ASTM D4320-02

(Test Method)Standard Test Method for Laboratory Preparation of Chemically Grouted Soil Specimens for Obtaining Design Strength Parameters

Standard Test Method for Laboratory Preparation of Chemically Grouted Soil Specimens for Obtaining Design Strength Parameters

SCOPE

1.1 This test method covers the laboratory preparation of chemically grouted soil specimens for use in laboratory tests to determine design strength parameters.

Note 1—This test method may not be applicable to grout mixtures with gel times shorter than the time required to saturate the specimen with grout.

1.2 The specimens are intended for both strength and modulus determination in unconfined and confined compression testing.

Note 2—Preparation methods for specimens to be used for other purposes are described in Test Methods D 4219 and D 5202.

1.3 This test method requires the injection of grout into soil specimens already fabricated to a desired density.

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4320–02

Standard Test Method for

Laboratory Preparation of Chemically Grouted Soil

1

Specimens for Obtaining Design Strength Parameters

This standard is issued under the fixed designation D 4320; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * 3. Terminology

1.1 This test method covers the laboratory preparation of 3.1 For common definitions of terms used in this test

chemically grouted soil specimens for use in laboratory tests to method, refer to Terminology D 653.

determine design strength parameters.

4. Significance and Use

NOTE 1—Thistestmethodmaynotbeapplicabletogroutmixtureswith

4.1 The purpose of this test method is to prepare specimens

gel times shorter than the time required to saturate the specimen with

of chemically grouted soils for testing in unconfined or triaxial

grout.

compression, when the test data is to be used for design

1.2 The specimens are intended for both strength and

purposes.

modulus determination in unconfined and confined compres-

NOTE 3—The quality of the result produced by this standard is

sion testing.

dependent on the competence of the personnel performing it, and the

NOTE 2—Preparation methods for specimens to be used for other

suitability of the equipment and facilities used. Agencies that meet the

purposes are described in Test Methods D 4219 and D 5202.

criteria of Practice D 3740 are generally considered capable of competent

and objective testing/sampling/inspection/etc. Users of this standard are

1.3 This test method requires the injection of grout into soil

cautioned that compliance with Practice D 3740 does not in itself assure

specimens already fabricated to a desired density.

reliable results. Reliable results depend on many factors; Practice D 3740

1.4 The values stated in inch-pound units are to be regarded

provides a means of evaluating some of those factors.

as the standard.

1.5 This standard does not purport to address all of the

5. Apparatus

safety problems, if any, associated with its use. It is the

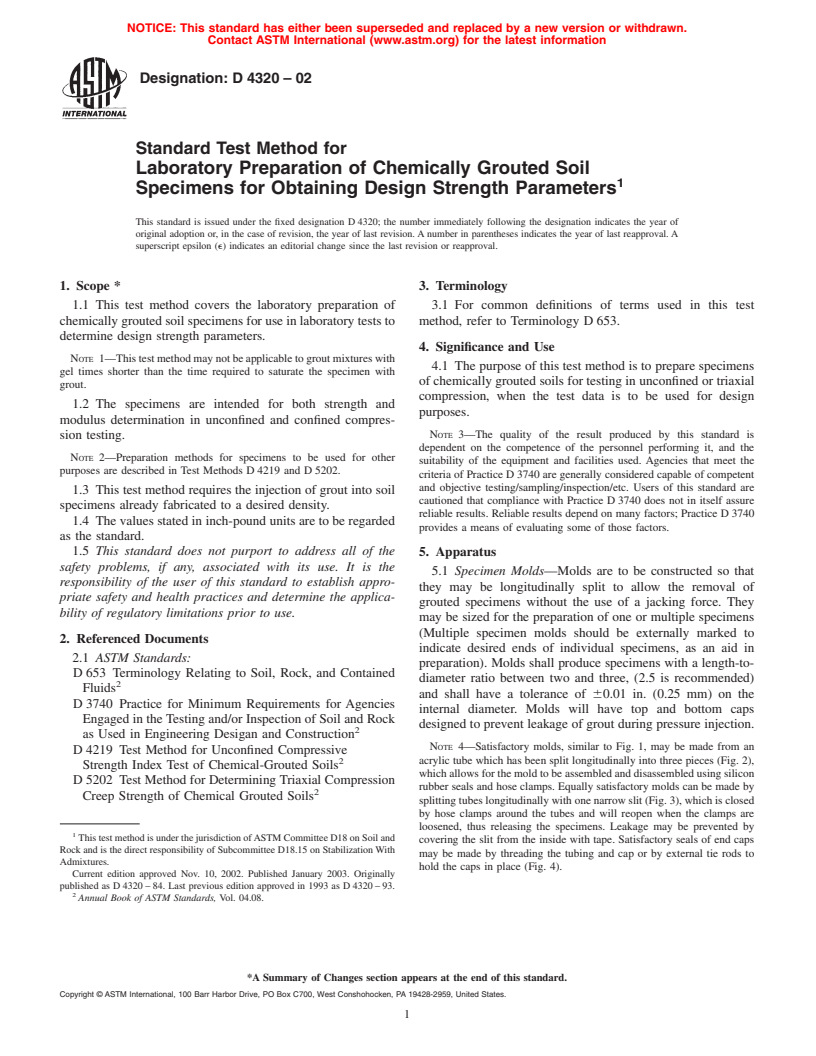

5.1 Specimen Molds—Molds are to be constructed so that

responsibility of the user of this standard to establish appro-

they may be longitudinally split to allow the removal of

priate safety and health practices and determine the applica-

grouted specimens without the use of a jacking force. They

bility of regulatory limitations prior to use.

may be sized for the preparation of one or multiple specimens

(Multiple specimen molds should be externally marked to

2. Referenced Documents

indicate desired ends of individual specimens, as an aid in

2.1 ASTM Standards:

preparation). Molds shall produce specimens with a length-to-

D 653 Terminology Relating to Soil, Rock, and Contained

diameter ratio between two and three, (2.5 is recommended)

2

Fluids

and shall have a tolerance of 60.01 in. (0.25 mm) on the

D 3740 Practice for Minimum Requirements for Agencies

internal diameter. Molds will have top and bottom caps

Engaged in the Testing and/or Inspection of Soil and Rock

designed to prevent leakage of grout during pressure injection.

2

as Used in Engineering Desigan and Construction

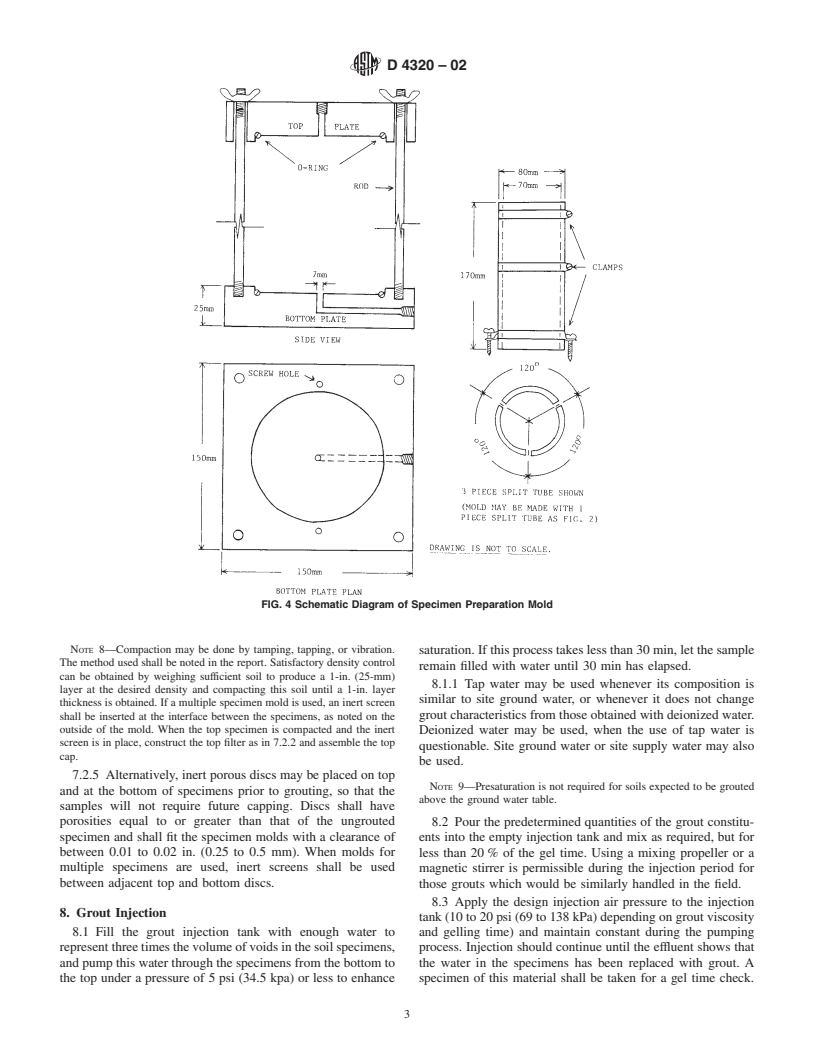

NOTE 4—Satisfactory molds, similar to Fig. 1, may be made from an

D 4219 Test Method for Unconfined Compressive

2 acrylic tube which has been split longitudinally into three pieces (Fig. 2),

Strength Index Test of Chemical-Grouted Soils

which allows for the mold to be assembled and disassembled using silicon

D 5202 Test Method for Determining Triaxial Compression

rubber seals and hose clamps. Equally satisfactory molds can be made by

2

Creep Strength of Chemical Grouted Soils

splitting tubes longitudinally with one narrow slit (Fig. 3), which is closed

by hose clamps around the tubes and will reopen when the clamps are

loosened, thus releasing the specimens. Leakage may be prevented by

1

This test method is under the jurisdiction ofASTM Committee D18 on Soil and

covering the slit from the inside with tape. Satisfactory seals of end caps

Rock and is the direct responsibility of Subcommittee D18.15 on Stabilization With

may be made by threading the tubing and cap or by external tie rods to

Admixtures.

hold the caps in place (Fig. 4).

Current edition approved Nov. 10, 2002. Published January 2003. Originally

published as D 4320 – 84. Last previous edition approved in 1993 as D 4320 – 93.

2

Annual Book of ASTM Standards, Vol. 04.08.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.