The RJP error in microvolts is algebraically approxi-

E 5 E 2 S ~T!dT (1)

*

RJP error observed AB

T

RJ

mated using Eq 3 for method B.

where:

E 5 E 2 E 10.010°C 3S 0°C (3)

~ !

RJP error observed expected AB

E = RJP error, in µV,

where:

RJP error

E = voltage indication, in µV,

observed

E = RJP error, in µV,

T = ambient source temperature, in °C, as measured RJP error

MJ

E = voltmeter indication, in µV,

by the reference thermometer, observed

E = thermocouple voltage, in µV, at the ambient

T = reference junction temperature, in °C (assumed expected

RJ

source temperature, as computed by the refer-

to be 0.000°C in Method A, 0.010°C in Method

ence function or interpolated from the thermo-

B, and measured by reference thermometer in

couple table, and

Method C), and

S (0°C) = Seebeck coefficient at 0°C, in µV/°C (refer to

S (T) = Seebeck coefficient at temperature T, in µV/°C. AB

AB

Table 1).

NOTE 7—Use the correct value for the S based on the actual

AB

7.1.11 The RJP error in microvolts is algebraically approxi-

temperature of the reference point temperature source. Values given are

based on the ice Melting Point (MP) (0.000°C). mated using Eq 4 for method C.

´2

E2730 − 10 (2015)

FIG. 2 Schematic Diagram of Calibration Method B

E 5 E 2 E 1S 0°C 3T (4)

~ !

RJP error observed expected AB RJ T = RJP correction, in °C,

RJP correction

where:

E = RJP error, in µV, and

RJP error

S (0°C) = Seebeck coefficient at temperature 0°C, in

AB

E = RJP error, in µV,

RJP error

µV/°C (refer to Table 1).

E = voltmeter indication, in µV,

observed

Warning—Eq 6 may provide incorrect results for thermo-

E = thermocouple voltage, in µV, at the ambient

expected

couples having significantly different values of S at 0°C and

source temperature, as computed by the refer- AB

25°C

ence function or interpolated from the thermo-

couple table,

7.2 Use of the RJP (Modes 1, 2, or 3).

T = reference junction temperature, in °C, as mea-

RJ

NOTE 9—The following instructions apply to the use of an ice bath,

sured by the reference thermometer, and

TPW cell, or variable temperature source for the reference point tempera-

S (0°C) = Seebeck coefficient at 0°C, in µV/°C (refer to

AB

ture. Thus, the equations are shown in the generalized form. When using

Table 1).

the equations, the value for t must be the assumed values for the ice bath

or TPW cell, or the actual measured temperature of the variable tempera-

7.1.12 Corrections are identical to errors in magnitude but

ture source, as applicable.

of opposite sign. Calculate the voltage correction in µV using

7.2.1 Mode 1—Use of the RJP as a reference junction in a

Eq 5.

thermocouple circuit. Refer to Fig. 4.

E 5 E (5)

RJP correction RJP error

7.2.1.1 Prepare the reference point temperature source.

where:

7.2.1.2 Connect the thermocouple end of the RJP to the

thermocouple to be measured using an approved thermocouple

E = RJP correction, in µV, and

RJP correction

connector.

E = RJP error, in µV.

RJP error

7.2.1.3 Connect the copper wire en

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2 ´2

Designation: E2730 − 10 (Reapproved 2015) E2730 − 10 (Reapproved 2015)

Standard Practice for

Calibration and Use of Thermocouple Reference Junction

Probes in Evaluation of Electronic Reference Junction

Compensation Circuits

This standard is issued under the fixed designation E2730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in JuneNote 12 was moved to a new location below Table 2 in No-

vember 2015.

1. Scope

1.1 This guide covers methods of calibration and use of thermocouple reference junction probes (cold junction compensation

probes) in the evaluation of electronic reference junction compensation circuits. Their use with instruments that measure only

voltage is also covered.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E230 Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

E344 Terminology Relating to Thermometry and Hydrometry

E563 Practice for Preparation and Use of an Ice-Point Bath as a Reference Temperature

E1129/E1129M Specification for Thermocouple Connectors

E1684 Specification for Miniature Thermocouple Connectors

E1750 Guide for Use of Water Triple Point Cells

E2623 Practice for Reporting Thermometer Calibrations

2.2 Other References:

NIST Monograph 175 Temperature-Electromotive Force Reference Functions and Tables for the Letter-Designated Thermo-

couple Types Based on the ITS-90

ASTM MNL12 Manual On The Use Of Thermocouples In Temperature Measurement

BIPM JCGM 100:2008 Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement

3. Terminology

3.1 Definitions—The definitions given in Terminology E344 shall apply to this guide.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 correction, n—an offset value added to the result of a measurement to obtain a correct result.

NOTE 1—This definition is from Test Method E220.

3.2.2 reference junction compensation, n—the electrical correction of the indication of a thermocouple such that the corrected

indication is equivalent to the emf or temperature the instrument would indicate if the reference junctions were physically

maintained at 0°C.

This practice is under the jurisdiction of ASTM Committee E20 on Temperature Measurement and is the direct responsibility of Subcommittee E20.04 on Thermocouples.

Current edition approved June 15, 2015. Published June 2015. Originally approved in 2010. Last previous edition approved in 2010 as E2730 – 10. DOI:10.1520/E2730-

10R15E01.DOI:10.1520/E2730-10R15E02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

E2730 − 10 (2015)

3.2.3 reference junction probe, n—a probe constructed from thermocouple materials and high purity copper wire for the purpose

of serving as the reference junction for a thermocouple assembly. Reference junction probes may be constructed as part of the

measuring probe or they can be manufactured separately and later attached to thermocouple sensors via plugs or other connection

types.

3.2.4 UUT, n—Unit Under Test.

4. Summary of Guide

4.1 Calibration of a Reference Junction Probe (RJP) consists of establishing the emf error in the RJP relative to the applicable

thermocouple reference function by placing the measuring junction and the reference junctions at known temperatures while

measuring the voltage with a digital voltmeter (DVM) or potentiometer. Three methods are described for establishing the two

known temperatures and thus the temperature difference. For the temperature measurement, many devices such as Standard

Platinum Resistance Thermometers (SPRTs), Platinum Resistance Thermometers (PRTs), thermistors, or thermocouples, and a

variety of readout instruments are suitable, depending on the required accuracy. The measured voltage at the copper leads indicates

the emf associated with the temperature difference of the references. Error is determined by comparing the observed emf to the

calculated emf for the known temperature difference. The emf error is then applied as a correction. The corrected emf can then

be converted to temperature.

NOTE 2—In particular, cold work should be avoided in the sections of copper and thermocouple wire that pass from the top of the ice bath to ambient

temperature continuing on to the terminal connection. Careful design of the RJP, with supporting sleeve and strain relief, can minimize cold work in these

sections.

4.2 Use of the calibrated RJP consists of applying the corrections obtained during calibration appropriately for the mode of use.

Three modes of use with corresponding application equations are described.

NOTE 3—Homogeneity is assumed in both the thermocouple and copper wires. Care should be taken to minimize the stress induced over time and

during use on both sets of wire. Cold work in particular should be avoided in the sections of the copper and thermocouple wire from a distance 5 cm

(2 in.) below the top of the ice/water mixture to a distance 5 cm (2 in.) above the top of the ice-point bath.

NOTE 4—Proper operation of the measuring instruments is not described in this guide. To ensure correct results, the operator must understand and apply

proper technique in the use of all measuring instruments involved.

5. Significance and Use

5.1 Many electronic instruments that are designed to be used with thermocouples use some method of reference junction

compensation. In many industrial applications it may be impractical to use a physical ice bath as a temperature reference in a

thermocouple circuit. The instrument must therefore be able to measure the temperature at the point of electrical connection of the

thermocouple and either add or subtract voltage to give a corrected equivalent of what that thermocouple would indicate had there

physically been 0°C reference junctions present in the circuit. There are two types of instruments that generally apply these

techniques: electronic thermometer readouts that use a thermocouple as the sensor, and calibrators designed to calibrate these

digital thermometer readouts. Additionally, the probe and circuit described in this guide can be used with a voltmeter to emulate

a thermometer or a voltage source to calibrate temperature-indicating instrumentation. In all cases the probe must be calibrated if

traceability or an uncertainty analysis, or both, is required.

6. Reagents

6.1 Laboratory or commercially produced distilled water is required to create an accurate ice bath. Clean tap water can be used

in cases where high accuracy is not a requirement; in this case the temperature of the bath should be measured directly. Chlorine,

fluorine, and other chemicals such as dissolved salts in the water or ice will depress the ice point and the amount can be significant

in some measurements. See Practice E563 for further guidance.

7. Procedure

7.1 Calibration of RJP (Methods A, B, or C).

7.1.1 Reference Point Temperature Source:

7.1.1.1 Method A: Ice Bath Method—Prepare the reference point temperature source using an ice-point bath in accordance with

Practice E563. Refer to Fig. 1.

NOTE 5—Be careful to closely follow the guidelines in Practice E563 for establishing and maintaining an Ice Point Reference as significant error can

occur over time without proper maintenance.

7.1.1.2 Method B: Triple Point of Water (TPW) Cell Method—Prepare the reference point temperature source using a triple point

of water cell in accordance with Guide E1750. Refer to Fig. 2.

NOTE 6—Be careful to closely follow the guidelines in Guide E1750 for establishing and maintaining a TPW cell as significant error can occur over

time without proper maintenance.

7.1.1.3 Method C: Variable Temperature Source Method—Prepare the reference point temperature source using a variable

temperature source (calibration bath or dryblock calibrator) set to 0.0°C and verify using a reference thermometer. Refer to Fig.

3.

´2

E2730 − 10 (2015)

FIG. 1 Schematic Diagram of Calibration Method A

7.1.2 Prepare the room temperature source using a variable temperature source (calibration bath or dry-block calibrator) set to

25°C and verify using a reference thermometer. The temperature of 25ºC is nominal; in actual testing the temperature of the bath

should be set as close as possible to the ambient room temperature. Throughout this procedure 25ºC will be used to designate the

ambient temperature. There are many cases where the terminal ends may be at a temperature higher than ambient temperature.

Connections inside an instrument or control box can reach temperatures of 40°C or higher. The RJP can be calibrated at multiple

temperatures and the resulting RJP correction can be modeled as a first- or second-order polynomial correction versus RJP

temperature.

7.1.3 Weld, solder, or braze the thermocouple wire ends of the RJP together to create a thermocouple measuring junction and

then insert it into a protective sheath. Twisting or crimping the wires is acceptable if a reliable electrical connection can be

achieved. The measuring junction should be electrically isolated from the sheath. All fluxes or chemicals that may have been used

should be thoroughly removed.

7.1.4 Place the measuring junction and protective sheath in the temperature source that has been stabilized at 25ºC nominal.

Place the reference junction probe in the reference point temperature source. Both the sheath and probe should be sufficiently

immersed to make stem conduction error negligible. Warning—The individual positive and negative connections must be

electrically isolated from each other and the sheath regardless of the type connection or temperature stabilizing method used.

7.1.5 Connect the copper leads of the RJP to the voltmeter.

7.1.6 Allow the setup to stabilize as indicated on the voltmeter; the stability required depends upon the level of uncertainty

required.

7.1.7 Measure the temperature of the 25°C source (T ) and the reference point temperature source (T ) if using method C.

MJ RJ

7.1.8 The RJP error in microvolts is given by Eq 1.

T

MJ

E 5 E 2 S T dT (1)

* ~ !

RJP error observed AB

T

RJ

where:

E = RJP error, in μV,

RJP error

E = voltage indication, in μV,

observed

T = ambient source temperature, in °C, as measured by the reference thermometer,

MJ

´2

E2730 − 10 (2015)

FIG. 2 Schematic Diagram of Calibration Method B

T = reference junction temperature, in °C (assumed to be 0.000°C in Method A, 0.010°C in Method B, and measured

RJ

by reference thermometer in Method C), and

S (T) = Seebeck coefficient at temperature T, in μV/°C.

AB

NOTE 7—Use the correct value for the S based on the actual temperature of the reference point temperature source. Values given are based on the

AB

ice Melting Point (MP) (0.000°C).

NOTE 8—The values given are taken from NIST Monograph 175.

7.1.9 The RJP error in microvolts is algebraically approximated using Eq 2 for method A.

E 5 E 2 E (2)

RJP error observed expected

where:

E = RJP error, in μV,

RJP error

E = voltmeter indication, in μV, and

observed

E = thermocouple voltage, in μV, at the ambient source temperature, as computed by the reference function or

expected

interpolated from the thermocouple table.

7.1.10 The RJP error in microvolts is algebraically approximated using Eq 3 for method B.

E 5 E 2 E 10.010°C 3S 0°C (3)

~ !

RJP error observed expected AB

where:

E = RJP error, in μV,

RJP error

E = voltmeter indication, in μV,

observed

E = thermocouple voltage, in μV, at the ambient source temperature, as computed by the reference function or

expected

interpolated from the thermocouple table, and

S (0°C) = Seebeck coefficient at 0°C, in μV/°C (refer to Table 1).

AB

7.1.11 The RJP error in microvolts is algebraically approximated using Eq 4 for method C.

E 5 E 2 E 1S 0°C 3T (4)

~ !

RJP error observed expected AB RJ

where:

´2

E2730 − 10 (2015)

FIG. 3 Schematic Diagram of Calibration Method C

TABLE 1 Seebeck Coefficients at 0°C for Some Common

A

Thermocouple Types

Calibration Type S (0°C) in μV/°C

AB

E 58.666

J 50.382

K 39.456

N 25.929

T 32.854

R 5.290

S 5.403

B 0.102

A

Source: Specification E230.

E = RJP error, in μV,

RJP error

E = voltmeter indication, in μV,

observed

E = thermocouple voltage, in μV, at the ambient source temperature, as computed by the reference function or

expected

interpolated from the thermocouple table,

T = reference junction temperature, in °C, as measured by the reference thermometer, and

RJ

S (0°C) = Seebeck coefficient at 0°C, in μV/°C (refer to Table 1).

AB

7.1.12 Corrections are identical to errors in magnitude but of opposite sign. Calculate the voltage correction in μV using Eq 5.

E 5 E (5)

RJP correction RJP error

where:

E = RJP correction, in μV, and

RJP correction

E = RJP error, in μV.

RJP error

´2

E2730 − 10 (2015)

7.1.13 Calculate the temperature correction in °C using Eq 6.

2 E

~ !

RJP error

T 5 (6)

RJP correction

S 0°C

~ !

AB

where:

T = RJP correction, in °C,

RJP correction

E = RJP error, in μV, and

RJP error

S (0°C) = Seebeck coefficient at temperature 0°C, in μV/°C (refer to Table 1).

AB

Warning—Eq 6 may provide incorrect results for thermocouples having significantly different values of S at 0°C and 25°C

AB

7.2 Use of the RJP (Modes 1, 2, or 3).

NOTE 9—The following instructions apply to the use of an ice bath, TPW cell, or variable temperature s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.