ASTM E3246-22

(Test Method)Standard Test Methods for Differential Indentation Depth Hardness of Metallic Materials

Standard Test Methods for Differential Indentation Depth Hardness of Metallic Materials

SIGNIFICANCE AND USE

4.1 The Differential Indentation Depth hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information can correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and can be useful in quality control and selection of materials.

4.2 Differential Indentation Depth hardness tests are considered satisfactory for acceptance testing of commercial shipments, and have been used in industry for this purpose.

4.3 Differential Indentation Depth hardness testing at a specific location on a part might not represent the physical characteristics of the whole part or end product. Machines that comply with this Standard are used when machines that comply with the regular hardness standards such as Test Methods E10, E18, E92, and E384 cannot be used. Test results obtained with these machines are comparable BUT NOT EQUIVALENT to those obtained with machines that comply with the above mentioned standards.

4.4 Differential Indentation Depth hardness testing machines covered by this standard do not comply with Test Methods E10, E18, E92, or E110.

SCOPE

1.1 This test method covers the determination of the Differential Indentation Depth hardness of metallic materials by the Differential Indentation Depth hardness principle. This standard provides the requirements for Differential Indentation Depth hardness testing machines and the procedures for performing Differential Indentation Depth hardness tests.

1.2 This standard includes additional requirements in annexes:

Verification of Differential Indentation Depth Hardness Testing Machines

Annex A1

Guidelines for Determining the Minimum Thickness of a Test Piece

Annex A2

1.3 This standard includes non-mandatory information in appendixes which relates to the Differential Indentation Depth hardness test.

List of ASTM Standards Giving Hardness Numbers Corresponding to Tensile Strength

Appendix X1

Examples of Procedures for Determining Differential Indentation Depth Hardness Uncertainty

Appendix X2

Examples of Indenters Used in Differential Indentation Depth Machines

Appendix X3

1.4 Units—This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in micrometers (µm). However, because of continued common usage, values are provided in other units of measure for information.

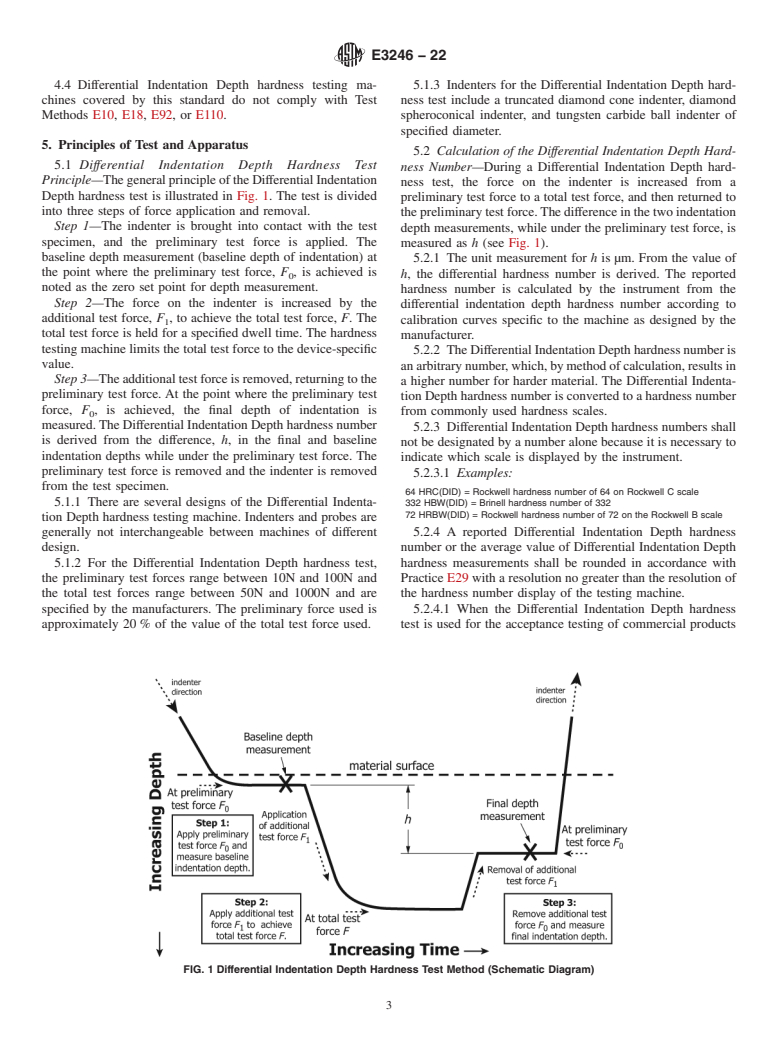

1.5 The test principles, testing procedures, and verification procedures are essentially identical for all the Differential Indentation Depth hardness testing instruments. The testing instruments may use different test forces and indenter shapes. The type and size of the indenters are matched to the design of the instrument by the manufacturer. Accordingly, the indenters, probes and other instrument components are generally not interchangeable among manufacturers.

1.6 The hardness number reported by these instruments are based on direct correlations to existing hardness scales as determined by each manufacturer for each instrument and hardness scale. Unless otherwise noted on the instrument or in the operating manual for the instrument, the hardness numbers reported by the instrument are only applicable to non-austenitic steels. See 5.6.1 for additional information.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organizati...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3246 − 22

Standard Test Methods for

Differential Indentation Depth Hardness of Metallic

1

Materials

This standard is issued under the fixed designation E3246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.6 The hardness number reported by these instruments are

based on direct correlations to existing hardness scales as

1.1 This test method covers the determination of the Differ-

determined by each manufacturer for each instrument and

ential Indentation Depth hardness of metallic materials by the

hardness scale. Unless otherwise noted on the instrument or in

Differential Indentation Depth hardness principle. This stan-

the operating manual for the instrument, the hardness numbers

dard provides the requirements for Differential Indentation

reported by the instrument are only applicable to non-austenitic

Depth hardness testing machines and the procedures for

steels. See 5.6.1 for additional information.

performing Differential Indentation Depth hardness tests.

1.7 This standard does not purport to address all of the

1.2 This standard includes additional requirements in an-

safety concerns, if any, associated with its use. It is the

nexes:

responsibility of the user of this standard to establish appro-

Verification of Differential Indentation Depth Annex A1

priate safety, health, and environmental practices and deter-

Hardness Testing Machines

mine the applicability of regulatory limitations prior to use.

Guidelines for Determining the Minimum Thickness Annex A2

of a Test Piece

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.3 This standard includes non-mandatory information in

ization established in the Decision on Principles for the

appendixes which relates to the Differential Indentation Depth

Development of International Standards, Guides and Recom-

hardness test.

mendations issued by the World Trade Organization Technical

List of ASTM Standards Giving Hardness Numbers Appendix X1

Barriers to Trade (TBT) Committee.

Corresponding to Tensile Strength

Examples of Procedures for Determining Appendix X2

Differential Indentation Depth Hardness

2. Referenced Documents

Uncertainty

2

Examples of Indenters Used in Differential Appendix X3

2.1 ASTM Standards:

Indentation Depth Machines

A370 Test Methods and Definitions for Mechanical Testing

1.4 Units—This standard specifies the units of force and

of Steel Products

length in the International System of Units (SI); that is, force in

E6 Terminology Relating to Methods of Mechanical Testing

Newtons (N) and length in micrometers (μm). However,

E10 Test Method for Brinell Hardness of Metallic Materials

because of continued common usage, values are provided in

E18 Test Methods for Rockwell Hardness of Metallic Ma-

other units of measure for information.

terials

E29 Practice for Using Significant Digits in Test Data to

1.5 The test principles, testing procedures, and verification

Determine Conformance with Specifications

procedures are essentially identical for all the Differential

E92 Test Methods for Vickers Hardness and Knoop Hard-

Indentation Depth hardness testing instruments. The testing

ness of Metallic Materials

instruments may use different test forces and indenter shapes.

E110 Test Method for Rockwell and Brinell Hardness of

The type and size of the indenters are matched to the design of

Metallic Materials by Portable Hardness Testers

the instrument by the manufacturer. Accordingly, the indenters,

E140 Hardness Conversion Tables for Metals Relationship

probes and other instrument components are generally not

Among Brinell Hardness, Vickers Hardness, Rockwell

interchangeable among manufacturers.

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

scope Hardness, and Leeb Hardness

1

These test methods are under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

2

Indentation Hardness Testing. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2021 as E3246–21. Last previous edition approved in 2021 as Standards volume information, refer to the standard’s Document Summary page on

E3246–21. DOI: 10.1520/E3246–22 the ASTM website.

*A Summary of Changes section appears

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E3246 − 21 E3246 − 22

Standard Test Methods for

Differential Indentation Depth Hardness of Metallic

1

Materials

This standard is issued under the fixed designation E3246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of the Differential Indentation Depth hardness of metallic materials by the

Differential Indentation Depth hardness principle. This standard provides the requirements for Differential Indentation Depth

hardness testing machines and the procedures for performing Differential Indentation Depth hardness tests.

1.2 This standard includes additional requirements in annexes:

Verification of Differential Indentation Depth Annex A1

Hardness Testing Machines

Guidelines for Determining the Minimum Thickness Annex A2

of a Test Piece

1.3 This standard includes non-mandatory information in appendixes which relates to the Differential Indentation Depth hardness

test.

List of ASTM Standards Giving Hardness Numbers Appendix X1

Corresponding to Tensile Strength

Examples of Procedures for Determining Appendix X2

Differential Indentation Depth Hardness

Uncertainty

Examples of Indenters Used in Differential Appendix X3

Indentation Depth Machines

1.4 Units—This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons

(N) and length in micrometers (μm). However, because of continued common usage, values are provided in other units of measure

for information.

1.5 The test principles, testing procedures, and verification procedures are essentially identical for all the Differential Indentation

Depth hardness testing instruments. The testing instruments may use different test forces and indenter shapes. The type and size

of the indenters are matched to the design of the instrument by the manufacturer. Accordingly, the indenters, probes and other

instrument components are generally not interchangeable among manufacturers.

1.6 The hardness number reported by these instruments are based on direct correlations to existing hardness scales as determined

1

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation

Hardness Testing.

Current edition approved Jan. 1, 2021April 1, 2022. Published March 2021May 2022. Originally approved in 2021 as E3246–21. Last previous edition approved in 2021

as E3246–21. DOI: 10.1520/E3246–2110.1520/E3246–22

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E3246 − 22

by each manufacturer for each instrument and hardness scale. Unless otherwise noted on the instrument or in the operating manual

for the instrument, the hardness numbers reported by the instrument are only applicable to non-austenitic steels. See 5.6.1 for

additional information.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

B19 Specification for Cartridge Brass Sheet, Strip, Plate, Bar, and Disks

B36/B36M Specification for Brass Plate, Sheet, Strip, And Rolled Bar

B96/B96M Specification for Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar for General Purposes and Pressure Vessels

B103/B103M Specification for Phosphor Bronze Plate, Sheet, Strip, and Rolled Bar

B121/B121M Specification for Leaded Brass Plate, Sheet, Strip, and Rolled Bar

B122/B122M Specification for Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel Silver), and Copp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.