ASTM D3385-94

(Test Method)Standard Test Method for Infiltration Rate of Soils in Field Using Double-Ring Infiltrometer

Standard Test Method for Infiltration Rate of Soils in Field Using Double-Ring Infiltrometer

SCOPE

1.1 This test method describes a procedure for field measurement of the rate of infiltration of liquid (typically water) into soils using double-ring infiltrometer.

1.2 Soils should be regarded as natural occurring fine or coarse-grained soils or processed materials or mixtures of natural soils and processed materials, or other porous materials, and which are basically insoluble and are in accordance with requirements of 1.5.

1.3 This test method is particularly applicable to relatively uniform fine-grained soils, with an absence of very plastic (fat) clays and gravel-size particles and with moderate to low resistance to ring penetration.

1.4 This test method may be conducted at the ground surface or at given depths in pits, and on bare soil or with vegetation in place, depending on the conditions for which infiltration rates are desired. However, this test method cannot be conducted where the test surface is below the ground water table or perched water table.

1.5 This test method is difficult to use or the resultant data may be unreliable, or both, in very pervious or impervious soils (soils with a hydraulic conductivity greater than about 10 -2 cm/s or less than about 1 X 10 -6 cm/s) or in dry or stiff soils that most likely will fracture when the rings are installed. For soils with hydraulic conductivity less than 1 X 10 -6 cm/s refer to Test Method D5093.

1.6 This test method cannot be used directly to determine the hydraulic conductivity (coefficient of permeability) of the soil (see 5.2).

1.7 The values stated in SI units are to be regarded as the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3385 – 94

Standard Test Method for

Infiltration Rate of Soils in Field Using Double-Ring

Infiltrometer

This standard is issued under the fixed designation D 3385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method describes a procedure for field mea- 2.1 ASTM Standards:

surement of the rate of infiltration of liquid (typically water) D 653 Terminology Relating to Soil, Rock, and Contained

into soils using double-ring infiltrometer. Fluids

1.2 Soils should be regarded as natural occurring fine or D 1452 Practice for Soil Investigation and Sampling by

coarse-grained soils or processed materials or mixtures of Auger Borings

natural soils and processed materials, or other porous materials, D 2216 Method for Laboratory Determination of Water

and which are basically insoluble and are in accordance with (Moisture) Content of Soil, Rock, and Soil-Aggregate

requirements of 1.5. Mixtures

1.3 This test method is particularly applicable to relatively D 2488 Practice for Description and Identification of Soils

uniform fine-grained soils, with an absence of very plastic (fat) (Visual-Manual Procedure)

clays and gravel-size particles and with moderate to low D 5093 Test Method for Field Measurement of Infiltration

resistance to ring penetration. Rate Using a Double-Ring Infiltrometer With a Sealed

1.4 This test method may be conducted at the ground Inner Ring

surface or at given depths in pits, and on bare soil or with

3. Terminology

vegetation in place, depending on the conditions for which

infiltration rates are desired. However, this test method cannot 3.1 Definitions:

3.1.1 incremental infiltration velocity—the quantity of flow

be conducted where the test surface is below the ground water

table or perched water table. per unit area over an increment of time. It has the same units

as the infiltration rate.

1.5 This test method is difficult to use or the resultant data

may be unreliable, or both, in very pervious or impervious soils 3.1.2 infiltration—the downward entry of liquid into the

−2

soil.

(soils with a hydraulic conductivity greater than about 10

−6

cm/s or less than about 1 3 10 cm/s) or in dry or stiff soils 3.1.3 infiltration rate—a selected rate, based on measured

incremental infiltration velocities, at which liquid can enter the

that most likely will fracture when the rings are installed. For

−6

soils with hydraulic conductivity less than 1 3 10 cm/s refer soil under specified conditions, including the presence of an

to Test Method D 5093. excess of liquid. It has the dimensions of velocity (that is,

3 −2 −1 −1

cm cm h =cm h ).

1.6 This test method cannot be used directly to determine

the hydraulic conductivity (coefficient of permeability) of the 3.1.4 infiltrometer—a device for measuring the rate of entry

of liquid into a porous body, for example, water into soil.

soil (see 5.2).

1.7 The values stated in SI units are to be regarded as the 3.1.5 For definitions of other terms used in this test method,

refer to Terminology D 653.

standard.

1.8 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 The double-ring infiltrometer method consists of driving

responsibility of the user of this standard to establish appro-

two open cylinders, one inside the other, into the ground,

priate safety and health practices and determine the applica-

partially filling the rings with water or other liquid, and then

bility of regulatory limitations prior to use.

maintaining the liquid at a constant level. The volume of liquid

added to the inner ring, to maintain the liquid level constant is

This test method is under the jurisdiction of ASTM Committee D-18 on Soil the measure of the volume of liquid that infiltrates the soil. The

and Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic

Properties of Soil and Rock.

Current edition approved Sept. 15, 1994. Published November 1994. Originally

published as D 3385 – 75. Last previous edition D 3385 – 88. Annual Book of ASTM Standards, Vol 04.08.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D3385–94

volume infiltrated during timed intervals is converted to an

incremental infiltration velocity, usually expressed in centime-

tre per hour or inch per hour and plotted versus elapsed time.

The maximum-steady state or average incremental infiltration

velocity, depending on the purpose/application of the test is

equivalent to the infiltration rate.

5. Significance and Use

5.1 This test method is useful for field measurement of the

infiltration rate of soils. Infiltration rates have application to

such studies as liquid waste disposal, evaluation of potential

septic-tank disposal fields, leaching and drainage efficiencies,

irrigation requirements, water spreading and recharge, and

canal or reservoir leakage, among other applications.

5.2 Although the units of infiltration rate and hydraulic

conductivity of soils are similar, there is a distinct difference

between these two quantities. They cannot be directly related

unless the hydraulic boundary conditions are known, such as

hydraulic gradient and the extent of lateral flow of water, or can

be reliably estimated.

5.3 The purpose of the outer ring is to promote one-

dimensional, vertical flow beneath the inner ring.

5.4 Many factors affect the infiltration rate, for example the FIG. 1 Infiltrometer Construction

soil structure, soil layering, condition of the soil surface,

degree of saturation of the soil, chemical and physical nature of

the soil and of the applied liquid, head of the applied liquid,

50 by 100 mm or 100 by 100 mm (2 by 4 in. or 4 by 4 in.), or

temperature of the liquid, and diameter and depth of embed-

a jack and reaction of suitable size.

ment of rings. Thus, tests made at the same site are not likely

6.4 Depth Gage—A hook gage, steel tape or rule, or length

to give identical results and the rate measured by the test

of steel or plastic rod pointed on one end, for use in measuring

method described in this standard is primarily for comparative

and controlling the depth of liquid (head) in the infiltrometer

use.

ring, when either a graduated Mariotte tube or automatic flow

5.5 Some aspects of the test, such as the length of time the

control system is not used.

tests should be conducted and the head of liquid to be applied,

6.5 Splash Guard—Several pieces of rubber sheet or burlap

must depend upon the experience of the user, the purpose for

150 mm (6 in.) square.

testing, and the kind of information that is sought.

6.6 Rule or Tape—Two-metre (6-ft) steel tape or 300-mm

(1-ft) steel rule.

6. Apparatus

6.7 Tamp—Any device that is basically rigid, has a handle

6.1 Infiltrometer Rings—Cylinders approximately 500 mm not less than 550 mm (22 in.) in length, and has a tamping foot

2 2

(20 in.) high and having diameters of about 300 and 600 mm with an area ranging from 650 to 4000 mm (1 to 6 in. ) and a

(12 and 24 in.). Larger cylinders may be used, providing the

maximum dimension of 150 mm (6 in.).

ratio of the outer to inner cylinders is about two. Cylinders can 6.8 Shovels—One long-handled shovel and one trenching

be made of 3-mm ( ⁄8-in.), hard-alloy, aluminum sheet or other

spade.

material sufficiently strong to withstand hard driving, with the 6.9 Liquid Containers:

bottom edge bevelled (see Fig. 1). The bevelled edges shall be

6.9.1 One 200-L (55-gal) barrel for the main liquid supply,

kept sharp. Stainless steel or strong plastic rings may have to along with a length of rubber hose to siphon liquid from the

be used when working with corrosive fluids. barrel to fill the calibrated head tanks (see 6.9.3).

6.2 Driving Caps—Disks of 13-mm ( ⁄2-in.) thick hard-alloy 6.9.2 A 13-L (12-qt) pail for initial filling of the infiltrom-

aluminum with centering pins around the edge, or preferably eters.

having a recessed groove about 5 mm (0.2 in.) deep with a 6.9.3 Two calibrated head tanks for measurement of liquid

width about 1 mm (0.05 in.) wider than the thickness of the flow during the test. These may be either graduated cylinders or

ring. The diameters of the disks should be slightly larger than Mariotte tubes having a minimum volume capacity of about

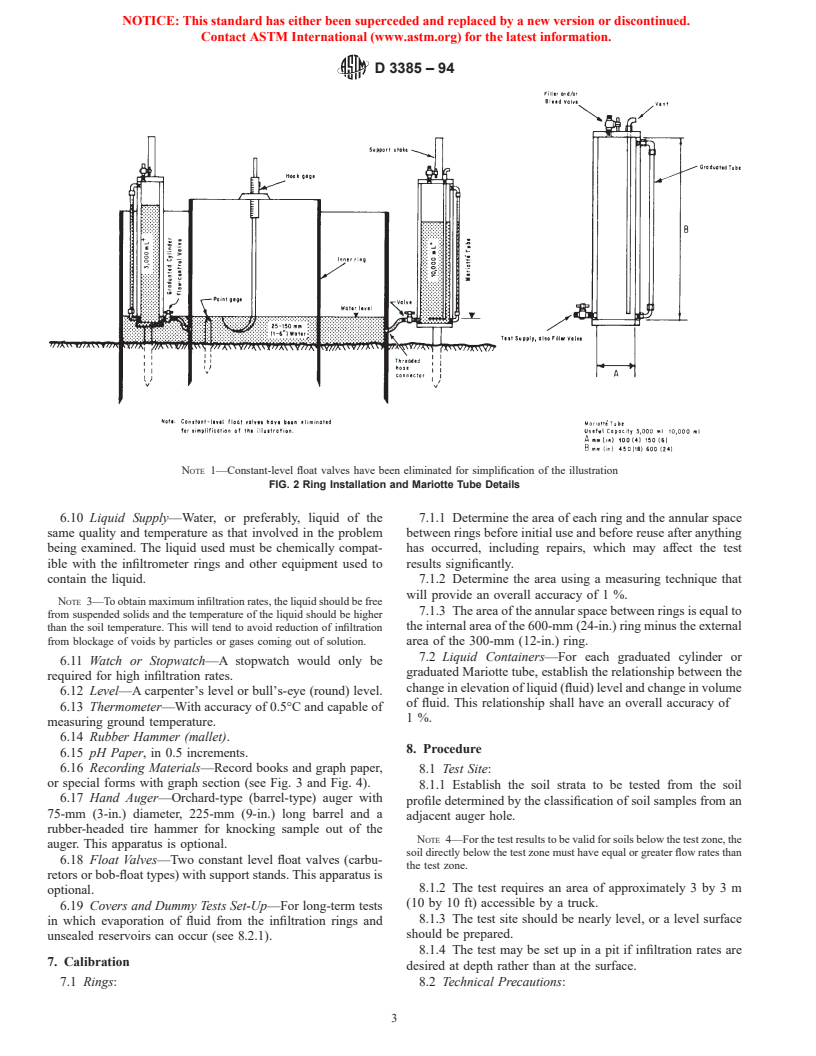

those of the infiltrometer rings. 3000 mL (see Note 1 and Note 2 and Fig. 2).

6.3 Driving Equipment—A 5.5-kg (12-lb) mall or sledge

NOTE 1—It is useful to have one head tank with a capacity of three

and a 600 or 900-mm (2 or 3-ft) length of wood approximately

times that of the other because the area of the annular space between the

rings is about three times that of the inner ring.

NOTE 2—In many cases, the volume capacity of these calibrated head

tanks must be significantly larger than 3000 mL, especially if the test has

Discussion of factors affecting infiltration rate is contained in the following

to continue overnight. Capacities of about 50 L (13 gal) would not be

reference: Johnson, A. I., A Field Method for Measurement of Infiltration, U.S.

Geological Survey Water-Supply Paper 1544-F, 1963, pp. 4–9. uncommon.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D3385–94

NOTE 1—Constant-level float valves have been eliminated for simplification of the illustration

FIG. 2 Ring Installation and Mariotte Tube Details

6.10 Liquid Supply—Water, or preferably, liquid of the 7.1.1 Determine the area of each ring and the annular space

same quality and temperature as that involved in the problem between rings before initial use and before reuse after anything

being examined. The liquid used must be chemically compat- has occurred, including repairs, which may affect the test

ible with the infiltrometer rings and other equipment used to results significantly.

contain the liquid. 7.1.2 Determine the area using a measuring technique that

will provide an overall accuracy of 1 %.

NOTE 3—To obtain maximum infiltration rates, the liquid should be free

7.1.3 The area of the annular space between rings is equal to

from suspended solids and the temperature of the liquid should be higher

the internal area of the 600-mm (24-in.) ring minus the external

than the soil temperature. This will tend to avoid reduction of infiltration

from blockage of voids by particles or gases coming out of solution. area of the 300-mm (12-in.) ring.

7.2 Liquid Containers—For each graduated cylinder or

6.11 Watch or Stopwatch—A stopwatch would only be

graduated Mariotte tube, establish the relationship between the

required for high infiltration rates.

change in elevation of liquid (fluid) level and change in volume

6.12 Level—A carpenter’s level or bull’s-eye (round) level.

of fluid. This relationship shall have an overall accuracy of

6.13 Thermometer—With accuracy of 0.5°C and capable of

1%.

measuring ground temperature.

6.14 Rubber Hammer (mallet).

8. Procedure

6.15 pH Paper, in 0.5 increments.

6.16 Recording Materials—Record books and graph paper,

8.1 Test Site:

or special forms with graph section (see Fig. 3 and Fig. 4).

8.1.1 Establish the soil strata to be tested from the soil

6.17 Hand Auger—Orchard-type (barrel-type) auger with

profile determined by the classification of soil samples from an

75-mm (3-in.) diameter, 225-mm (9-in.) long barrel and a

adjacent auger hole.

rubber-headed tire hammer for knocking sample out of the

NOTE 4—For the test results to be valid for soils below the test zone, the

auger. This apparatus is optional.

soil directly below the test zone must have equal or greater flow rates than

6.18 Float Valves—Two constant level float valves (carbu-

the test zone.

retors or bob-float types) with support stands. This apparatus is

8.1.2 The test requires an area of approximately 3 by 3 m

optional.

(10 by 10 ft) accessible by a truck.

6.19 Covers and Dummy Tests Set-Up—For long-term tests

8.1.3 The test site should be nearly level, or a level surface

in which evaporation of fluid from the infiltration rings and

should be prepared.

unsealed reservoirs can occur (see 8.2.1).

8.1.4 The test may be set up in a pit if infiltration rates are

7. Calibration

desired at depth rather than at the surface.

7.1 Rings: 8.2 Technical Precautions:

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D3385–94

FIG. 3 Data Form for Infiltration Test with Sample Data

NOTE 5—Driving rings with a jack is preferred; see 8.4.

8.2.1 For long-term tests, avoid unattended sites where

interference with test equipment is possible, such as sites near

8.3.1 Place the driving cap on the outer ring and center it

children or in pastures with livestock. Also, evaporation of

thereon. Place the wood block (see 6.3) on the driving cap.

fluid from the rings and unsealed reservoirs can lead to errors

8.3.2 Drive the outer ring into the soil with blows of a heavy

in the measured infiltration rate. Therefore, in such tests,

sledge on the wood block to a depth that will (a) prevent the

completely cover the top of the rings and unsealed reservoirs

test fluid from leaking to the ground surface surrounding the

with a relatively airtight material, but vented to the atmosphere

ring, and (b) be deeper than the depth to which the inner ring

through a small hole or tube. In addition, make measurements

will be driven. A depth of about 150 mm (6 in.) is usually

to verify that the rate of evaporation in a similar test configu-

adequate. Use blows of medium force to prevent fracturing of

ration (without any infiltration into the soil) is less than 20% of

the soil surface. Move the wood block around the edge of the

the infiltration rate being measured.

driving cap every one or two blows so that the ring will

8.2.2 Make provisions to protect the test apparatus and fluid

penetrate the soil uniformly. A second person standing on the

from direct sunlight and temperature variations that are large

wood block and driving cap will usually facilitate driving the

enough to affect the slow measurements significantly,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.