ASTM B913-00e1

(Test Method)Standard Test Method for Evaluation of Crimped Electrical Connections to 16-Gauge and Smaller Diameter Stranded and Solid Conductors

Standard Test Method for Evaluation of Crimped Electrical Connections to 16-Gauge and Smaller Diameter Stranded and Solid Conductors

SCOPE

1.1 This test method establishes the requirements for a standardized method of evaluating the quality of crimped-type electrical connections to solid or stranded conductors. This test method applies to 16-gauge and smaller diameter copper wire, coated or uncoated.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:B913–00

Standard Test Method for

Evaluation of Crimped Electrical Connections to 16-Gauge

1

and Smaller Diameter Stranded and Solid Conductors

This standard is issued under the fixed designation B 913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Keywords were added editorially in November 2003.

1. Scope 3.2.4 crimp terminal—an electrical component designed to

be electrically and mechanically attached to a wire by deform-

1.1 This test method establishes the requirements for a

ing a portion of the component in a crimping operation to form

standardized method of evaluating the quality of crimped-type

anattachmenttothewire.Theotherendoftheterminalusually

electrical connections to solid or stranded conductors. This test

has a ring, fork, spade, tab, or related configuration designed to

method applies to 16-gauge and smaller diameter copper wire,

attach to another connection such as a screw or terminal block.

coated or uncoated.

4. Summary of Test Method

2. Referenced Documents

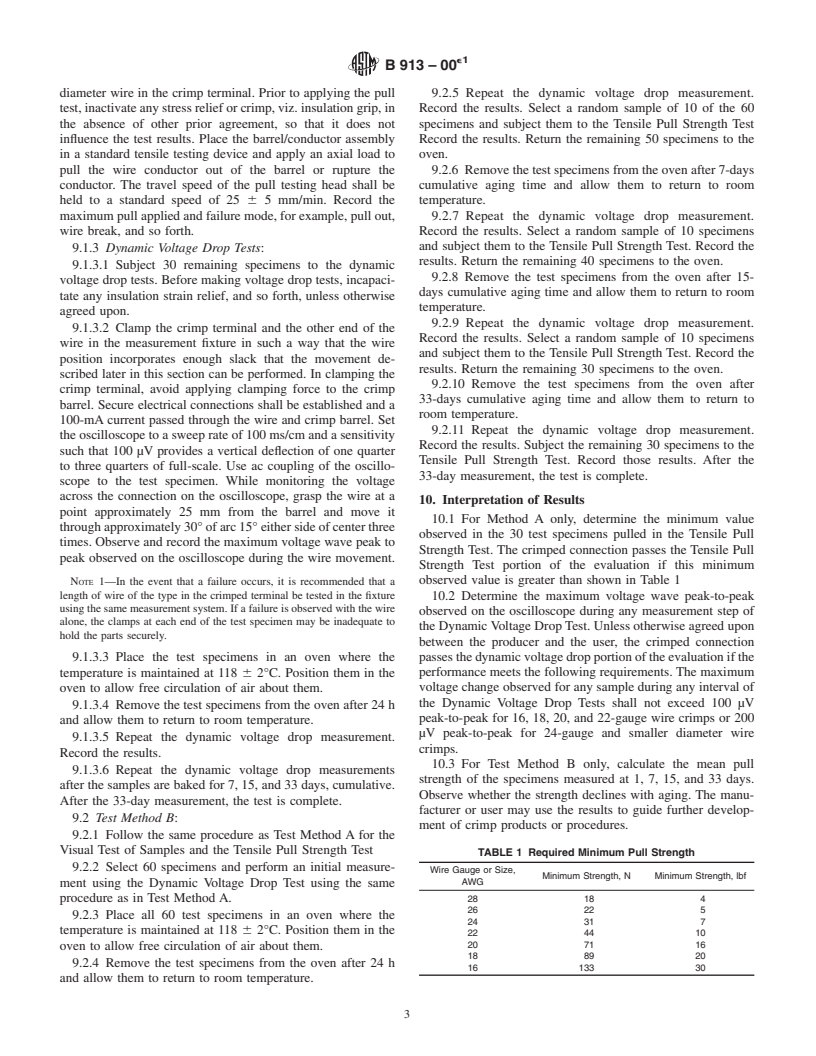

4.1 A test lot of test specimens of the crimp terminal

2.1 ASTM Standards:

crimpedtoashortlengthofwireisprepared.Thewireispulled

B 8 Specification for Concentric-Lay-Stranded Copper

2

from a group of the specimens in a tensile pull and the force

Conductors, Hard, Medium-Hard, or Soft

compared to set requirements based on wire diameter. A

B 258 Specification for Standard Nominal Diameters and

separate group of specimens is subjected to an electrical test

Cross-SectionalAreasofAWGSizesofSolidRoundWires

2

where resistance stability of the specimen is evaluated during

Used as Electrical Conductors

deflectionofthewireattheexitofthecrimpedconnection.The

B 542 Terminology Relating to Electrical Contacts and

3

group is then aged for 33 days at 118°C and periodically

Their Use

retested in the electrical test. The electrical test results are

3. Terminology

compared to a standard value based on wire diameter.Atest lot

passes the evaluation if it passes both the mechanical pull test

3.1 Definitions—Many terms related to electrical contacts

and the electrical test. In Method B, additional pull tests are

used in this test method are defined in Terminology B 542.

performed on subgroups of parts during and after the aging test

3.2 Definitions of Terms Specific to This Standard:

to provide information on progressive degradation in perfor-

3.2.1 crimp, v—to establish an electrical and mechanical

mance.

attachmentbetweenthetwomembersbymechanicallydeform-

ing one contact member around another. In most cases, one

5. Significance and Use

member is a wire or group of wires, the other is a hollow

5.1 This test method establishes the requirements for a

cylinder or partial cylinder that is deformed around the wires.

standardized method of evaluating the performance of

3.2.2 crimp barrel, crimp tab—the portion of the crimp

crimped-type electrical connections having solid or stranded

terminal that is deformed in the crimping operation.

conductors.

3.2.3 crimped connection—a mechanical and electrical con-

5.2 In order to achieve a successful crimped connection, the

nection between a conductor and a component.The connection

crimping tool must deform the material of the crimp barrel or

is made by compressing (crimping) the component (crimp

barrel tab(s) around the conductor. As a consequence, the

barrel) or tab(s) of the component about the conductor using a

conductor surfaces are placed under compression by the crimp

tool specifically designed for the purpose

terminal and areas of contact are established between the

conductorandthecrimpbarrel.Theseareasprovidethedesired

1

electrical connection.Areliable crimped connection is one that

This test method is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

is capable of maintaining the contact between the conductor

B02.11 on Electrical Contact Test Methods.

and crimp barrel so that a stable electrical connection is

Current edition approved Oct. 10, 2000. Published December 2000.

2

maintainedwhenitisexposedtotheconditionsitwasdesigned

Annual Book of ASTM Standards, Vol 02.03.

3

Annual Book of ASTM Standards, Vol 02.04. to endure during its useful life.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

B913–00

5.3 Evaluation testing is designed to ensure that a particular 8.2.2 Wire conductor stranding,

design crimped connection system consisting of conductor and 8.2.3 Wire coating or plating,

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.