ASTM A511-96

(Specification)Standard Specification for Seamless Stainless Steel Mechanical Tubing

Standard Specification for Seamless Stainless Steel Mechanical Tubing

SCOPE

1.1 This specification covers seamless stainless tubing for use in mechanical applications where corrosion-resistant or high-temperature strength is needed. The grades covered are listed in Tables 1 and 2.

1.2 This specification covers seamless cold-finished mechanical tubing and seamless hot-finished mechanical tubing in sizes up to 12 3/4 in. (313.8 mm) in outside diameter (for round tubing) with wall thicknesses as required.

1.3 Tubes shall be furnished in one of the following shapes, as specified by the purchaser: round, square, rectangular, or special.

1.4 Optional supplementary requirements are provided and when desired, shall be stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 511 – 96

Standard Specification for

Seamless Stainless Steel Mechanical Tubing

This standard is issued under the fixed designation A 511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Ordering Information

1.1 This specification covers seamless stainless tubing for 3.1 Orders for material under this specification should

use in mechanical applications where corrosion-resistant or include the following as required to describe the desired

high-temperature strength is needed. The grades covered are material adequately:

listed in Table 1 and Table 2. 3.1.1 Quantity (feet, mass, or number of pieces),

1.2 This specification covers seamless cold-finished me- 3.1.2 Name of material (seamless stainless steel mechanical

chanical tubing and seamless hot-finished mechanical tubing in tubing),

sizes up to 12 ⁄4 in. (313.8 mm) in outside diameter (for round 3.1.3 Form (round, square, rectangular, special, see Section

tubing) with wall thicknesses as required. 1),

1.3 Tubes shall be furnished in one of the following shapes, 3.1.4 Dimensions (round, outside diameter and wall thick-

as specified by the purchaser: round, square, rectangular, or ness, see Section 9; square and rectangular, outside dimensions

special. and wall thickness, see Section 10; other, specify),

1.4 Optional supplementary requirements are provided and 3.1.5 Length (specific or random, see 9.3),

when desired, shall be stated in the order. 3.1.6 Manufacture (cold- or hot-finished, see 4.5),

1.5 The values stated in inch-pound units are to be regarded 3.1.7 Grade (Section 6),

as the standard. 3.1.8 Condition (annealed, as cold worked, or with special

heat treatment, controlled microstructural characteristics, or

2. Referenced Documents

other condition as required, see Section 5),

2.1 ASTM Standards:

3.1.9 Surface finish (special pickling, shot blasting, or

A 370 Test Methods and Definitions for Mechanical Testing

polishing, as required, see Supplementary Requirement S5),

of Steel Products 3.1.10 Specification designation,

A 450/A450M Specification for General Requirements for

3.1.11 Report of Chemical Analysis, if required (Sections 7

Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes and 8),

E 59 Practice for Sampling Steel and Iron for Determination

3.1.12 Individual supplementary requirements, if required,

of Chemical Composition 3.1.13 End use,

2.2 Military Standards:

3.1.14 Packaging,

MIL-STD-129 Marking for Shipment and Storage 3.1.15 Special marking (see 15.2),

MIL-STD-163 Steel Mill Products Preparation for Ship-

3.1.16 Special packing (see 16.2), and

ment and Storage 3.1.17 Special requirements.

2.3 Federal Standard:

4. Materials and Manufacture

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

4.1 The steel may be made by any process.

4.2 If a specific type of melting is required by the purchaser,

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

it shall be as stated on the purchase order.

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

4.3 The primary melting may incorporate separate degas-

A01.10 on Tubing.

sing or refining and may be followed by secondary melting,

Current edition approved June 10, 1996. Published August 1996. Originally

published as A 511 – 64. Last previous edition A 511 – 90(95)e .

such as electroslag remelting or vacuum-arc remelting. If

Annual Book of ASTM Standards, Vol 01.03.

secondary melting is employed, the heat shall be defined as all

Annual Book of ASTM Standards, Vol 01.01.

of the ingots remelted from a single primary heat.

Annual Book of ASTM Standards, Vol 03.05.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 511–96

TABLE 1 Chemical Requirements of Austenitic Stainless Steels

Composition, %

Phos- Sul- Columbium

Grade

Manga- pho- fur, Silicon, plus

Carbon Nickel Chromium Molybdenum

Titanium Selenium

nese, max rus, max max Tantalum

max

MT 302 0.08 to 0.20 2.00 0.040 0.030 1.00 8.0–10.0 17.0–19.0 . . . .

MT 303Se 0.15 max 2.00 0.040 0.040 1.00 8.0–11.0 17.0–19.0 . . . 0.12–0.2

MT 304 0.08 max 2.00 0.040 0.030 1.00 8.0–11.0 18.0–20.0 . . . .

A

MT 304L 0.035 max 2.00 0.040 0.030 1.00 8.0–13.0 18.0–20.0 . . . .

MT 305 0.12 2.00 0.040 0.030 1.00 10.0–13.0 17.0–19.0 . . . .

MT 309S 0.08 max 2.00 0.040 0.030 1.00 12.0–15.0 22.0–24.0 . . . .

MT 310S 0.08 max 2.00 0.040 0.030 1.00 19.0–22.0 24.0–26.0 . . . .

MT 316 0.08 max 2.00 0.040 0.030 1.00 11.0–14.0 16.0–18.0 2.0–3.0 . . .

A

MT 316L 0.035 max 2.00 0.040 0.030 1.00 10.0–15.0 16.0–18.0 2.0–3.0 . . .

MT 317 0.08 max 2.00 0.040 0.030 1.00 11.0–14.0 18.0–20.0 3.0–4.0 . . .

B

MT 321 0.08 max 2.00 0.040 0.030 1.00 9.0–13.0 17.0–20.0 . . .

C

MT 347 0.08 max 2.00 0.040 0.030 1.00 9.0–13.0 17.0–20.0 . . .

A

For small diameter or thin wall tubing or both, where many drawing passes are required, a maximum of 0.040 % carbon is necessary in grades MT-304L and MT-316L.

Small outside diameter tubes are defined as those under a 0.500 in. outside diameter and light-wall tubes as those under an 0.049 in. average wall thickness (0.044 in.

min wall thickness).

B

The titanium content shall be not less than five times the carbon content and not more than 0.60 %.

C

The columbium plus tantalum content shall be not less than ten times the carbon content and not more than 1.00 %.

TABLE 2 Chemical Requirements of Ferritic and Martensitic Stainless Steels

Composition, %

Manga- Phos- Sulfur,

Grade

Silicon, Molyb-

Carbon, max nese, phorus, max Nickel Chromium Aluminum Copper Nitrogen

Selenium

max denum

max max

Martensitic

MT 403 0.15 1.00 0.040 0.030 0.50 0.50 max 11.5–13.0 0.60 max

MT 410 0.15 1.00 0.040 0.030 1.00 0.50 max 11.5–13.5 . . . . .

MT 414 0.15 1.00 0.040 0.030 1.00 1.25–2.50 11.5–13.5 . . . . .

MT 416Se 0.15 1.25 0.060 0.060 1.00 0.50 max 12.0–14.0 . . . . 0.12–0.20

MT 431 0.20 1.00 0.040 0.030 1.00 1.25–2.50 15.0–17.0 . . . . .

MT 440A 0.60 to 0.75 1.00 0.040 0.030 1.00 . 16.0–18.0 0.75 max . . . .

Ferritic

MT 405 0.08 1.00 0.040 0.030 1.00 0.50 max 11.5–14.5 . 0.10–0.30 . . .

MT 429 0.12 1.00 0.040 0.030 1.00 0.50 max 14.0–16.0 . . . . .

MT 430 0.12 1.00 0.040 0.030 1.00 0.50 max 16.0–18.0 . . . . .

MT 443 0.20 1.00 0.040 0.030 1.00 0.50 max 18.0–23.0 . . 0.90–1.25 . .

MT 446–1 0.20 1.50 0.040 0.030 1.00 0.50 max 23.0–30.0 . . . 0.25 max .

A

MT 446–2 0.12 1.50 0.040 0.030 1.00 0.50 max 23.0–30.0 . . . 0.25 max .

29-4 0.010 0.30 0.025 0.020 0.20 0.15 max 28.0–30.0 3.5–4.2 . 0.15 max 0.020 max .

B

29-4-2 0.010 0.30 0.025 0.020 0.20 2.0–2.5 28.0–30.0 3.5–4.2 . 0.15 max 0.020 max .

A

MT446-2 is a lower carbon version of MT446-1, that has a lower tensile strength but improved ductility and toughness.

B

Carbon plus nitrogen = 0.025 max %.

4.4 Steel may be cast in ingots or may be strand cast. When generally supplied annealed prior to final cold shaping. If some

steel of different grades is sequentially strand cast, identifica- other condition is desired, details shall be included in the order.

tion of the resultant transition material is required. The

5.2 The thermal treatment for ferritic and martensitic steels

producer shall remove the transition material by an established

shall be performed by a method and at a temperature selected

procedure that positively separates the grades.

by the manufacturer unless otherwise specified by the pur-

4.5 The tubes shall be made by a seamless process and by

chaser.

either cold working or hot working as specified. Seamless steel

5.3 Unless otherwise specified, all austenitic tubes shall be

tubing is a tubular product made without a welded seam. It is

furnished in the annealed condition. The anneal shall consist of

usually manufactured by hot working steel and then cold

heating the material to a minimum temperature of 1900°F

finishing the hot-worked tubing to produce the desired shape,

(1040°C) and quenching in water or rapidly cooling by other

dimensions, and properties.

means. Alternatively, immediately following hot forming while

the temperature of the tubes is not less than the specified

5. Condition

minimum solution treatment temperature, tubes may be indi-

5.1 Round seamless stainless mechanical tubing is generally vidually quenched in water or rapidly cooled by other means.

supplied in the cold-worked and annealed condition (see 5.2 This anneal shall precede final cold work, when cold-worked

through 5.4). Square, rectangular, or other shapes of tubing are tempers are required.

A 511–96

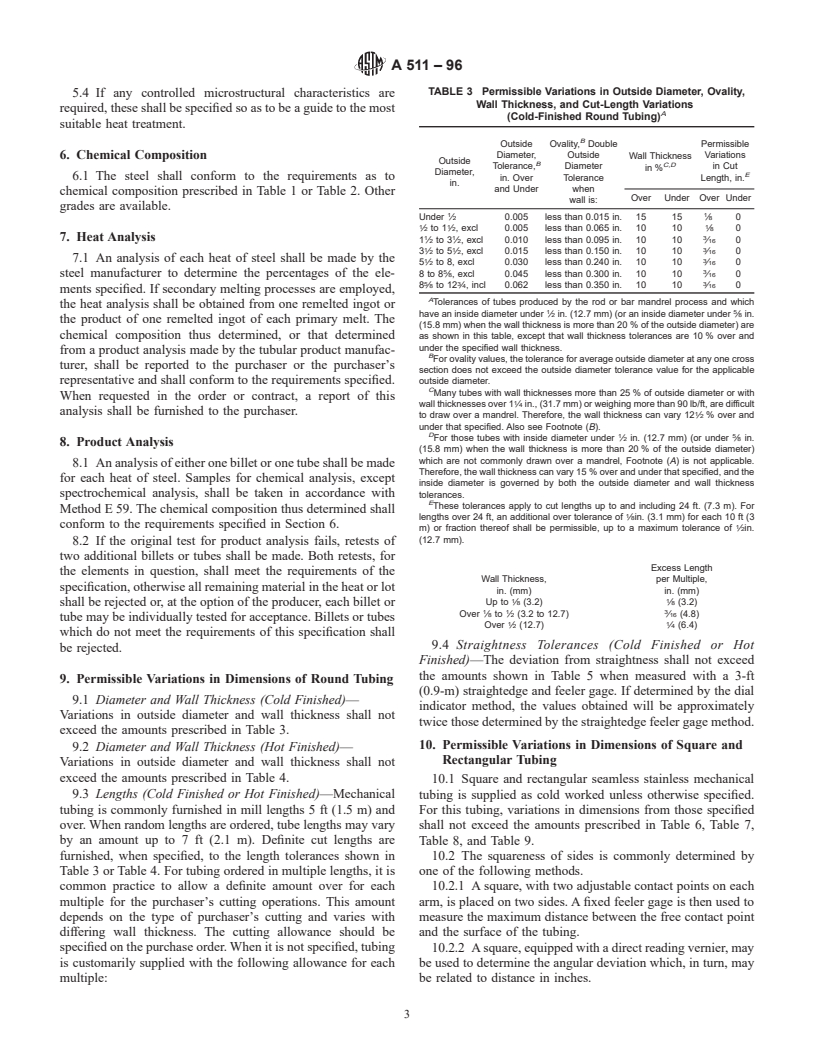

TABLE 3 Permissible Variations in Outside Diameter, Ovality,

5.4 If any controlled microstructural characteristics are

Wall Thickness, and Cut-Length Variations

required, these shall be specified so as to be a guide to the most

A

(Cold-Finished Round Tubing)

suitable heat treatment.

B

Outside Ovality, Double Permissible

Diameter, Outside Variations

6. Chemical Composition Wall Thickness

Outside

B

C,D

Tolerance, Diameter in Cut

in %

Diameter,

E

6.1 The steel shall conform to the requirements as to

in. Over Tolerance Length, in.

in.

and Under when

chemical composition prescribed in Table 1 or Table 2. Other

Over Under Over Under

wall is:

grades are available.

1 1

Under ⁄2 0.005 less than 0.015 in. 15 15 ⁄8 0

1 1 1

⁄2 to 1 ⁄2, excl 0.005 less than 0.065 in. 10 10 ⁄8 0

1 1 3

7. Heat Analysis 1 ⁄2 to 3 ⁄2, excl 0.010 less than 0.095 in. 10 10 ⁄16 0

1 1 3

3 ⁄2 to 5 ⁄2, excl 0.015 less than 0.150 in. 10 10 ⁄16 0

7.1 An analysis of each heat of steel shall be made by the

1 3

5 ⁄2 to 8, excl 0.030 less than 0.240 in. 10 10 ⁄16 0

5 3

steel manufacturer to determine the percentages of the ele- 8to8 ⁄8, excl 0.045 less than 0.300 in. 10 10 ⁄16 0

5 3 3

8 ⁄8 to 12 ⁄4, incl 0.062 less than 0.350 in. 10 10 ⁄16 0

ments specified. If secondary melting processes are employed,

A

Tolerances of tubes produced by the rod or bar mandrel process and which

the heat analysis shall be obtained from one remelted ingot or

1 5

have an inside diameter under ⁄2 in. (12.7 mm) (or an inside diameter under ⁄8 in.

the product of one remelted ingot of each primary melt. The

(15.8 mm) when the wall thickness is more than 20 % of the outside diameter) are

chemical composition thus determined, or that determined

as shown in this table, except that wall thickness tolerances are 10 % over and

under the specified wall thickness.

from a product analysis made by the tubular product manufac-

B

For ovality values, the tolerance for average outside diameter at any one cross

turer, shall be reported to the purchaser or the purchaser’s

section does not exceed the outside diameter tolerance value for the applicable

representative and shall conform to the requirements specified. outside diameter.

C

Many tubes with wall thicknesses more than 25 % of outside diameter or with

When requested in the order or contract, a report of this

wall thicknesses over 1 ⁄4 in., (31.7 mm) or weighing more than 90 lb/ft, are difficult

analysis shall be furnished to the purchaser. 1

to draw over a mandrel. Therefore, the wall thickness can vary 12 ⁄2 % over and

under that specified. Also see Footnote (B).

D

1 5

For those tubes with inside diameter under ⁄2 in. (12.7 mm) (or under ⁄8 in.

8. Product Analysis

(15.8 mm) when the wall thickness is more than 20 % of the outside diameter)

which are not commonly drawn over a mandrel, Footnote (A) is not applicable.

8.1 An analysis of either one billet or one tube shall be made

Therefore, the wall thickness can vary 15 % over and under that specified, and the

for each heat of steel. Samples for chemical analysis, except

inside diameter is governed by both the outside diameter and wall thickness

spectrochemical analysis, shall be taken in accordance with tolerances.

E

These tolerances apply to cut lengths up to and including 24 ft. (7.3 m). For

Method E 59. The chemical composition thus determined shall

lengths over 24 ft, an additional over tolerance of ⁄8in. (3.1 mm) for each 10 ft (3

conform to the requirements specified in Section 6. 1

m) or fraction thereof shall be permissible, up to a maximum tolerance of ⁄2in.

(12.7 mm).

8.2 If the original test for product analysis fails, retests of

two additional billets or tubes shall be made. Both retests, for

Excess Length

the elements in question, shall meet the requirements of the

Wall Thickness, per Multiple,

specification, otherwise all remaining material in the heat or lot

in. (mm) in. (mm)

1 1

Up to ⁄8 (3.2) ⁄8 (3.2)

shall be rejected or, at the option of the producer, each billet or

1 1 3

Over ⁄8 to ⁄2 (3.2 to 12.7) ⁄16 (4.8)

tube may be individually tested for acceptance. Billets or tubes

1 1

Over ⁄2 (12.7) ⁄4 (6.4)

which do not meet the requirements of this specification shall

9.4 Straightness Tolerances (Cold Finished or Hot

be rejected.

Finished)—The deviation from straightness shall not exceed

the amounts shown in Table 5 when measured with a 3-ft

9. Permissible Variations in Dimensions of Round Tubing

(0.9-m) straightedge and feeler gage. If determined by the dial

9.1 Diameter and Wall Thickness (Cold Finished)—

indicator method, the values obtained will be approximately

Variations in outside diameter and wall thickness shall not

twice those determined by the straightedge feeler gage method.

exceed the amounts prescribed in Table 3.

10. Permissible Variations in Dimensions of Square and

9.2 Diameter and Wall Thickness (Hot Finished)—

Rectangular Tubing

Variations in outside diameter and wall thickness shall not

exceed the amounts prescribed in Table 4.

10.1 Square and rectangular seamless stainless mechanical

9.3 Lengths (Cold Finished or Hot Finished)—Mechanical tubing is supplied as cold worked unless otherwise specified.

tubing is commonly furnished in mill lengths 5 ft (1.5 m) and For this tubing, variations in dimensions from those specified

over. When random lengths are ordered, tube lengths may vary shall not exceed the amounts prescribed in Table 6, Table 7,

by an amount up to 7 ft (2.1 m). Definite cut lengths are Table 8, and Table 9.

furnished, when specified, to the length tolerances shown in 10.2 The squareness of sides is commonly dete

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.