ASTM G47-98(2019)

(Test Method)Standard Test Method for Determining Susceptibility to Stress-Corrosion Cracking of 2XXX and 7XXX Aluminum Alloy Products

Standard Test Method for Determining Susceptibility to Stress-Corrosion Cracking of 2XXX and 7XXX Aluminum Alloy Products

SIGNIFICANCE AND USE

4.1 The 3.5 % NaCl solution alternate immersion test provides a test environment for detecting materials that would be likely to be susceptible to SCC in natural outdoor environments, especially environments with marine influences.3,4,5 For determining actual serviceability of a material, other stress-corrosion tests should be performed in the intended service environment under conditions relating to the end use, including protective measures.

4.2 Although this test method is intended for certain alloy types and for testing products primarily in the short-transverse stressing direction, this method is useful for some other types of alloys and stressing directions.

SCOPE

1.1 This test method covers a uniform procedure for characterizing the resistance to stress-corrosion cracking (SCC) of high-strength aluminum alloy wrought products for the guidance of those who perform stress-corrosion tests, for those who prepare stress-corrosion specifications, and for materials engineers.

1.2 This test method covers method of sampling, type of specimen, specimen preparation, test environment, and method of exposure for determining the susceptibility to SCC of 2XXX (with 1.8 to 7.0 % copper) and 7XXX (with 0.4 to 2.8 % copper) aluminum alloy products, particularly when stressed in the short-transverse direction relative to the grain structure.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses are provided for information.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G47 −98 (Reapproved 2019)

Standard Test Method for

Determining Susceptibility to Stress-Corrosion Cracking of

2XXX and 7XXX Aluminum Alloy Products

This standard is issued under the fixed designation G47; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope G38 Practice for Making and Using C-Ring Stress-

Corrosion Test Specimens

1.1 This test method covers a uniform procedure for char-

G44 PracticeforExposureofMetalsandAlloysbyAlternate

acterizing the resistance to stress-corrosion cracking (SCC) of

Immersion in Neutral 3.5 % Sodium Chloride Solution

high-strength aluminum alloy wrought products for the guid-

G49 Practice for Preparation and Use of Direct Tension

anceofthosewhoperformstress-corrosiontests,forthosewho

Stress-Corrosion Test Specimens

prepare stress-corrosion specifications, and for materials engi-

G139 Test Method for Determining Stress-Corrosion Crack-

neers.

ing Resistance of Heat-Treatable Aluminum Alloy Prod-

1.2 This test method covers method of sampling, type of

ucts Using Breaking Load Method

specimen, specimen preparation, test environment, and method

ofexposurefordeterminingthesusceptibilitytoSCCof2XXX

3. Summary of Test Method

(with 1.8 to 7.0 % copper) and 7XXX (with 0.4 to 2.8 %

3.1 This test method provides a comprehensive procedure

copper) aluminum alloy products, particularly when stressed in

foracceleratedstress-corrosiontestinghigh-strengthaluminum

the short-transverse direction relative to the grain structure.

alloy product forms, particularly when stressed in the short-

1.3 The values stated in SI units are to be regarded as

transverse grain direction. It specifies tests of constant-strain-

standard. The inch-pound units in parentheses are provided for

loaded, 3.18-mm (0.125-in.) tension specimens or C-rings

information.

exposed to 3.5 % sodium chloride (NaCl) solution by alternate

1.4 This standard does not purport to address all of the immersion, and includes procedures for sampling various

safety concerns, if any, associated with its use. It is the manufactured product forms, examination of exposed test

responsibility of the user of this standard to establish appro-

specimens, and interpretation of test results.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4. Significance and Use

1.5 This international standard was developed in accor-

4.1 The 3.5 % NaCl solution alternate immersion test pro-

dance with internationally recognized principles on standard-

vides a test environment for detecting materials that would be

ization established in the Decision on Principles for the

likely to be susceptible to SCC in natural outdoor

Development of International Standards, Guides and Recom-

environments, especially environments with marine

3,4,5

mendations issued by the World Trade Organization Technical

influences. For determining actual serviceability of a

Barriers to Trade (TBT) Committee.

material, other stress-corrosion tests should be performed in

the intended service environment under conditions relating to

2. Referenced Documents

the end use, including protective measures.

2.1 ASTM Standards:

1 3

This test method, which was developed by a joint task group with the Romans, H. B., Stress Corrosion Testing, ASTM STP 425, ASTM, 1967, pp.

AluminumAssociation, Inc., is under the jurisdiction ofASTM Committee G01 on 182–208.

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Brown, R. H., Sprowls, D. O., and Shumaker, M. B., “The Resistance of

Environmentally Assisted Cracking. Wrought High Strength Aluminum Alloys to Stress Corrosion Cracking,” Stress

Current edition approved June 15, 2019. Published June 2019. Originally CorrosionCrackingofMetals—AStateoftheArt,ASTMSTP518,ASTM,1972,pp.

approved in 1976. Last previous edition approved in 2011 as G47 – 98 (2011). DOI: 87–118.

10.1520/G0047-98R19. Sprowls, D. O., Summerson, T. J., Ugiansky, G. M., Epstein, S. G., and Craig,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or H. L., Jr., “Evaluation of a Proposed Standard Method of Testing for Susceptibility

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM to Stress-Corrosion Cracking of High-Strength 7XXX Series Aluminum Alloy

Standards volume information, refer to the standard’s Document Summary page on Products,” Stress Corrosion-New Approaches, ASTM STP 610, ASTM, 1976, pp.

the ASTM website. 3–31.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G47−98 (2019)

4.2 Although this test method is intended for certain alloy also in the longitudinal direction, the stress shall be applied in

types and for testing products primarily in the short-transverse a direction parallel to the smallest dimension of the product.

stressing direction, this method is useful for some other types

7.2 Location of Specimens:

of alloys and stressing directions.

7.2.1 For products stress relieved by stretching (TX51,

TX510,TX511,TXX51,TXX510,TXX511),samplesshallnot

5. Interferences

be taken from the portion under the stretcher grips.

5.1 A disadvantage of the 3.5 % NaCl solution alternate

7.2.2 Rolled Plate—Short-transverse specimens shall be

immersion test is that severe pitting may develop in the

taken so that the region of maximum stress is centered on the

specimens. Such pitting in tension specimens with relatively 1

mid-plane of the plate and at least 2 ⁄2 plate thicknesses away

small cross section can markedly reduce the effective cross-

from a side of the plate. (The side of the plate is defined as the

sectional area and produce a net section stress greater than the

edge parallel to the rolling direction.)

nominal gross section stress, resulting in either: (1) fracture by

7.2.3 Hand Forgings—Short-transverse specimens shall be

mechanical overload of a material that is not susceptible to

taken so that the stress is applied in a direction perpendicular

SCC; or (2) SCC of a material at an actual stress higher than

to the forging flow lines. The region of maximum stress shall

the intended nominal test stress. The occurrence of either of

be centered in the forging thickness and approximately on the

these phenomena might then interfere with a valid evaluation

longitudinal center line of the forging, no less than ⁄2 the

of materials with relatively high resistance to stress corrosion.

section thickness away from “as-heat treated” edges of the

forging.

6. Test Specimen

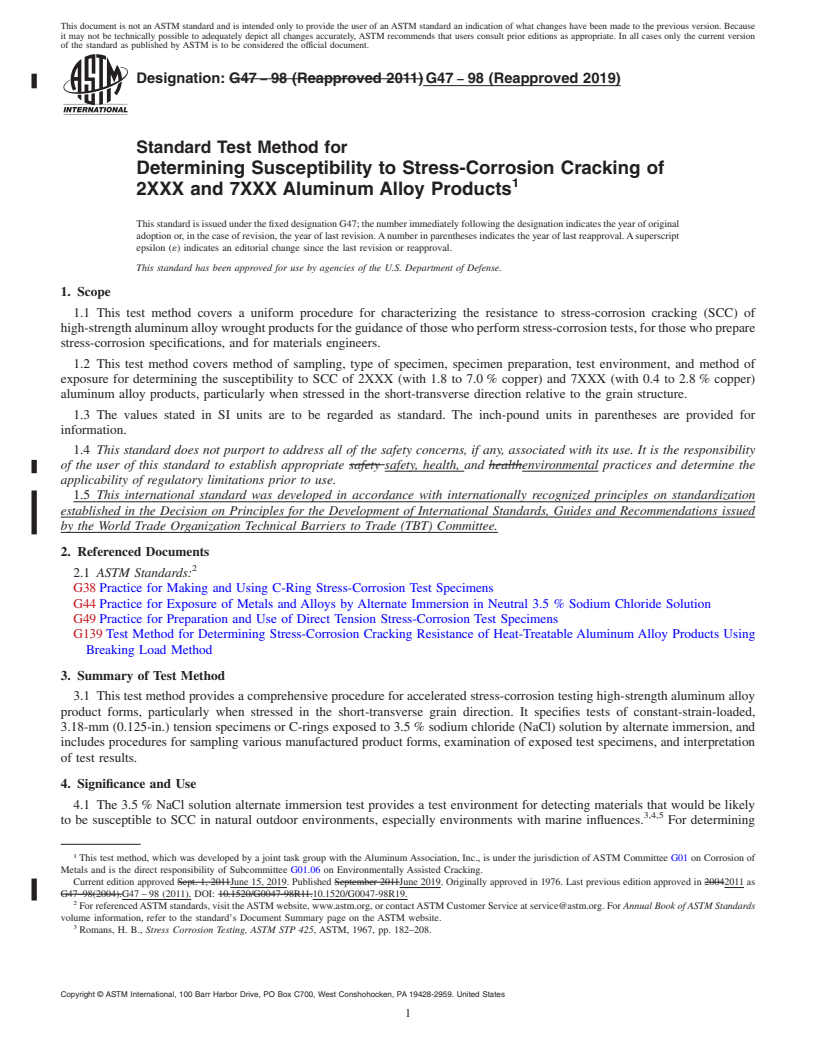

7.2.4 Die Forgings—Because of the wide variety of con-

6.1 TypeandSize—No single configuration of test specimen

figurations of die forgings, guidelines are provided for only

is applicable for the many complex shapes and sizes of

certain common types of shapes that are widely used. Short-

products that must be evaluated. A tension specimen is pre-

transverse specimens shall be taken so that the stress is applied

ferred because it more consistently provides definite evidence

in a direction perpendicular to the forging flow lines and, if

of cracking and should be used whenever the size and shape of

possible, with the region of maximum stress centered on the

the product permits; it also provides a more severe test.

parting plane. The metal flow pattern in die forgings cannot

6.1.1 Tension Specimen—The diameter of the reduced sec-

always be predicted, so only a few general rules are given, and

tion shall be 3.17 6 0.03 mm (0.125 6 0.001 in.).

they are illustrated in Fig. 1. Departures from these rules

6.1.2 C-Ring (see Practices G38)—The use of C-rings

should be made only on the basis of a study of forging flow

permits short-transverse tests to be made of sections that are

lines indicating that the intended type of test would not be

too thin or complex for practical tests with a tension specimen.

C-rings may be of various sizes as required for the product to

be tested, but in no case less than 15.88 6 0.05 mm (0.625 6

0.002 in.) in outside diameter. The ratio of diameter to wall

thickness shall be kept in the range from 11:1 to 16:1.

6.2 Stressing Direction:

6.2.1 Short-Transverse Tests:

6.2.1.1 For specified material thicknesses of 38.10 mm

(1.500 in.) and over, the tension specimen shall be used.

6.2.1.2 For specified material thicknesses of 17.78 through

38.08 mm (0.700 through 1.499 in.), a C-ring shall be used.A

tension specimen may be used if consistent with the provisions

of Practice G49.

6.2.2 For other stress directions in materials of 6.35 mm

(0.250 in.) and over, the tension specimen shall be used.

6.3 Surface Preparation—Test specimens shall be

degreased prior to exposure.

7. Sampling and Number of Tests

7.1 Unless otherwise specified, tests shall be performed in

the short-transverse direction; the intention is to orient the

specimen so that the applied tensile stress is perpendicular to

the metal flow lines and in the short-transverse direction

relative to the grain structure. In rolled or extruded sections

that are approximately round or square, there is no true

short-transverse direction because in a transverse plane the

grainstendtobeequiaxial;and,insuchcases,thestressshould

NOTE 1—Similar to that of typical machined part.

be directed simply in the transverse direction. If, in certain

FIG. 1Recommended Specimen Type and Location for Various

unusual cases, the grain structure is or tends to be equiaxial Configurations of Die Forgings

G47−98 (2019)

obtained. In every case, a diagram should be filed with the test 9.1.1 TensionSpecimens—Stresstensionspecimensin“con-

results to illustrate specimen locations and orientations. stant strain”-type fixtures, as in Fig. 3 of Practice G49.

9.1.2 C-rings—Stress C-rings by a method that provides

7.2.4.1 Flanges—The centerline of the specimen shall be

12.70 61.27mm(0.500 60.050in.)fromthebaseofthefillet constant strain and produces a tensile stress on the ring outside

diameter in accordance with Practice G38.

of the flash except for flanges that are too thin, in which case,

the specimen should be centered.

9.2 Magnitude of Applied Stress—Stress specimens to one

7.2.4.2 Flat-Top Die—The tension specimen should be per-

or more levels as specified or as required to determine

pendicular to the parting plane and, if possible, centered in the

comparative stress corrosion resistance. The application of a

width.

stress less than about 103 MPa (15 ksi) is not practicable.

7.2.4.3 Boss or Small Cylinder—The C-ring specimen

9.3 Examination of Specimens:

should be centered on the parting plane and with the outside

9.3.1 Interim Inspection—Visually inspect specimens each

diameter of the ring being 1.52 6 0.25 mm (0.060 6 0.010 in.)

working day for evidence of cracking without removal of

from the forging surface (see Fig. 1).

corrosion products. Inspection may be facilitated by wetting

7.2.4.4 Large Cylinder—The centerline of tension speci-

the specimen with the test solution and by examination at low

mens shall be 12.70 6 1.27 mm (0.500 6 0.050 in.) from the

magnifications.

base of the flash. If a C-ring is required, its outside diameter

9.3.2 Final Examination—Perform final examination at a

shall be 1.52 6 0.25 mm (0.060 6 0.010 in.) from the forging

magnification of at least 10X on all surviving specimens after

surface (see Fig. 1).

cleaning them in concentrated (70 %) nitric acid (HNO)at

7.2.5 Extruded, Rolled, or Cold Finished Rod, Bar, and

room temperature followed by a water rinse. Section and

Shapes:

metallographically examine any C-ring that is considered

7.2.5.1 Width-to-Thickness Ratio Greater than 2—Short-

suspect, as evidenced by linear pitting, to determine whether or

transverse specimens shall be taken so that the region of

not SCC is present. Similar examination of fractured or

maximum stress is centered in the section thickness, at least

cracked tension specimens also can be useful to verify SCC as

onesectionthicknessawayfromthesidesoftheproduct.Inthe

the cause of failure.

case of complex configurations for which the grain direction-

ality cannot be predicted, specimen location shall be deter-

10. Interpretation of Results

mined by means of macroetched transverse sections to ensure

a short-transverse specimen and to avoid regions of nearly 10.1 Criterion of Failure:

10.1.1 Asample shall be considered to have failed the test if

equiaxial (transverse) grain flow.

one or more of the specimens fail, except that the retest

7.2.5.2 Width-to-Thickness Ratio of 2 or Less—Specimens

provisions of Section 11 shall apply.

shall be centered in the section thickness so that the region of

10.1.2 A specimen that has fractured or which exhibits

maximum stress application will be at least one half the section

cracking shall be considered as a stress corrosion failure unless

thickness away from a fabricated surface, if possible. These

proved otherwise by the provisions of 10.2 and 10.3.

specimens shall be considered to have a “transverse” orienta-

tion to the grain structure. When C-rings are required, they

10.2 Macroscopic Examination—Cracking should be

shall be taken so that the region of maximum tensile stress is

clearly differentiated from lined-up pitting. If the presence of

3.18 6 0.25 mm (0.125 6 0.010 in.) from the product surface.

SCC is questionable, metallographic examinations should be

performed to determine whether or not SCC is present.

7.3 Number of Specimens—For each sample, which shall be

uniform in thickness and grain structure, a minimum of three

NOTE 1—When a specimen fractures within a relatively short time after

adjacent replicate specimens shall be tested.

exposure (ten days or less), metallographic examination is not necessary

because such rapid failures are characteristically due to SCC.

8. Test Environment

10.3 Metallographic Examination:

10.3.1 Aspecimen that reveals intergranular cracking, even

8.1 Corrosion Test Environment—Specimens shall be ex-

when accompanied by transgranular cracking, shall be consid-

posedtothealternate10-minimmersion—50-mindryingcycle

ered as an SCC failure. Intergranular fissures that are no deeper

in accordance with Practice G44.

than the width of localized areas of intergranular corrosion or,

8.2 Length of Exposure—The test duration for 3.18-mm

in the case of C-rings, not deeper than those in unstressed or

(0.125-in.) tension specimens and C-rings shall be 10 days for

compressively stressed surfaces, shall not be considered as an

2XXX all

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G47 − 98 (Reapproved 2011) G47 − 98 (Reapproved 2019)

Standard Test Method for

Determining Susceptibility to Stress-Corrosion Cracking of

2XXX and 7XXX Aluminum Alloy Products

This standard is issued under the fixed designation G47; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a uniform procedure for characterizing the resistance to stress-corrosion cracking (SCC) of

high-strength aluminum alloy wrought products for the guidance of those who perform stress-corrosion tests, for those who prepare

stress-corrosion specifications, and for materials engineers.

1.2 This test method covers method of sampling, type of specimen, specimen preparation, test environment, and method of

exposure for determining the susceptibility to SCC of 2XXX (with 1.8 to 7.0 % copper) and 7XXX (with 0.4 to 2.8 % copper)

aluminum alloy products, particularly when stressed in the short-transverse direction relative to the grain structure.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses are provided for

information.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

G38 Practice for Making and Using C-Ring Stress-Corrosion Test Specimens

G44 Practice for Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solution

G49 Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

G139 Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using

Breaking Load Method

3. Summary of Test Method

3.1 This test method provides a comprehensive procedure for accelerated stress-corrosion testing high-strength aluminum alloy

product forms, particularly when stressed in the short-transverse grain direction. It specifies tests of constant-strain-loaded,

3.18-mm (0.125-in.) tension specimens or C-rings exposed to 3.5 % sodium chloride (NaCl) solution by alternate immersion, and

includes procedures for sampling various manufactured product forms, examination of exposed test specimens, and interpretation

of test results.

4. Significance and Use

4.1 The 3.5 % NaCl solution alternate immersion test provides a test environment for detecting materials that would be likely

3,4,5

to be susceptible to SCC in natural outdoor environments, especially environments with marine influences. For determining

This test method, which was developed by a joint task group with the Aluminum Association, Inc., is under the jurisdiction of ASTM Committee G01 on Corrosion of

Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally Assisted Cracking.

Current edition approved Sept. 1, 2011June 15, 2019. Published September 2011June 2019. Originally approved in 1976. Last previous edition approved in 20042011 as

G47–98(2004).G47 – 98 (2011). DOI: 10.1520/G0047-98R11.10.1520/G0047-98R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Romans, H. B., Stress Corrosion Testing, ASTM STP 425, ASTM, 1967, pp. 182–208.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G47 − 98 (2019)

actual serviceability of a material, other stress-corrosion tests should be performed in the intended service environment under

conditions relating to the end use, including protective measures.

4.2 Although this test method is intended for certain alloy types and for testing products primarily in the short-transverse

stressing direction, this method is useful for some other types of alloys and stressing directions.

5. Interferences

5.1 A disadvantage of the 3.5 % NaCl solution alternate immersion test is that severe pitting may develop in the specimens.

Such pitting in tension specimens with relatively small cross section can markedly reduce the effective cross-sectional area and

produce a net section stress greater than the nominal gross section stress, resulting in either: (1) fracture by mechanical overload

of a material that is not susceptible to SCC; or (2) SCC of a material at an actual stress higher than the intended nominal test stress.

The occurrence of either of these phenomena might then interfere with a valid evaluation of materials with relatively high

resistance to stress corrosion.

6. Test Specimen

6.1 Type and Size—No single configuration of test specimen is applicable for the many complex shapes and sizes of products

that must be evaluated. A tension specimen is preferred because it more consistently provides definite evidence of cracking and

should be used whenever the size and shape of the product permits; it also provides a more severe test.

6.1.1 Tension Specimen—The diameter of the reduced section shall be 3.17 6 0.03 mm (0.125 6 0.001 in.).

6.1.2 C-Ring (see Practices G38)—The use of C-rings permits short-transverse tests to be made of sections that are too thin or

complex for practical tests with a tension specimen. C-rings may be of various sizes as required for the product to be tested, but

in no case less than 15.88 6 0.05 mm (0.625 6 0.002 in.) in outside diameter. The ratio of diameter to wall thickness shall be

kept in the range from 11:1 to 16:1.

6.2 Stressing Direction:

6.2.1 Short-Transverse Tests:

6.2.1.1 For specified material thicknesses of 38.10 mm (1.500 in.) and over, the tension specimen shall be used.

6.2.1.2 For specified material thicknesses of 17.78 through 38.08 mm (0.700 through 1.499 in.), a C-ring shall be used. A tension

specimen may be used if consistent with the provisions of Practice G49.

6.2.2 For other stress directions in materials of 6.35 mm (0.250 in.) and over, the tension specimen shall be used.

6.3 Surface Preparation—Test specimens shall be degreased prior to exposure.

7. Sampling and Number of Tests

7.1 Unless otherwise specified, tests shall be performed in the short-transverse direction; the intention is to orient the specimen

so that the applied tensile stress is perpendicular to the metal flow lines and in the short-transverse direction relative to the grain

structure. In rolled or extruded sections that are approximately round or square, there is no true short-transverse direction because

in a transverse plane the grains tend to be equiaxial; and, in such cases, the stress should be directed simply in the transverse

direction. If, in certain unusual cases, the grain structure is or tends to be equiaxial also in the longitudinal direction, the stress shall

be applied in a direction parallel to the smallest dimension of the product.

7.2 Location of Specimens:

7.2.1 For products stress relieved by stretching (TX51, TX510, TX511, TXX51, TXX510, TXX511), samples shall not be taken

from the portion under the stretcher grips.

7.2.2 Rolled Plate—Short-transverse specimens shall be taken so that the region of maximum stress is centered on the mid-plane

of the plate and at least 2 ⁄2 plate thicknesses away from a side of the plate. (The side of the plate is defined as the edge parallel

to the rolling direction.)

7.2.3 Hand Forgings—Short-transverse specimens shall be taken so that the stress is applied in a direction perpendicular to the

forging flow lines. The region of maximum stress shall be centered in the forging thickness and approximately on the longitudinal

center line of the forging, no less than ⁄2 the section thickness away from “as-heat treated” edges of the forging.

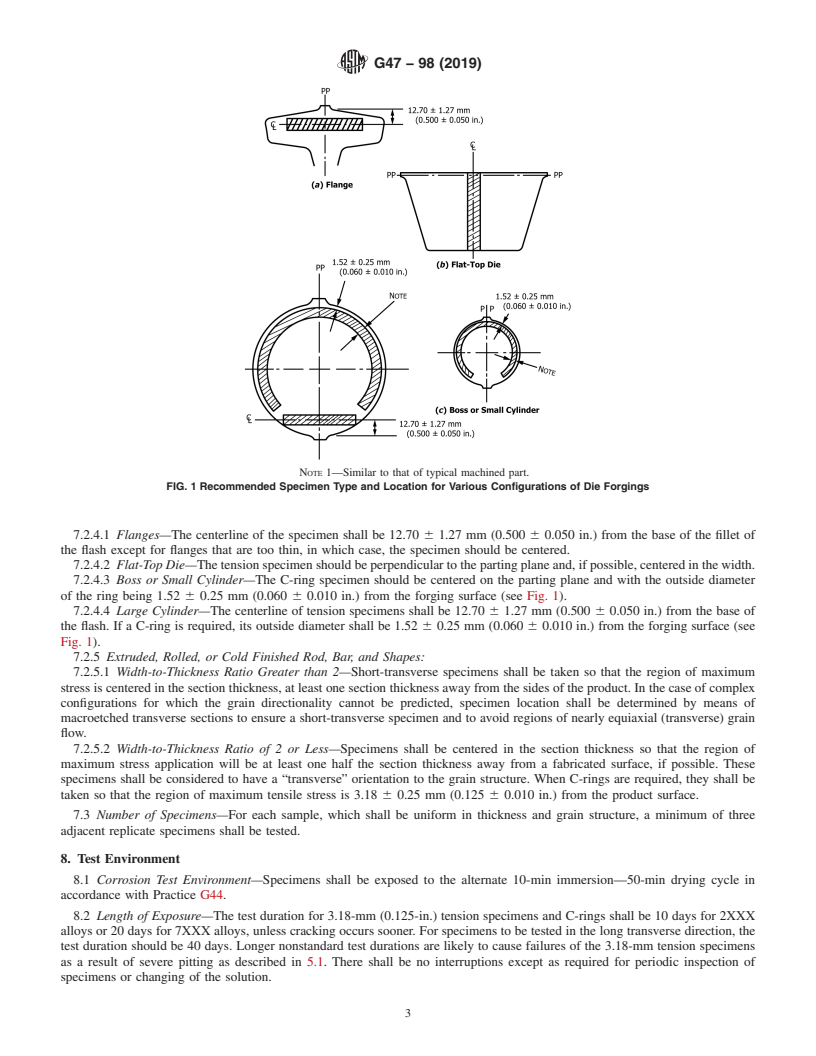

7.2.4 Die Forgings—Because of the wide variety of configurations of die forgings, guidelines are provided for only certain

common types of shapes that are widely used. Short-transverse specimens shall be taken so that the stress is applied in a direction

perpendicular to the forging flow lines and, if possible, with the region of maximum stress centered on the parting plane. The metal

flow pattern in die forgings cannot always be predicted, so only a few general rules are given, and they are illustrated in Fig. 1.

Departures from these rules should be made only on the basis of a study of forging flow lines indicating that the intended type of

test would not be obtained. In every case, a diagram should be filed with the test results to illustrate specimen locations and

orientations.

Brown, R. H., Sprowls, D. O., and Shumaker, M. B., “The Resistance of Wrought High Strength Aluminum Alloys to Stress Corrosion Cracking,” Stress Corrosion

Cracking of Metals—A State of the Art, ASTM STP 518, ASTM, 1972, pp. 87–118.

Sprowls, D. O., Summerson, T. J., Ugiansky, G. M., Epstein, S. G., and Craig, H. L., Jr., “Evaluation of a Proposed Standard Method of Testing for Susceptibility to

Stress-Corrosion Cracking of High-Strength 7XXX Series Aluminum Alloy Products,” Stress Corrosion-New Approaches, ASTM STP 610, ASTM, 1976, pp. 3–31.

G47 − 98 (2019)

NOTE 1—Similar to that of typical machined part.

FIG. 1 Recommended Specimen Type and Location for Various Configurations of Die Forgings

7.2.4.1 Flanges—The centerline of the specimen shall be 12.70 6 1.27 mm (0.500 6 0.050 in.) from the base of the fillet of

the flash except for flanges that are too thin, in which case, the specimen should be centered.

7.2.4.2 Flat-Top Die—The tension specimen should be perpendicular to the parting plane and, if possible, centered in the width.

7.2.4.3 Boss or Small Cylinder—The C-ring specimen should be centered on the parting plane and with the outside diameter

of the ring being 1.52 6 0.25 mm (0.060 6 0.010 in.) from the forging surface (see Fig. 1).

7.2.4.4 Large Cylinder—The centerline of tension specimens shall be 12.70 6 1.27 mm (0.500 6 0.050 in.) from the base of

the flash. If a C-ring is required, its outside diameter shall be 1.52 6 0.25 mm (0.060 6 0.010 in.) from the forging surface (see

Fig. 1).

7.2.5 Extruded, Rolled, or Cold Finished Rod, Bar, and Shapes:

7.2.5.1 Width-to-Thickness Ratio Greater than 2—Short-transverse specimens shall be taken so that the region of maximum

stress is centered in the section thickness, at least one section thickness away from the sides of the product. In the case of complex

configurations for which the grain directionality cannot be predicted, specimen location shall be determined by means of

macroetched transverse sections to ensure a short-transverse specimen and to avoid regions of nearly equiaxial (transverse) grain

flow.

7.2.5.2 Width-to-Thickness Ratio of 2 or Less—Specimens shall be centered in the section thickness so that the region of

maximum stress application will be at least one half the section thickness away from a fabricated surface, if possible. These

specimens shall be considered to have a “transverse” orientation to the grain structure. When C-rings are required, they shall be

taken so that the region of maximum tensile stress is 3.18 6 0.25 mm (0.125 6 0.010 in.) from the product surface.

7.3 Number of Specimens—For each sample, which shall be uniform in thickness and grain structure, a minimum of three

adjacent replicate specimens shall be tested.

8. Test Environment

8.1 Corrosion Test Environment—Specimens shall be exposed to the alternate 10-min immersion—50-min drying cycle in

accordance with Practice G44.

8.2 Length of Exposure—The test duration for 3.18-mm (0.125-in.) tension specimens and C-rings shall be 10 days for 2XXX

alloys or 20 days for 7XXX alloys, unless cracking occurs sooner. For specimens to be tested in the long transverse direction, the

test duration should be 40 days. Longer nonstandard test durations are likely to cause failures of the 3.18-mm tension specimens

as a result of severe pitting as described in 5.1. There shall be no interruptions except as required for periodic inspection of

specimens or changing of the solution.

G47 − 98 (2019)

9. Procedure

9.1 Method of Loading:

9.1.1 Tension Specimens—Stress tension specimens in “constant strain”-type fixtures, as in Fig. 3 of Practice G49.

9.1.2 C-rings—Stress C-rings by a method that provides constant strain and produces a tensile stress on the ring outside

diameter in accordance with Practice G38.

9.2 Magnitude of Applied Stress—Stress specimens to one or more levels as specified or as required to determine comparative

stress corrosion resistance. The application of a stress less than about 103 MPa (15 ksi) is not practicable.

9.3 Examination of Specimens:

9.3.1 Interim Inspection: Inspection—Visually inspect specimens each working day for evidence of cracking without removal

of corrosion products. Inspection may be facilitated by wetting the specimen with the test solution and by examination at low

magnifications.

9.3.2 Final Examination—Perform final examination at a magnification of at least 10X on all surviving specimens after cleaning

them in concentrated (70%)(70 %) nitric acid (HNO ) at room temperature followed by a water rinse. Section and

metallographically examine any C-ring that is considered suspect, as evidenced by linear pitting, to determine whether or not SCC

is present. Similar examination of fractured or cracked tension specimens also can be useful to verify SCC as the cause of failure.

10. Interpretation of Results

10.1 Criterion of Failure:

10.1.1 A sample shall be considered to have failed the test if one or more of the specimens fail, except that the retest provisions

of Section 11 shall apply.

10.1.2 A sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.