ASTM E2176-01

(Test Method)Standard Test Method for Measuring the Coefficient of Retroreflected Luminance (RL) of Pavement Markings in a Standard Condition of Continuous Wetting

Standard Test Method for Measuring the Coefficient of Retroreflected Luminance (R<sub>L</sub>) of Pavement Markings in a Standard Condition of Continuous Wetting

SIGNIFICANCE AND USE

The quality of the pavement marking is determined by the coefficient of retroreflected luminance, RL, be it dry or wet, and depends on the materials used, age, and wear pattern. These conditions shall be observed and noted by the user.

Under identical conditions of headlight illumination and driver’viewing, larger values of RL correspond to higher levels of visual performance at corresponding geometry.

The pavement marking’measured performance in conditions of continuous wetting may be used to characterize the performance of the marking on the road as water is continuously falling on it and may be representative to a period of rain. This performance of the marking may be different than that experienced when the markings are just wet or damp.

Retroreflectivity of pavement (road) markings degrades with traffic wear and requires periodic measurement to ensure that sufficient line visibility is provided to drivers. For example see Specification D 6359 for dry reflectivity requirements.

For a given viewing distance, measurements of RL made with a retroreflectometer having a geometry corresponding to that viewing distance are a good indicator of the visual ranking of the material measured.

As specified by Test Method E 1710, the measurement geometry of the instrument is based on a viewing distance of 30 m, an eye height of 1.2 m and a headlight mounting height of 0.65 m (see Appendix X1).

Newly installed pavement markings may have a natural surface tension or release agents which prevent the wetting out of the product by rain/water. This phenomenon produces an interference when assessing the wet characteristics of a pavement marking. Attempt to measure markings with this surface “non-wetting” of the water may give higher values. This condition is short lived and markings that have been on the road for one month or more do not exhibit this non-wetting.

It shall be the responsibility of the user to employ an instrument having the specified observation and ent...

SCOPE

1.1 This test method covers the measurement of the wet retroreflective (RL) properties of horizontal pavement marking materials, such as traffic stripes and road surface symbols, using a portable or mobile retroreflectometer that can be placed on or before the road marking to measure the retroreflection at the prescribed geometry.

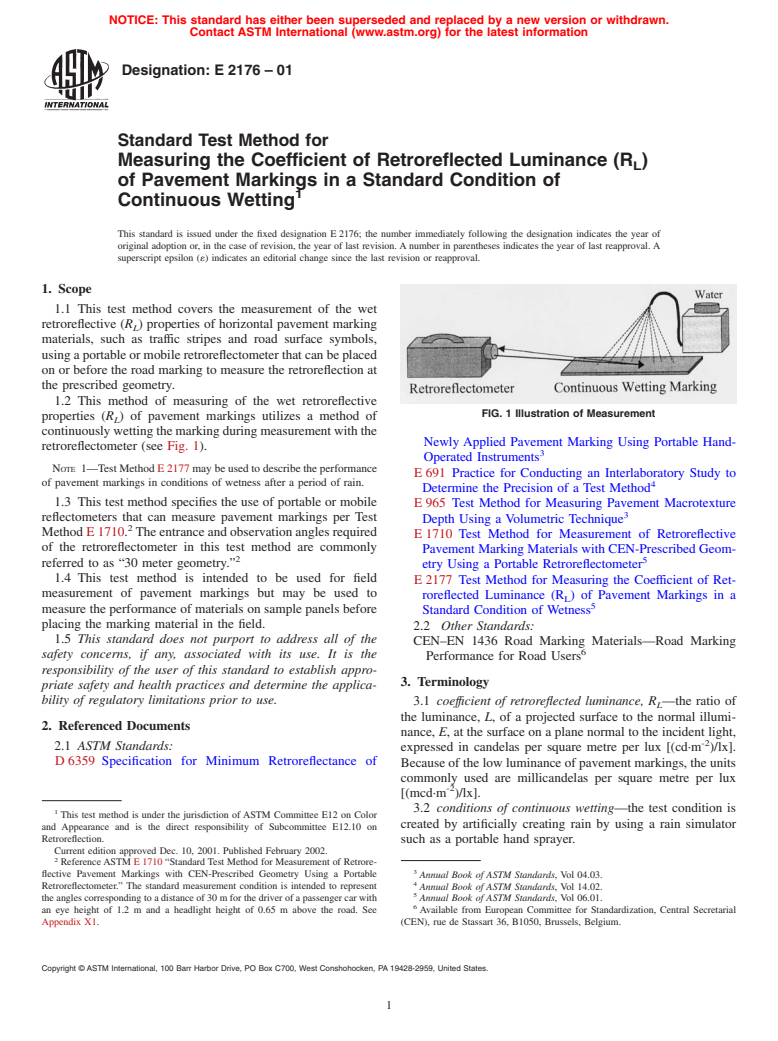

1.2 This method of measuring of the wet retroreflective properties (RL) of pavement markings utilizes a method of continuously wetting the marking during measurement with the retroreflectometer (see Fig 1).

Note 1—Test Method E 2177 may be used to describe the performance of pavement markings in conditions of wetness after a period of rain.

1.3 This test method specifies the use of portable or mobile reflectometers that can measure pavement markings per Test Method E 1710. The entrance and observation angles required of the retroreflectometer in this test method are commonly referred to as "30 meter geometry."

1.4 This test method is intended to be used for field measurement of pavement markings but may be used to measure the performance of materials on sample panels before placing the marking material in the field.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2176 – 01

Standard Test Method for

Measuring the Coefficient of Retroreflected Luminance (R )

L

of Pavement Markings in a Standard Condition of

Continuous Wetting

This standard is issued under the fixed designation E 2176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the wet

retroreflective (R ) properties of horizontal pavement marking

L

materials, such as traffic stripes and road surface symbols,

using a portable or mobile retroreflectometer that can be placed

on or before the road marking to measure the retroreflection at

the prescribed geometry.

1.2 This method of measuring of the wet retroreflective

FIG. 1 Illustration of Measurement

properties (R ) of pavement markings utilizes a method of

L

continuouslywettingthemarkingduringmeasurementwiththe

Newly Applied Pavement Marking Using Portable Hand-

retroreflectometer (see Fig. 1).

Operated Instruments

NOTE 1—Test Method E 2177 may be used to describe the performance

E 691 Practice for Conducting an Interlaboratory Study to

of pavement markings in conditions of wetness after a period of rain.

Determine the Precision of a Test Method

1.3 This test method specifies the use of portable or mobile

E 965 Test Method for Measuring Pavement Macrotexture

reflectometers that can measure pavement markings per Test

Depth Using a Volumetric Technique

Method E 1710. The entrance and observation angles required

E 1710 Test Method for Measurement of Retroreflective

of the retroreflectometer in this test method are commonly

Pavement Marking Materials with CEN-Prescribed Geom-

referred to as “30 meter geometry.”

etry Using a Portable Retroreflectometer

1.4 This test method is intended to be used for field

E 2177 Test Method for Measuring the Coefficient of Ret-

measurement of pavement markings but may be used to

roreflected Luminance (R ) of Pavement Markings in a

L

measure the performance of materials on sample panels before

Standard Condition of Wetness

placing the marking material in the field.

2.2 Other Standards:

1.5 This standard does not purport to address all of the

CEN–EN 1436 Road Marking Materials—Road Marking

safety concerns, if any, associated with its use. It is the

Performance for Road Users

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1 coeffıcient of retroreflected luminance, R —the ratio of

L

the luminance, L, of a projected surface to the normal illumi-

2. Referenced Documents

nance, E, at the surface on a plane normal to the incident light,

-2

2.1 ASTM Standards:

expressed in candelas per square metre per lux [(cd·m )/lx].

D 6359 Specification for Minimum Retroreflectance of

Because of the low luminance of pavement markings, the units

commonly used are millicandelas per square metre per lux

-2

[(mcd·m )/lx].

3.2 conditions of continuous wetting—the test condition is

This test method is under the jurisdiction of ASTM Committee E12 on Color

created by artificially creating rain by using a rain simulator

and Appearance and is the direct responsibility of Subcommittee E12.10 on

Retroreflection.

such as a portable hand sprayer.

Current edition approved Dec. 10, 2001. Published February 2002.

ReferenceASTM E 1710 “Standard Test Method for Measurement of Retrore-

flective Pavement Markings with CEN-Prescribed Geometry Using a Portable Annual Book of ASTM Standards, Vol 04.03.

Retroreflectometer.” The standard measurement condition is intended to represent Annual Book of ASTM Standards, Vol 14.02.

the angles corresponding to a distance of 30 m for the driver of a passenger car with Annual Book of ASTM Standards, Vol 06.01.

an eye height of 1.2 m and a headlight height of 0.65 m above the road. See Available from European Committee for Standardization, Central Secretarial

Appendix X1. (CEN), rue de Stassart 36, B1050, Brussels, Belgium.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2176–01

3.3 external beam retroreflectometers—retroreflectometers of the product by rain/water. This phenomenon produces an

that illuminate a measurement area outside of the instruments interference when assessing the wet characteristics of a pave-

body.

ment marking. Attempt to measure markings with this surface

3.4 internal beam retroreflectometers—retroreflectometers

“non-wetting” of the water may give higher values. This

that illuminate a measurement area inside of the instruments

condition is short lived and markings that have been on the

body.

road for one month or more do not exhibit this non-wetting.

3.5 mobile retroreflectometer—a retroreflectometer that has

4.8 It shall be the responsibility of the user to employ an

been mounted to a vehicle for purposes of taking measure-

instrument having the specified observation and entrance

ments while the vehicle is moving.

angles.

3.6 portable retroreflectometer—an instrument that can be

used in the field or laboratory for measuring the coefficient of

5. Apparatus

retroreflected luminance, R .

L

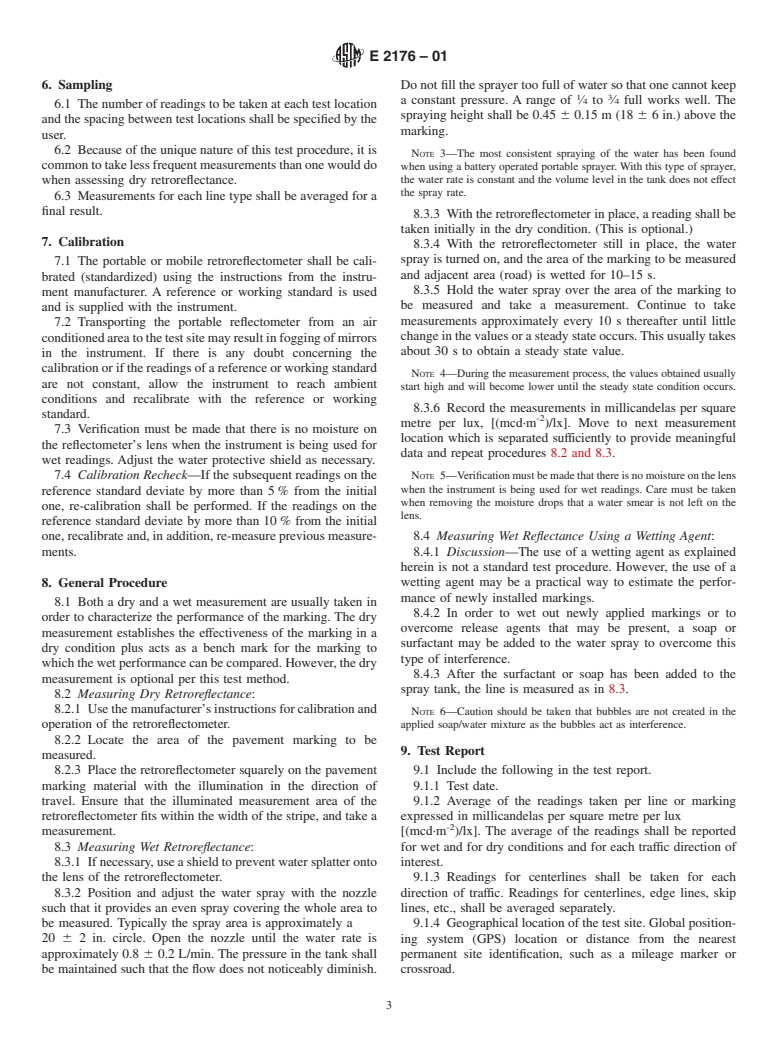

3.7 R —The retroreflectance value, R , obtained while 5.1 Retroreflectometer—Portable or Mobile:

L-Rain L

the marking is being continuously wetted during the measure-

5.1.1 The retroreflectometer shall be an external beam

ment. See graph (Fig. 2). The value recorded is the average of

instrument and shall be designed and constructed so that stray

two to three readings in the steady state area.

light will not affect the reading.

5.1.2 The retroreflectometer shall meet the requirements of

4. Significance and Use

Test Method E 1710.

4.1 The quality of the pavement marking is determined by

5.2 Retroreflectometer Setup—Rain/Water Shield:

the coefficient of retroreflected luminance, R , be it dry or wet,

L

5.2.1 The retroreflectometer, if necessary, shall be modified

and depends on the materials used, age, and wear pattern.

with a rain/water shield to protect its lens from splattering

These conditions shall be observed and noted by the user.

rain/water during wet measurement.

4.2 Under identical conditions of headlight illumination and

driver’s viewing, larger values of R correspond to higher

5.2.2 Adjust the shield such that it does not block the

L

levels of visual performance at corresponding geometry. projected light and diminish readings. Determine area of

4.3 The pavement marking’s measured performance in con-

marking being illuminated with the projected light. Adjust

ditions of continuous wetting may be used to characterize the

shield so that it does not cover any of this area and thus prevent

performance of the marking on the road as water is continu-

complete wetting.

ouslyfallingonitandmayberepresentativetoaperiodofrain.

5.3 Rain Simulator (Water Sprayer):

This performance of the marking may be different than that

5.3.1 The rain maker (simulator) shall bea8L(2 gal)

experienced when the markings are just wet or damp.

minimum capacity, adjustable nozzle garden sprayer. The rate

4.4 Retroreflectivity of pavement (road) markings degrades

of water spray should be approximately 0.8 L/min. A battery

with traffic wear and requires periodic measurement to ensure

operated sprayer performs the best since the battery allows a

that sufficient line visibility is provided to drivers. For example

constant rate/volume of water spray.

see Specification D 6359 for dry reflectivity requirements.

5.3.2 Clean tap water shall be used.

4.5 For a given viewing distance, measurements of R made

L

with a retroreflectometer having a geometry corresponding to

5.4 Wetting Agent:

that viewing distance are a good indicator of the visual ranking

5.4.1 Discussion—The use of a wetting agent as explained

of the material measured.

herein is not a standard test procedure. However, the use of a

4.6 As specified by Test Method E 1710, the measurement

wetting agent may be a practical way to estimate the perfor-

geometry of the instrument is based on a viewing distance of

mance of newly installed markings.

30 m, an eye height of 1.2 m and a headlight mounting height

5.4.2 In that newly installed pavement markings may have a

of 0.65 m (see Appendix X1).

natural surface tension or release agents which prevent the

4.7 Newly installed pavement markings may have a natural

wettingoutoftheproductbyrain/water,apracticalmethodcan

surface tension or release agents which prevent the wetting out

be used to estimate the performance of newly placed markings.

The addition of a small amount of soap or surfactant to the

water in the sprayer eliminates this interference without

damage to the installed line or sample panel. Recommended

solution mixtures are: (a) 0.10 % by volume liquid soap

solution; and (b) a fluorocarbon surfactant solution, 1 mL in

8L.

NOTE 2—Pavement markings that have been installed on the road for

one month prior to testing usually do not exhibit this non-wetting

phenomena. When testing new markings using the soap/surfactant agents

above, visually examine the appearance of the marking as the water is

applied. The water should not form small beads of water on top of the

marking. If small beads are formed, increase the soap/surfactant level

FIG. 2 Definition of R slightly and retry.

L-Rain

E2176–01

6. Sampling Do not fill the sprayer too full of water so that one cannot keep

1 3

a constant pressure. A range of ⁄4 to ⁄4 full works well. The

6.1 The number of readings to be taken at each test location

spraying height shall be 0.45 6 0.15 m (18 6 6 in.) above the

and the spacing between test locations shall be specified by the

marking.

user.

6.2 Because of the unique nature of this test procedure, it is

NOTE 3—The most consistent spraying of the water has been found

commontotakelessfrequentmeasurementsthanonewoulddo when using a battery operated portable sprayer. With this type of sprayer,

the water rate is constant and the volume level in the tank does not effect

when assessing dry retroreflectance.

the spray rate.

6.3 Measurements for each line type shall be averaged for a

final result.

8.3.3 With the retroreflectometer in place, a reading shall be

taken initially in the dry condition. (This is optional.)

7. Calibration

8.3.4 With the retroreflectometer still in place, the water

spray is turned on, and the area of the marking to be measured

7.1 The portable or mobile retroreflectometer shall be cali-

and adjacent area (road) is wett

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.