ASTM D7084-04(2017)

(Test Method)Standard Test Method for Determination of Bulk Crush Strength of Catalysts and Catalyst Carriers

Standard Test Method for Determination of Bulk Crush Strength of Catalysts and Catalyst Carriers

SIGNIFICANCE AND USE

5.1 This test method is a means of determining the crushing strength of a catalyst in a bed. Techniques to measure the crushing strength of formed catalyst particles is limited to crushing of individual particles, which may not be related to how the catalyst will crush in a reactor or bed. For some catalysts, such as granules, this technique may be the only viable method for obtaining crushing strength. The production of fines in a reactor is not desired because of the potential of bed compaction and the pressure buildup in the reactor.

SCOPE

1.1 This test method covers the determination of bulk crush strength of a bed of formed catalyst particles 1/32 to 3/16 in. (0.8 to 4.8 mm) in diameter and is intended to provide information concerning the ability of the catalyst material to maintain physical integrity.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7084 − 04 (Reapproved 2017)

Standard Test Method for

Determination of Bulk Crush Strength of Catalysts and

Catalyst Carriers

This standard is issued under the fixed designation D7084; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of bulk crush

3.1 Definitions:

1 3

strength of a bed of formed catalyst particles ⁄32 to ⁄16 in. (0.8

3.1.1 See also Terminology D3766.

to 4.8 mm) in diameter and is intended to provide information

3.1.2 bulk crush strength—pressure that generates 1 % fines

concerning the ability of the catalyst material to maintain

for a sample contained in a cylindrical sample holder and

physical integrity.

crushed with a piston.

1.2 The values stated in inch-pound units are to be regarded

3.1.3 generated fines—particle size after crushing that

as standard. The values given in parentheses are mathematical

passes through a sieve one-half of the diameter of the catalyst

conversions to SI units that are provided for information only

pellet.

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Arepresentativesampleisplacedinacylindricalsample

priate safety, health, and environmental practices and deter-

holder, which is fitted with a piston. The piston is allowed to

mine the applicability of regulatory limitations prior to use.

compress the catalyst at a known pressure. The percent of

1.4 This international standard was developed in accor-

generated fines is determined by sieving.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 5.1 This test method is a means of determining the crushing

Barriers to Trade (TBT) Committee.

strength of a catalyst in a bed. Techniques to measure the

crushing strength of formed catalyst particles is limited to

2. Referenced Documents

crushing of individual particles, which may not be related to

2.1 ASTM Standards: how the catalyst will crush in a reactor or bed. For some

D3766 Terminology Relating to Catalysts and Catalysis

catalysts, such as granules, this technique may be the only

D4180 Test Method for Vibratory Packing Density of

viable method for obtaining crushing strength. The production

Formed Catalyst Particles and Catalyst Carriers

of fines in a reactor is not desired because of the potential of

E177 Practice for Use of the Terms Precision and Bias in

bed compaction and the pressure buildup in the reactor.

ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

6. Apparatus

E691 Practice for Conducting an Interlaboratory Study to

6.1 Hydraulic Press, capable of 3200 lb (1450 kg) loading,

Determine the Precision of a Test Method

including a force gage. Maximum load capacity of the press

should match with the accuracy measuring the applied force.

This test method is under the jurisdiction of ASTM Committee D32 on

NOTE 1—Lower maximum load may be acceptable for testing less

Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-

strong materials.

Mechanical Properties.

Current edition approved Sept. 1, 2017. Published October 2017. Originally

6.2 U.S. Standard Sieves, set (Tyler Equivalent).

approved in 2004. Last previous edition approved in 2009 as D7084–04(2009).

DOI: 10.1520/D7084-04R17.

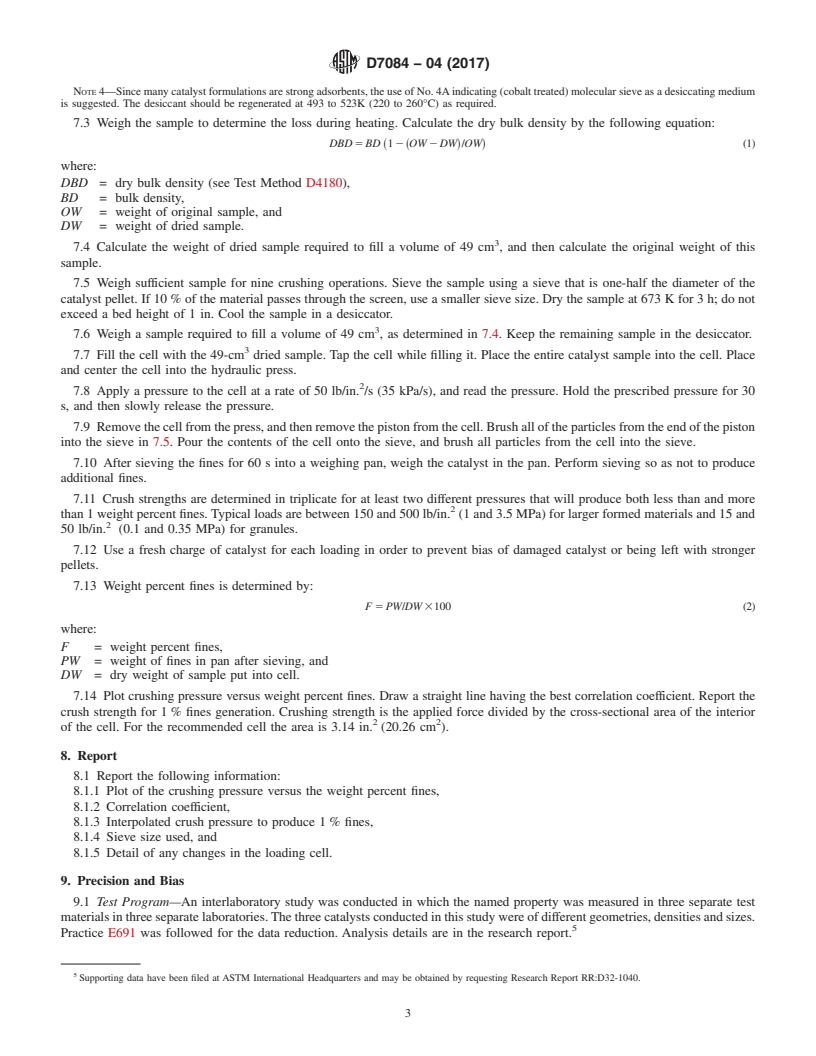

6.3 Test Cell, (Fig. 1).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 2—Atop loading cell can be used, but reproducibility of this test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

is a function of the volume being crushed and therefore the constant

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. volume cell, as shown in Fig. 1, is recommended. A smaller l/d ratio for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7084 − 04 (2017)

FIG. 1 Test Cell

the cell will alter the results, and for certain applications, it may be more

7.3 Weigh the sample to determine the loss during heating.

3,4

desirable.

Calculate the dry bulk density by the following equation:

6.4 Drying Oven.

DBD 5 BD ~1 2 ~OW 2 DW!/OW! (1)

6.5 Balance, having a sensitivity of 0.1 g.

where:

6.6 Glass Cylinders,with 250-mLfeed capacity. Measure in

DBD = dry bulk density (see Test Method D4180),

accordance with Test Method D4180.

BD = bulk density,

OW = weight of original sample, and

6.7 Vibrator, conventional, handheld, with hard rubber or

DW = weight of dried sample.

metal impactor, in accordance with Test Method D4180.

7.4 Calculate the weight of dried sample required to fill a

6.8 Feed Funnel.

volumeof49cm ,andthencalculatetheoriginalweightofthis

6.9 Desiccator, with grade molecular sieve, such as 4A.

sample.

7. Procedure

7.5 Weigh sufficient sample for nine crushing operations.

Sieve the sample using a sieve that is one-half the diameter of

7.1 Determine the bulk density in accordance with Test

Method D4180. the catalyst pellet. If 10 % of the material passes through the

screen, use a smaller sieve size. Dry the sample at 673 K for 3

7.2 Weigh 100 mL of the sample and dry at 673 6 15 K

h; do not exceed a bed height of 1 in. Cool the sample in a

(400°C) for 3 h.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7084 − 04 (Reapproved 2009) D7084 − 04 (Reapproved 2017)

Standard Test Method for

Determination of Bulk Crush Strength of Catalysts and

Catalyst Carriers

This standard is issued under the fixed designation D7084; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1 3

1.1 This test method covers the determination of bulk crush strength of a bed of formed catalyst particles ⁄32 to ⁄16 in. (0.8 to

4.8 mm) in diameter and is intended to provide information concerning the ability of the catalyst material to maintain physical

integrity.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D3766 Terminology Relating to Catalysts and Catalysis

D4180 Test Method for Vibratory Packing Density of Formed Catalyst Particles and Catalyst Carriers

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 See also Terminology D3766.

3.1.2 bulk crush strength—pressure that generates 1 % fines for a sample contained in a cylindrical sample holder and crushed

with a piston.

3.1.3 generated fines—particle size after crushing that passes through a sieve one-half of the diameter of the catalyst pellet.

4. Summary of Test Method

4.1 A representative sample is placed in a cylindrical sample holder, which is fitted with a piston. The piston is allowed to

compress the catalyst at a known pressure. The percent of generated fines is determined by sieving.

5. Significance and Use

5.1 This test method is a means of determining the crushing strength of a catalyst in a bed. Techniques to measure the crushing

strength of formed catalyst particles is limited to crushing of individual particles, which may not be related to how the catalyst will

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-Mechanical

Properties.

Current edition approved March 1, 2009Sept. 1, 2017. Published March 2009October 2017. Originally approved in 2004. Last previous edition approved in 20042009 as

D7084D7084–04(2009).–04. DOI: 10.1520/D7084-04R09.10.1520/D7084-04R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7084 − 04 (2017)

crush in a reactor or bed. For some catalysts, such as granules, this technique may be the only viable method for obtaining crushing

strength. The production of fines in a reactor is not desired because of the potential of bed compaction and the pressure buildup

in the reactor.

6. Apparatus

6.1 Hydraulic Press, capable of 3200 lb (1450 kg) loading, including a force gage. Maximum load capacity of the press should

match with the accuracy measuring the applied force.

NOTE 1—Lower maximum load may be acceptable for testing less strong materials.

6.2 U.S. Standard Sieves, set (Tyler Equivalent).

6.3 Test Cell, (Fig. 1).

NOTE 2—A top loading cell can be used, but reproducibility of this test is a function of the volume being crushed and therefore the constant volume

3,4

cell, as shown in Fig. 1, is recommended. A smaller l/d ratio for the cell will alter the results, and for certain applications, it may be more desirable.

6.4 Drying Oven.

6.5 Balance, having a sensitivity of 0.1 g.

6.6 Glass Cylinders, with 250-mL feed capacity. Measure in accordance with Test Method D4180.

6.7 Vibrator, conventional, handheld, with hard rubber or metal impactor, in accordance with Test Method D4180.

6.8 Feed Funnel.

6.9 Desiccator, with grade molecular sieve, such as 4A.

7. Procedure

7.1 Determine the bulk density in accordance with Test Method D4180.

7.2 Weigh 100 mL of the sample and dry at 673 6 15 K (400°C) for 3 h. Cool the sample in a desiccator using freshly

regenerated 4A molecular sieves as a desiccant.

NOTE 3—These conditions may not be appropriate for all materials.

Bradley, S. A., Pitzer, E., and Koves, W. J., “Bulk Crush Testing of Catalysts,” Characterization and Catalyst Development, ACS Symposium Series 411, Bradley, S.

A., Gattuso, M. J., and Bertolacini, R. J., Eds., 1989, pp. 398-406.

Adams, A. R., Sartor, A. F., and Welsh, J. G., “Problems in Standardizing Catalyst Tests,” Chemical Engineering Progress, Vol 71, 1975, pp. 35-37.

FIG. 1 Test Cell

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.