ASTM D5187-10

(Test Method)Standard Test Method for Determination of Crystallite Size (Lc of Calcined Petroleum Coke by X-Ray Diffraction

Standard Test Method for Determination of Crystallite Size (L<inf>c</inf> of Calcined Petroleum Coke by X-Ray Diffraction

SIGNIFICANCE AND USE

The crystallinity of petroleum coke, as reflected by the Lc value, is a general measure of quality affecting suitability for end use and is a function of the heat treatment.

The crystallite thickness is used to determine the extent of such heat treatment, for example, during calcination. The value of the Lc determined is not affected by coke microporosity or the presence of foreign, non-crystalline materials such as dedust oil.

SCOPE

1.1 This test method covers the determination of the mean crystallite thickness of a representative, pulverized sample of calcined petroleum coke by interpretation of a X-ray diffraction pattern produced through conventional X-ray scanning techniques.

1.2 Calcined petroleum coke contains crystallites of different thicknesses. This test method covers the determination of the average thickness of all crystallites in the sample by empirical interpretation of the X-ray diffraction pattern. The crystallite diameter (La) is not determined by this test method.

1.3 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5187 − 10

StandardTest Method for

Determination of Crystallite Size (L of Calcined Petroleum

c

1

Coke by X-Ray Diffraction

This standard is issued under the fixed designation D5187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 This test method covers the determination of the mean 3.1 Definitions of Terms Specific to This Standard:

crystallite thickness of a representative, pulverized sample of

3.1.1 crystallites—stacks of graphitic carbon platelets lo-

calcinedpetroleumcokebyinterpretationofaX-raydiffraction

cated parallel to one another.

pattern produced through conventional X-ray scanning tech-

3.1.2 L —the mean or average thickness of crystallites in a

c

niques.

sample.Itisexpressedasalineardimensioninangstromunits,

−1

1.2 Calcined petroleum coke contains crystallites of differ- ˚

A (10 nm).

ent thicknesses. This test method covers the determination of

3.1.3 hkl(002)—the Miller indices of the crystalline planes

the average thickness of all crystallites in the sample by

of graphite corresponding to a lattice spacing (d) of 3.35 Å.

empirical interpretation of the X-ray diffraction pattern. The

crystallite diameter (L ) is not determined by this test method.

3.1.4 Θ—theglancingangleproducedwhenaparallelbeam

a

of uniform X-rays impinges upon a crystalline lattice. This

1.3 The values stated in SI (metric) units are to be regarded

angle is measured by the X-ray goniometer and is usually

as the standard. The inch-pound units given in parentheses are

expressed in ° 2Θ.

provided for information purposes only.

1.4 This standard does not purport to address all of the

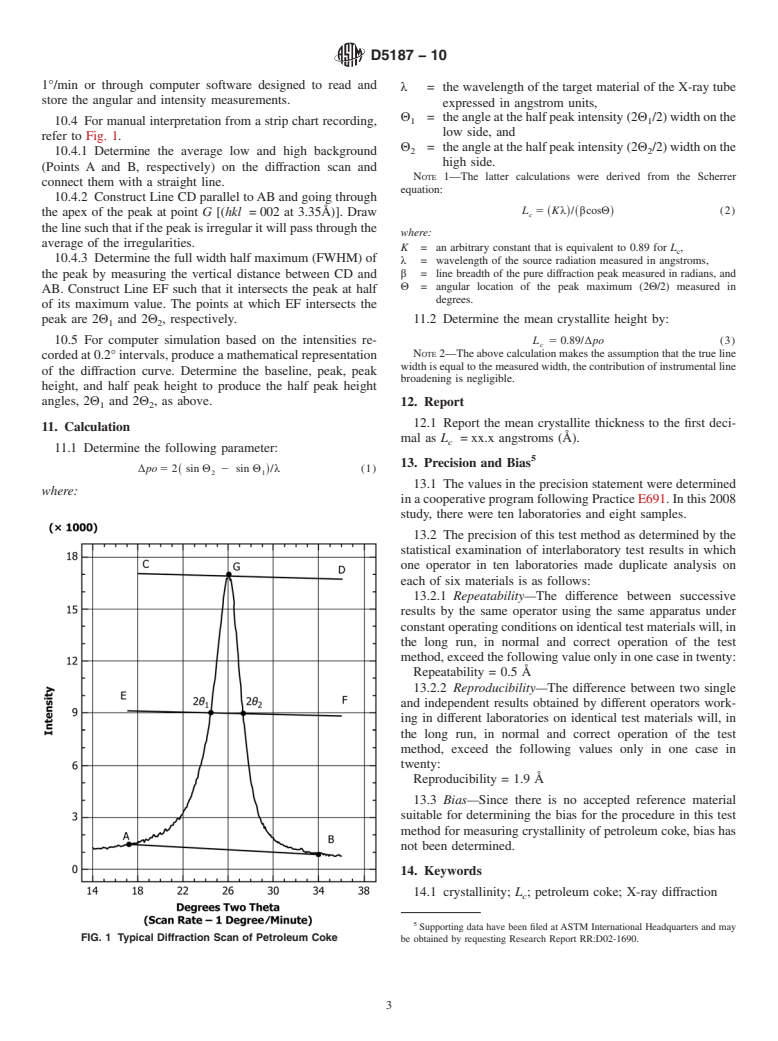

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 A packed sample pulverized to less than 75 µm is

priate safety and health practices and determine the applica- subjected to a monochromatic X-ray beam and rotated to

bility of regulatory limitations prior to use. produce a diffraction pattern under specific conditions. The

˚

locationandshapeofthepeakwith hkl =(002)at d =3.35;A

2. Referenced Documents

is used to calculate the L by manual interpretation of the peak

c

2 or by computer simulation.

2.1 ASTM Standards:

D346Practice for Collection and Preparation of Coke

5. Significance and Use

Samples for Laboratory Analysis

D2013Practice for Preparing Coal Samples for Analysis

5.1 The crystallinity of petroleum coke, as reflected by the

D2234/D2234MPractice for Collection of a Gross Sample

L value,isageneralmeasureofqualityaffectingsuitabilityfor

c

of Coal

end use and is a function of the heat treatment.

D4057Practice for Manual Sampling of Petroleum and

5.2 The crystallite thickness is used to determine the extent

Petroleum Products

of such heat treatment, for example, during calcination. The

E691Practice for Conducting an Interlaboratory Study to

value of the L determined is not affected by coke microporo-

c

Determine the Precision of a Test Method

sity or the presence of foreign, non-crystalline materials such

as dedust oil.

1

This test method is under the jurisdiction of ASTM Committee D02 on

6. Apparatus

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

6.1 X-Ray Powder Diffractometer , equipped with an X-ray

Current edition approved May 1, 2010. Published July 2010. Originally

source, a monochromator or filter for restricting the wave-

published in 1991. Last previous edition approved in 2007 as D5187–91(2007).

DOI: 10.1520/D5187-10.

length range, a sample holder, a radiation detector, a signal

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

processor, and readout (chart or computer memory). The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

diffractometer must be capable of rate scanning at 1° per

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. minute or incrementally step scanning at 0.2° per step.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5187 − 10

6.2 Sample Holders, as specified by the manufacturer of the 8.5.2 Front Fill Technique—Place a confining ring over the

diffractometer that enables packing of a pulverized sample of round sample holder and fill the holder cavity and ring with

sufficient thickn

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.