ASTM D6369-99(2006)

(Guide)Standard Guide for Design of Standard Flashing Details for EPDM Roof Membranes (Withdrawn 2015)

Standard Guide for Design of Standard Flashing Details for EPDM Roof Membranes (Withdrawn 2015)

SIGNIFICANCE AND USE

This guide illustrates general details for typical conditions that may be encountered on an EPDM sheet roofing system.

This guide does not address all requirements associated with the installation of EPDM membrane flashing, such as membrane cleaning and surface preparation, fastener spacing, adhesive application and other seaming requirements which may vary by membrane system supplier.

Insulation, fastener types, protection mats, stone ballast, pavers, and requirements for perimeter attachment are not covered by this guide. The designer shall review the project requirements and consult the membrane system supplier, building insurer, and local building codes for specific requirements.

SCOPE

1.1 This guide covers the design of details for typical conditions encountered in new ballasted, mechanically attached or fully adhered ethylene propylene diene terpolymer (EPDM) sheet roof systems.

1.2 This guide illustrates general details for typical conditions that may be encountered on an EPDM sheet roofing system. The guide will assist the designer in preparing details for each specific condition that may occur on a project.

1.3 The values stated in SI units are to be regarded as standard. The conventional units given in parentheses are provided for information purposes only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This guide covered the design of details for typical conditions encountered in new ballasted, mechanically attached or fully adhered ethylene propylene diene terpolymer (EPDM) sheet roof systems.

Formerly under the jurisdiction of Committee D08 on Roofing and Waterproofing, this guide was withdrawn in July 2015 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6369 − 99(Reapproved 2006)

Standard Guide for

Design of Standard Flashing Details for EPDM Roof

Membranes

This standard is issued under the fixed designation D6369; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.4 mechanically attached sheet roofing, n—a system which

incorporates a mechanically fastened vulcanized EPDM sheet

1.1 This guide covers the design of details for typical

over a secured and accepted substrate.

conditions encountered in new ballasted, mechanically at-

tached or fully adhered ethylene propylene diene terpolymer

4. Significance and Use

(EPDM) sheet roof systems.

4.1 This guide illustrates general details for typical condi-

1.2 This guide illustrates general details for typical condi-

tions that may be encountered on an EPDM sheet roofing

tions that may be encountered on an EPDM sheet roofing

system.

system. The guide will assist the designer in preparing details

4.2 This guide does not address all requirements associated

for each specific condition that may occur on a project.

with the installation of EPDM membrane flashing, such as

1.3 The values stated in SI units are to be regarded as

membrane cleaning and surface preparation, fastener spacing,

standard. The conventional units given in parentheses are

adhesive application and other seaming requirements which

provided for information purposes only.

may vary by membrane system supplier.

1.4 This standard does not purport to address all of the

4.3 Insulation, fastener types, protection mats, stone ballast,

safety concerns, if any, associated with its use. It is the

pavers, and requirements for perimeter attachment are not

responsibility of the user of this standard to establish appro-

covered by this guide. The designer shall review the project

priate safety and health practices and determine the applica-

requirementsandconsultthemembranesystemsupplier,build-

bility of regulatory limitations prior to use.

ing insurer, and local building codes for specific requirements.

2. Referenced Documents

5. Drawings

2.1 ASTM Standards:

5.1 This guide is not all-inclusive. The designer shall detail

D1079Terminology Relating to Roofing and Waterproofing

all typical and special conditions on the project. Particular

3. Terminology

attention shall be given to transitions in plane and intersection

of different details. The membrane system supplier or system

3.1 Definitions— For definitions of terms used in this guide

applicator shall provide shop drawings of each condition to

and not listed below, see Terminology D1079.

confirmfieldconditionsandtoverifytheirunderstandingofthe

3.2 ballasted sheet roofing, n—a system which incorporates

design intent.

alooselaidvulcanizedEPDMsheetoveranacceptedsubstrate

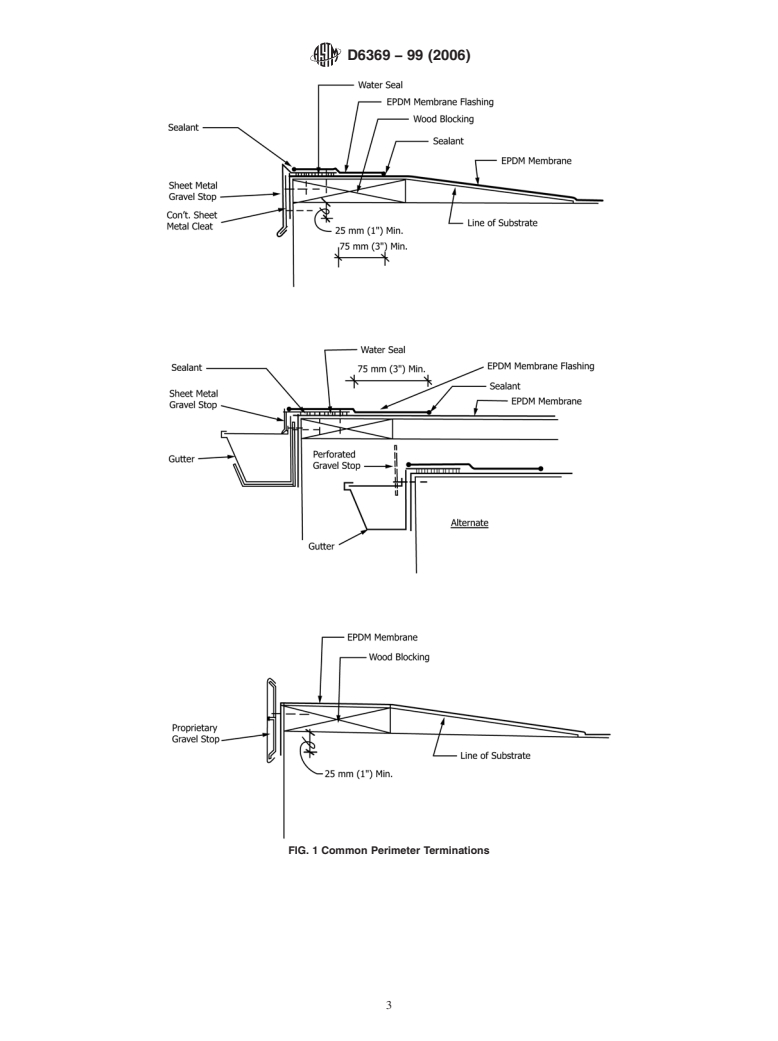

5.2 Insulation, protection mats, stone ballast and pavers

and is held in place with either stone ballast, pavers, or a

have been omitted for clarity.

combination thereof.

3.3 fully adhered sheet roofing, n—a system which incorpo- 5.3 Treated wood blocking shall be installed to provide

rates a vulcanized EPDM sheet fully adhered over a secured attachment for accessory items such as gravel stops, metal

and accepted substrate. sleeves, etc.

6. Penetrations

This guide is under the jurisdiction ofASTM Committee D08 on Roofing and

Waterproofing and is the direct responsibility of Subcommittee D08.18 on Nonbi-

6.1 Flashing at penetrations shall accommodate differential

tuminous Organic Roof Coverings.

movement between the deck and penetration (that is, pipe,

Current edition approved Dec. 1, 2006. Published December 2006. Originally

conduit, column or drain).

approved in 1999. Last previous edition approved in 1999 as D6369–99. DOI:

10.1520/D6369-99R06.

6.1.1 Where “H” or “I” column sections occur, install

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

blocking between flanges to facilitate installation of flashing.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Weld sloping steel hoods to column. Extend vertical leg of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. hood a minimum 100 mm (4 in.) over flashing.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6369 − 99 (2006)

6.1.2 Set cast iron drains with the top of the flange level shall lap the joint between the wood blocking and parapet

with or slightly below the surrounding deck area. When surface a minimum 25 mm (1 in.).

insulation is installed below the sheet membrane provide a

8.6 Expansion Joints—AsshowninFig.6,expansionjoints

minimum 900 by 900 mm (36 by 36 in.) transition sump. Do

shall be raised above the roof membrane a minimum 200 mm

not run field or factory seams within 600 mm (24 in.) of drain

(8 in.). A compressible tube or proprietary formed member is

flange edge.

used to permit the membrane to flex. An EPDM hammock is

installed to support the joint insulation and tube. If the

7. Expansion Joints

expansion joint curb is constructed of wood blocking, then the

top surfaces shall be beveled to provide a positive slope away

7.1 Expansion joints are designed to permit independent

from the joint.An alternate method is to install a prefabricated

movement of structural elements on each side of the joint.

ormetalexpansionjointcovertothetopoftheexpansionjoint.

Expansion joint curbs and flashings shall be designed to

accommodate this movement. Expansion joints shall be raised

8.7 Scuppers—Scuppers shall be fabricated from sheet

a minimum 200 mm (8 in.) above the roof membrane.

metal with soldered or sealed seams as shown in Fig. 7. The

flanges shall be set in water seal and flashed. Seal the exterior

8. Explanatory Notes

portion of the scupper to the vertical surfaces.

8.8 Membrane Termination on Vertical Surface—Where the

8.1 Perimeter Terminations—The most common perimeter

membrane terminates on a vertical surface (see Fig. 8), it shall

terminations are shown in Fig. 1. Extend sheet roofing mem-

be secured with fasteners a maximum 200 mm (8 in.) outside

brane down the building face covering the joint between the

circumference or a metal termination bar that is fastened a

wood blocking and exterior building finish a minimum 25 mm

maximum 200 mm (8 in.) outside circumference. Extend

(1 in.). Install the gravel stop as specified by the designer or

membrane under the cap flashing a minimum 75 mm (3 in.).

manufacturer. Where sheet metal gravel stops are installed,

Surface mounted metal counterflas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.