ASTM B974/B974M-10

(Specification)Standard Specification for Free-Cutting Bismuth Brass Rod, Bar and Wire

Standard Specification for Free-Cutting Bismuth Brass Rod, Bar and Wire

ABSTRACT

This specification establishes the requirements for free-cutting a bismuth brass rod, bar and wire of UNS Alloy No.C49250 and C49260 suitable for high-speed screw machine work or for general applications. Typically, products made to this specification are furnished as straight lengths or coils when requested. The material shall conform to the chemical composition requirements, tensile strength requirements, and elongation requirements stated in this specification.

SCOPE

1.1 This specification establishes the requirements for free-cutting bismuth brass rod, bar and wire of UNS Alloy No. C49250 and C49260 suitable for high-speed screw machine work, or for general applications.

1.2 Typically, product made to this specification is furnished as straight lengths, or coils when requested.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B974/B974M – 10

Standard Specification for

Free-Cutting Bismuth Brass Rod, Bar and Wire

This standard is issued under the fixed designation B974/B974M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E92 Test Method for Vickers Hardness of Metallic Materi-

als

1.1 This specification establishes the requirements for free-

E478 TestMethodsforChemicalAnalysisofCopperAlloys

cutting bismuth brass rod, bar and wire of UNS Alloy No.

2.2 Other Standards:

C49250 and C49260 suitable for high-speed screw machine

JIS H 1068:2005 Method for Determination of Bismuth in

work, or for general applications.

Copper and Copper Alloys

1.2 Typically,productmadetothisspecificationisfurnished

ISO 5959-1984 Copper and copper alloys – determination

as straight lengths, or coils when requested.

of bismuth content – Diethyldithiocarbamate spectromet-

1.3 Units—The values stated in either SI units or inch-

ric method

pound units are to be regarded separately as standard. The

values stated in each system may not be exact equivalents;

3. General Requirements

therefore,eachsystemshallbeusedindependentlyoftheother.

3.1 The following sections of Specification B249/B249M

Combining values from the two systems may result in non-

constitute a part of this specification:

conformance with the standard.

3.1.1 Terminology,

1.4 This standard does not purport to address all of the

3.1.2 Materials and Manufacture,

safety concerns, if any, associated with its use. It is the

3.1.3 Sampling,

responsibility of the user of this standard to establish appro-

3.1.4 Number of Tests and Retests,

priate safety and health practices and determine the applica-

3.1.5 Specimen Preparation,

bility of regulatory limitations prior to use.

3.1.6 Test Methods,

2. Referenced Documents 3.1.7 Inspection,

3.1.8 Certification,

2.1 ASTM Standards:

3.1.9 Test Reports.

B249/B249M Specification for General Requirements for

3.2 In addition, when a section with a title identical to that

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

referenced in 3.1 appears in this specification, it contains

Forgings

additional requirements which supplement those appearing in

B250/B250M Specification for General Requirements for

Specification B249/B249M.

Wrought Copper Alloy Wire

B846 Terminology for Copper and Copper Alloys

4. Terminology

E8 Test Methods for Tension Testing of Metallic Materials

4.1 For definitions of terms related to copper and copper

E8M Test Methods for Tension Testing of Metallic Materi-

3 alloys, refer to Terminology B846.

als [Metric]

E53 Test Method for Determination of Copper in Unalloyed

5. Ordering Information

Copper by Gravimetry

5.1 Include the following information in orders for prod-

E54 Test Methods for ChemicalAnalysis of Special Brasses

3 ucts:

and Bronzes

5.1.1 ASTM designation and year of issue,

5.1.2 Copper UNS No. designation,

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

5.1.3 Howfurnished(rodorbarinstraightlength,orwirein

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

coils)

Bar, Wire, Shapes and Forgings.

5.1.4 Temper,

Current edition approved Oct. 1, 2010. Published November 2010.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Japanese Industrial Standards through http://www.JIS.or.jp, or

the ASTM website. www.webstore.jsa.or.jp/webstore/JIS/Flowcontrol.JSP.

3 5

Withdrawn. The last approved version of this historical standard is referenced Available from International Organization of Standards, http://www.ISO/ISO/

on www.astm.org. store.htm.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B974/B974M – 10

5.1.5 Cross section (round, hexagonal, square, rectangular), 7.2 These composition limits do not preclude the presence

5.1.6 Dimensions; diameter or distance between parallel of other elements. Limits may be established and analysis

surfaces, width and thickness, required for unnamed elements by agreement between the

5.1.7 How furnished: straight lengths or coils, manufacturer and the purchaser.

5.1.8 Quantity: total weight or total length, or number of 7.3 For alloys in which zinc is listed as “remainder”, zinc is

pieces of each size, the difference between the sum of results of all elements

5.1.9 If the product is purchased for agencies of the U.S. determined and 100%. When all elements in Table 1 are

Government (see the Supplemental Requirements section of determined, the sum of the results shall be 99.5% min.

Specifications B249/B249M or B250/B250M for additional

8. Temper

requirements, if specified).

8.1 The standard tempers for products described in this

5.2 The following options are available and should be

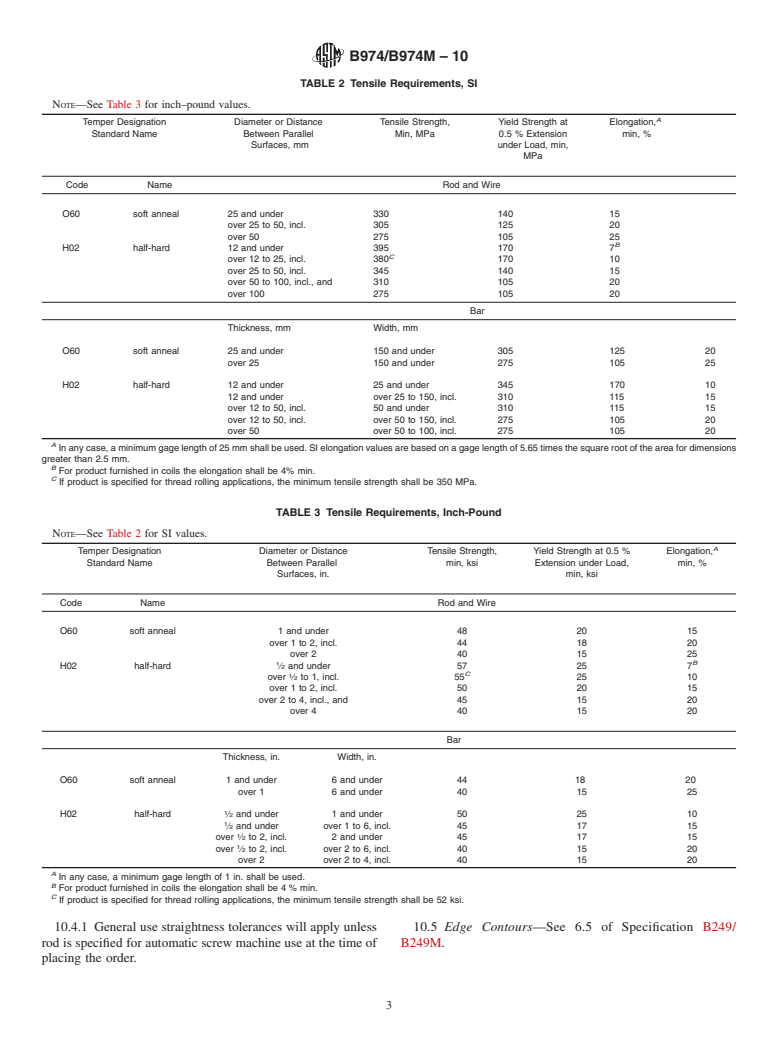

specification are given in Table 2.

specified at the time of placing the order when required:

8.1.1 Rod (round, hexagonal, and octagonal), and bar shall

5.2.1 Heat identification or traceability details.

be furnished for general use in O60 temper for maximum

5.2.2 Certification.

formability, and H02 (half-hard) for applications involving

5.2.3 Mill Test Report.

5.2.4 Automatic screw machine straightness (see 10.4). moderate cold forming.

5.2.5 Yield strength test required (see 14.2).

9. Mechanical Property Requirements

5.2.6 Resistivity test required (see 10.1).

9.1 The product shall conform to the tensile strength and

5.2.7 Marking of specification number (see 21.2).

elongation requirements of Tables 2 and 3 when tested in

accordance with Test Methods E8 and E8M.

6. Materials and Manufacture

9.2 When specified in the contract or purchase order, the

6.1 Materials:

yield strength shall be determined and conform with the yield

6.1.1 ThematerialofmanufactureshallbeaformofCopper

strength requirements of Table 2 when tested in accordance

Alloy UNS Nos. C49250 or C49260 of such purity and

with Test Methods E8 and E8M.

soundness as to be suitable for processing into the products

prescribed herein.

10. Dimensions, Mass, and Permissible Variations

6.1.2 In the event heat identification or traceability is

10.1 The dimensions and tolerances for rod and material

required, the purchaser shall specify the details desired.

described by this specification shall be as specified in Specifi-

NOTE 1—Due to the discontinuous nature of the processing of castings

cations B249/B249M or B250/B250M with particular refer-

into wrought products, it is not always practical to identify a specific

ence to the following tables and related paragraphs in those

casting analysis with a specific quantity of finished material.

specifications.

6.2 Manufacture:

10.2 Diameter or Distance Between Parallel Surfaces:

6.2.1 The product shall be manufactured by such hot work-

10.2.1 Rod (Round, Hexagonal, and Octagonal)—See 6.2

ing, cold working, and annealing processes as to produce a

and Table 1 of Specification B249/B249M.

uniform wrought structure in the finished product.

10.2.2 Bar(RectangularandSquare)—See6.2andTables7

6.2.2 Theproductshallbehotorcoldworkedtothefinished

and 10 of Specification B249/B249M.

size, and subsequently annealed when required, to meet the

10.2.3 Wire—See 6.2 and Table 1 of Specification B250/

temper properties specified.

B250M.

10.3 Lengths—O60 (soft anneal) and H02 (half hard) tem-

7. Chemical Composition

per rod and bar, See 6.3 and Tables 13 and 14 of Specification

7.1 The material shall conform to the chemical composition B249/B249M.

requirements in Table 1 for the UNS Number specified in the 10.4 Straightness—See 6.4 and Table 16 of Specification

ordering information. B249/B249M.

TABLE 1 Chemical Requirements

Element Composition, %

Copper or Copper Alloy UNS No.

C49250 C49260

Copper (incl silver) 58.0 - 61.0% 58.0 – 63.0%

Zinc Remainder Remainder

Bismuth 1.8 – 2.4% 0.50 – 1.8%

Lead 0.09% max 0.09% max

Iron 0.50% max 0.50% max

Tin 0.30% max 0.50% max

Cadmium 0.001% max 0.001% max

Phosphorus -- 0.05 – 0.15%

Silicon -- 0.10% max

Cu + sum of named elements, 99.5% min. 99.5% min

B974/B974M – 10

TABLE 2 Tensile Requirements, SI

NOTE—See Table 3 for inch–pound values.

A

Temper Designation Diameter or Distance Tensile Strength, Yield Strength at Elongation,

Standard Name Between Parallel Min, MPa 0.5 % Extension min, %

Surfaces, mm under Load, min,

MPa

Code Name Rod and Wire

O60 soft anneal 25 and under 330 140 15

over 25 to 50, incl. 305 125 20

over 50 275 105 25

B

H02 half-hard 12 and under 395 170 7

C

over 12 to 25, incl. 380 170 10

over 25 to 50, incl. 345 140 15

over 50 to 100, incl., and 310 105 20

over 100 275 105 20

Bar

Thickness, mm Width, mm

O60 soft anneal 25 and under 150 and under 305 125 20

over 25 150 and under 275 105 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.