ASTM D8353-20

(Guide)Standard Guide for Determination of Individual Particle Strength of Low Surface Area Catalysts and Catalyst Carriers by Drop Test onto a Steel Plate

Standard Guide for Determination of Individual Particle Strength of Low Surface Area Catalysts and Catalyst Carriers by Drop Test onto a Steel Plate

SIGNIFICANCE AND USE

5.1 This guide is intended to provide information concerning the ability of formed catalysts or catalyst carriers to resist particle size reduction during use. It can be used by itself or in conjunction with other methods to assess catalytic material integrity, such as Test Methods D4058 and D7084.

5.2 There are no known restrictions on sample geometry, as spheres, pellets, and hollow cylinders are suitable for testing.

5.3 This guide, as written, is suitable for use for catalytic materials from about 1/8 in. to about 3/4 in. It can also be used for larger parts, but this requires using a larger diameter pipe.

5.4 This guide is suitable for specification acceptance, manufacturing control, and research and development processes.

SCOPE

1.1 The resistance to breakage of formed catalysts, catalyst carriers, or catalyst pieces is determined by dropping a quantity of sample through a 25 ft length of 1 in. internal diameter pipe onto a steel plate.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8353 − 20

Standard Guide for

Determination of Individual Particle Strength of Low Surface

Area Catalysts and Catalyst Carriers by Drop Test onto a

1

Steel Plate

This standard is issued under the fixed designation D8353; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions—See Terminology D3766.

1.1 The resistance to breakage of formed catalysts, catalyst

carriers, or catalyst pieces is determined by dropping a quantity

3.2 Definitions of Terms Specific to This Standard:

of sample through a 25 ft length of 1 in. internal diameter pipe

3.2.1 low surface area, n—describesmaterialwithmeasured

2

onto a steel plate.

surface areas of less than 10 m /g (see IEEE/ASTM 10).

1.2 This standard does not purport to address all of the

4. Summary of Guide

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

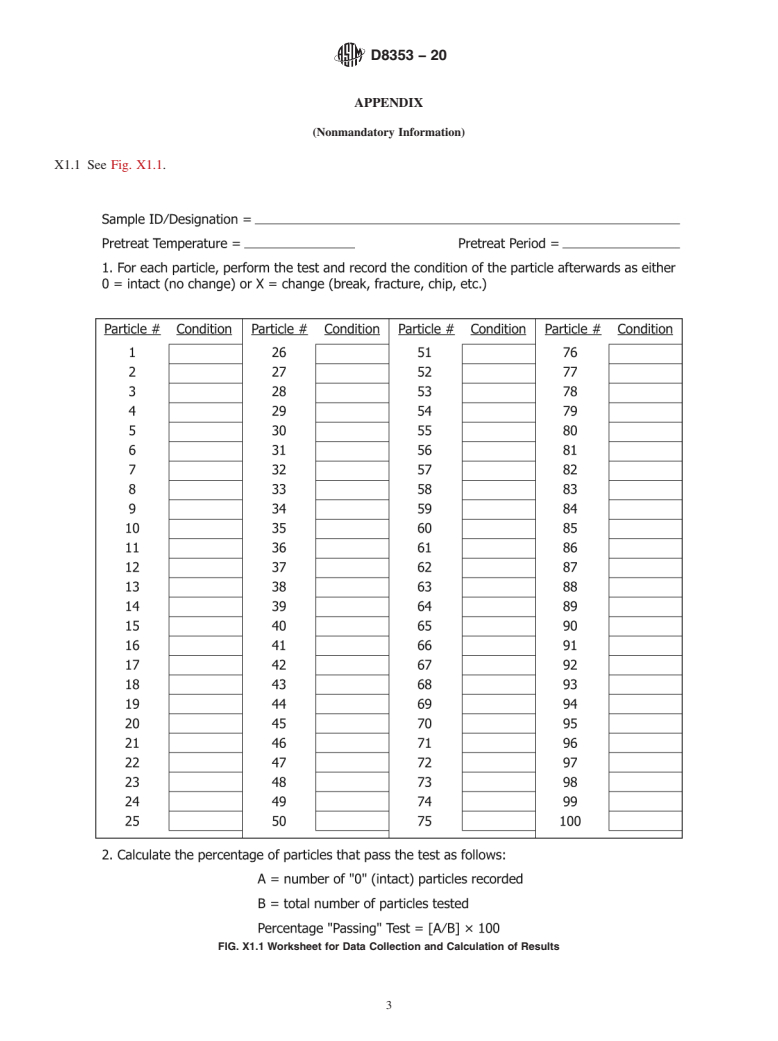

4.1 The resistance to breakage of formed catalysts, catalyst

priate safety, health, and environmental practices and deter-

carriers, or catalyst pieces is determined by dropping a quantity

mine the applicability of regulatory limitations prior to use.

of sample through a 25 ft pipe of 1 in. internal diameter onto a

1.3 This international standard was developed in accor-

steel plate. Particle strength is measured on a pass (no

dance with internationally recognized principles on standard-

breakage) or fail (breakage) basis and is calculated as percent-

ization established in the Decision on Principles for the age passing the test without breakage.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 This guide is intended to provide information concern-

ing the ability of formed catalysts or catalyst carriers to resist

2. Referenced Documents

particle size reduction during use. It can be used by itself or in

2

2.1 ASTM Standards: conjunction with other methods to assess catalytic material

integrity, such as Test Methods D4058 and D7084.

D3766 Terminology Relating to Catalysts and Catalysis

D4058 Test Method for Attrition and Abrasion of Catalysts

5.2 There are no known restrictions on sample geometry, as

and Catalyst Carriers

spheres, pellets, and hollow cylinders are suitable for testing.

D7084 Test Method for Determination of Bulk Crush

5.3 This guide, as written, is suitable for use for catalytic

Strength of Catalysts and Catalyst Carriers

1 3

materials from about ⁄8 in. to about ⁄4 in. It can also be used

3

2.2 Other ASTM Documents:

for larger parts, but this requires using a larger diameter pipe.

STP447A Manual on Test Sieving Methods

5.4 This guide is suitable for specification acceptance,

IEEE/ASTM 10 American National Standard for Metric

manufacturing control, and research and development pro-

Practice

cesses.

6. Apparatus

1

This guide is under the jurisdiction ofASTM Committee D32 on Catalysts and

is the direct responsibility of Subcommittee D32.02 on Physical-Mechanical

6.1 Steel (or Plastic) Pipe, 25 ft long by 1.25 in. outside

Properties.

diameter (1 in. inside diameter), mounted vertically about 6 in.

Current edition approved Oct. 1, 2020. Published November 2020. DOI:

above the metal plate.

10.1520/D8353-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2 Steel Plate, approximately 15 in. x 15 in, x 0.5 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.3 Bottom-less Box—Users might find it helpful to sur-

the ASTM website.

3

round the steel plate with a bottom-less box to retain the tested

Visit theASTM website, www.astm.org, or contactASTM Customer Service at

service@astm.org. particles and facilitate cleanup.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8353 − 20

7. Reagents and Materials activation step to remove moisture prior to testing. This

activation step entails heating the sample to 400 °C for a period

7.1 A reference material of similar composition to the

of at least 3 h prior to testing.

samples to be tested, assigned a consensus value, and ex-

changed between the laboratories using the method.

12. Procedure

12.1 Place the steel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.