ASTM D4395-84(1998)

(Test Method)Standard Test Method for Determining the In Situ Modulus of Deformation of Rock Mass Using the Flexible Plate Loading Method

Standard Test Method for Determining the In Situ Modulus of Deformation of Rock Mass Using the Flexible Plate Loading Method

SCOPE

1.1 This test method covers the preparation, equipment, test procedure, and data reduction for determining in situ modulus of deformation of a rock mass using the flexible plate loading method.

1.2 This test method is designed to be conducted in an adit or small underground chamber; however, with suitable modifications it could be conducted at the surface.

1.3 This test method is usually conducted parallel or perpendicular to the anticipated axis of thrust, as dictated by the design load.

1.4 Time-dependent tests can be performed but are to be reported in another standard.

1.5 The values stated in inch-pound units are to be regarded as the standard.

1.6 The references appended to this standard contain further information on this test method.

1.7 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precaution statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4395 – 84 (Reapproved 1998)

Standard Test Method for

Determining the In Situ Modulus of Deformation of Rock

Mass Using the Flexible Plate Loading Method

This standard is issued under the fixed designation D 4395; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 flexible plate—theoretically, a plate having no stiff-

ness.

1.1 This test method covers the preparation, equipment, test

3.1.3 load—total force acting on the rock face.

procedure, and data reduction for determining in situ modulus

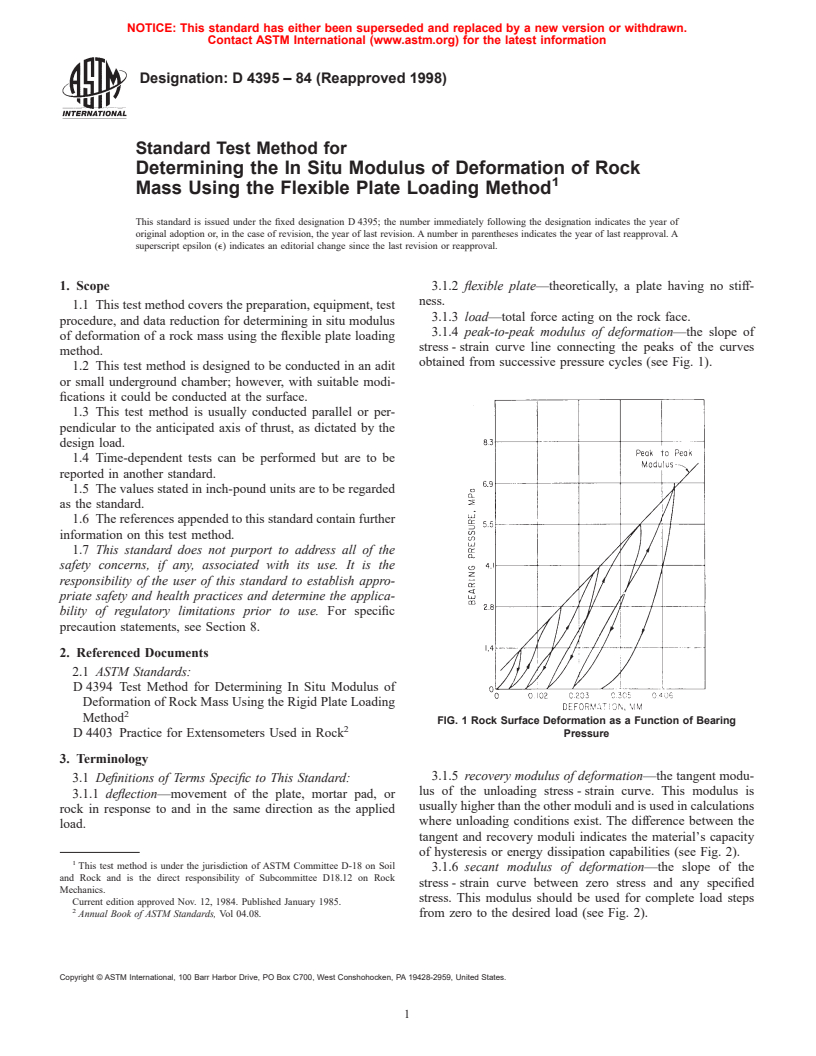

3.1.4 peak-to-peak modulus of deformation—the slope of

of deformation of a rock mass using the flexible plate loading

stress - strain curve line connecting the peaks of the curves

method.

obtained from successive pressure cycles (see Fig. 1).

1.2 This test method is designed to be conducted in an adit

or small underground chamber; however, with suitable modi-

fications it could be conducted at the surface.

1.3 This test method is usually conducted parallel or per-

pendicular to the anticipated axis of thrust, as dictated by the

design load.

1.4 Time-dependent tests can be performed but are to be

reported in another standard.

1.5 The values stated in inch-pound units are to be regarded

as the standard.

1.6 The references appended to this standard contain further

information on this test method.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

precaution statements, see Section 8.

2. Referenced Documents

2.1 ASTM Standards:

D 4394 Test Method for Determining In Situ Modulus of

Deformation of Rock Mass Using the Rigid Plate Loading

Method

FIG. 1 Rock Surface Deformation as a Function of Bearing

D 4403 Practice for Extensometers Used in Rock Pressure

3. Terminology

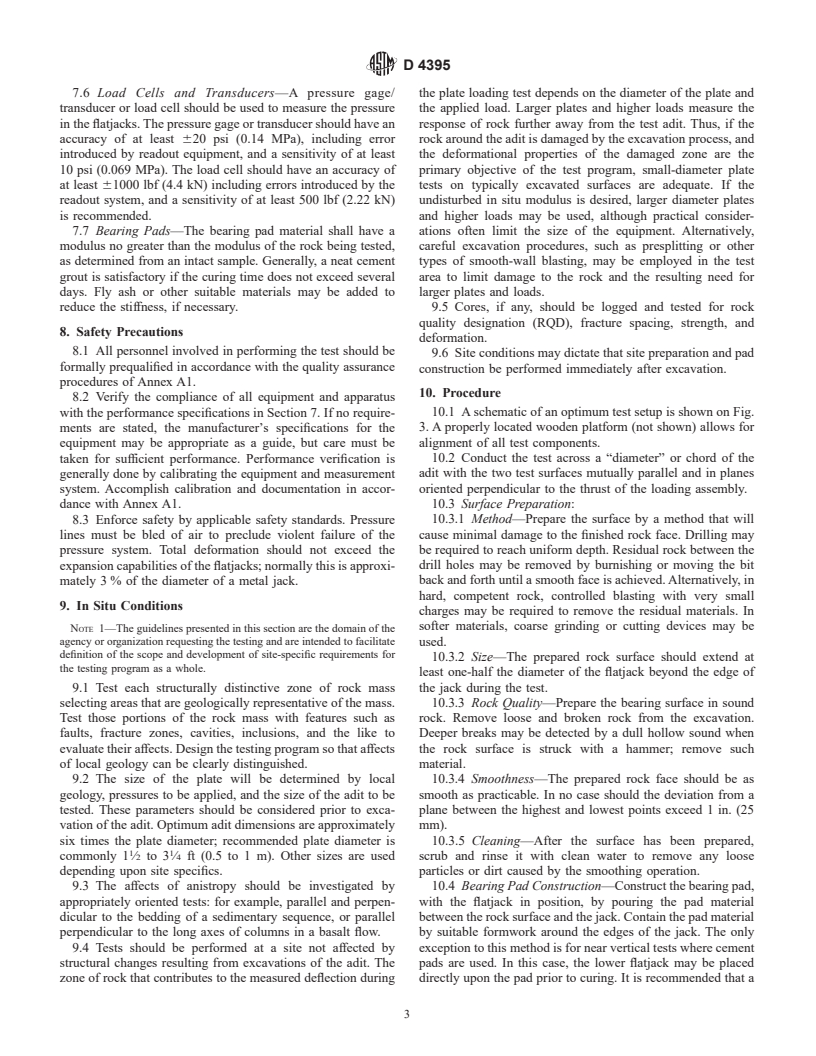

3.1.5 recovery modulus of deformation—the tangent modu-

3.1 Definitions of Terms Specific to This Standard:

lus of the unloading stress - strain curve. This modulus is

3.1.1 deflection—movement of the plate, mortar pad, or

usually higher than the other moduli and is used in calculations

rock in response to and in the same direction as the applied

where unloading conditions exist. The difference between the

load.

tangent and recovery moduli indicates the material’s capacity

of hysteresis or energy dissipation capabilities (see Fig. 2).

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

3.1.6 secant modulus of deformation—the slope of the

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

stress - strain curve between zero stress and any specified

Mechanics.

stress. This modulus should be used for complete load steps

Current edition approved Nov. 12, 1984. Published January 1985.

Annual Book of ASTM Standards, Vol 04.08. from zero to the desired load (see Fig. 2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4395

6.2 Measurement of the deflection within the rock mass can

utilize a finite gage length to reflect the average rock mass

deformation properties between the measuring points. This

approach entails three drawbacks, however. First, the rock

mass is tested at very low stress levels unless the measurement

points are very close to the rock surface and because of this, the

same problems as with surface measurements occur. Tests at

low stress levels may give unrealistical modulus values be-

cause microfractures, joints, and other discontinuities in the

FIG. 2 Relationship Between Tangent, Secant, and Recovery

rock are open. Secondly, the disturbance caused by implanting

Moduli

the deflection transducer in the rock mass is difficult to

evaluate. The techniques in this test method are designed to

produce minimal disturbance. Thirdly, in rocks with very high

3.1.7 tangent modulus of deformation—the slope of the

modulus, the accuracy of the instruments may be insufficient to

stress - strain curve obtained over the segment of the loading

provide reliable results.

curve judged as the most representative of elastic response by

6.3 Time-rate of loading has negligible influence on the

the investigator. It neglects the end effects of the curve and is

modulus.

better suited to small stress changes. The ratio between the

6.4 Calculations neglect the stress history of the rock.

secant modulus and the tangent modulus can be used as a

6.5 This test method is insensitive to Poisson’s ratio, which

means of measuring the stress damage of the material (see Fig.

must be assumed or obtained from laboratory testing.

2).

7. Apparatus

4. Summary of Test Method

7.1 Equipment necessary for accomplishing this test method

4.1 Areas on two opposing parallel faces of a test adit are

includes items for: preparing the test site, drilling and logging

flattened and smoothed.

the instrumentation holes, measuring the rock deformation,

4.2 A hydraulic loading system consisting of flatjacks,

applying and restraining test loads, recording test data, and

reaction members, and associated hardware is constructed

transporting various components to the test site.

between the two faces and a mortar pad is placed on each face.

7.2 Test Site Preparation Equipment— This should include

4.3 If deflection is to be measured within the rock mass,

an assortment of excavation tools, such as drills and chipping

install extensometer instruments in the rock in accordance with

hammers. Blasting should not be allowed during final prepa-

Practice D 4403.

ration of the test site. The drill for the instrumentation holes

4.4 The two faces are loaded and unloaded incrementally

should, if possible, have the capability of retrieving cores from

and the deformations of the rock mass at the surfaces and, if

depths of at least 30 ft (10 m).

desired, within the rock, are measured after each increment.

7.3 Borehole Viewing Device—Some type of device is

The modulus of deformation is then calculated.

desirable for examination of the instrumentation holes to

compare and verify geologic features observed in the core if

5. Significance and Use

core recovery is poor or if it is not feasible to retrieve oriented

5.1 Results of this type of test method are used to predict

cores.

displacements in rock mass caused by loads from a structure or

7.4 Deformation Measuring Instruments— Instruments for

from underground construction. It is one of several tests that

measuring deformations should include a reliable multiple

should be performed. The resulting in-situ modulus is com-

position borehole extensometer (MPBX) for each instrumen-

monly less than the elastic modulus determined in the labora-

tation hole and a tunnel diameter gage. For surface measure-

tory.

ments, dial gages, or linear variable differential transformers

5.2 The modulus is determined using an elastic solution for

(LVDTs) are generally used. An accuracy of at least6 0.0001

a uniformly distributed load (uniform stress) over a circular

in. (0.0025 mm), including the error of the readout equipment,

area acting on a semi-infinite elastic medium.

and a sensitivity of at least 0.00005 in. (0.0013 mm) is

5.3 This test method is normally performed at ambient

recommended. Errors in excess of 0.0004 in. (0.01 mm) can

temperature, but equipment can be modified or substituted for

invalidate test results when the modulus of rock mass exceeds

6 4

operations at other temperatures.

5 3 10 psi (3.5 3 10 MPa).

7.5 Loading Equipment—The loading equipment includes

6. Interferences

the device for applying the load and the reaction members

6.1 The rock under the loaded area is generally not homo- (usually thick-walled aluminum or steel pipes) which transmit

geneous, as assumed in theory. Rock will respond to the load the load. Flatjacks at each rock face should be used to apply the

according to its local deformational characteristics. Therefore, load and should have sufficient range to allow for deflection of

deflection measurements at discrete points on the rock surface the rock and maintain pressure to within 3 %. They should be

tend to be heavily influenced by the deformational character- constructed so that the two main plates move apart in a parallel

istics of the rock mass at that location and may give results that manner over the usable portion of the range. A spherical

are unrepresentative of the rock mass. The use of the average bearing of suitable capacity should be incorporated in the

plate deflection will mitigate this problem. reaction members.

D 4395

7.6 Load Cells and Transducers—A pressure gage/ the plate loading test depends on the diameter of the plate and

transducer or load cell should be used to measure the pressure the applied load. Larger plates and higher loads measure the

in the flatjacks. The pressure gage or transducer should have an response of rock further away from the test adit. Thus, if the

accuracy of at least 620 psi (0.14 MPa), including error rock around the adit is damaged by the excavation process, and

introduced by readout equipment, and a sensitivity of at least the deformational properties of the damaged zone are the

10 psi (0.069 MPa). The load cell should have an accuracy of primary objective of the test program, small-diameter plate

at least 61000 lbf (4.4 kN) including errors introduced by the tests on typically excavated surfaces are adequate. If the

readout system, and a sensitivity of at least 500 lbf (2.22 kN) undisturbed in situ modulus is desired, larger diameter plates

is recommended. and higher loads may be used, although practical consider-

7.7 Bearing Pads—The bearing pad material shall have a ations often limit the size of the equipment. Alternatively,

modulus no greater than the modulus of the rock being tested, careful excavation procedures, such as presplitting or other

as determined from an intact sample. Generally, a neat cement types of smooth-wall blasting, may be employed in the test

grout is satisfactory if the curing time does not exceed several area to limit damage to the rock and the resulting need for

days. Fly ash or other suitable materials may be added to larger plates and loads.

reduce the stiffness, if necessary. 9.5 Cores, if any, should be logged and tested for rock

quality designation (RQD), fracture spacing, strength, and

8. Safety Precautions

deformation.

8.1 All personnel involved in performing the test should be

9.6 Site conditions may dictate that site preparation and pad

formally prequalified in accordance with the quality assurance

construction be performed immediately after excavation.

procedures of Annex A1.

10. Procedure

8.2 Verify the compliance of all equipment and apparatus

with the performance specifications in Section 7. If no require- 10.1 A schematic of an optimum test setup is shown on Fig.

ments are stated, the manufacturer’s specifications for the 3. A properly located wooden platform (not shown) allows for

equipment may be appropriate as a guide, but care must be alignment of all test components.

taken for sufficient performance. Performance verification is 10.2 Conduct the test across a “diameter” or chord of the

generally done by calibrating the equipment and measurement adit with the two test surfaces mutually parallel and in planes

system. Accomplish calibration and documentation in accor- oriented perpendicular to the thrust of the loading assembly.

10.3 Surface Preparation:

dance with Annex A1.

8.3 Enforce safety by applicable safety standards. Pressure 10.3.1 Method—Prepare the surface by a method that will

cause minimal damage to the finished rock face. Drilling may

lines must be bled of air to preclude violent failure of the

pressure system. Total deformation should not exceed the be required to reach uniform depth. Residual rock between the

drill holes may be removed by burnishing or moving the bit

expansion capabilities of the flatjacks; normally this is approxi-

mately 3 % of the diameter of a metal jack. back and forth until a smooth face is achieved. Alternatively, in

hard, competent rock, controlled blasting with very small

9. In Situ Conditions

charges may be required to remove the residual materials. In

softer materials, coarse grinding or cutting devices may be

NOTE 1—The guidelines presented in this section are the domain of the

agency or organization requesting the testing and are intended to facilitate

used.

definition of the scope and development of site-specific requirements for

10.3.2 Size—The prepared rock surface should extend at

the testing program as a whole.

least one-half the diameter of the flatjack beyond the edge of

9.1 Test each structurally distinctive zone of rock mass the jack during the test.

selecting areas that are geologically representative of the mass. 10.3.3 Rock Quality—Prepare the bearing surface in sound

Test those portions of the rock mass with features such as rock. Remove loose and broken rock from the excavation.

faults, fracture zones, cavities, inclusions, and the like to Deeper breaks may be detected by a dull hollow sound when

evaluate their affects. Design the testing program so that affects the rock surface is struck with a hammer; remove such

of local geology can be clearly distinguished. material.

9.2 The size of the plate will be determined by local 10.3.4 Smoothness—The prepared rock face should be as

geology, pressures to be applied, and the size of the adit to be smooth as practicable. In no case should the deviation from a

tested. These parameters should be considered prior to exca- plane between the highest and lowest points exceed 1 in. (25

vation of the adit. Optimum adit dimensions are approximately mm).

six times the plate diameter; recommended plate diameter is 10.3.5 Cleaning—After the surface has been prepared,

1 1

commonly 1 ⁄2 to 3 ⁄4 ft (0.5 to 1 m). Other sizes are used scrub and rinse it with clean water to remove any loose

depending upon site specifics. particles or dirt caused by the smoothing operation.

9.3 The affects of anistropy should be investigated by 10.4 Bearing Pad Construction—Construct the bearing pad,

appropriately oriented tests: for example, parallel and perpen- with the flatjack in position, by pouring the pad material

dicular to the bedding of a sedimentary sequence, or parallel between the rock surface and the jack. Contain the pad material

perpendicular to the long axes of columns in a basalt flow. by suitable formwork aroun

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.