ASTM B937-04

(Specification)Standard Specification for Copper-Beryllium Seamless Tube (UNS Nos. C17500 and C17510)

Standard Specification for Copper-Beryllium Seamless Tube (UNS Nos. C17500 and C17510)

SCOPE

1.1 This specification establishes the requirements for copper-beryllium alloy seamless tube in straight lengths. Copper-cobalt-beryllium alloy UNS No. C17500 and copper-nickel-beryllium alloy UNS No. C17510 will be the alloys furnished whenever this specification is specified.

1.2 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method(s) described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B937 – 04

Standard Specification for

Copper-Beryllium Seamless Tube (UNS Nos. C17500 and

C17510)

This standard is issued under the fixed designation B937; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E18 Test Methods for Rockwell Hardness of Metallic Ma-

terials

1.1 This specification establishes the requirements for

E255 Practice for Sampling Copper and Copper Alloys for

copper-beryllium alloy seamless tube in straight lengths.

the Determination of Chemical Composition

Copper-cobalt-beryllium alloy UNS No. C17500 and copper-

E1004 Test Method for Determining Electrical Conductiv-

nickel-beryllium alloy UNS No. C17510 will be the alloys

ity Using the Electromagnetic (Eddy-Current) Method

furnished whenever this specification is specified.

1.2 Units—The values stated in inch-pound units are to be

3. General Requirements

regarded as standard. The values given in parentheses are

3.1 The following sections of Specification B251 (as noted)

mathematical conversions to SI units, which are provided for

constitute a part of this specification:

information only and are not considered standard.

3.1.1 Workmanship, Finish, and Appearance,

1.3 The following safety hazard caveat pertains only to the

3.1.2 Number of Tests and Retests,

test method(s) described in this specification. This standard

3.1.3 Significance of Numerical Limits,

does not purport to address all of the safety concerns, if any,

3.1.4 Inspection,

associated with its use. It is the responsibility of the user of this

3.1.5 Rejection and Rehearing,

standard to establish appropriate safety and health practices

3.1.6 Certification,

and to determine the applicability of regulatory limitations

3.1.7 Mill Test Report, and

prior to use.

3.1.8 Packaging and Package Marking.

2. Referenced Documents

4. Terminology

2.1 The following documents of the issue in effect on date

4.1 For definitions of terms related to copper and copper

of material purchase form a part of this specification to the

alloys, refer to Terminology B846.

extent referenced herein:

2 4.2 Definitions of Terms Specific to This Standard:

2.2 ASTM Standards:

4.2.1 average diameter (for round tubes only), n—the

B193 Test Method for Resistivity of Electrical Conductor

average of the maximum and minimum outside diameters, or

Materials

maximum and minimum inside diameters, whichever is appli-

B194 Specification for Copper-Beryllium Alloy Plate,

cable, as determined at any one cross section of the tube.

Sheet, Strip, and Rolled Bar

4.2.2 lengths, n—straight pieces of the product

B251 Specification for General Requirements for Wrought

4.2.2.1 ends, n—straight pieces, shorter than the nominal

Seamless Copper and Copper-Alloy Tube

length, left over after cutting the product into mill lengths,

B601 Classification for Temper Designations for Copper

stock lengths, or specific lengths.They are subject to minimum

and Copper Alloys—Wrought and Cast

length and maximum weight requirements.

B846 Terminology for Copper and Copper Alloys

4.2.2.2 specific, adj—straight lengths that are uniform in

E8 Test Methods for Tension Testing of Metallic Materials

length, as specified, and subject to established length toler-

ances.

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.2.2.3 specific with ends, adj—specific lengths, including

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

ends.

and Tube.

4.2.2.4 stock, n—straightlengthsthataremillcutandstored

Current edition approved May 1, 2004. Published May 2004. DOI: 10.1520/

B0937-04. in advance of orders. They are usually 8, 10, 12, or 20 ft (2.44,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.05, 3.66, or 6.10 m) and subject to established length

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tolerances.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B937 – 04

TABLE 1 Chemical Composition

4.2.2.5 stock with ends, adj—stock lengths, including ends.

4.2.3 tube, n—a hollow product of round or any other cross Concentration, %

section having a continuous periphery.

Copper Alloy Copper Alloy

Element UNS No. UNS No.

4.2.3.1 tube, seamless, adj—a tube produced with a con-

C17500 C17510

tinuous periphery in all stages of the operations.

Beryllium 0.4-0.7 0.2-0.6

Cobalt 2.4-2.7 0.3 max

5. Ordering Information

Nickel … 1.4-2.2

Iron, max 0.10 0.10

5.1 Include the following information when placing orders

Aluminum, max 0.20 0.20

for product under this specification, as applicable:

Silicon, max 0.20 0.20

5.1.1 Quantity, number of pieces or pounds,

Copper Remainder Remainder

5.1.2 Copper Alloy UNS No. designation (see 1.1),

5.1.3 Temper (see section 8)

5.1.4 Dimensions, including length if applicable. For tube

7. Chemical Composition

or pipe specify either OD/ID, OD/wall, or ID/wall.

7.1 The material shall conform to the chemical composition

5.1.5 How furnished: stock lengths with or without ends,

requirements in Table 1 for the copper alloy designated in the

specific lengths with or without ends,

ordering information.

5.1.6 ASTM designation and year of issue,

7.2 These composition limits do not preclude the presence

5.1.7 Special tests or exceptions, if any,

ofotherelements.Byagreementbetweenthemanufacturerand

5.1.8 Hardness tests, if required,

purchaser, limits may be established and analysis required for

5.1.9 Special tests such as tension test, if required,

unnamed elements

5.1.10 Special marking or packaging, if required,

7.3 For alloys in which copper is listed as “Remainder,”

5.1.11 Inspection, if required (see Specification B251),

copper is the difference between the sum of results of all

5.1.12 Certification, if required (see Specification B251),

elements determined and 100 %. When all elements in Table 1

5.1.13 Mill test report, if required (see Specification B251).

are determined, the sum of results shall be 99.5 % min.

5.2 When material is purchased for agencies of the U.S.

government, this shall be specified in the contract or purchase

8. Temper

order, and the material shall conform to the Supplementary

8.1 Tempers, as described in Classification B601, available

Requirements as defined in the current issue of Specification

B251. under this specification are: TB00 (solution treated (A)), TF00

(precipitation hardened (AT)), TD04 (solution heat-treated and

6. Materials and Manufacture

cold worked: hard (H)), and TH04 (hard and precipitation

heat-treated (HT)). These products meet property requirements

6.1 Materials:

in Table 2.

6.1.1 The material of manufacture shall be UNS Alloy No.

C17500 or C17510, cast and worked into tubular form, and of

9. Precipitation Heat Treatment

such purity and soundness as to be suitable for processing into

the products prescribed herein. 9.1 When material is purchased in the TB00 (A) or the

6.1.2 The tube shall have heat traceable identity. TD04 (H) tempers, the precipitation heat treatment is per-

6.2 Manufacture: formed by the purchaser.

6.2.1 The product shall be manufactured by a combination 9.2 Conformance to the TF00 (AT) and TH04 (HT) speci-

of hot working or cold working, or both; annealing; or fication limits shown in Table 2, for products supplied in the

precipitation heat treatment, or both, as to produce a uniform TB00 (A) or the TD04 (H) tempers, shall be determined by

wrought structure in the finished product, to meet the temper testing test specimens heat-treated at a uniform temperature of

specified. 850 to 900°F for the times shown in Table 3.

A

TABLE 2 Tensile Strength and Rockwell Hardness Requirements

Temper Designation As Supplied

Tensile Rockwell Electrical

Standard Former Strength Hardness, Conductivity

B C

Ksi (MPa ) B Scale IACS min, %

TB00 Solution heat-treated (A) 35-55 (240-380) 50 max 20

TD04 Solution heat-treated and 65-80 (450-550) 60-80 20

cold-worked hard (H)

After Precipitation Heat Treatment

D

TF00 Precipitation hardened (AT) 100-130 (690-895) 92-100 45

D

TH04 Hard and precipitation heat- 110-140 (760-965) 95-102 48

treated (HT)

A

These values apply to mill products. See Section 10 for exceptions in end products.

B

ksi = 1000 psi.

C

See Appendix.

D

The upper limits in the tensile strength column are for design guidance only.

B937 – 04

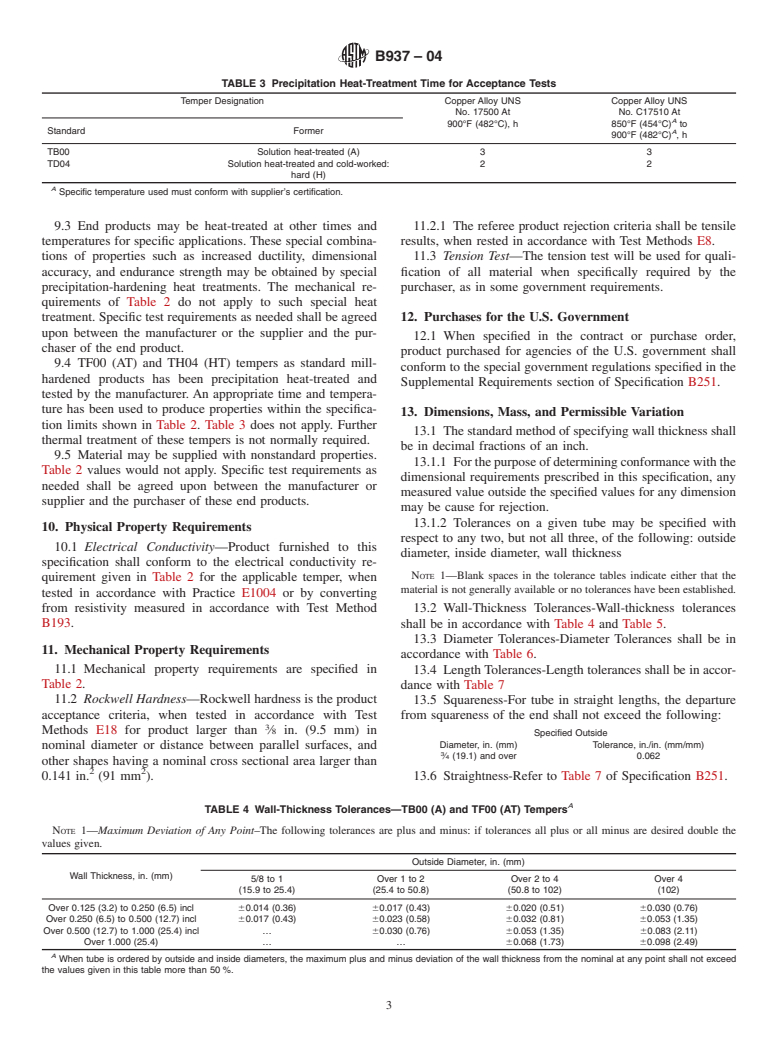

TABLE 3 Precipitation Heat-Treatment Time for Acceptance Tests

Temper Designation Copper Alloy UNS Copper Alloy UNS

No. 17500 At No. C17510 At

A

900°F (482°C), h 850°F (454°C) to

Standard Former

A

900°F (482°C) ,h

TB00 Solution heat-treated (A) 3 3

TD04 Solution heat-treated and cold-worked: 22

hard (H)

A

Specific temperature used must conform with supplier’s certification.

9.3 End products may be heat-treated at other times and 11.2.1 The referee product rejection criteria shall be tensile

temperatures for specific applications. These special combina- results, when rested in accordance with Test Methods E8.

tions of properties such as increased ductility, dimensional 11.3 Tension Test—The tension test will be used for quali-

accuracy, and endurance strength may be obtained by special fication of all material when specifically required by the

precipitation-hardening heat treatments. The mechanical re- purchaser, as in some government requirements.

quirements of Table 2 do not apply to such special heat

12. Purchases for the U.S. Government

treatment. Specific test requirements as needed shall be agreed

upon between the manufacturer or the supplier and the pur-

12.1 When specified in the contract or purchase order,

chaser of the end product.

product purchased for agencies of the U.S. government shall

9.4 TF00 (AT) and TH04 (HT) tempers as standard mill-

conform to the special government regulations specified in the

hardened products has been precipitation heat-treated and

Supplemental Requirements section of Specification B251.

tested by the manufacturer. An appropriate time and tempera-

tu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.