ASTM F2986-12

(Specification)Standard Specification for Corrugated Polyethylene Pipe and Fittings for Mine Leachate Applications

Standard Specification for Corrugated Polyethylene Pipe and Fittings for Mine Leachate Applications

SCOPE

1.1 This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, testing, and marking of corrugated polyethylene (PE) pipe and fittings for mine drainage and leachate collection and transmission pipe. It covers nominal sizes 3 in. (75 mm), 4 in. (100 mm), 6 in. (150 mm), 8 in. (200 mm), 10 in. (250 mm) 12 in. (300 mm), 15 in. (375 mm), 18 in. (450 mm) and 24 in. (600 mm) diameter.

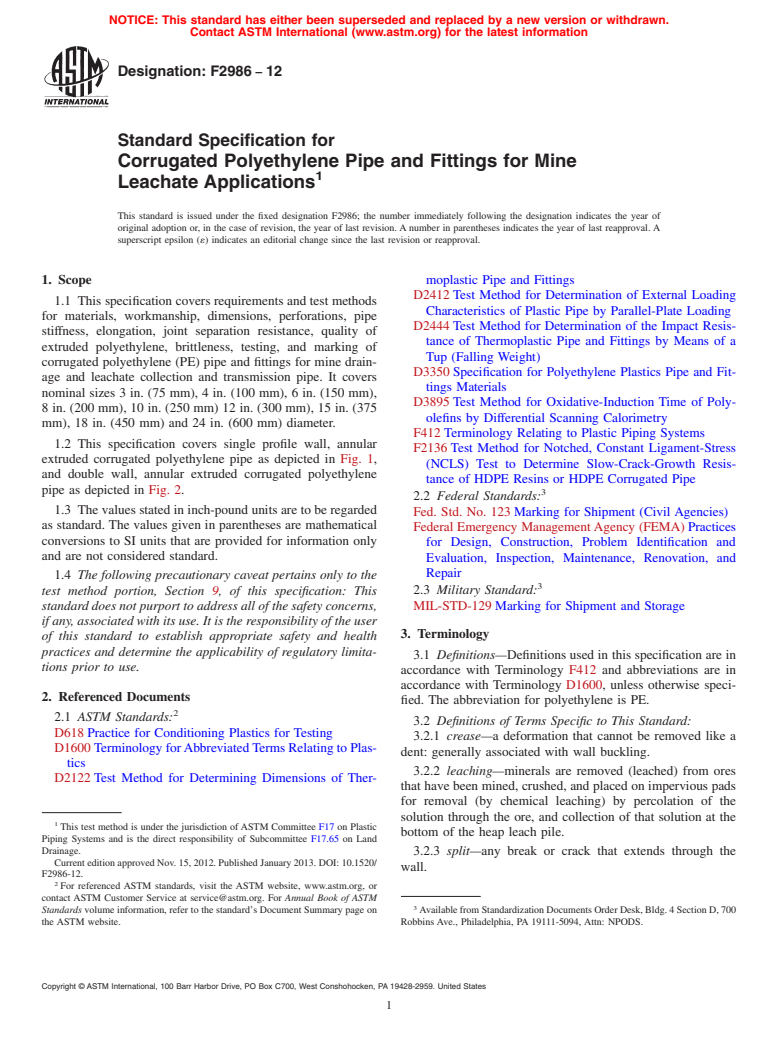

1.2 This specification covers single profile wall, annular extruded corrugated polyethylene pipe as depicted in Fig. 1, and double wall, annular extruded corrugated polyethylene pipe as depicted in Fig. 2.FIG. 1 Typical Single Wall Profile Cross-SectionFIG. 2 Typical Double Wall Profile Cross-Section

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2986 −12

Standard Specification for

Corrugated Polyethylene Pipe and Fittings for Mine

Leachate Applications

This standard is issued under the fixed designation F2986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope moplastic Pipe and Fittings

D2412 Test Method for Determination of External Loading

1.1 This specification covers requirements and test methods

Characteristics of Plastic Pipe by Parallel-Plate Loading

for materials, workmanship, dimensions, perforations, pipe

D2444 Test Method for Determination of the Impact Resis-

stiffness, elongation, joint separation resistance, quality of

tance of Thermoplastic Pipe and Fittings by Means of a

extruded polyethylene, brittleness, testing, and marking of

Tup (Falling Weight)

corrugated polyethylene (PE) pipe and fittings for mine drain-

D3350 Specification for Polyethylene Plastics Pipe and Fit-

age and leachate collection and transmission pipe. It covers

tings Materials

nominal sizes 3 in. (75 mm), 4 in. (100 mm), 6 in. (150 mm),

D3895 Test Method for Oxidative-Induction Time of Poly-

8 in. (200 mm), 10 in. (250 mm) 12 in. (300 mm), 15 in. (375

olefins by Differential Scanning Calorimetry

mm), 18 in. (450 mm) and 24 in. (600 mm) diameter.

F412 Terminology Relating to Plastic Piping Systems

1.2 This specification covers single profile wall, annular

F2136 Test Method for Notched, Constant Ligament-Stress

extruded corrugated polyethylene pipe as depicted in Fig. 1,

(NCLS) Test to Determine Slow-Crack-Growth Resis-

and double wall, annular extruded corrugated polyethylene

tance of HDPE Resins or HDPE Corrugated Pipe

pipe as depicted in Fig. 2.

2.2 Federal Standards:

1.3 The values stated in inch-pound units are to be regarded

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

as standard. The values given in parentheses are mathematical

Federal Emergency ManagementAgency (FEMA) Practices

conversions to SI units that are provided for information only

for Design, Construction, Problem Identification and

and are not considered standard.

Evaluation, Inspection, Maintenance, Renovation, and

Repair

1.4 The following precautionary caveat pertains only to the

test method portion, Section 9, of this specification: This 2.3 Military Standard:

standard does not purport to address all of the safety concerns, MIL-STD-129 Marking for Shipment and Storage

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3.1 Definitions—Definitions used in this specification are in

tions prior to use.

accordance with Terminology F412 and abbreviations are in

accordance with Terminology D1600, unless otherwise speci-

2. Referenced Documents

fied. The abbreviation for polyethylene is PE.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D618 Practice for Conditioning Plastics for Testing

3.2.1 crease—a deformation that cannot be removed like a

D1600 Terminology forAbbreviatedTerms Relating to Plas-

dent: generally associated with wall buckling.

tics

3.2.2 leaching—minerals are removed (leached) from ores

D2122 Test Method for Determining Dimensions of Ther-

that have been mined, crushed, and placed on impervious pads

for removal (by chemical leaching) by percolation of the

solution through the ore, and collection of that solution at the

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

bottom of the heap leach pile.

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

Drainage.

3.2.3 split—any break or crack that extends through the

Current edition approved Nov. 15, 2012. Published January 2013. DOI: 10.1520/

wall.

F2986-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2986−12

FIG. 1Typical Single Wall Profile Cross-Section

FIG. 2Typical Double Wall Profile Cross-Section

4. Ordering Information the procedure described in 9.12. Samples shall be taken from

the extruded pipe supplied to the project. The average failure

4.1 Orders for product made to this specification shall

time of the five test specimens shall exceed 24 h with no single

include the following information to adequately describe the

test specimen’s failure time less than 17 h. Samples taken from

desired product:

the extruded pipe supplied to the project shall have a minimum

4.1.1 This ASTM designation and year of issue,

Oxidative-Induction-Time of 20 minutes when tested in accor-

4.1.2 Perforations:

dance with Test Method D3895.

4.1.2.1 With perforations,

4.1.2.2 Without perforations,

6.2 Rework Material—Clean rework material, generated

4.1.3 Diameters,

from the manufacturer’s own production of this product, may

4.1.4 Total footage of each pipe diameter involved,

be used by the manufacturer provided that the tubing and

4.1.5 Pipe laying length,

fittings produced meet all requirements of this specification.

4.1.6 Fitting type(s):

4.1.6.1 Size and type of fittings, including mainline and

7. General Requirements

branch diameters, and

7.1 Workmanship—The pipe and fittings shall be homoge-

4.1.6.2 Number of fittings per diameter.

neous throughout and be as uniform as commercially practical

in color, opacity, and density. The pipe walls shall be free of

5. Significance and Use

cracks, holes, blisters, voids, foreign inclusions, or other

5.1 Corrugated PE pipe and fittings in this standard are

defects that are visible to the naked eye and that may affect the

intendedfordeepundergroundapplicationsunderharshchemi-

wallintegrity.Theendsshallbecutcleanlyandsquarely.Holes

cal exposure from a corrosive effluent where they serve as

intentionally placed in perforated pipe are acceptable.

leachate pipe under a mine heap or dump leaching process.

7.1.1 Visible defects, cracks, creases, splits, obstruction to

Their major use is to collect or convey ore leachate to a facility

flow in perforations or in pipe, are not permissible.

for processing and extraction of the desired metal or mineral.

7.2 Dimensions and Tolerance:

Heap leaching is used to extract copper, gold, lead, nickel,

silver, uranium, or zinc. The solution may be either acidic or 7.2.1 Nominal Size—The nominal size for the pipe and

alkaline, depending on the metal being extracted. fittings for single profile wall and double profile wall shall be

the minimum inside diameter as shown in Table 1 and Table 2,

6. Materials

respectively, rounded to the closest whole number.

6.1 Pipe and Fittings—The pipe and fittings shall be made 7.2.2 Inside Diameter—The actual inside diameter for

of virgin PE plastic compound meeting the requirements of single profile wall and double profile wall shall be the

Specification D3350 cell classification 435400C or 435400E, minimum inside diameter with a +4.5 % or – 0 % tolerance

except that carbon black content shall be equal to or greater when measured in accordance with 9.3 and as shown in Table

than 2.0 % but not exceed 3.0 %. Compounds that have a 1 and Table 2, respectively.

highercellclassificationinoneormoreperformanceproperties

NOTE 1—The outside diameters and the corrugation pitch of products

shallbepermittedifallotherproductrequirementsaremet.For

manufactured to this specification are not specified; therefore, compatibil-

slow crack-growth resistance, resins shall be evaluated using

ity between pipe and fittings from different manufacturers or the same

the notched constant ligament stress (NCLS) test according to manufacturer shall be verified.

F2986−12

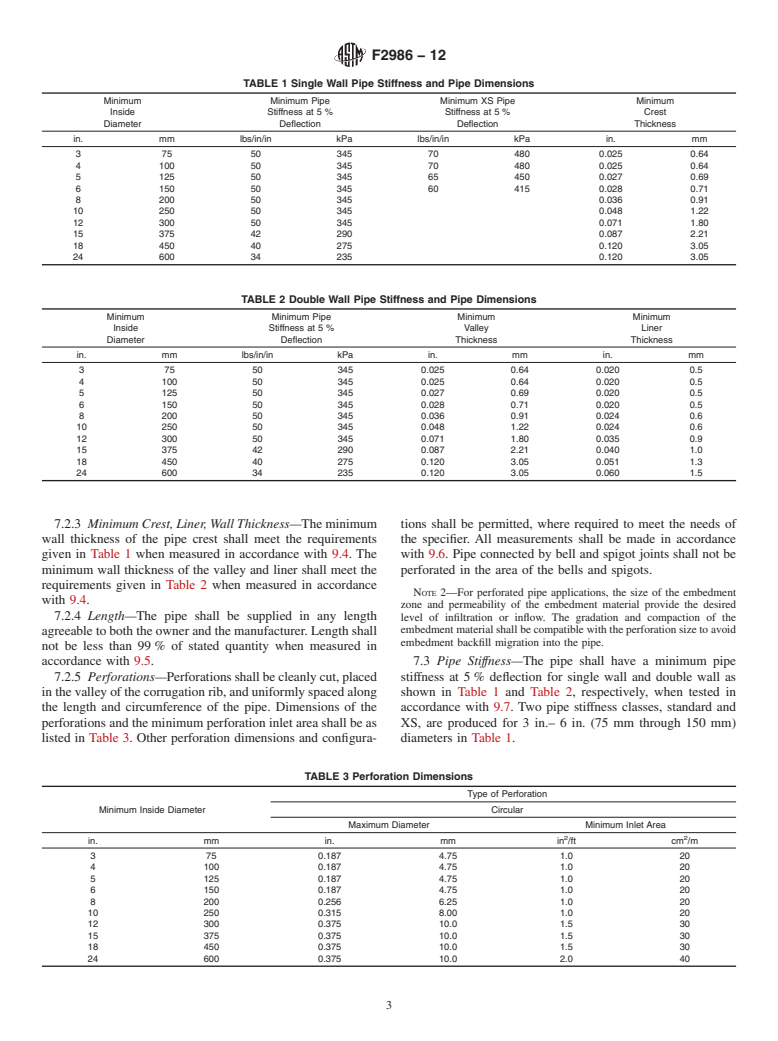

TABLE 1 Single Wall Pipe Stiffness and Pipe Dimensions

Minimum Minimum Pipe Minimum XS Pipe Minimum

Inside Stiffness at 5 % Stiffness at 5 % Crest

Diameter Deflection Deflection Thickness

in. mm lbs/in/in kPa lbs/in/in kPa in. mm

3 75 50 345 70 480 0.025 0.64

4 100 50 345 70 480 0.025 0.64

5 125 50 345 65 450 0.027 0.69

6 150 50 345 60 415 0.028 0.71

8 200 50 345 0.036 0.91

10 250 50 345 0.048 1.22

12 300 50 345 0.071 1.80

15 375 42 290 0.087 2.21

18 450 40 275 0.120 3.05

24 600 34 235 0.120 3.05

TABLE 2 Double Wall Pipe Stiffness and Pipe Dimensions

Minimum Minimum Pipe Minimum Minimum

Inside Stiffness at 5 % Valley Liner

Diameter Deflection Thickness Thickness

in. mm lbs/in/in kPa in. mm in. mm

3 75 50 345 0.025 0.64 0.020 0.5

4 100 50 345 0.025 0.64 0.020 0.5

5 125 50 345 0.027 0.69 0.020 0.5

6 150 50 345 0.028 0.71 0.020 0.5

8 200 50 345 0.036 0.91 0.024 0.6

10 250 50 345 0.048 1.22 0.024 0.6

12 300 50 345 0.071 1.80 0.035 0.9

15 375 42 290 0.087 2.21 0.040 1.0

18 450 40 275 0.120 3.05 0.051 1.3

24 600 34 235 0.120 3.05 0.060 1.5

7.2.3 Minimum Crest, Liner, Wall Thickness—Theminimum tions shall be permitted, where required to meet the needs of

wall thickness of the pipe crest shall meet the requirements the specifier. All measurements shall be made in accordance

given in Table 1 when measured in accordance with 9.4. The with 9.6. Pipe connected by bell and spigot joints shall not be

minimum wall thickness of the valley and liner shall meet the perforated in the area of the bells and spigots.

requirements given in Table 2 when measured in accordance

NOTE 2—For perforated pipe applications, the size of the embedment

with 9.4.

zone and permeability of the embedment material provide the desired

7.2.4 Length—The pipe shall be supplied in any length

level of infiltration or inflow. The gradation and compaction of the

embedment material shall be compatible with the perforation size to avoid

agreeable to both the owner and the manufacturer. Length shall

embedment backfill migration into the pipe.

not be less than 99 % of stated quantity when measured in

accordance with 9.5. 7.3 Pipe Stiffness—The pipe shall have a minimum pipe

7.2.5 Perforations—Perforationsshallbecleanlycut,placed stiffness at 5 % deflection for single wall and double wall as

inthevalleyofthecorrugationrib,anduniformlyspacedalong shown in Table 1 and Table 2, respectively, when tested in

the length and circumference of the pipe. Dimensions of the accordance with 9.7. Two pipe stiffness classes, standard and

perforations and the minimum perforation inlet area shall be as XS, are produced for 3 in.– 6 in. (75 mm through 150 mm)

listed in Table 3. Other perforation dimensions and configura- diameters in Table 1.

TABLE 3 Perforation Dimensions

Type of Perforation

Minimum Inside Diameter Circular

Maximum Diameter Minimum Inlet Area

2 2

in. mm in. mm in /ft cm /m

3 75 0.187 4.75 1.0 20

4 100 0.187 4.75 1.0 20

5 125 0.187 4.75 1.0 20

6 150 0.187 4.75 1.0 20

8 200 0.256 6.25 1.0 20

10 250 0.315 8.00 1.0 20

12 300 0.375 10.0 1.5 30

15 375 0.375 10.0 1.5 30

18 450 0.375 10.0 1.5 30

24 600 0.375 10.0 2.0 40

F2986−12

7.4 Elongation—For single wall pipe only; continuously 9.4 Minimum Crest and Liner Wall Thickness—Measure the

extrudedpipethatelongatesmorethan5 %,butlessthan10 %, thickness of the crest, valley and liner (when applicable) wall

when tested in accordance with 9.8, shall meet the require- thickness in accordance with Test Method D2122. Each speci-

ments of 7.3 when tested in accordance with 9.9. Pipe that men shall be cut perpendicular to the seam line of the pipe

elongates more than 10 % shall be rejected. directly through a corrugation allowing a plain view of the

inner wall 360 degrees around the circumference in order to

7.5 Brittleness—Pipeandfittingspecimensshallbetestedin

obtain a minimum of eight measurements in accordance with

accordance with 9.11.

Test Method D2122 As an alternative to Test Method D2122

7.6 Bond—The bond between layers of spirally laminated

minimum liner thickness is allowed to be determined with the

pipe shall be strong and uniform. There shall be no separation

use of a calibrated ultrasonic thickness gauge.

of layers when the pipe is deflected 20 %, in accordance with

NOTE 6—Test Method D2122 also permits the use of alternate mea-

Test Method D2412, nor shall it be possible to separate the

surement methods such as ultrasonic gauges.

layerswiththepointofaknifewhenthepipeisinthedeflected

9.5 Length—Measurepipewithanysuitabledeviceaccurate

condition.

to 6 ⁄32 in. in 10 ft (1 mm in 3 m). Make all measurements on

NOTE 3—This test may be conducted as a continuation of pipe stiffness

the pipe while it is resting on a relatively flat surface, in a

testing as specified in 9.7.

straight line, with no external tensile or compressive forces

7.7 Fitting Requirements:

exerted on the pipe.

7.7.1 The fittings shall not reduce or impair the overall

integrity or function of the pipe line.

9.6 Perforations—Measure dimensions of perforations on a

straight specimen without external forces applied. Linear

NOTE 4—Common corrugated fittings include in-line joint fittings, such

measurements shall be made with an instrument with calibra-

as tees, Y’s, reducers, couplers, elbows, and end caps. These fittings are

installed internally or externally by various methods, such as snap-on, tion increments of 0.01 in. (0.25 mm).

V-insertion, screw-on, or wrap around.

9.7 Pipe Stiffness—Select a minimum of three pipe speci-

NOTE 5—Some corrugated fittings will not fit all pipe. Only fittings

supplied or recommended by the pipe manufacturer should be used.

mens and test for pipe stiffness F/∆y, as described in Test

Method D2412, except for the following conditions: (1) The

7.7.2 Joints made with couplers, installed in accordance

test specimens shall be at least as long as the outside diameter;

with the manufacturer’s instructions, shall not separate when

the exact length shall be an integer multiple of corrugation

tested in accordance with 9.10.

pitch. (2) Locate the first specimen of all annular (tubularly)

7.7.3 Fitting specimens shall not crack or split when tested

extruded pipe in the loading machine with the imaginary line

in accordance with 9.11.

between the two corrugation seams (end view) parallel to the

8. Sampling and Retest

loading plates. The specimen must lay flat on the plate within

⁄8 in. (3 mm) and may be straightened by hand bending at

8.1 Sampling—Samples of pipe and fittings sufficient to

roomtemperature.Usethefi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.