ASTM D3617/D3617M-17(2022)

(Practice)Standard Practice for Sampling and Analysis of Built-Up Roof Systems During Application

Standard Practice for Sampling and Analysis of Built-Up Roof Systems During Application

ABSTRACT

This practice describes the standard procedure for sampling, analysis, and removal of specimens in built-up bituminous roof systems during application, but before the application of flood coating and top surfacing, for determining the approximate quantities of the components and the possible presence of moisture, or dry spots between plies, in the field. These components may be composed of insulation (when part of the roof membrane system), plies of roofing felt, interply layers of bituminous material, and top coating (if present, before any surfacing aggregate has been applied). Appropriate calculation procedures are also indicated herein.

SCOPE

1.1 This practice is a guide for removing specimens for built-up bituminous roof systems during application, but before the application of flood coating and top surfacing, for determining the approximate quantities of the components and the possible presence of moisture, or dry spots between plies, in the field. Components may consist of:

1.1.1 Insulation, when part of the roof membrane system,

1.1.2 Plies of roofing felt,

1.1.3 Interply layers of bituminous material, and

1.1.4 Top coating, if present, before any surfacing aggregate has been applied.

1.2 This practice is applicable to both 914 mm [36 in.] and 1000 mm [393/8 in.] wide felt rolls.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3617/D3617M − 17 (Reapproved 2022)

Standard Practice for

Sampling and Analysis of Built-Up Roof Systems During

Application

This standard is issued under the fixed designation D3617/D3617M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice is a guide for removing specimens for

D226/D226M Specification for Asphalt-Saturated Organic

built-upbituminousroofsystemsduringapplication,butbefore

Felt Used in Roofing and Waterproofing

the application of flood coating and top surfacing, for deter-

D227/D227M Specification for Coal-Tar-Saturated Organic

mining the approximate quantities of the components and the

Felt Used in Roofing and Waterproofing

possible presence of moisture, or dry spots between plies, in

D250 Standard Specification forAsphalt-SaturatedAsbestos

the field. Components may consist of:

Felt Used in Roofing and Waterproofing (Withdrawn

1.1.1 Insulation, when part of the roof membrane system,

1991)

1.1.2 Plies of roofing felt,

D2178/D2178M SpecificationforAsphaltGlassFeltUsedin

1.1.3 Interply layers of bituminous material, and

Roofing and Waterproofing

D2626/D2626M Specification for Asphalt-Saturated and

1.1.4 Top coating, if present, before any surfacing aggregate

has been applied. Coated Organic Felt Base Sheet Used in Roofing

D3158 Specification for Asphalt Saturated and Coated Or-

1.2 This practice is applicable to both 914 mm [36 in.] and 3

ganic Felt Used in Roofing (Withdrawn 1983)

1000 mm [39 ⁄8 in.] wide felt rolls.

D3378 Specification for Asphalt-Saturated and Coated As-

bestos Felt Base Sheet Used in Roofing (Withdrawn

1.3 The values stated in either SI units or inch-pound units

1985)

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

3. Sampling

system shall be used independently of the other. Combining

3.1 Unless otherwise specified, take at least one specimen

values from the two systems may result in nonconformance

2 2

for each separate roof, plus one for each 929 m [10 000 ft ];

with the standard.

take specimens at random.

1.4 This standard does not purport to address all of the

3.2 If deficiencies are indicated in the membrane, additional

safety concerns, if any, associated with its use. It is the

Practice D3617/D3617M test cuts shall be taken at four

responsibility of the user of this standard to establish appro-

locations diagonally—3 m [10 ft] in each direction—from the

priate safety, health, and environmental practices and deter-

original test cut and examined in the same manner as the

mine the applicability of regulatory limitations prior to use.

original test cut was examined.

1.5 This international standard was developed in accor-

4. Test Specimen

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 Sweep the surface of the membrane clean where each

Development of International Standards, Guides and Recom-

test specimen will be taken.

mendations issued by the World Trade Organization Technical

4.2 For determining approximate quantities of components,

Barriers to Trade (TBT) Committee.

cut a 300 by 300 mm [12 by 12 in.] specimen from the

membrane using a template (Fig. 1).

1 2

ThispracticeisunderthejurisdictionofASTMCommitteeD08onRoofingand For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Membrane Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2022. Published November 2022. Originally the ASTM website.

approved in 1977. Last previous edition approved in 2017 as D3617/D3617M – 17. The last approved version of this historical standard is referenced on

DOI: 10.1520/D3617_D3617M-17R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3617/D3617M − 17 (2022)

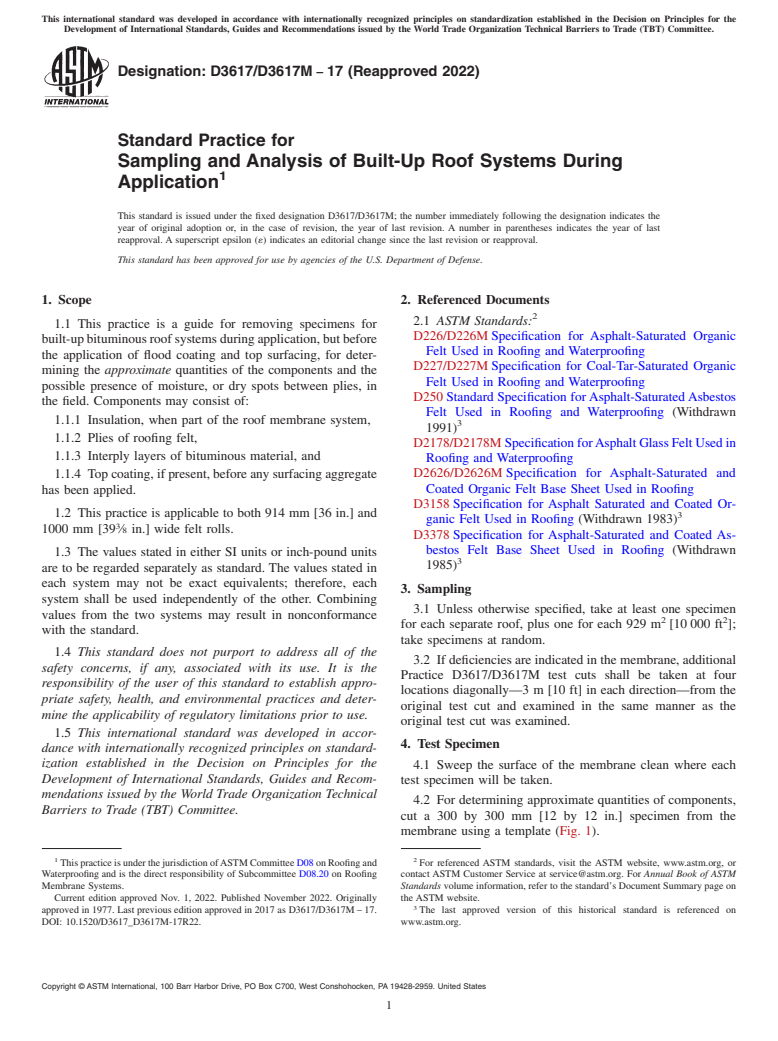

Square (4.2) Rectangular (4.3)

Dimension

mm in. mm in.

A 300 12 100 4

B 300 12 1000 40

C 150 6 150 6

D 40 1.5 40 1.5

E 40 1.5 40 1.5

1 1

F3 ⁄8 3 ⁄8

FIG. 1 Dimensions of Templates for Roof Sampling

4.2.1 If the membrane is adhered to the insulation, remove 5.4 Determine the number of plies and lap spacing by visual

the membrane from the adhering insulation. examination of the 100 by 1118 mm [4 by 44 in.] specimen, if

4.2.2 If the membrane is adhered directly to the roof deck, lap spacing is desired.

estimate the quantity of bitumen remaining on the deck after

6. Calculation (See Table 1 for Form and Sample

the specimen is removed.

Computation)

4.3 For the purpose of determining the felt spacing, cut a

6.1 Calculate the mass (weight) per unit area of the original

100 by 111 mm [4 by 44 in.] rectangular specimen from the

specimen by dividing the specimen’s weight by its area (and

membrane, using a template (Fig. 1) placed at right angles to

multiplying by 100 if U.S. customary units are used).

the long dimension of the felts.

6.2 Divide the sum of the individual felt areas by the area of

4.4 Identify each specimen by location and record the

the original specimen, and record as the “number of plies.”

presence of insulation or the estimated quantity of bitumen

remaining on the deck.

6.3 Calculate the mass per unit area of the saturated felts in

the original specimen by dividing the individual felt areas by

4.5 If practicable, return the cut membrane specimen to its

the area of the original specimen, and then multiplying by the

original location in the roof. Make adequate repairs to the

following values. Add the masses per unit area for each felt to

roofing system, using at least the same number of felt plies as

find the total mass per unit area of the original felts. If all the

the original roof membrane after testing.

plies are the same, multiply

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.