ASTM E531-76(2007)

(Practice)Standard Practice for Surveillance Testing of High-Temperature Nuclear Component Materials

Standard Practice for Surveillance Testing of High-Temperature Nuclear Component Materials

SIGNIFICANCE AND USE

The requirements contained herein can be used as a basis for establishing conditions for safe operation of critical components. The requirements provide for general plant assessment and verification that materials meet design criteria. The test specimens and procedures presented in this practice are for guidance when establishing a surveillance program.

This practice for high-temperature materials surveillance programs is used when nuclear reactor component materials are monitored by specimen testing. Periodic testing is performed through the service life of the components to assess changes in selected material properties that are caused by neutron irradiation and thermal effects. The properties are those used as design criteria for the respective nuclear components. The extent of material property change caused by neutron irradiation depends on the composition and structure of the initial material, its conditioning in component fabrication, as well as the nature of the irradiation exposure. The need for surveillance arises from a concern of specific material behavior under all irradiation conditions including spectrum and rate effects on material properties.

SCOPE

1.1 This practice covers procedures for specimen testing to establish changes occurring in the mechanical properties due to irradiation and thermal effects of nuclear component metallic materials where these materials are used for high temperature applications above 370°C (700°F).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E531 − 76(Reapproved 2007)

Standard Practice for

Surveillance Testing of High-Temperature Nuclear

Component Materials

This standard is issued under the fixed designation E531; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E399 Test Method for Linear-Elastic Plane-Strain Fracture

Toughness K of Metallic Materials

Ic

1.1 This practice covers procedures for specimen testing to

E453 Practice for Examination of Fuel Element Cladding

establishchangesoccurringinthemechanicalpropertiesdueto

Including the Determination of the Mechanical Properties

irradiation and thermal effects of nuclear component metallic

E482 Guide for Application of Neutron Transport Methods

materials where these materials are used for high temperature

for Reactor Vessel Surveillance, E706 (IID)

applications above 370°C (700°F).

E844 Guide for Sensor Set Design and Irradiation for

Reactor Surveillance, E 706 (IIC)

2. Referenced Documents

2.1 ASTM Standards:

3. Significance and Use

A370 Test Methods and Definitions for Mechanical Testing

3.1 The requirements contained herein can be used as a

of Steel Products

E3 Guide for Preparation of Metallographic Specimens basis for establishing conditions for safe operation of critical

components. The requirements provide for general plant as-

E8 Test Methods for Tension Testing of Metallic Materials

E21 TestMethodsforElevatedTemperatureTensionTestsof sessment and verification that materials meet design criteria.

The test specimens and procedures presented in this practice

Metallic Materials

E23 Test Methods for Notched Bar Impact Testing of Me- are for guidance when establishing a surveillance program.

tallic Materials

3.2 This practice for high-temperature materials surveil-

E29 Practice for Using Significant Digits in Test Data to

lance programs is used when nuclear reactor component

Determine Conformance with Specifications

materialsaremonitoredbyspecimentesting.Periodictestingis

E45 Test Methods for Determining the Inclusion Content of

performed through the service life of the components to assess

Steel

changes in selected material properties that are caused by

E112 Test Methods for Determining Average Grain Size

neutronirradiationandthermaleffects.Thepropertiesarethose

E139 Test Methods for Conducting Creep, Creep-Rupture,

used as design criteria for the respective nuclear components.

and Stress-Rupture Tests of Metallic Materials

The extent of material property change caused by neutron

E185 Practice for Design of Surveillance Programs for

irradiation depends on the composition and structure of the

Light-Water Moderated Nuclear Power Reactor Vessels

initial material, its conditioning in component fabrication, as

E206 Definitions of Terms Relating to Fatigue Testing and

well as the nature of the irradiation exposure. The need for

the Statistical Analysis of Fatigue Data; Replaced by

surveillancearisesfromaconcernofspecificmaterialbehavior

E 1150 (Withdrawn 1988)

under all irradiation conditions including spectrum and rate

E261 Practice for Determining Neutron Fluence, Fluence

effects on material properties.

Rate, and Spectra by Radioactivation Techniques

4. Description of Term

This recommended practice is under the jurisdiction ofASTM Committee E10

4.1 test specimen—a coupon or a piece of metal cut from a

on Nuclear Technology andApplicationsand is the direct responsibility of Subcom-

larger metal piece which is then formed to final size for testing

mittee E10.02 on Behavior and Use of Nuclear Structural Materials.

to determine physical or mechanical properties.

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

in 1975. Last previous edition approved in 2001 as E531–76(2001). DOI: 10.1520/

E0531-76R07.

5. Test Specimens

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Pre-Exposure Material Characterization—It is impor-

Standards volume information, refer to the standard’s Document Summary page on

tant that test specimen materials be characterized prior to

the ASTM website.

exposure and that the following should be considered as a

The last approved version of this historical standard is referenced on

www.astm.org. minimum:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E531 − 76 (2007)

5.1.1 Process history, material designation, manufacturer, for surveillance specimens, the archive, base line, and thermal

heat number, weld and fabrication procedures used, and heat control specimens shall be identical with the surveillance

treatment, specimens.

5.1.2 Original location and orientation in the parent 5.3.3 Surface Condition—Test specimens where surface

material, condition is critical to the test results should not be finish

machined in such critical areas (Charpy notch, fatigue speci-

5.1.3 Specimen weight and dimensions,

mentestarea,surfaceofdensitychangesample)untiljustprior

5.1.4 Metallographic characteristics (grain size,

to test. Specimens should be oversized to allow for removal of

microstructure,andinclusioncontentestablishedinaccordance

at least 0.1 mm of surface prior to test. Where possible, test

with Test Methods E45 and E112),

specimens with the exception of weight change specimens

5.1.5 Chemical analysis results,

shall be encapsulated in an inert environment so as to deter-

5.1.6 All specimens shall be taken from the specified

mine only the effect of neutron irradiation and temperature on

location and orientation specified in Test Methods and Defini-

mechanical or physical properties. It is recognized the integrity

tions A370 and Test Methods E8, and

of the encapsulation may be breached in some cases during

5.1.7 Mechanical properties including yield strength, tensile

longexposureandanallowanceforfinalmachiningevenofthe

strength, stress rupture life, creep strength, fatigue strength,

encapsulated specimens should be considered.This will ensure

and impact strength as a function of test temperature.

a meaningful comparison between baseline and exposed speci-

5.1.8 The information described in 5.1.1-5.1.7 should be

mens.

reported in a single document.

5.3.4 Number of Specimens—The number of specimens

5.2 Post Exposure Material Characterization—After

employedformechanicalpropertytestingshouldbeselectedso

exposure, the following should be reported:

astoincludeeachcriticalcomponentthatvariessignificantlyin

5.2.1 Observations from visual examination,

composition, processing, or in exposure conditions from simi-

5.2.2 Changes in specimen weight and dimensions,

lar components. Specific recommendations as to number of

5.2.3 Metallographic characteristics (grain size,

specimens will be found in the respective specimen sections.

microstructure, and inclusion content), At least four sets of specimens shall be included in each

5.2.4 Results of chemical analysis, surveillance program.

5.2.5 Appropriate mechanical properties being surveyed 5.3.5 Material—Test specimens shall be taken from the

material used in component fabrication. The material shall be

including considerations of changes in tensile strength, stress-

to-rupture strength, creep strength, fatigue strength, impact processed at the same time as the component or processed in a

fashion identical to the component surveyed. Weld and heat-

strength (control tests are recommended to be performed

affected zone test specimens shall be taken from equivalent

simultaneously with the tests of exposed specimens to ensure

material welded at the same time as the particular component

that deviations in test results can be attributed to the exposed

or equivalent material welded with the same welding param-

specimen’s environment and not to variations in testing

eters. It is not necessary to include each heat or minor

methods), and

variation, but only to select those receiving the highest expo-

5.2.6 Optional quantitative examination of surface chemis-

sure or those previously found to be most sensitive to neutron

try and subsequent changes.

irradiation and temperature or those that can restrict the

5.2.7 Exposed test specimens should be cleaned in accor-

operation of the reactor. Test specimens may be taken from

dance with accepted cleaning procedures. (Refer to Subcom-

components periodically removed from the reactor for other

mittee G01.08 for practices for preparing, cleaning, and evalu-

reasons. These specimens can be used to provide supplemental

ating test specimens.)

surveillanceinformation.Forthisinformationtobemeaningful

5.3 Specimen Preparation—Test specimens shall be stan-

a full characterization of the pre-exposure condition must be

dard recommended specimens where possible as described in

available along with measured exposure conditions.

Test Methods E8, E21 and E23 and Practice E139. The use of

5.4 Tension Test Specimens—The type and size of specimen

the word specimen or words test specimen as used in this

to be used shall conform to the smaller sizes as recommended

practice is described in Section 4.

in Test Methods E8 and E21. Either threaded or button-head

5.3.1 The test area of a specimen (for example, Charpy

ends will be acceptable. For plate or sheet specimens, pin ends

notch, reduced section of a fatigue specimen) may be left

as described in Test Methods E8 are recommended. The

unfinished if further environmental exposure prior to testing is

location and orientation of test specimens shall be as defined in

anticipated.

Test Methods E8 or Test Methods and Definitions A370,orin

5.3.2 Size—In general, due to the limited space available in

Practice E185. Both base metal and weld metal specimens will

surveillance capsules the smaller sizes of test specimens are

be taken.Aset of tension specimens shall consist of three each

recommended.Where it is not possible to use specimens of the

base metal and weld metal.

recommended size, the least deviation possible from recom-

mended sizes should be adhered to. Non-standard specimens 5.5 Creep and Stress-Rupture in Specimens—The type and

shall be evaluated prior to use as surveillance specimens to size of specimen to be used shall be the same as those used for

ensure that test results from the use of non-standard specimens tension specimens except that button-head or pinned-end

can be correlated with test results from specimens of recom- specimens are recommended for high-temperature testing.

mendedsize.Intheeventthatnon-standardspecimensareused Practice E453 describes the attention that must be paid to

E531 − 76 (2007)

specimen alignment and dimensional tolerances. One set of to be made, the test specimen may be electropolished in

tests shall be conducted at the operating temperature of the accordance with Methods E3. Test specimens that are suscep-

component of interest. A set shall comprise a minimum of six tible to corrosion in room-temperature air shall be stored as

stress rupture tests at six different stress levels. The stress soon as practicable after preparation in an inert dry gas or

levels should be selected so that the time-to-rupture ranges vacuum. A set of specimens shall consist of ten each of base

from not less than 100 h to at least 3000 h. Creep strain metal and weld metal.

measurements may be made if desired.

5.7 Swelling Specimens—The swelling specimens shall be

right circular cylinders 5.0 mm diameter and 10.0 mm long.

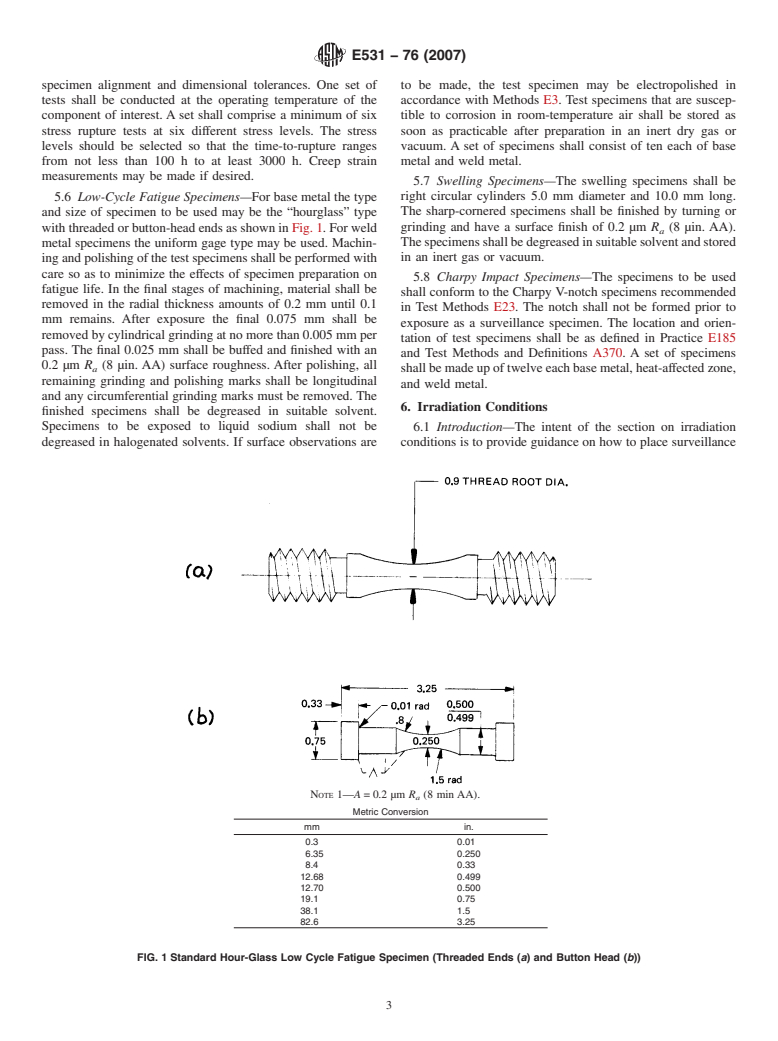

5.6 Low-Cycle Fatigue Specimens—For base metal the type

The sharp-cornered specimens shall be finished by turning or

and size of specimen to be used may be the “hourglass” type

grinding and have a surface finish of 0.2 µm R (8 µin. AA).

with threaded or button-head ends as shown in Fig. 1. For weld

a

Thespecimensshallbedegreasedinsuitablesolventandstored

metal specimens the uniform gage type may be used. Machin-

in an inert gas or vacuum.

ing and polishing of the test specimens shall be performed with

care so as to minimize the effects of specimen preparation on

5.8 Charpy Impact Specimens—The specimens to be used

fatigue life. In the final stages of machining, material shall be

shall conform to the Charpy V-notch specimens recommended

removed in the radial thickness amounts of 0.2 mm until 0.1

in Test Methods E23. The notch shall not be formed prior to

mm remains. After exposure the final 0.075 mm shall be

exposure as a surveillance specimen. The location and orien-

removed by cylindrical grinding at no more than 0.005 mm per

tation of test specimens shall be as defined in Practice E185

pass. The final 0.025 mm shall be buffed and finished with an

and Test Methods and Definitions A370. A set of specimens

0.2 µm R (8 µin. AA) surface roughness. After polishing, all

a shallbemadeupoftwelveeachbasemetal,heat-affectedzone,

remaining grinding and polishing marks shall be longitudinal

and weld metal.

and any circumferential grinding marks must be removed. The

6. Irradiation Conditions

finished specimens shall be degreased in suitable solvent.

Specimens to be exposed to liquid sodium shall not be 6.1 Introduction—The intent of the section on irradiation

degreased in halogenated solvents. If surface observations are conditions is to provide guidance on how to place surveillance

NOTE 1—A = 0.2 µm R (8 min AA).

a

Metric Conversion

mm in.

0.3 0.01

6.35 0.250

8.4 0.33

12.68 0.499

12.70 0.500

19.1 0.75

38.1 1.5

82.6 3.25

FIG. 1 Standard Hour-Glass Low Cycle Fatigue Specimen (Threaded Ends (a) and Button Head (b))

E531 − 76 (2007)

samples to obtain the desired irradiation conditions in terms of 6.5 Specimen Withdrawal Schedule—The specimen with-

temperature, neutron flux, and neutron spectrum to ensure a drawal schedule shall be as specified in Practice E185, Case B,

based on the percentage of component life as specified inTable

realistic evaluation of the component that the surveillance

1.

specimen is representing.

6.2 Irradiation Temperature—It is very important that ad-

7. Measurement of Neutron Exposure

equate consideration be given to test specimens to ensure that

7.1 The neutron flux and neutron energy spectrum at the

they experience the correct temperature during irradiation.

surveillance location shall be given as well as the method used

Temperature must be controlled for the surveillance specimens

for determination. All assumptions should be clearly stated,

to match as nearly as possible the temperature of the compo-

and all physical constants, such as cross sections, half lives,

nent being surveyed.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.