ASTM D5731-95

(Test Method)Standard Test Method for Determination of the Point Load Strength Index of Rock

Standard Test Method for Determination of the Point Load Strength Index of Rock

SCOPE

1.1 This test method covers the guidelines, requirements, and procedures for determining the point load strength index of rock. Specimens in the form of rock cores, blocks, or irregular lumps can be tested by this test method. This test method can be performed in the field or laboratory because the testing machine is portable. This is an index test and is intended to be used to classify and characterize rock.

1.2 This test method applies to hard rock (compressive strength over 15 MPa (2200 psi)).

1.3 The values stated in the SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5731 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of the Point Load Strength Index of Rock

This standard is issued under the fixed designation D 5731; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope occurs by splitting the specimen. The concentrated load is

applied through coaxial, truncated conical platens. The failure

1.1 This test method covers the guidelines, requirements,

load is used to calculate the point load strength index and to

and procedures for determining the point load strength index of

estimate the uniaxial compressive strength.

rock. Specimens in the form of rock cores, blocks, or irregular

lumps can be tested by this test method. This test method can

5. Significance and Use

be performed in the field or laboratory because the testing

5.1 The uniaxial compression test (see Test Method D 2938)

machine is portable. This is an index test and is intended to be

is used to determine compressive strength of rock specimens,

used to classify and characterize rock.

but it is a time-consuming and expensive test that requires

1.2 This test method applies to hard rock (compressive

specimen preparation. When extensive testing is required for

strength over 15 MPa (2200 psi)).

preliminary and reconnaissance information, alternative tests

1.3 The values stated in the SI units are to be regarded as

such as the point load test can be used in the field to reduce the

standard.

time and cost of compressive strength tests.

1.4 This standard does not purport to address all of the

5.2 The point load strength test is used as an index test for

safety concerns, if any, associated with its use. It is the

strength classification of rock materials. The test results should

responsibility of the user of this standard to establish appro-

not be used for design or analytical purposes.

priate safety and health practices and determine the applica-

5.3 This test method is performed to determine the point

bility of regulatory limitations prior to use.

load strength index (I (50)) of rock specimens, and the point

s

2. Referenced Documents load strength anisotropy index (I (50)) that is the ratio of point

a

load strengths on different axes that result in the greatest and

2.1 ASTM Standards:

least values.

D 653 Terminology Relating to Soil, Rock, and Contained

5.4 Rock specimens in the form of either core (the diametral

Fluids

and axial tests), cut blocks (the block test), or irregular lumps

D 2216 Test Method for Laboratory Determination of Water

(the irregular lump test) are tested by application of concen-

(Moisture) Content of Soil and Rock

trated load through a pair of truncated, conical platens. Little or

D 2938 Test Method for Unconfined Compressive Strength

no specimen preparation is required.

of Intact Rock Core Specimens

6. Apparatus

3. Terminology

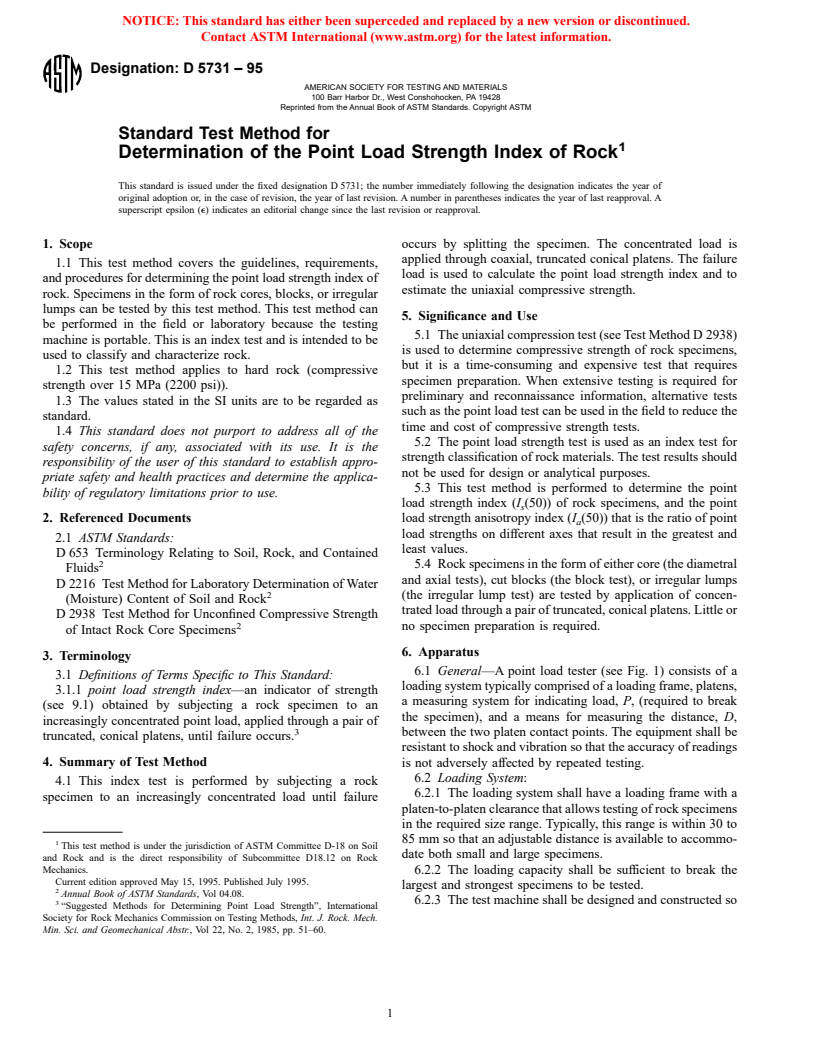

6.1 General—A point load tester (see Fig. 1) consists of a

3.1 Definitions of Terms Specific to This Standard:

loading system typically comprised of a loading frame, platens,

3.1.1 point load strength index—an indicator of strength

a measuring system for indicating load, P, (required to break

(see 9.1) obtained by subjecting a rock specimen to an

the specimen), and a means for measuring the distance, D,

increasingly concentrated point load, applied through a pair of

between the two platen contact points. The equipment shall be

truncated, conical platens, until failure occurs.

resistant to shock and vibration so that the accuracy of readings

4. Summary of Test Method is not adversely affected by repeated testing.

6.2 Loading System:

4.1 This index test is performed by subjecting a rock

6.2.1 The loading system shall have a loading frame with a

specimen to an increasingly concentrated load until failure

platen-to-platen clearance that allows testing of rock specimens

in the required size range. Typically, this range is within 30 to

85 mm so that an adjustable distance is available to accommo-

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

date both small and large specimens.

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

Mechanics.

6.2.2 The loading capacity shall be sufficient to break the

Current edition approved May 15, 1995. Published July 1995.

largest and strongest specimens to be tested.

Annual Book of ASTM Standards, Vol 04.08.

3 6.2.3 The test machine shall be designed and constructed so

“Suggested Methods for Determining Point Load Strength”, International

Society for Rock Mechanics Commission on Testing Methods, Int. J. Rock. Mech.

Min. Sci. and Geomechanical Abstr., Vol 22, No. 2, 1985, pp. 51–60.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5731

6.3.3 Failure is often sudden and a peak load indicator is

required so the failure load can be recorded after each test.

6.3.4 The system should be capable of using interchange-

able measuring devices in order to be consistent with the

estimated strength of rock (point load strength of rock is

usually an order of magnitude lower than the compressive

strength of rock).

6.4 Distance Measuring System:

6.4.1 The distance measuring system, a vernier direct read-

ing scale, should connect to the loading frame for measuring

the distance, D, between specimen-platen contact points and

conform to requirements 6.4.2 and 6.4.3.

6.4.2 Measurements of D shall be to an accuracy of 62%

or better of distance between contact points, irrespective of the

size and strength of specimen that is tested.

6.4.3 The measuring system shall allow a check of the“ zero

displacement” value when the two platens are in contact and

should include a zero adjustment.

6.4.4 An instrument such as a caliper or a steel rule is

required to measure the width, W, (with an accuracy of 65%)

of specimens for all but the diametral test.

6.5 Miscellaneous Items—Diamond saw, chisels, towels,

FIG. 1 An Example of a Loading System (The Point Load

marking pens, and plotting paper.

Strength Index Test)

7. Test Specimens

that it does not permanently distort during repeated applica-

7.1 Sampling—Rock samples are grouped on the basis of

tions of the maximum test load, and so that the platens remain

both rock type and estimated strength. When testing core or

coaxial within 60.2 mm throughout testing. No spherical seat

block specimens at least ten specimens are selected. When

or other nonrigid component is permitted in the loading

testing irregular-shaped specimens obtained by other means at

system. Loading system rigidity is essential to avoid slippage

least 20 specimens are selected. Specimens in the form of core

when specimens of irregular geometry are tested.

are preferred for a more precise classification.

6.2.4 Truncated, conical platens, as shown on Fig. 2, are to

7.2 Dimensions—The specimen’s external dimensions shall

be used. The 60° cone and 5-mm radius spherical platen tip

not be less than 30 mm and not more than 85 mm with the

shall meet tangentially. The platens shall be of hard material

preferred dimension about 50 mm.

(Rockwell 58 HRC) such as tungsten carbide or hardened steel

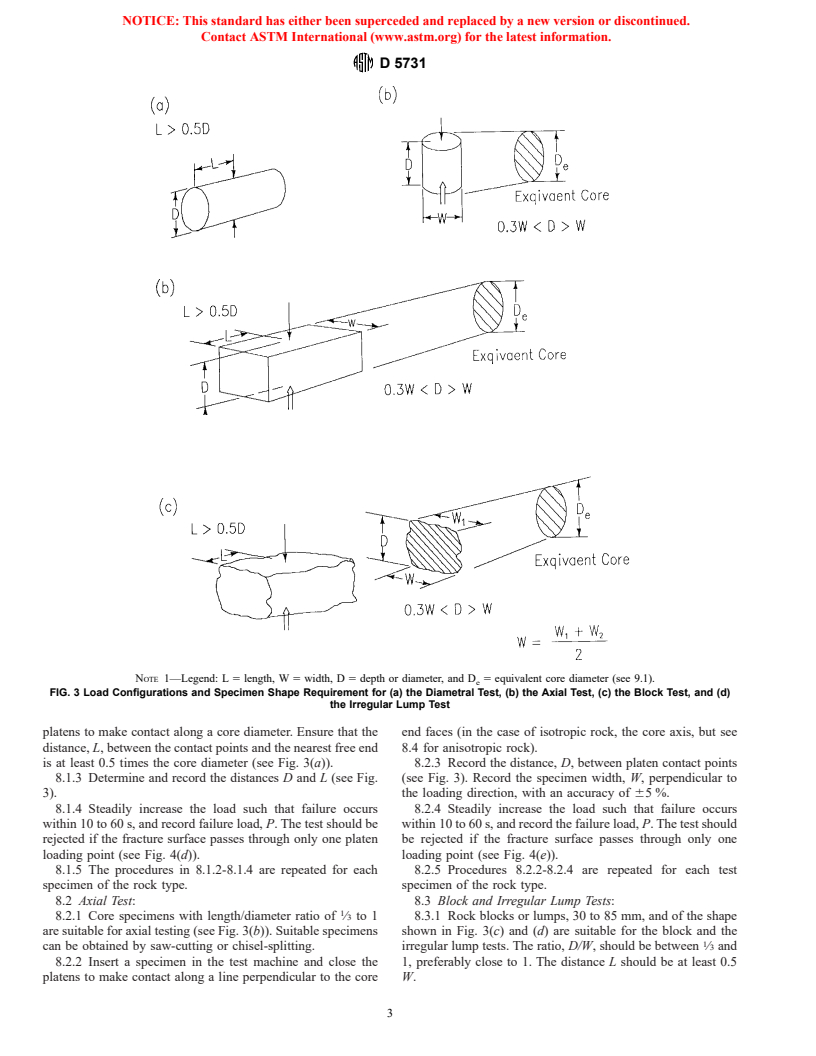

7.3 Size and Shape—The size and shape requirements for

so they remain undamaged during testing.

diametral, axial, block, or irregular lump testing shall conform

6.3 Load Measuring System:

with the recommendations shown on Fig. 3. The sides of the

6.3.1 A load measuring system, for example a load cell or a

specimens shall be free from abrupt irregularities that can

hydraulic pressure gage, that will indicate failure load, P,

generate stress concentrations. No specimen preparation is

required to break specimen. The system should conform to the

required.

requirements of 6.3.2-6.3.4.

7.4 Water Content—Using Test Method D 2216, determine

6.3.2 Measurements of failure load, P, shall be to a preci-

the water content of each specimen after testing since it can

sion of 65 % or better of full-scale load-measuring system,

affect the value of the point load strength.

irrespective of the size and strength of specimen that is tested.

7.5 Marking and Measuring Specimens—The specimens

shall be properly marked and measured.

7.5.1 Marking—The desired test orientation of the speci-

men shall be indicated by marking lines on the specimen.

These lines are used for centering the specimen in the testing

machine, and to ensure proper orientation during testing. These

lines may also be used as reference lines for measuring

thickness and diameter.

7.5.2 Measuring—Measure each dimension of a specimen

at three different places, and calculate the averages.

8. Procedure

8.1 Diametral Test:

8.1.1 Core specimens with length/diameter ratio greater

than one are suitable for diametral testing.

FIG. 2 Platen Dimensions (Point Load Strength Index Test) 8.1.2 Insert a specimen in the test device and close the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5731

NOTE 1—Legend: L 5 length, W 5 width, D 5 depth or diameter, and D 5 equivalent core diameter (see 9.1).

e

FIG. 3 Load Configurations and Specimen Shape Requirement for (a) the Diametral Test, (b) the Axial Test, (c) the Block Test, and (d)

the Irregular Lump Test

platens to make contact along a core diameter. Ensure that the end faces (in the case of isotropic rock, the core axis, but see

distance, L, between the contact points and the nearest free end 8.4 for anisotropic rock).

is at least 0.5 times the core diameter (see Fig. 3(a)). 8.2.3 Record the distance, D, between platen contact points

8.1.3 Determine and record the distances D and L (see Fig. (see Fig. 3). Record the specimen width, W, perpendicular to

3). the loading direction, with an accuracy of 65%.

8.1.4 Steadily increase the load such that failure occurs 8.2.4 Steadily increase the load such that failure occurs

within 10 to 60 s, and record failure load, P. The test should be within 10 to 60 s, and record the failure load, P. The test should

rejected if the fracture surface passes through only one platen be rejected if the fracture surface passes through only one

loading point (see Fig. 4(d)). loading point (see Fig. 4(e)).

8.1.5 The procedures in 8.1.2-8.1.4 are repeated for each 8.2.5 Procedures 8.2.2-8.2.4 are repeated for each test

specimen of the rock type. specimen of the rock type.

8.2 Axial Test: 8.3 Block and Irregular Lump Tests:

8.2.1 Core specimens with length/diameter ratio of ⁄3 to 1 8.3.1 Rock blocks or lumps, 30 to 85 mm, and of the shape

are suitable for axial testing (see Fig. 3(b)). Suitable specimens shown in Fig. 3(c) and (d) are suitable for the block and the

can be obtained by saw-cutting or chisel-splitting. irregular lump tests. The ratio, D/W, should be between ⁄3 and

8.2.2 Insert a specimen in the test machine and close the 1, preferably close to 1. The distance L should be at least 0.5

platens to make contact along a line perpendicular to the core W.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5731

NOTE 1—(a) Valid diametral tests; (b) valid axial tests; (c) valid block tests; (d) invalid core test; and (e) invalid axial test (point load strength index

test).

FIG. 4 Typical Modes of Failure for Valid and Invalid Tests

8.3.2 Insert a specimen in the testing machine and close the 8.4.1 When a rock sample is shaley, bedded, schistose, or

platens to make contact with the smallest dimension of the

otherwise observably anisotropic, it should be tested in direc-

lump or block, away from edges and corners (see Fig. 3(c) and tions that will give the greatest and least strength values, in

(d).

general, parallel and normal to the planes of anisotropy.

8.3.3 Record the distance D between platen contact points.

8.4.2 If the sample consists of core drilled through weakness

Record the smallest specimen width, W, perpendicular to the

planes, a set of diametral tests may be completed first, spaced

loading direction. If the sides are not parallel, then calculate W

at intervals that will yield pieces that can then be tested axially.

as (W + W )/2 as shown on Fig. 3. This width, W, is used in

1 2

8.4.3 Strongest test results are obtained when the core axis

calculating point load strength index irrespective of the actual

is perpendicular to the planes of weakness; therefore, when

mode of failure (see Fig. 3 and Fig. 4).

possible, the core should be drilled in this direction. The angle

8.3.4 Steadily increase the load such that failure occurs

between the core axis and the normal to the direction of least

within 10 to 60 s, and record the failure load, P. The test should

strength should preferably not exceed 30°.

be rejected if the fracture surface passes through only one

8.4.4 For measurement of the point load strength index (I )

loading point (see examples for other shapes in Fig. 4(d)or(e).

s

8.3.5 Procedures 8.3.2-8.3.4 are repeated for each test value in the direction of least strength, ensure that load is

applied along a single weakness plane. Similarly, when testing

specimen in the sample.

8.4 Anisotropic Rock: for the I value in the direction of greatest strength, ensure that

s

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5731

the load is applied perpendicular to the direction of least the size correction described in 9.2.4 or 9.2.5 must be applied.

strength. 9.2.4 The most reliable method of size correction is to test

8.4.5 If the sample consists of blocks or irregular lumps, it the specimen over a range of D or D values and to plot

e

should be tested as two subsamples, with load first applied graphically the relation between P and D . If a log-log plot is

e

perpendicular to, then along the observable planes of weak- used, the relation is a straight line (see Fig. 5). Points that

ness. Again, the required minimum strength value is obtained deviate substantially from the straight line may be disregarded

when the platens make con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.