ASTM C1248-18

(Test Method)Standard Test Method for Staining of Porous Substrate by Joint Sealants

Standard Test Method for Staining of Porous Substrate by Joint Sealants

SIGNIFICANCE AND USE

5.1 Staining of building materials is an aesthetically undesirable occurrence. This test method evaluates the likelihood of a sealant causing an early stain on a porous substrate due to exudation of materials from the sealant. Since this is an accelerated test, it does not necessarily predict that the tested sealants will not stain or discolor porous substrates over longer periods of time.

SCOPE

1.1 This test method covers four types of laboratory tests to determine if a joint sealant has a probability of staining a porous substrate (such as marble, limestone, sandstone, and granite). The tests are on compressed samples and include (1) storage under standard laboratory conditions, (2) storage in an oven, and (3) exposure in a fluorescent UV/condensation device, and (4) exposure in a xenon arc device.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1248 − 18

Standard Test Method for

1

Staining of Porous Substrate by Joint Sealants

This standard is issued under the fixed designation C1248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G151 Practice for Exposing Nonmetallic Materials inAccel-

erated Test Devices that Use Laboratory Light Sources

1.1 This test method covers four types of laboratory tests to

G154 Practice for Operating Fluorescent Ultraviolet (UV)

determine if a joint sealant has a probability of staining a

Lamp Apparatus for Exposure of Nonmetallic Materials

porous substrate (such as marble, limestone, sandstone, and

G155 Practice for Operating XenonArc LightApparatus for

granite). The tests are on compressed samples and include (1)

Exposure of Non-Metallic Materials

storage under standard laboratory conditions, (2) storage in an

oven, and (3) exposure in a fluorescent UV/condensation

3. Terminology

device, and (4) exposure in a xenon arc device.

3.1 Definitions:

1.2 The values stated in SI units are to be regarded as the

3.1.1 Refer to Terminology C717 and G113 for definitions

standard. The values given in parentheses are for information

of terms used in this test method.

only.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

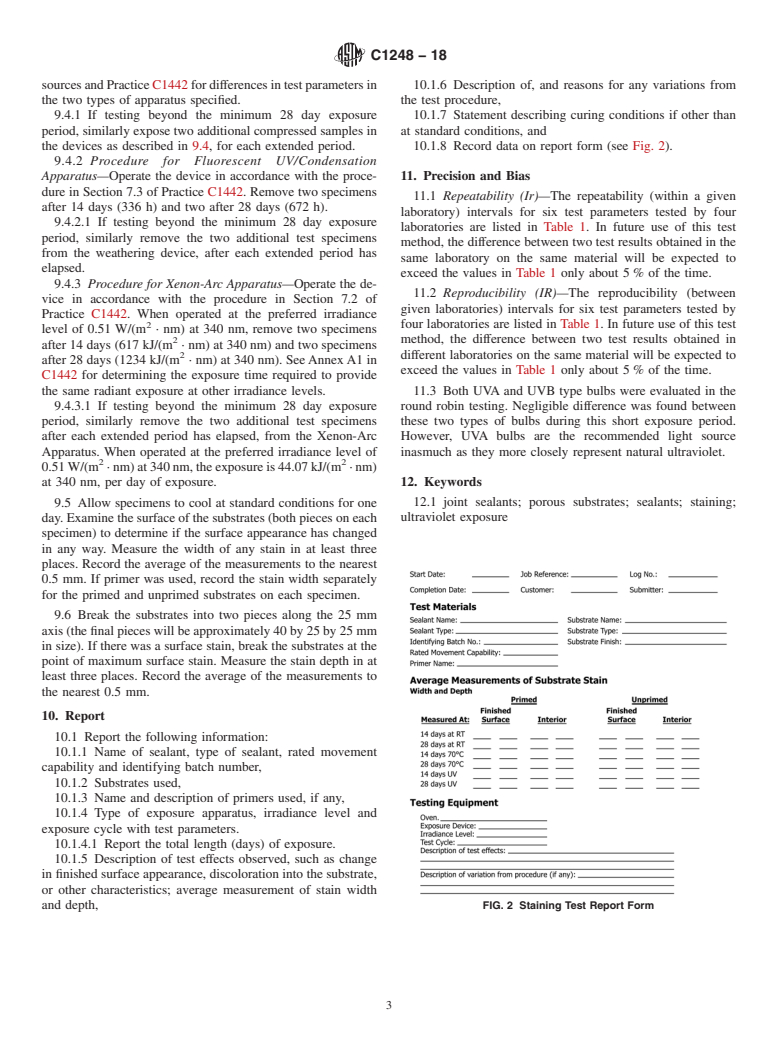

4.1 In this test method standard joint specimens are com-

responsibility of the user of this standard to establish appro-

pressed and clamped at the manufacturer’s rated movement

priate safety, health, and environmental practices and deter-

capabilityandsubjectedtothefollowingtreatments;(a)fourof

mine the applicability of regulatory limitations prior to use.

the specimens are stored at standard conditions while under

1.4 Thecommitteewithjurisdictionoverthisstandardisnot

compression for up to 28 days; (b) four of the specimens are

aware of any comparable standards published by other orga-

exposed in an oven while under compression for up to 28 days;

nizations.

(c) four of the specimens are exposed either in a fluorescent

1.5 This international standard was developed in accor-

UV/condensation device or in a xenon arc device while under

dance with internationally recognized principles on standard-

compression for up to 28 days.

ization established in the Decision on Principles for the

4.1.1 This test method allows for additional exposure be-

Development of International Standards, Guides and Recom-

yond the minimum 28 day exposure period as described in 4.1.

mendations issued by the World Trade Organization Technical

If it is desired to extend the exposure period beyond 28 days,

Barriers to Trade (TBT) Committee.

prepare an additional six specimens for each extended expo-

sure period. Of these six specimens prepared, two specimens

2. Referenced Documents

each should be stored as described in the three conditions

2

2.1 ASTM Standards: named in 4.1.

C717 Terminology of Building Seals and Sealants

4.2 The effects of the test are evaluated by visual inspection

C1442 Practice for Conducting Tests on Sealants Using

for changes in surface appearance and average measurements

Artificial Weathering Apparatus

of any stain depth and stain width.

G113 Terminology Relating to Natural andArtificial Weath-

4.3 This test method is applicable to any type of elastomeric

ering Tests of Nonmetallic Materials

joint sealant and any type of porous substrate.

5. Significance and Use

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealants and is the direct responsibility of Subcommittee C24.40 on

5.1 Staining of building materials is an aesthetically unde-

Weathering.

sirable occurrence.This test method evaluates the likelihood of

Current edition approved June 1, 2018. Published June 2018. Originally

a sealant causing an early stain on a porous substrate due to

approved in 1993. Last previous edition approved in 2012 as C1248-08(2012). DOI:

10.1520/C1248-18.

exudation of materials from the sealant. Since this is an

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

accelerated test, it does not necessarily predict that the tested

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sealants will not stain or discolor porous substrates over longer

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. periods of time.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1248 − 18

6. Appara

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1248 − 08 (Reapproved 2012) C1248 − 18

Standard Test Method for

1

Staining of Porous Substrate by Joint Sealants

This standard is issued under the fixed designation C1248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers four types of laboratory tests to determine if a joint sealant has a probability of staining a porous

substrate (such as marble, limestone, sandstone, and granite). The tests are on compressed samples and include (1) storage under

standard laboratory conditions, (2) storage in an oven, and (3) exposure in a fluorescent UV/condensation device, and (4) exposure

in a xenon arc device.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any comparable standards published by other

organizations.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

C1442 Practice for Conducting Tests on Sealants Using Artificial Weathering Apparatus

G113 Terminology Relating to Natural and Artificial Weathering Tests of Nonmetallic Materials

G151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources

G154 Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials

G155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

3. Terminology

3.1 Definitions:

3.1.1 Refer to Terminology C717 and G113 for definitions of terms used in this test method.

4. Summary of Test Method

4.1 In this test method standard joint specimens are compressed and clamped at the manufacturer’s rated movement capability

and subjected to the following treatments; (a) four of the specimens are stored at standard conditions while under compression for

up to 28 days; (b) four of the specimens are exposed in an oven while under compression for up to 28 days; (c) four of the

specimens are exposed either in a fluorescent UV/condensation device or in a xenon arc device while under compression for up

to 28 days.

4.1.1 This test method allows for additional exposure beyond the minimum 28 day exposure period as described in 4.1. If it is

desired to extend the exposure period beyond 28 days, prepare an additional six specimens for each extended exposure period. Of

these six specimens prepared, two specimens each should be stored as described in the three conditions named in 4.1.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.40 on

Weathering.

Current edition approved Dec. 1, 2012June 1, 2018. Published December 2012June 2018. Originally approved in 1993. Last previous edition approved in 20082012 as

C1248C1248-08(2012).-08. DOI: 10.1520/C1248-08R12.10.1520/C1248-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1248 − 18

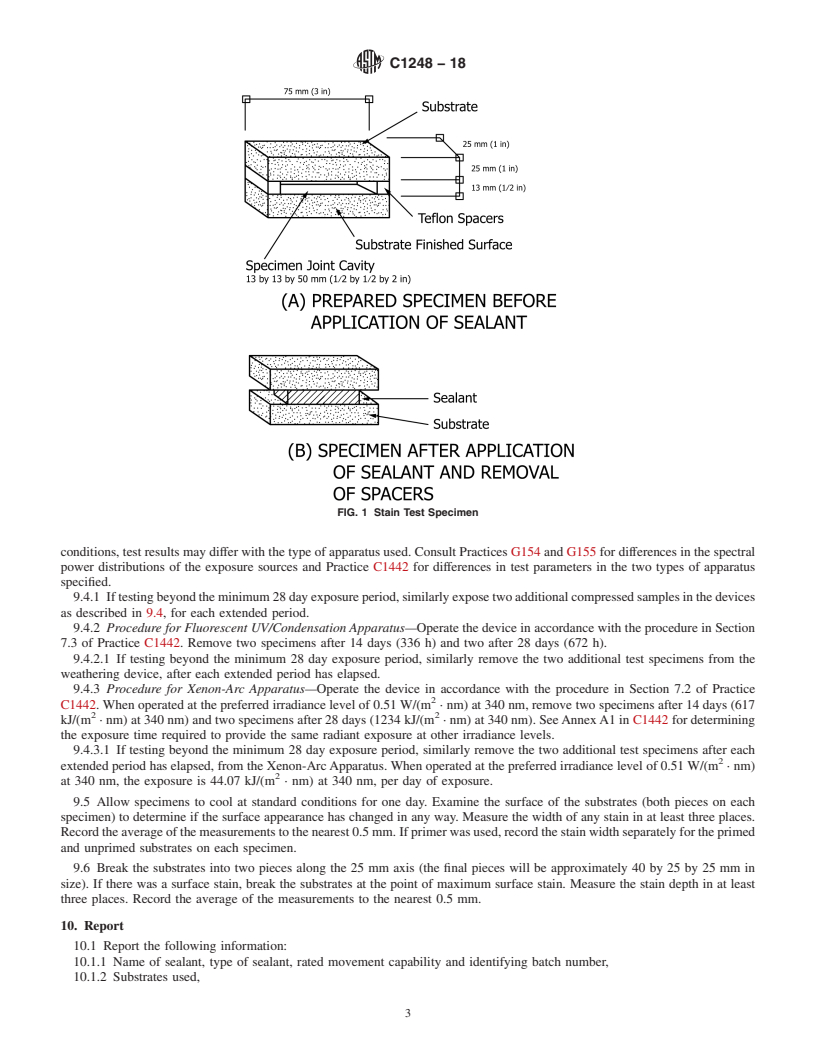

4.2 The effects of the test are evaluated by visual inspection for changes in surface appearance and average measurements of

any stain depth and stain width.

4.3 This test method is applicable to any type of elastomeric joint sealant and any type of porous substrate.

5. Significance and Use

5.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.