ASTM C1087-16

(Test Method)Standard Test Method for Determining Compatibility of Liquid-Applied Sealants with Accessories Used in Structural Glazing Systems

Standard Test Method for Determining Compatibility of Liquid-Applied Sealants with Accessories Used in Structural Glazing Systems

SIGNIFICANCE AND USE

5.1 In structural sealant glazing systems, the sealant functions as the structural adhesive and may also function as the primary weather seal. As the structural adhesive, the integrity of the adhesive bond is critical.

5.2 Changes in color and adhesion after exposure are two of the criteria that can be used to determine the compatibility of the system. Experience has shown that accessories that cause loss of adhesion or discoloration in this test method may also cause these occurrences in actual use.

SCOPE

1.1 This test method covers a laboratory screening procedure for determining the compatibility of liquid-applied structural sealant glazing sealants when in contact with accessories such as dry glazing gaskets, spacers, shims, and setting blocks after exposure to heat and ultraviolet light.

1.2 This test method includes the observation of three parameters as follows:

1.2.1 Changes in the color of the sealant,

1.2.2 Changes in the adhesion of the sealant to glass, and

1.2.3 Changes in the adhesion of the sealant to the accessory being tested.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1: At this time, no comparable ISO standard exists.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1087 − 16

Standard Test Method for

Determining Compatibility of Liquid-Applied Sealants with

1

Accessories Used in Structural Glazing Systems

This standard is issued under the fixed designation C1087; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope spacer, structural sealant, standard conditions, and structural

sealant glazing.

1.1 This test method covers a laboratory screening proce-

dure for determining the compatibility of liquid-applied struc-

4. Summary of Test Method

tural sealant glazing sealants when in contact with accessories

4.1 The test specimens are placed beneath ultraviolet lamps

such as dry glazing gaskets, spacers, shims, and setting blocks

so that the radiation will hit the sealant directly on one

after exposure to heat and ultraviolet light.

specimen, and through the glass, on the other specimen (see

1.2 This test method includes the observation of three

Fig. 1).

parameters as follows:

4.2 The control specimens for this test method are prepared

1.2.1 Changes in the color of the sealant,

and tested identically to the test specimens except that the

1.2.2 Changes in the adhesion of the sealant to glass, and

accessory is eliminated.

1.2.3 Changes in the adhesion of the sealant to the accessory

being tested.

4.3 After the specimens are exposed, the test specimens are

compared to the control specimens.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4.4 In the testing of the specimens, any color change in the

only.

sealant between the test specimen and the control is noted as

are any changes in the adhesion of the sealant to either the glass

1.4 This standard does not purport to address all of the

or to the accessory. This test method requires the preparation of

safety concerns, if any, associated with its use. It is the

eight test specimens (four controls and four test specimens for

responsibility of the user of this standard to establish appro-

each accessory being evaluated).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

NOTE 1—At this time, no comparable ISO standard exists.

5.1 In structural sealant glazing systems, the sealant func-

tions as the structural adhesive and may also function as the

2. Referenced Documents

primary weather seal. As the structural adhesive, the integrity

2

2.1 ASTM Standards:

of the adhesive bond is critical.

C717 Terminology of Building Seals and Sealants

5.2 Changes in color and adhesion after exposure are two of

3. Terminology

the criteria that can be used to determine the compatibility of

the system. Experience has shown that accessories that cause

3.1 Definitions—Definitions of the following terms used in

loss of adhesion or discoloration in this test method may also

this test method are listed in Terminology C717: adhesive

cause these occurrences in actual use.

failure (adhesion loss), bead, bond breaker, cohesive failure,

compatibility, gasket, glazing, sealant, setting blocks, shim,

6. Apparatus and Materials

6.1 Glass Panels, clear float glass, approximately 76.2 by

1 1

This test method is under the jurisdiction of ASTM Committee C24 on Building 50.8 by 6.4 mm (3 by 2 by ⁄4 in.). Eight panels are required for

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

each material being tested.

General Test Methods.

Current edition approved June 1, 2016. Published July 2016. Originally approved 6.2 Bond Breaker Tape, 25.4 by 76.2-mm (1 by 3-in.) piece

in 1987. Last previous edition approved in 2011 as C1087 – 00 (2011). DOI:

for each panel. The bond breaker tape must be compatible with

10.1520/C1087-16.

the sealants being tested.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Thermometer, for example, 28.9 to 100°C (20 to 212°F).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.4 Ultraviolet (UV) lamps, UVA-340 lamps.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1087 − 16

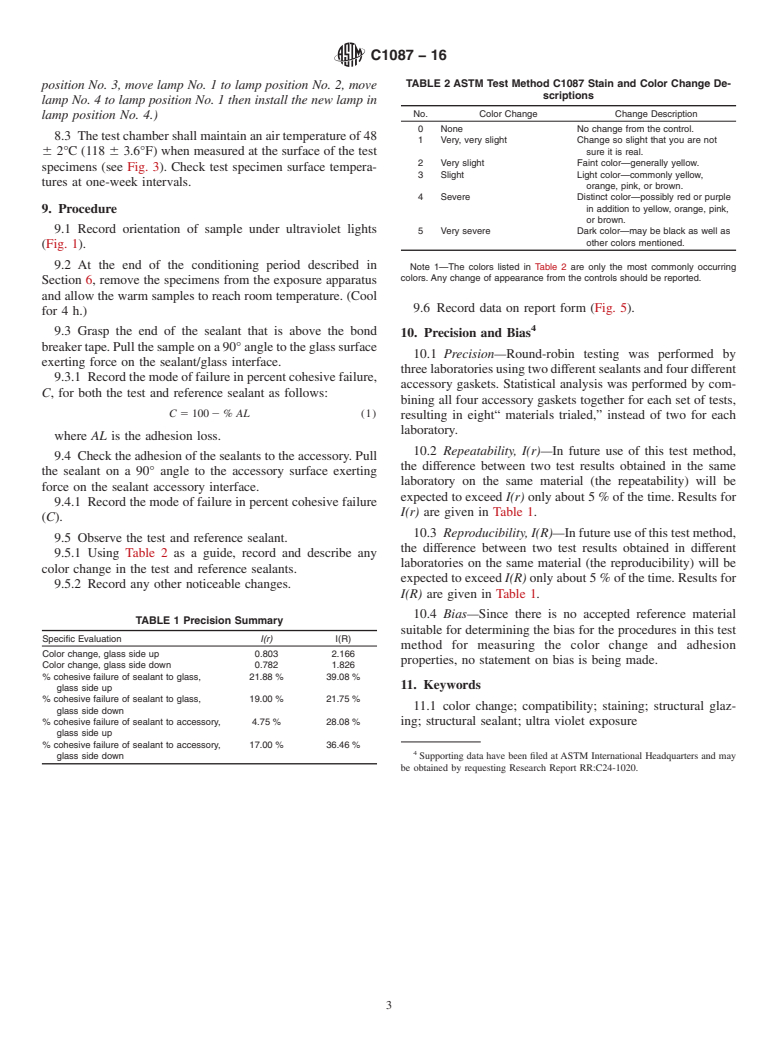

FIG. 4 UV Lamp Rotation

6.8 Reference Sealant—A light or translucent sealant of the

same composition as the test sealant. If none is available,

contact the sealant supplier for recommendations on a suitable

FIG. 1 Orientation of Test Specimen Under Lamps

alternative.

7. Preparation of Test Speci

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1087 − 00 (Reapproved 2011) C1087 − 16

Standard Test Method for

Determining Compatibility of Liquid-Applied Sealants with

1

Accessories Used in Structural Glazing Systems

This standard is issued under the fixed designation C1087; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory screening procedure for determining the compatibility of liquid-applied structural

sealant glazing sealants when in contact with accessories such as dry glazing gaskets, spacers, shims, and setting blocks after

exposure to heat and ultraviolet light.

1.2 This test method includes the observation of three parameters as follows:

1.2.1 Changes in the color of the sealant,

1.2.2 Changes in the adhesion of the sealant to glass, and

1.2.3 Changes in the adhesion of the sealant to the accessory being tested.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—At this time, no comparable ISO standard exists.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

3. Terminology

3.1 Definitions—Definitions of the following terms used in this test method are listed in Terminology C717: adhesive failure

(adhesion loss), bead, bond breaker, cohesive failure, compatibility, gasket, glazing, sealant, setting blocks, shim, spacer, structural

sealant, standard conditions, and structural sealant glazing.

4. Summary of Test Method

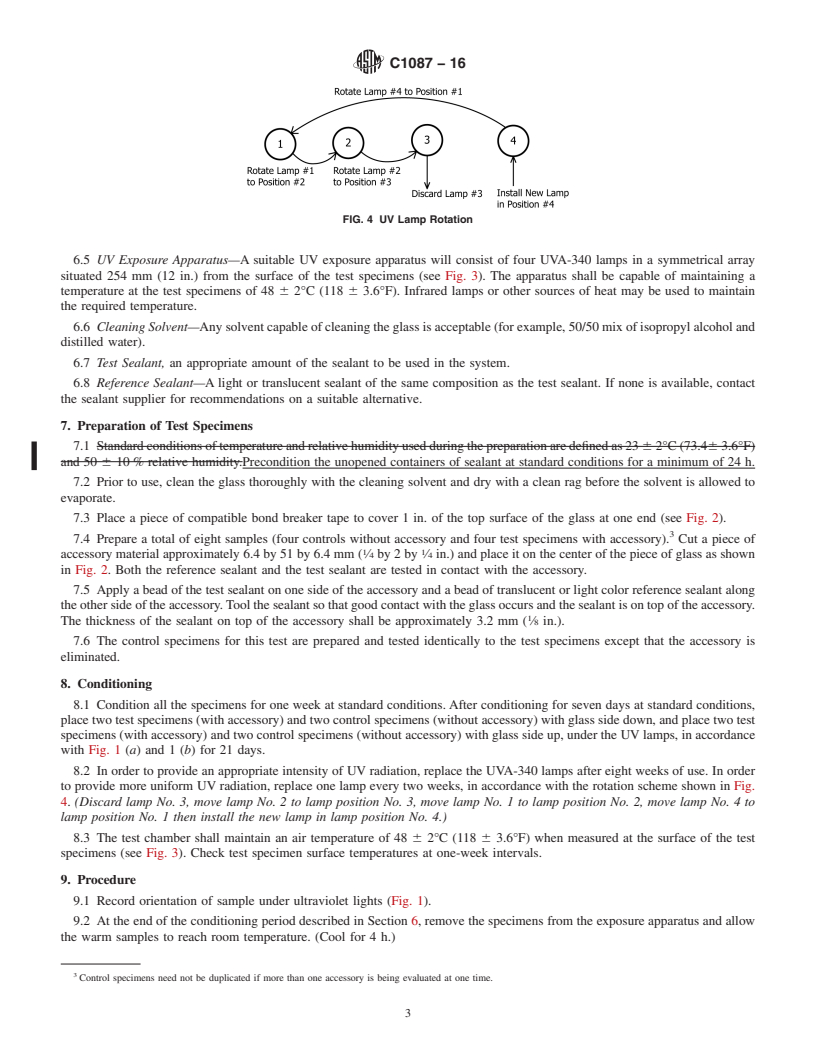

4.1 The test specimens are placed beneath ultraviolet lamps so that the radiation will hit the sealant directly on one specimen,

and through the glass, on the other specimen (see Fig. 1).

4.2 The control specimens for this test method are prepared and tested identically to the test specimens except that the accessory

is eliminated.

4.3 After the specimens are exposed, the test specimens are compared to the control specimens.

4.4 In the testing of the specimens, any color change in the sealant between the test specimen and the control is noted as are

any changes in the adhesion of the sealant to either the glass or to the accessory. This test method requires the preparation of eight

test specimens (four controls and four test specimens for each accessory being evaluated).

5. Significance and Use

5.1 In structural sealant glazing systems, the sealant functions as the structural adhesive and may also function as the primary

weather seal. As the structural adhesive, the integrity of the adhesive bond is critical.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on General

Test Methods.

Current edition approved June 1, 2011June 1, 2016. Published August 2011July 2016. Originally approved in 1987. Last previous edition approved in 20062011 as

ε1

C1087 – 00 (2006)(2011). . DOI: 10.1520/C1087-00R11.10.1520/C1087-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1087 − 16

FIG. 1 Orientation of Test Specimen Under Lamps

FIG. 2 View of Test Specimen

FIG. 3 UV Exposure Apparatus

5.2 Changes in color and adhesion after exposure are two of the criteria that can be used to determine the compatibility of the

system. Experience has shown that accessories that cause loss of adhesion or discoloration in this test method may also cause these

occurrences in actual use.

6. Apparatus and Materials

1

6.1 Glass Panels, clear float glass, approximately 76.2 by 50.8 by 6.4 mm (3 by 2 by ⁄4 in.). Eight panels are required for each

material being tested.

6.2 Bond Breaker Tape, 25.4 by 76.2-mm (1 by 3-in.) piece for each panel. The bond break

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.