ASTM D7223-05

(Specification)Standard Specification for Aviation Certification Turbine Fuel

Standard Specification for Aviation Certification Turbine Fuel

SCOPE

1.1 This specification covers the use of purchasing agencies in formulating specifications for purchases of aviation turbine fuel under contract.

1.2 This specification defines one specific type of aviation turbine fuel for civil use in the certification of aircraft. The specification can be used as a standard in describing the quality of this aviation fuel from the refinery to the aircraft.

1.3 This specification does not include the fuels that are commonly used in aviation turbine engines. Those are listed in Specification D 1655.

1.4 The aviation turbine fuel defined by this specification may be used in other than turbine engines that are specifically designed and certified for this fuel.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D7223 – 05

Standard Specification for

Aviation Certification Turbine Fuel

This standard is issued under the fixed designation D7223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1298 Test Method for Density, Relative Density (Specific

Gravity), or API Gravity of Crude Petroleum and Liquid

1.1 This specification covers the use of purchasing agencies

Petroleum Products by Hydrometer Method

in formulating specifications for purchases of aviation turbine

D1319 Test Method for Hydrocarbon Types in Liquid

fuel under contract.

Petroleum Products by Fluorescent Indicator Adsorption

1.2 This specification defines one specific type of aviation

D1322 Test Method for Smoke Point of Kerosine and

turbine fuel for civil use in the certification of aircraft. The

Aviation Turbine Fuel

specificationcanbeusedasastandardindescribingthequality

D1655 Specification for Aviation Turbine Fuels

of this aviation fuel from the refinery to the aircraft.

D1840 TestMethodforNaphthaleneHydrocarbonsinAvia-

1.3 This specification does not include the fuels that are

tion Turbine Fuels by Ultraviolet Spectrophotometry

commonly used in aviation turbine engines. Those are listed in

D2386 Test Method for Freezing Point of Aviation Fuels

Specification D1655.

D2622 Test Method for Sulfur in Petroleum Products by

1.4 The aviation turbine fuel defined by this specification

Wavelength Dispersive X-ray Fluorescence Spectrometry

may be used in other than turbine engines that are specifically

D2624 TestMethodsforElectricalConductivityofAviation

designed and certified for this fuel.

and Distillate Fuels

1.5 The values stated in SI units are to be regarded as

D2887 Test Method for Boiling Range Distribution of

standard. No other units of measurement are included in this

Petroleum Fractions by Gas Chromatography

standard.

D3227 Test Method for (Thiol Mercaptan) Sulfur in Gaso-

2. Referenced Documents

line, Kerosine, Aviation Turbine, and Distillate Fuels

(Potentiometric Method)

2.1 ASTM Standards:

D3241 Test Method for Thermal Oxidation Stability of

D56 Test Method for Flash Point by Tag Closed Cup Tester

Aviation Turbine Fuels (JFTOT Procedure)

D86 Test Method for Distillation of Petroleum Products at

D3242 Test Method for Acidity in Aviation Turbine Fuel

Atmospheric Pressure

D3338 Test Method for Estimation of Net Heat of Combus-

D130 Test Method for Corrosiveness to Copper from Pe-

tion of Aviation Fuels

troleum Products by Copper Strip Test

D3828 Test Methods for Flash Point by Small Scale Closed

D381 Test Method for Gum Content in Fuels by Jet Evapo-

Cup Tester

ration

D4052 Test Method for Density, Relative Density, and API

D445 Test Method for Kinematic Viscosity of Transparent

Gravity of Liquids by Digital Density Meter

and Opaque Liquids (and Calculation of Dynamic Viscos-

D4057 Practice for Manual Sampling of Petroleum and

ity)

Petroleum Products

D1094 Test Method for Water Reaction of Aviation Fuels

D4171 Specification for Fuel System Icing Inhibitors

D1266 Test Method for Sulfur in Petroleum Products

D4294 Test Method for Sulfur in Petroleum and Petroleum

(Lamp Method)

Products by Energy Dispersive X-ray Fluorescence Spec-

trometry

D4306 Practice for Aviation Fuel Sample Containers for

This specification is under the jurisdiction of ASTM Committee D02 on

Tests Affected by Trace Contamination

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D4529 Test Method for Estimation of Net Heat of Combus-

D02.J0 on Aviation Fuels.

tion of Aviation Fuels

Current edition approved Nov. 1, 2005. Published January 2006. DOI: 10.1520/

D7223-05.

D4809 Test Method for Heat of Combustion of Liquid

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Hydrocarbon Fuels by Bomb Calorimeter (Precision

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Method)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. D4952 Test Method for Qualitative Analysis for Active

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7223 – 05

Sulfur Species in Fuels and Solvents (Doctor Test) 5.2.1.5 55 % minimum 2,4-dimethyl-6-tertiary-butyl phe-

D5001 Test Method for Measurement of Lubricity ofAvia- nol, plus 15 % minimum 2,6-ditertiary-butyl-4-methyl phenol,

tion Turbine Fuels by the Ball-on-Cylinder Lubricity remainder as monomethyl and dimethyl tertiary-butyl phenols.

Evaluator (BOCLE) 5.2.1.6 72 % minimum 2,4-dimethyl-6-tertiary-butyl phe-

D5006 Test Method for Measurement of Fuel System Icing nol, 28 % maximum monomethyl and dimethyl-tertiary-butyl

Inhibitors (Ether Type) in Aviation Fuels phenols.

D5191 Test Method for Vapor Pressure of Petroleum Prod- 5.2.2 Metal Deactivator Additive (MDA), in amount not to

ucts (Mini Method) exceed 2.0 mg/L (not including weight of solvent) on initial

D5453 Test Method for Determination of Total Sulfur in fuel manufacture at the refinery. Higher initial concentrations

Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel are permitted in circumstances where copper contamination is

Engine Fuel, and Engine Oil by Ultraviolet Fluorescence suspected to occur during distribution. Cumulative concentra-

D5972 Test Method for Freezing Point of Aviation Fuels tion of MDA when retreating the fuel shall not exceed

(Automatic Phase Transition Method) 5.7 mg/L:

D6469 Guide for Microbial Contamination in Fuels and 5.2.2.1 N,N-disalicylidene-1,2-propane diamine.

Fuel Systems 5.2.3 Electrical Conductivity Additive—Stadis 450 not to

E29 Practice for Using Significant Digits in Test Data to exceed 3 mg/L.

Determine Conformance with Specifications 5.2.3.1 When loss of fuel conductivity necessitates retreat-

ment with electrical conductivity additive, the following con-

3. General

centration limits apply:

At Manufacture:

3.1 Thisspecification,unlessotherwiseprovided,prescribes

Stadis 450 3 mg/L, max

the required properties of aviation certification turbine fuel at

Retreatment:

the time and place of delivery.

Stadis 450 cumulative total 5 mg/L, max

5.2.4 Leak Detection Additive—Tracer A (LDTA-A) may

4. Classification

be added to the fuel in amounts not to exceed 1 mg/kg.

4.1 Onetypeofaviationturbinefuelisprovided,asfollows:

5.2.5 Other additives are permitted. These include fuel

4.1.1 Jet C-1—A relatively wide boiling range volatile

system icing inhibitor and special purpose additives such as

distillate.

biocides.The quantities and types must be declared by the fuel

supplier and agreed to by the purchaser. Only additives

5. Materials and Manufacture

approved by the aircraft certifying authority are permitted in

5.1 Aviation turbine fuel, except as otherwise specified in

the fuel on which an aircraft is operated.

this specification, shall consist of blends of refined hydrocar-

5.2.5.1 Biocidaladditivesareavailableforcontrolledusage.

bons derived from conventional sources including crude oil,

Where such an additive is used in the fuel, the approval status

natural gas liquid condensates, heavy oil, shale oil, and oil

of the additive and associated conditions must be checked for

sands. The use of jet fuel blends, containing components from

the specific aircraft and engines to be operated.

other sources, is only permitted on a specific, individual basis

5.2.5.2 Fuel System Icing Inhibitor:

(see Annex A1 on fuels from non-conventional sources in

(1) Diethylene Glycol Monomethyl Ether (DIEGME), con-

Specification D1655).

forming to the requirements of Specification D4171, Type III,

5.1.1 Fuels used in engines and aircraft are ultimately

may be used in concentrations of 0.10 to 0.15 volume %.

approved by the certifying authority subsequent to formal

(2) Test Method D5006 may be used to determine the

submission of evidence to the authority as part of the type

concentration of DIEGME in aviation fuels.

certification program for that aircraft and engine model.

5.3 Guidance material is presented in Appendix X3 of

Additives to be used as supplements to an approved fuel must

Specification D1655 concerning the need to control processing

also be similarly approved on an individual basis (see Speci-

additives in jet fuel production.

fication D1655).

5.2 Additives—May be added to this aviation turbine fuel in

6. Detailed Requirements

the amount and of the composition specified in the following

3 6.1 The aviation turbine fuel shall conform to the require-

list of approved material:

ments prescribed in Table 1.

5.2.1 Antioxidants—In amounts not to exceed 24.0 mg/L

6.2 Test results shall not exceed the maximum or be less

active ingredients (not including weight of solvent):

than the minimum values specified in Table 1. No allowance

5.2.1.1 2,6-ditertiary-butyl phenol.

shall be made for the precision of the test methods. To

5.2.1.2 2,6-ditertiary-butyl-4-methyl phenol.

determine conformance to the specification requirement, a test

5.2.1.3 2,4-dimethyl-6-tertiary-butyl phenol.

resultmayberoundedtothesamenumberofsignificantfigures

5.2.1.4 75 % minimum 2,6-ditertiary-butyl phenol, plus

25 % maximum mixed tertiary and tritertiary-butyl phenols.

Stadis 450 is a registered trademark marketed by Innospec Inc., Innospec

Supporting data (Guidelines for Approval or Disapproval of Additives) have Manufacturing Park, Oil Sites Road, Ellesmere Port, Cheshire, CH65 4EY, UK.

been filed at ASTM International Headquarters and may be obtained by requesting Tracer A (LDTA-A) is a registered trademark of Tracer Research Corp., 3755

Research Report D02-1125. N. Business Center Dr., Tucson, AZ 85705.

D7223 – 05

A

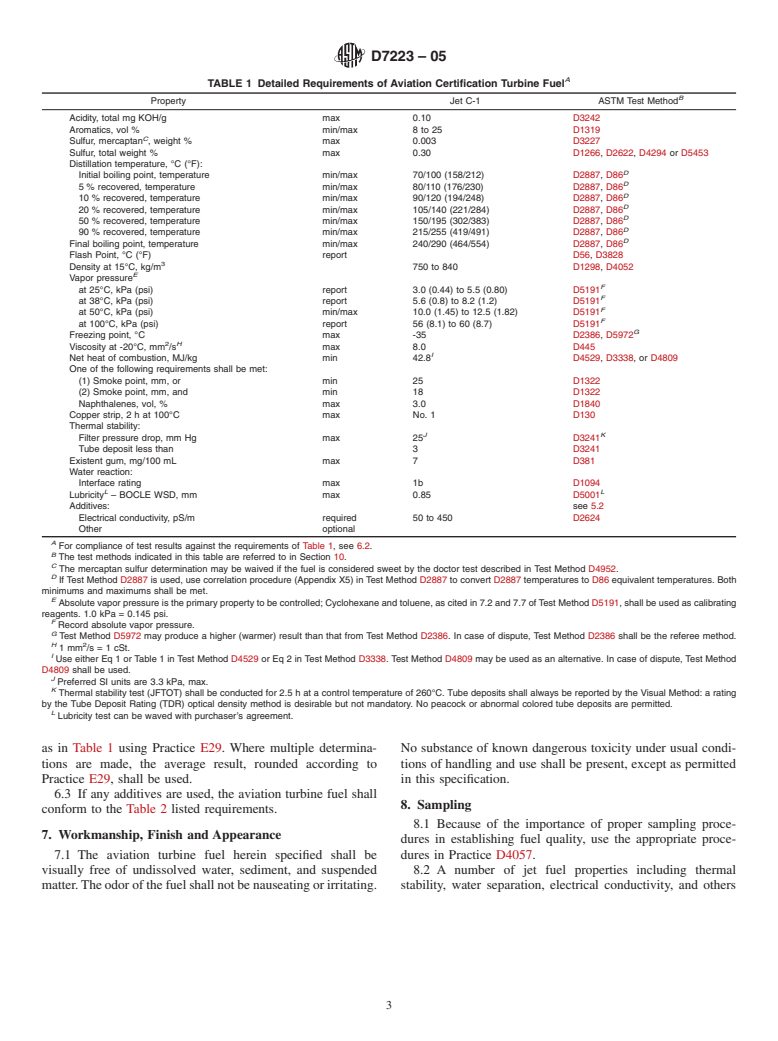

TABLE 1 Detailed Requirements of Aviation Certification Turbine Fuel

B

Property Jet C-1 ASTM Test Method

Acidity, total mg KOH/g max 0.10 D3242

Aromatics, vol % min/max 8 to 25 D1319

C

Sulfur, mercaptan , weight % max 0.003 D3227

Sulfur, total weight % max 0.30 D1266, D2622, D4294 or D5453

Distillation temperature, °C (°F):

D

Initial boiling point, temperature min/max 70/100 (158/212) D2887, D86

D

5 % recovered, temperature min/max 80/110 (176/230) D2887, D86

D

10 % recovered, temperature min/max 90/120 (194/248) D2887, D86

D

20 % recovered, temperature min/max 105/140 (221/284) D2887, D86

D

50 % recovered, temperature min/max 150/195 (302/383) D2887, D86

D

90 % recovered, temperature min/max 215/255 (419/491) D2887, D86

D

Final boiling point, temperature min/max 240/290 (464/554) D2887, D86

Flash Point, °C (°F) report D56, D3828

Density at 15°C, kg/m 750 to 840 D1298, D4052

E

Vapor pressure

F

at 25°C, kPa (psi) report 3.0 (0.44) to 5.5 (0.80) D5191

F

at 38°C, kPa (psi) report 5.6 (0.8) to 8.2 (1.2) D5191

F

at 50°C, kPa (psi) min/max 10.0 (1.45) to 12.5 (1.82) D5191

F

at 100°C, kPa (psi) report 56 (8.1) to 60 (8.7) D5191

G

Freezing point, °C max -35 D2386, D5972

2 H

Viscosity at -20°C, mm /s max 8.0 D445

I

Net heat of combustion, MJ/kg min 42.8 D4529, D3338,or D4809

One of the following requirements shall be met:

(1) Smoke point, mm, or min 25 D1322

(2) Smoke point, mm, and min 18 D1322

Naphthalenes, vol, % max 3.0 D1840

Copper strip, 2 h at 100°C max No. 1 D130

Thermal stability:

J K

Filter pressure drop, mm Hg max 25 D3241

Tube deposit less than 3 D3241

Existent gum, mg/100 mL max 7 D381

Water reaction:

Interface rating max 1b D1094

L L

Lubricity – BOCLE WSD, mm max 0.85 D5001

Additives: see 5.2

Electrical conductivity, pS/m required 50 to 450 D2624

Other optional

A

For compliance of test results against the requirements of Table 1, see 6.2.

B

The test methods indicated in this table are referred to in Section 10.

C

The mercaptan sulfur determination may be waived if the fuel is considered sweet by the doctor test described in Test Method D4952.

D

If Test Method D2887 is used, use correlation procedure (Appendix X5) in Test Method D2887 to convert D2887 temperatures to D86 equivalent temperatures. Both

minimums and maximums shall be met.

E

Absolute vapor pressure is the primary property to be controlled; Cyclohexane and toluene, as cited in 7.2 and 7.7 of Test Method D5191, shall be used as calibrating

reagents. 1.0 kPa = 0.145 psi.

F

Record absolute vapor pressure.

G

Test Method D5972 may produce a higher (warmer) result than that from Test Method D2386. In case of dispute, Test Method D2386 shall be the referee method.

H 2

1mm /s=1cSt.

I

Use either Eq 1 or Table 1 in Test Method D4529 or Eq 2 in Test Method D3338. Test Method D4809 may be used as an alternative. In case of dispute, Test Method

D4809 shall be used.

J

Preferred SI units are 3.3 kPa, max.

K

Thermal stability test (JFTOT) shall be conducted for 2.5 h at a control temperature of 260°C. Tube deposits shall always be reported by the Visual Method: a rating

by the Tube Deposit Rating (TDR) optical density method is desirable but not mandatory. No peacock or abnormal colored tube deposits are permitted.

L

Lubricity test can be waved with purchaser’s agreement.

as in Table 1 using Practice E29. Where multiple determina- No substance of known dangerous toxicity under usual condi-

tions are made, the average result, rounded according to tions of handling and use shall be present, except as permitted

Practice E29, shall be used. in this specification.

6.3 If any additives are used, the aviation turbine fuel shall

8. Sampling

conform to the Table 2 listed requirements.

8.1 Because of the importance of proper sampling proce-

7. Workmanship, Finish and Appearance

dures in establishing fuel quality, use the appropriate proce-

7.1 The aviation turbine fuel herein specified shall be dures in Practice D4057.

visually free of undissolved water, sediment, and suspended 8.2 A number of jet fuel properties including thermal

matter.Theodorofthefuelshallnotbenauseatingorirritating. stability, water separation, electrical conductivity, and others

D7223 – 05

TABLE 2 Detailed Requirements for Additives in Aviation Turbine Fuels

Fuel Performance Enhancing Additive Dosage

A,B C

Antioxidants 24.0 mg/L max

One of the following:

2,6 ditertiary-butyl phenol

2,6 ditertiary-butyl-4-methyl phenol

2,4 dimethyl-6-tertiary-butyl-phenol

75 % minimum, 2,6 ditertiary-butyl phenol plus

25 % maximum mixed tertiary and tritertiary butyl-phenols

55 % minimum 2,4 dimethyl-6-tertiary-butyl phenol plus

15 % minimum 2,6 ditertiary-butyl-4-methyl phenol,

remainder as monomethyl and dimethyl tertiary-butyl phenols

72 % minimum 2,4 dimethyl-6-tertiary-butyl phenol plus

28 % maximum mo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.