ASTM D3300-00(2006)

(Test Method)Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of Petroleum Origin Under Impulse Conditions

Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of Petroleum Origin Under Impulse Conditions

SIGNIFICANCE AND USE

This test method is most commonly performed using a negative polarity point opposing a grounded sphere (NPS). The NPS breakdown voltage of fresh unused oils measured in the highly divergent field in this configuration depends on oil composition, decreasing with increasing concentration of aromatic, particularly polyaromatic, hydrocarbon molecules.

This test method may be used to evaluate the continuity of composition of an oil from shipment to shipment. The NPS impulse breakdown voltage of an oil can also be substantially lowered by contact with materials of construction, by service aging, and by other impurities. Test results lower than those expected for a given fresh oil may also indicate use or contamination of that oil.

Although polarity of the voltage wave has little or no effect on the breakdown strength of an oil in uniform fields, polarity does have a marked effect on the breakdown voltage of an oil in nonuniform electric fields.

Transient voltages may also vary over a wide range in both the time to reach crest value and the time to decay to half crest or to zero magnitude. The IEEE standard lightning impulse test (see 2.2) specifies a 1.2 by 50-μs negative polarity wave.

SCOPE

1.1 This test method covers the determination of the dielectric breakdown voltage of insulating oils in a highly divergent field under impulse conditions.

1.2 The values stated in inch-pound units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3300–00 (Reapproved 2006)

Standard Test Method for

Dielectric Breakdown Voltage of Insulating Oils of

Petroleum Origin Under Impulse Conditions

This standard is issued under the fixed designation D3300; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope aging, and by other impurities. Test results lower than those

expected for a given fresh oil may also indicate use or

1.1 This test method covers the determination of the dielec-

contamination of that oil.

tric breakdown voltage of insulating oils in a highly divergent

3.3 Although polarity of the voltage wave has little or no

field under impulse conditions.

effect on the breakdown strength of an oil in uniform fields,

1.2 The values stated in inch-pound units are to be regarded

polaritydoeshaveamarkedeffectonthebreakdownvoltageof

as the standard.

an oil in nonuniform electric fields.

1.3 This standard does not purport to address all of the

3.4 Transient voltages may also vary over a wide range in

safety concerns, if any, associated with its use. It is the

both the time to reach crest value and the time to decay to half

responsibility of the user of this standard to establish appro-

crest or to zero magnitude. The IEEE standard lightning

priate safety and health practices and determine the applica-

impulse test (see 2.2) specifies a 1.2 by 50-µs negative polarity

bility of regulatory limitations prior to use.

wave.

2. Referenced Documents

4. Apparatus

2.1 ASTM Standards:

4.1 Impulse Generator, capable of producing a standard 1.2

D923 Practices for Sampling Electrical Insulating Liquids

by 50-µs full wave adjustable to positive or negative polarity.

D2864 Terminology Relating to Electrical Insulating Liq-

The generator shall have a nominal voltage rating of at least

uids and Gases

300 kV adjustable in 10-kV steps. Generators having a

2.2 IEEE Documents:

capability of 1000 W·s (1000 J) at 300 kV have been found

IEEE Standard 4-1995 Techniques for High-Voltage Test-

satisfactory.

ing

4.2 Voltage-Control Equipment—The controls shall include

3. Significance and Use

a suitable measuring device for predetermining the crest

voltage to within 65 %.Avoltage stabilizer is desirable at the

3.1 This test method is most commonly performed using a

input to the d-c power supply used for charging the impulse-

negativepolaritypointopposingagroundedsphere(NPS).The

generator capacitors.

NPS breakdown voltage of fresh unused oils measured in the

4.3 Electrodes:

highly divergent field in this configuration depends on oil

4.3.1 Theelectrodesshallconsistofapolishedsteelorbrass

composition, decreasing with increasing concentration of aro-

sphere of 0.5 in. (12.7 mm) diameter and a steel point. The

matic, particularly polyaromatic, hydrocarbon molecules.

point may be an ordinary steel phonograph needle with a 0.06

3.2 This test method may be used to evaluate the continuity

mm 6 20 % radius of curvature of point or a No. 18 Filter

of composition of an oil from shipment to shipment. The NPS

Point needle. Needles with drawn tips are not recommended.

impulse breakdown voltage of an oil can also be substantially

4.3.2 The effect of variation in the radius of curvature of

lowered by contact with materials of construction, by service

point is subject to further investigation. Both electrodes shall

be easily replaceable.

This test method is under the jurisdiction of ASTM Committee D27 on 4.4 Test Cell:

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

4.4.1 The test cell shall be made of a material of high

mittee D27.05 on Electrical Test.

dielectric strength and of such dimensions that the electrical

Current edition approved Nov. 1, 2006. Published January 2007. Originally

breakdown is restricted to the electrode gap.Test cell materials

approved in 1974. Last previous edition approved in 2000 as D3300 – 00. DOI:

10.1520/D3300-00R06.

shall resist attack by, and be insoluble in, any of the cleaning

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. The following steel needle has been found satisfactory for this method: Dean

Available from the Institute of Electrical and Electronics Engineers, 445 Hoes No. 18 Filter Point Needle, available from John Dean, Inc., 20 Mechanic St.,

Lane, Piscataway, NJ 08855-1331. Putnam, CT 06260.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3300–00 (2006)

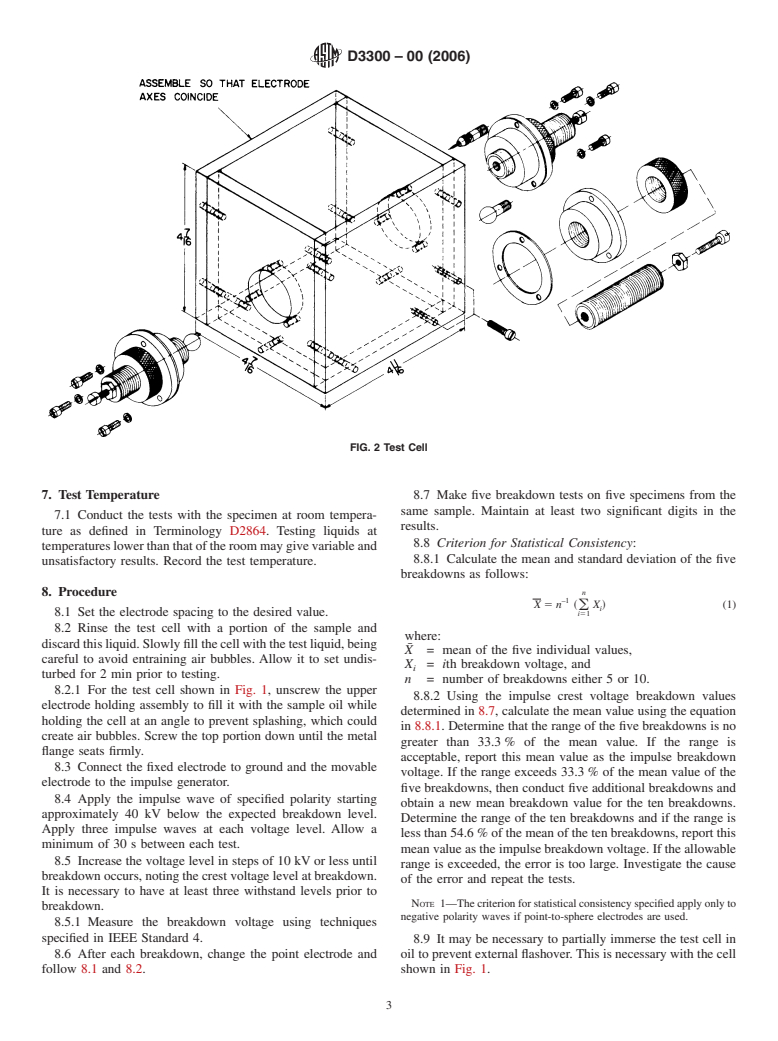

ortestliquidsused.TestcellssuchasthoseshowninFig.1and 6.1.3 The gap spacings shall be 1.0 in. (25.4 mm) for

Fig. 2 have been found satisfactory. point-to-sphere and 0.15 in. (3.8 mm) for sphere-to-sphere

4.4.2 The sphere electrode shall be rigidly fixed and the

electrode configuration.

point electrode mounted such that the gap may be adjusted

6.2 Cleaning—Degrease the cell and electrodes by rinsing

from zero to the required value.

them with reagent grade petroleum ether, washing with deter-

gent and hot water, rinsing thoroughly in hot tap water, and

5. Sampling

then rinsing them with distilled water. Dry the cell and

5.1 Obtain a sample of the liquid to be tested using

hardware in an oven for 2 h at approximately 105 to 110°C,

appropriate ASTM sampling apparatus in accordance with

remove, and store in a desiccator until needed.

Practices D923.

6.3 Daily Use—Use new or polished sphere electrodes at

6. Adjustments and Care of Electrodes and Test Cell

the beginning of each day’s testing. Discard the point electrode

and replace it after each breakdown; replace the sphere

6.1 Electrode Spacing:

electrodes after every five breakdowns when testing point-to-

6.1.1 For the cell shown in Fig. 1, reduce the electrode gap

sphere. More frequent replacement may be necessary when

to zero spacing. Proceed very carefully to avoid damaging the

testingsphere-to-sphere.Sphereelectrodesmaybecleanedand

point.Thepointofcontactshallbeestablishedelectricallywith

polished for reuse in point-to-sphere testing. However, the use

anohmmeter.Openthegaptothespecifi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.