ASTM C1224-99

(Specification)Standard Specification for Reflective Insulation for Building Applications

Standard Specification for Reflective Insulation for Building Applications

SCOPE

1.1 This specification covers the general requirements and physical properties of reflective insulations for use in building applications. These insulation materials consist of one or more low emittance surfaces, such as metallic foil or metallic deposits, unmounted or mounted on substrates. Reflective insulations derive their thermal performance from surfaces with an emittance of 0.1 or less, facing enclosed air spaces.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1224 – 99

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Reflective Insulation for Building Applications

This standard is issued under the fixed designation C 1224; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 1371 Test Method for Determination of Emittance of

Materials Near Room Temperature Using Portable Emis-

1.1 This specification covers the general requirements and

someters

physical properties of reflective insulations for use in building

D 3310 Test Method for Determining Corrosivity of Adhe-

applications. These insulation materials consist of one or more

sive Materials

low emittance surfaces, such as metallic foil or metallic

E 84 Test Method for Surface Burning Characteristics of

deposits, unmounted or mounted on substrates. Reflective

Building Materials

insulations derive their thermal performance from surfaces

E 96 Test Methods for Water Vapor Transmission of Mate-

with an emittance of 0.1 or less, facing enclosed air spaces.

rials

1.2 The values stated in inch-pound units are to be regarded

2.2 Other Standard:

as the standard. The values given in parentheses are provided

TAPPI Standard T 512 om-86, Creasing of Flexible Pack-

for information only.

aging Material Paper Specimens for Testing

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions—Terminology C 168 shall apply to the

priate safety and health practices and determine the applica-

terms in this specification.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2.1 reflective insulation—thermal insulation consisting of

one or more low emittance surfaces, bounding one or more

2.1 ASTM Standards:

enclosed air spaces.

C 168 Terminology Relating to Thermal Insulating Materi-

als

4. Ordering Information

C 177 Test Method for Steady-State Heat Flux Measure-

4.1 Prior to purchase, for sampling and acceptance proce-

ments and Thermal Transmission Properties by Means of

2 dures, Criteria C 390 can be agreed upon between the pur-

the Guarded-Hot-Plate Apparatus

chaser and the manufacturer.

C 236 Test Method for Steady State Thermal Performance

2 4.2 Specify the required thermal resistance by the direction

of Building Assemblies by Means of a Guarded Hot Box

of the heat flow.

C 390 Criteria for Sampling and Acceptance of Preformed

2 4.3 Specify the width, depth, and total area to be insulated.

Thermal Insulation Lots

4.4 Specify special markings, if required.

C 518 Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of

5. Materials and Manufacture

the Heat Flow Meter Apparatus

5.1 Reflective insulation materials shall consist of low

C 727 Practice for Use and Installation of Reflective Insu-

2 emittance surface(s) in combination with substrates and adhe-

lation in Building Constructions

sives required to meet the specified thermal performance and

C 976 Test Method for Thermal Performance of Building

2 physical properties.

Assemblies by Means of a Calibrated Hot Box

C 1338 Test Method for Determining Fungi Resistance of

6. Physical Properties Requirements

Insulation Materials and Facings

6.1 Low emittance materials shall have an emittance of 0.1

C 1363 Test Method for the Thermal Performance of Build-

or less, as determined in accordance with Test Method C 1371.

ing Assemblies by Means of a Hot Box Apparatus

6.2 Water Vapor Transmission—If the reflective insulation

is to serve as a vapor retarder, the permeance of the material

This specification is under the jurisdiction of ASTM Committee C-16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.21 on

Reflective Insulation. Annual Book of ASTM Standards, Vol 15.06.

Current edition approved March 10, 1999. Published May 1999. Originally Annual Book of ASTM Standards, Vol 04.07.

published as C 1224–93. Last previous edition C 1224–97. Available from TAPPI, Technology Park/Atlanta, P.O. Box 105113, Atlanta,

Annual Book of ASTM Standards, Vol 04.06. GA 30348.

C 1224

shall not exceed 1 perm, as determined in accordance with Test 9. Test Methods

Methods E 96.

9.1 Thermal Performance—The thermal performance of

6.3 Multiple layer reflective insulations shall be designed to

reflective insulations shall be determined in accordance with

attain the intended separation of layers in normal application.

Test Methods C 236, C 976 or C 1363 using the following

Such multiple layer insulation shall form an attachment flange

criteria.

suitable for stapling, or other means of attachment.

9.1.1 In order to determine the thermal performance of the

6.4 Widths—Insulation shall be furnished in widths to fit

reflective insulation materials used in a test panel, a uniform

between framing members set at spacings standard in the

method of adjustment of the test panel results is needed.

construction industry, or as specifically agreed upon between

9.1.2 The test panel shall consist of wood framing members

the producer and the buyer.

sheathed with ⁄4 in. thick plywood on each side. The width and

6.5 Surface burning characteristics shall be determined in

depth of the cavities shall be representative of the installation

accordance with Test Method E 84, in a configuration consis-

for which the insulation product is intended. (See Sections 5

tent with the intended application.

and 7 of Test Method C 236 or Sections 3 and 6 of Test Method

6.6 Corrosivity—The laminates of the reflective insulation

C 976). The reflective insulation shall be installed in the test

shall be tested in accordance with Test Method D 3310.

panel according to the manufacturer’s specifications.

Evidence of corrosion shall be cause for rejection.

9.1.3 The testing of the reflective insulation shall be per-

6.7 Adhesive Performance:

formed at a cavity mean temperature of 75 6 4°F (24 6 2°C)

6.7.1 Bleeding—Adhesives when used in bonding shall

with a temperature difference across the insulated cavity of

show no sign of bleeding when tested in accordance with the

306 2°F (16.5 6 1°C).

test procedure in 9.2.1. Bleeding at cut edges may be disre-

9.1.3.1 To determine the cavity mean temperature and

garded. Bleeding or delamination, covering over 2 % of the

sample area, shall be cause for rejection. temperature difference, sufficient temperature instrumentation

shall be applied to the interior surfaces of the plywood

6.7.2 Pliability—Specimens tested in accordance with the

sheathing to measure the average temperature of these sur-

test procedure in 9.2.2 shall not show cracking or delamination.

faces. Recommended temperature sensor layouts for 8 ft by 8

6.8 Mold and Mildew— Resistance shall be tested in accor-

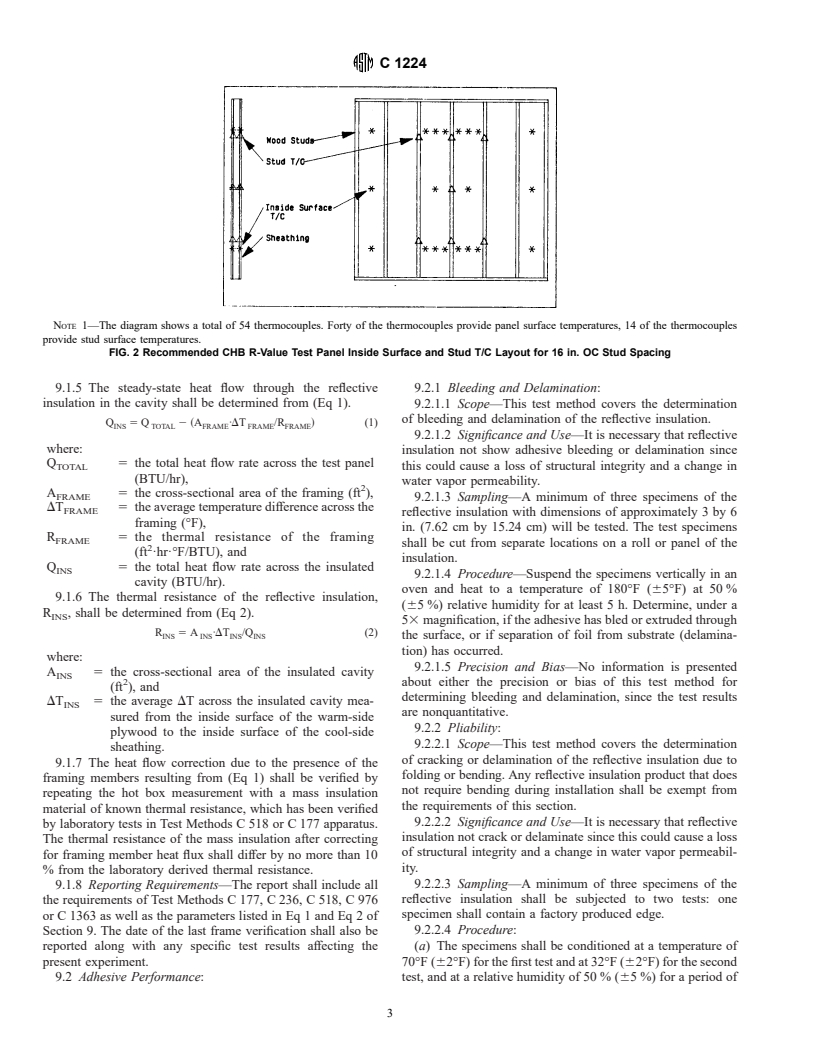

ft guarded and calibrated hot boxes are shown in Fig. 1 and Fig.

dance with Test Method C 1338. Use interpretation of results in

2, respectively.

7.2 of Test Method C 1338.

6.9 Thermal Resistance—Determine the thermal resistance

9.1.4 To determine the heatflow in the cavity area, the net

in accordance with procedures in 9.1. heat flow shall be adjusted to account for the heat flow through

the framing members. To perform this adjustment, the thermal

7. Workmanship, Finish, and Appearance

resistance of the framing material must be known to within

7.1 The insulation shall be manufactured, packaged, and 610 % and the average temperature difference across the

framing members shall be measured.

shipped in such a manner that, when received by the customer,

it shall be suitable for installation in accordance with Practice

9.1.4.1 A sufficient number of temperature sensors shall be

C 727.

installed to determine the average temperature difference

across the framing members. Recommended framing member

8. Sampling

temperature sensor layouts for 8 ft by 8 ft guarded and

8.1 Sampling shall be performed in accordance with Criteria calibrated hot boxes are shown in Fig. 1 and Fig. 2, respec-

C 390. tively.

NOTE 1—The diagram shows a total of 30 thermocouples. Eighteen of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.