ASTM D5222-16

(Specification)Standard Specification for High Fire-Point Mineral Electrical Insulating Oils

Standard Specification for High Fire-Point Mineral Electrical Insulating Oils

ABSTRACT

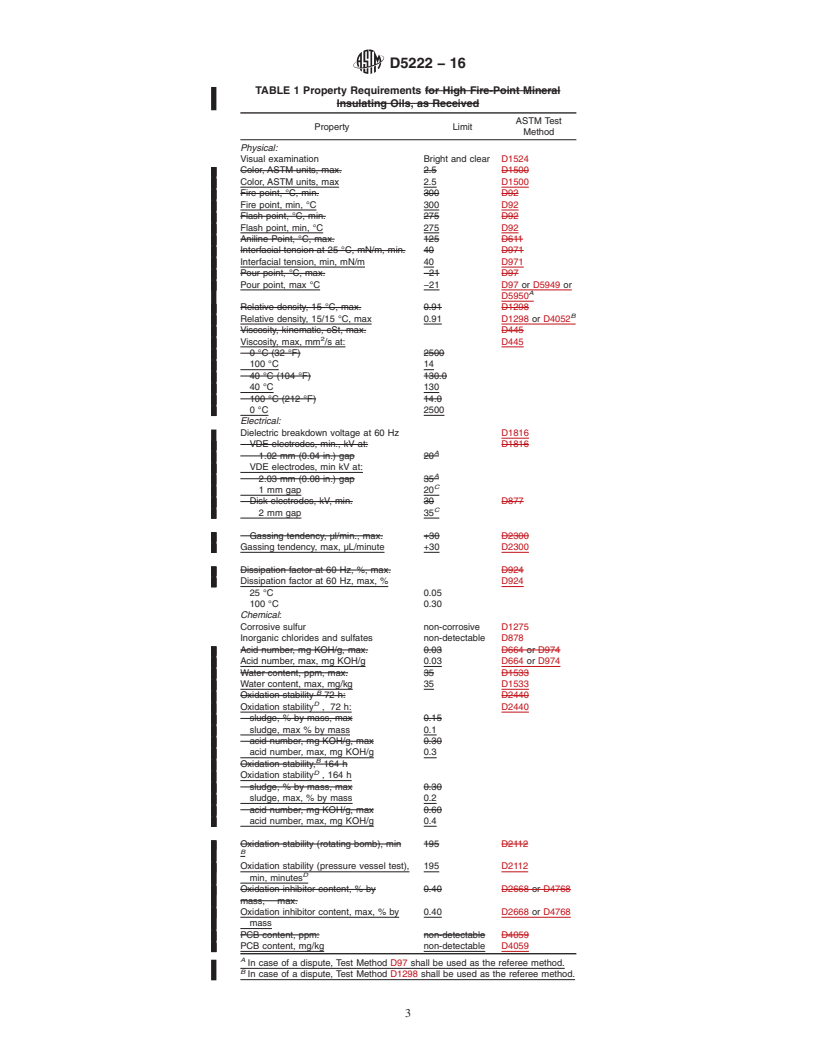

This specification describes a high fire-point mineral oil based electrical insulating fluid, for use as a dielectric and cooling medium in new and existing power and distribution electrical apparatuses, such as transformers and switchgear. The material discussed here is miscible with other petroleum based insulating oils, and may not be miscible with electrical insulating liquids of non-petroleum origin. The insulating oils shall be compatible with typical material of construction of existing apparatus and will satisfactorily maintain its functional characteristic in its application. This specification applies only to new insulating material oil as received prior to any processing. Sampled specimens shall undergo appropriate tests, and shall conform correspondingly to specified physical (appearance upon visual examination, color in ASTM units, fire point, flash point, aniline point, interfacial tension, pour point, relative density, and kinematic viscosity), electrical (dielectric breakdown voltage, gassing tendency, and dissipation factor), and chemical (corrosion behavior against sulfur, inorganic chlorides and sulfates content, acid number, water content, oxidation stability, oxidation inhibitor content, and PCB content) property requirements.

SCOPE

1.1 This specification describes a high fire-point mineral oil based insulating fluid, for use as a dielectric and cooling medium in new and existing power and distribution electrical apparatus, such as transformers and switchgear.

1.2 High fire-point insulating oil differs from conventional mineral insulating oil by possessing a fire-point of at least 300°C. High fire-point mineral insulating oils are also referred to as “less flammable” mineral insulating oils.This property is necessary in order to comply with certain application requirements of the National Electrical Code (Article 450-23) or other agencies. The material discussed in this specification is miscible with other petroleum based insulating oils. Mixing high fire-point liquids with lower fire point hydrocarbon insulating oils (for example, Specification D3487 mineral oil) may result in fire points of less than 300°C.

1.3 This specification is intended to define a high fire-point electrical mineral insulating oil that is compatible with typical material of construction of existing apparatus and will satisfactorily maintain its functional characteristic in its application in this application. The material described in this specification may not be miscible with electrical insulating liquids of non-petroleum origin. The user should contact the manufacturer of the high fire-point insulating oil for guidance in this respect.

1.4 This specification applies only to new insulating material oil as received prior to any processing. Information on in-service maintenance testing is available in appropriate guides.2 The user should contact the manufacturers of the equipment or oil if questions of recommended characteristics or maintenance procedures arise.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5222 − 16

Standard Specification for

1

High Fire-Point Mineral Electrical Insulating Oils

This standard is issued under the fixed designation D5222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 This specification describes a high fire-point mineral oil

2.1 ASTM Standards:

based insulating fluid, for use as a dielectric and cooling

D92 Test Method for Flash and Fire Points by Cleveland

medium in new and existing power and distribution electrical

Open Cup Tester

apparatus, such as transformers and switchgear.

D97 Test Method for Pour Point of Petroleum Products

D117 Guide for Sampling, Test Methods, and Specifications

1.2 High fire-point insulating oil differs from conventional

for Electrical Insulating Oils of Petroleum Origin

mineral insulating oil by possessing a fire-point of at least

D445 Test Method for Kinematic Viscosity of Transparent

300°C. High fire-point mineral insulating oils are also referred

and Opaque Liquids (and Calculation of Dynamic Viscos-

to as “less flammable” mineral insulating oils.This property is

ity)

necessary in order to comply with certain application require-

ments of the National Electrical Code (Article 450-23) or other D664 Test Method for Acid Number of Petroleum Products

agencies. The material discussed in this specification is mis- by Potentiometric Titration

cible with other petroleum based insulating oils. Mixing high

D878 Test Method for Inorganic Chlorides and Sulfates in

fire-point liquids with lower fire point hydrocarbon insulating

Insulating Oils (Withdrawn)

oils (for example, Specification D3487 mineral oil) may result

D923 Practices for Sampling Electrical Insulating Liquids

in fire points of less than 300°C.

D924 Test Method for Dissipation Factor (or Power Factor)

and Relative Permittivity (Dielectric Constant) of Electri-

1.3 This specification is intended to define a high fire-point

cal Insulating Liquids

electrical mineral insulating oil that is compatible with typical

D971 Test Method for Interfacial Tension of Oil Against

material of construction of existing apparatus and will satis-

Water by the Ring Method

factorily maintain its functional characteristic in its application

D974 Test Method for Acid and Base Number by Color-

in this application. The material described in this specification

Indicator Titration

may not be miscible with electrical insulating liquids of

D1275 Test Method for Corrosive Sulfur in Electrical Insu-

non-petroleum origin. The user should contact the manufac-

lating Liquids

turer of the high fire-point insulating oil for guidance in this

respect. D1298 Test Method for Density, Relative Density, or API

Gravity of Crude Petroleum and Liquid Petroleum Prod-

1.4 This specification applies only to new insulating mate-

ucts by Hydrometer Method

rial oil as received prior to any processing. Information on

D1500 Test Method for ASTM Color of Petroleum Products

in-service maintenance testing is available in appropriate

2 (ASTM Color Scale)

guides. The user should contact the manufacturers of the

D1524 Test Method for Visual Examination of Used Elec-

equipment or oil if questions of recommended characteristics

trical Insulating Liquids in the Field

or maintenance procedures arise.

D1533 Test Method for Water in Insulating Liquids by

1.5 The values stated in SI units are to be regarded as

Coulometric Karl Fischer Titration

standard. No other units of measurement are included in this

D1816 Test Method for Dielectric Breakdown Voltage of

standard.

Insulating Liquids Using VDE Electrodes

D2112 Test Method for Oxidation Stability of Inhibited

Mineral Insulating Oil by Pressure Vessel

1

This specification is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

mittee D27.01 on Mineral.

3

Current edition approved Nov. 1, 2016. Published December 2016. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1992. Last previous edition approved in 2008 as D5222–08. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D5222-16. Standards volume information, refer to the standard’s Document Summary page on

2

Refer to IEEE C57.121. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5222 − 16

TABLE 1 Property Requirements

D2300 Test Method for Gassing of Electrical Insulating

Liquids Under Electric

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5222 − 08 D5222 − 16

Standard Specification for

1

High Fire-Point Mineral Electrical Insulating Oils

This standard is issued under the fixed designation D5222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification describes a high fire-point mineral oil based insulating fluid, for use as a dielectric and cooling medium

in new and existing power and distribution electrical apparatus, such as transformers and switchgear.

1.2 High fire-point insulating oil differs from conventional mineral insulating oil by possessing a fire-point of at least 300°C.

High fire-point mineral insulating oils are also referred to as “less flammable” mineral insulating oils.This property is necessary

in order to comply with certain application requirements of the National Electrical Code (Article 450-23) or other agencies. The

material discussed in this specification is miscible with other petroleum based insulating oils. Mixing high fire-point liquids with

lower fire point hydrocarbon insulating oils (for example, Specification D3487 mineral oil) may result in fire points of less than

300°C.

1.3 This specification is intended to define a high fire-point electrical mineral insulating oil that is compatible with typical

material of construction of existing apparatus and will satisfactorily maintain its functional characteristic in its application in this

application. The material described in this specification may not be miscible with electrical insulating liquids of non-petroleum

origin. The user should contact the manufacturer of the high fire-point insulating oil for guidance in this respect.

1.4 This specification applies only to new insulating material oil as received prior to any processing. Information on in-service

2

maintenance testing is available in appropriate guides. The user should contact the manufacturers of the equipment or oil if

questions of recommended characteristics or maintenance procedures arise.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

2. Referenced Documents

3

2.1 ASTM Standards:

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

D97 Test Method for Pour Point of Petroleum Products

D117 Guide for Sampling, Test Methods, and Specifications for Electrical Insulating Oils of Petroleum Origin

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D611 Test Methods for Aniline Point and Mixed Aniline Point of Petroleum Products and Hydrocarbon Solvents

D664 Test Method for Acid Number of Petroleum Products by Potentiometric Titration

D877D878 Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using Disk ElectrodesInorganic Chlorides and

Sulfates in Insulating Oils (Withdrawn)

4

D878 (Withdrawn 2015)

D923 Practices for Sampling Electrical Insulating Liquids

D924 Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical

Insulating Liquids

D971 Test Method for Interfacial Tension of Oil Against Water by the Ring Method

D974 Test Method for Acid and Base Number by Color-Indicator Titration

D1275 Test Method for Corrosive Sulfur in Electrical Insulating Liquids

1

This specification is under the jurisdiction of ASTM Committee D27 on Electrical Insulating Liquids and Gases and is the direct responsibility of Subcommittee D27.01

on Mineral.

Current edition approved Jan. 1, 2008Nov. 1, 2016. Published February 2008December 2016. Originally approved in 1992. Last previous edition approved in 20002008

as D5222–00.–08. DOI: 10.1520/D5222-08.10.1520/D5222-16.

2

Refer to American National Standard C57.121 IEEE Guide for Acceptance and Maintenance of Less Flammable Hydrocarbon Fluid in Transformers.IEEE C57.121.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5222 − 16

D1298 Test Method for Density, Relative Density, or API

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.