ASTM B221M-21

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes (Metric)

Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes (Metric)

SCOPE

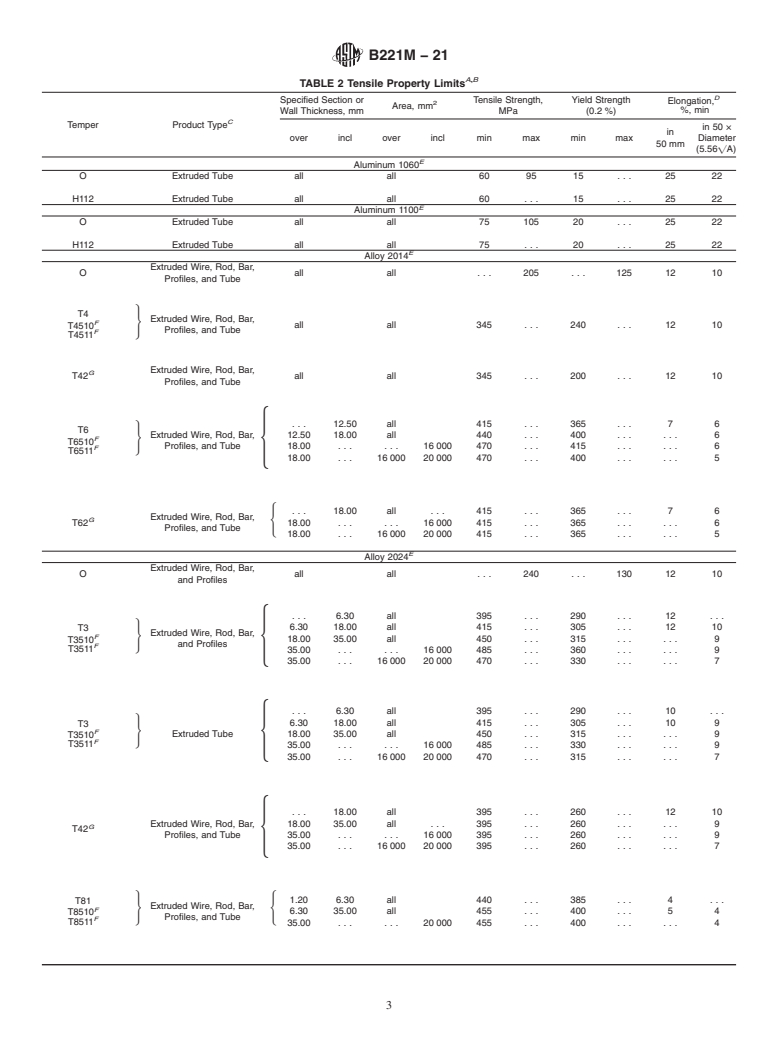

1.1 This specification covers aluminum and aluminum-alloy extruded bars, rods, wires, profiles, and tubes in the aluminum alloys (Note 1) and tempers shown in Table 2.

Note 1: Throughout this specification the use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

Note 2: For rolled or cold-finished bars and rods refer to Specification B211/B211M, for drawn seamless tube used in pressure applications, Specification B210/B210M, for structural pipe and tube, Specification B429/B429M, and for seamless pipe and tube used in pressure applications, Specification B241/B241M.

Note 3: Pipe and tube products listed in this specification are intended for general purpose applications. This specification may not address the manufacturing processes, integrity testing, and verification required for fluid-carrying applications involving pressure. See Specification B210/B210M, B241/B241M, or both as appropriate for seamless pipe and tube used in fluid-carrying applications involving pressure. See Specification B234M, as appropriate, for use in surface condensers, evaporators, and heat exchangers.

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1M. The equivalent Unified Numbering System alloy designations are those of Table 1 preceded by A9, for example, A91100 for Aluminum 1100 in accordance with Practice E527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 This specification is the metric counterpart of Specification B221.

1.5 The values stated in SI are to be regarded as standard. No other units of measurement are included in this specification.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B221M −21

Standard Specification for

Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire,

1

Profiles, and Tubes (Metric)

This standard is issued under the fixed designation B221M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 Thisspecificationcoversaluminumandaluminum-alloy

extruded bars, rods, wires, profiles, and tubes in the aluminum

2. Referenced Documents

alloys (Note 1) and tempers shown in Table 2.

2.1 The following documents of the issue in effect on the

NOTE 1—Throughout this specification the use of the term alloy in the

dateofmaterialpurchaseformapartofthisspecificationtothe

general sense includes aluminum as well as aluminum alloy.

extent referenced herein:

NOTE2—Forrolledorcold-finishedbarsandrodsrefertoSpecification

2

B211/B211M, for drawn seamless tube used in pressure applications,

2.2 ASTM Standards:

Specification B210/B210M, for structural pipe and tube, Specification

B210/B210MSpecification for Aluminum and Aluminum-

B429/B429M, and for seamless pipe and tube used in pressure

Alloy Drawn Seamless Tubes

applications, Specification B241/B241M.

NOTE3—Pipeandtubeproductslistedinthisspecificationareintended B211/B211MSpecification for Aluminum and Aluminum-

for general purpose applications. This specification may not address the

Alloy Rolled or Cold Finished Bar, Rod, and Wire

manufacturing processes, integrity testing, and verification required for

B234MSpecification for Aluminum and Aluminum-Alloy

fluid-carrying applications involving pressure. See Specification B210/

Drawn Seamless Tubes for Surface Condensers,

B210M, B241/B241M, or both as appropriate for seamless pipe and tube

Evaporators, and Heat Exchangers (Metric)

used in fluid-carrying applications involving pressure. See Specification

B234M, as appropriate, for use in surface condensers, evaporators, and B241/B241MSpecification for Aluminum and Aluminum-

heat exchangers.

Alloy Seamless Pipe and Seamless Extruded Tube

B429/B429MSpecification for Aluminum-Alloy Extruded

1.2 Alloy and temper designations are in accordance with

Structural Pipe and Tube

ANSI H35.1/H35.1M. The equivalent Unified Numbering

B557MTest Methods forTensionTestingWrought and Cast

SystemalloydesignationsarethoseofTable1precededbyA9,

Aluminum- and Magnesium-Alloy Products (Metric)

for example, A91100 for Aluminum 1100 in accordance with

B594Practice for Ultrasonic Inspection ofAluminum-Alloy

Practice E527.

Wrought Products

1.3 For acceptance criteria for inclusion of new aluminum

B660Practices for Packaging/Packing of Aluminum and

and aluminum alloys in this specification, see Annex A2.

Magnesium Products

1.4 This specification is the metric counterpart of Specifi-

B666/B666MPractice for Identification Marking of Alumi-

cation B221.

num and Magnesium Products

B807/B807MPractice for Extrusion Press Solution Heat

1.5 The values stated in SI are to be regarded as standard.

Treatment for Aluminum Alloys

No other units of measurement are included in this specifica-

B881Terminology Relating toAluminum- and Magnesium-

tion.

Alloy Products

1.6 This international standard was developed in accor-

B918/B918MPractice for Heat Treatment of Wrought Alu-

dance with internationally recognized principles on standard-

minum Alloys

ization established in the Decision on Principles for the

B945Practice forAluminumAlloy Extrusions Press Cooled

Development of International Standards, Guides and Recom-

from an Elevated Temperature Shaping Process for Pro-

duction of T1, T2, T5 and T10–Type Tempers

1

This specification is under the jurisdiction ofASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

2

Aluminum Alloy Wrought Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2021. Published November 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1979. Last previous edition approved in 2013 as B221M–13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0221M-21. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-

...

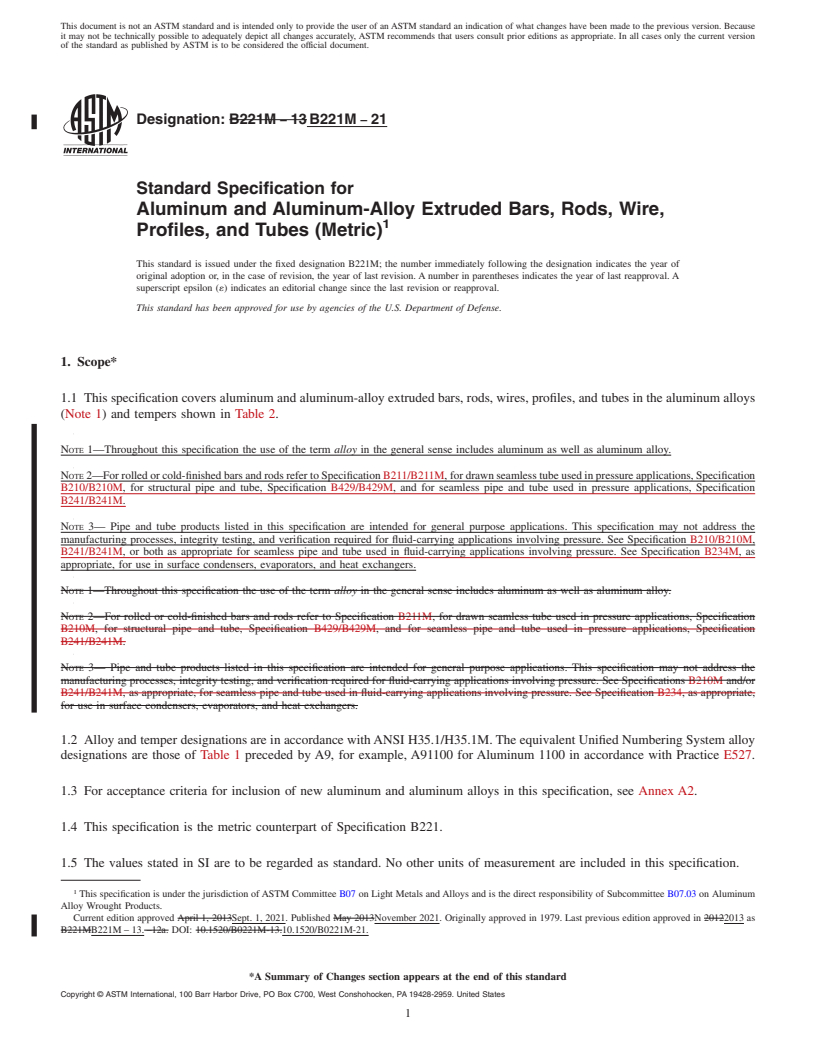

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B221M − 13 B221M − 21

Standard Specification for

Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire,

1

Profiles, and Tubes (Metric)

This standard is issued under the fixed designation B221M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers aluminum and aluminum-alloy extruded bars, rods, wires, profiles, and tubes in the aluminum alloys

(Note 1) and tempers shown in Table 2.

NOTE 1—Throughout this specification the use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

NOTE 2—For rolled or cold-finished bars and rods refer to Specification B211/B211M, for drawn seamless tube used in pressure applications, Specification

B210/B210M, for structural pipe and tube, Specification B429/B429M, and for seamless pipe and tube used in pressure applications, Specification

B241/B241M.

NOTE 3— Pipe and tube products listed in this specification are intended for general purpose applications. This specification may not address the

manufacturing processes, integrity testing, and verification required for fluid-carrying applications involving pressure. See Specification B210/B210M,

B241/B241M, or both as appropriate for seamless pipe and tube used in fluid-carrying applications involving pressure. See Specification B234M, as

appropriate, for use in surface condensers, evaporators, and heat exchangers.

NOTE 1—Throughout this specification the use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

NOTE 2—For rolled or cold-finished bars and rods refer to Specification B211M, for drawn seamless tube used in pressure applications, Specification

B210M, for structural pipe and tube, Specification B429/B429M, and for seamless pipe and tube used in pressure applications, Specification

B241/B241M.

NOTE 3— Pipe and tube products listed in this specification are intended for general purpose applications. This specification may not address the

manufacturing processes, integrity testing, and verification required for fluid-carrying applications involving pressure. See Specifications B210M and/or

B241/B241M, as appropriate, for seamless pipe and tube used in fluid-carrying applications involving pressure. See Specification B234, as appropriate,

for use in surface condensers, evaporators, and heat exchangers.

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1M. The equivalent Unified Numbering System alloy

designations are those of Table 1 preceded by A9, for example, A91100 for Aluminum 1100 in accordance with Practice E527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 This specification is the metric counterpart of Specification B221.

1.5 The values stated in SI are to be regarded as standard. No other units of measurement are included in this specification.

1

This specification is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum

Alloy Wrought Products.

Current edition approved April 1, 2013Sept. 1, 2021. Published May 2013November 2021. Originally approved in 1979. Last previous edition approved in 20122013 as

B221MB221M – 13. –12a. DOI: 10.1520/B0221M-13.10.1520/B0221M-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

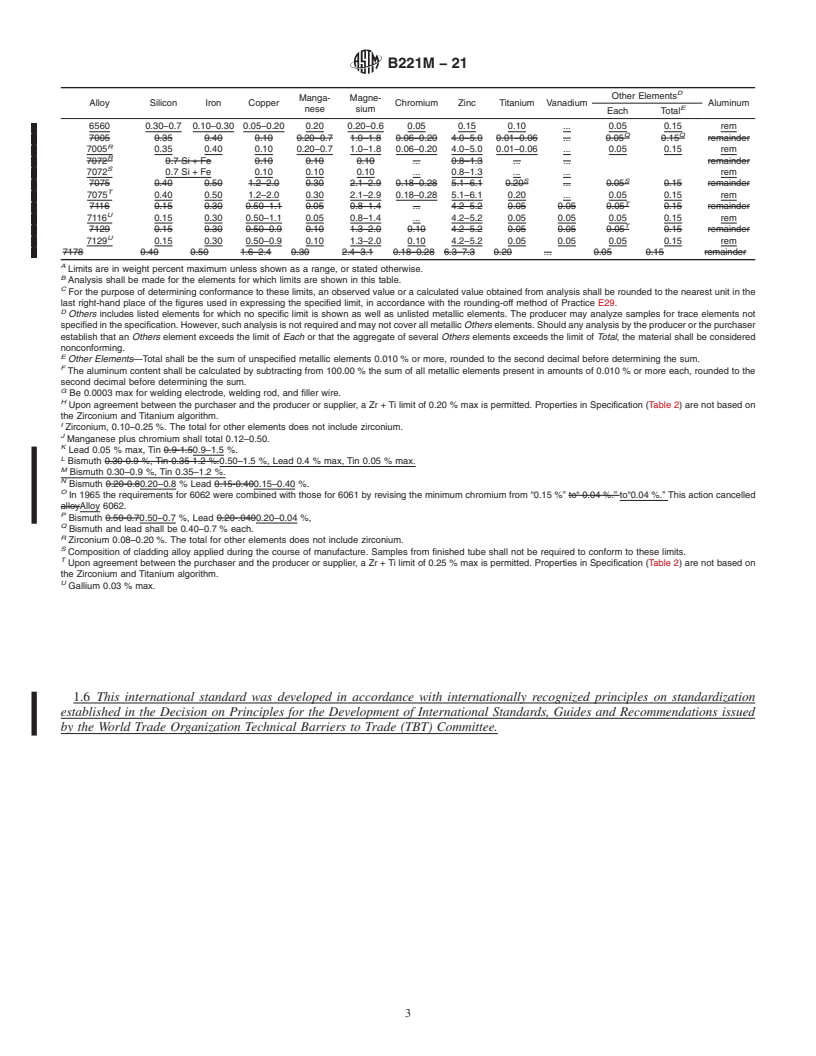

B221M − 21

A,B,C

TABLE 1 Chemical Composition Limits

NOTE 1—In case of a discrepancy between the values listed in Table 1 and those listed in the “International Alloy Designations and Chemical

Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys”(known as the “Teal Sheets”), the composition limits registered with the

Aluminum Association and published in the “Teal Sheets” should be considered the controlling composition. The “Teal Sheets” are available at

http://www.aluminum.org/tealsheets.

D

Other Elements

Manga- Magne-

Alloy Silicon Iron Copper Chromium Zinc Titanium Vanadium Aluminum

E

nese sium

Each Total

F

1060 0.25 0.35 0.05 0.03 0.03 . 0.05 0.03 0.05 0.03 . 99.60 min

G

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.