ASTM F588-97

(Test Method)Standard Test Methods for Measuring the Forced Entry Resistance of Window Assemblies, Excluding Glazing Impact

Standard Test Methods for Measuring the Forced Entry Resistance of Window Assemblies, Excluding Glazing Impact

SCOPE

1.1 These test methods determine the ability of window assemblies of various types to restrain, delay, or frustrate forced entry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 588 – 97

Standard Test Methods for

Measuring the Forced Entry Resistance of Window

Assemblies, Excluding Glazing Impact

This standard is issued under the fixed designation F 588; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 These test methods determine the ability of window 3.1 Definitions: Definitions for standard terminology can be

assemblies of various types to restrain, delay, or frustrate found in Terminology E 631.

forced entry. 3.2 Definitions of Terms Specific to This Standard:

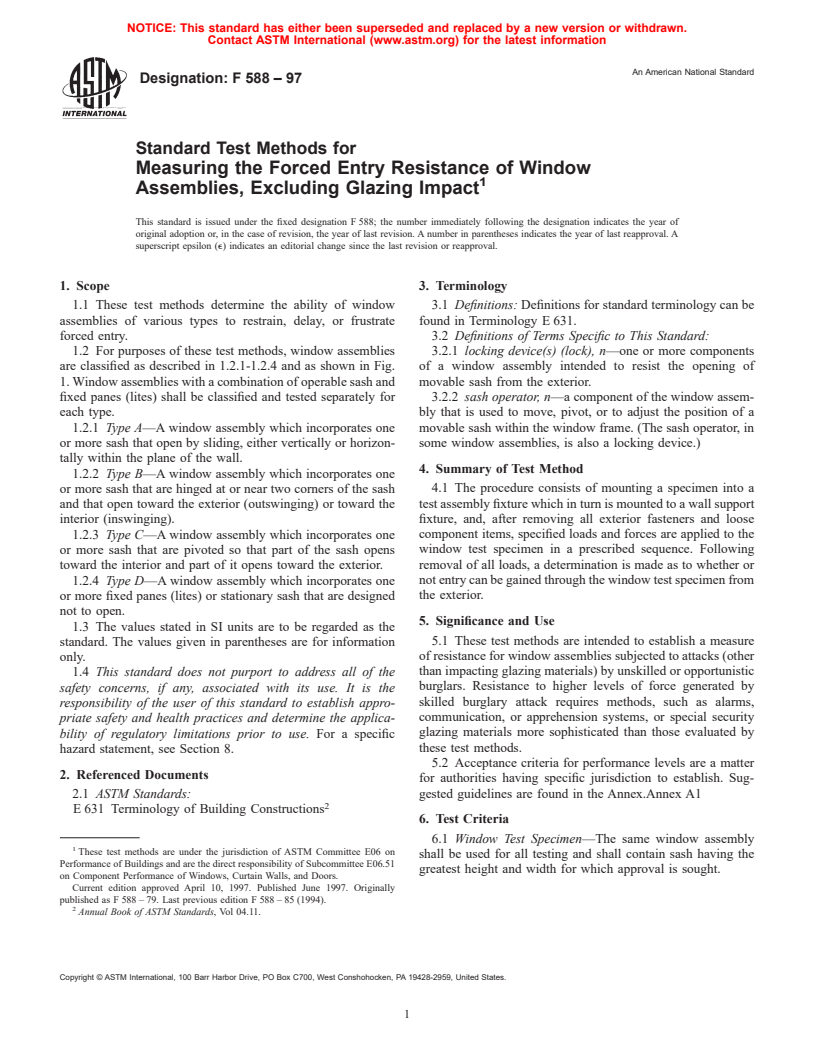

1.2 For purposes of these test methods, window assemblies 3.2.1 locking device(s) (lock), n—one or more components

are classified as described in 1.2.1-1.2.4 and as shown in Fig. of a window assembly intended to resist the opening of

1. Window assemblies with a combination of operable sash and movable sash from the exterior.

fixed panes (lites) shall be classified and tested separately for 3.2.2 sash operator, n—a component of the window assem-

each type. bly that is used to move, pivot, or to adjust the position of a

1.2.1 Type A—A window assembly which incorporates one movable sash within the window frame. (The sash operator, in

or more sash that open by sliding, either vertically or horizon- some window assemblies, is also a locking device.)

tally within the plane of the wall.

4. Summary of Test Method

1.2.2 Type B—A window assembly which incorporates one

or more sash that are hinged at or near two corners of the sash 4.1 The procedure consists of mounting a specimen into a

test assembly fixture which in turn is mounted to a wall support

and that open toward the exterior (outswinging) or toward the

interior (inswinging). fixture, and, after removing all exterior fasteners and loose

component items, specified loads and forces are applied to the

1.2.3 Type C—A window assembly which incorporates one

or more sash that are pivoted so that part of the sash opens window test specimen in a prescribed sequence. Following

removal of all loads, a determination is made as to whether or

toward the interior and part of it opens toward the exterior.

not entry can be gained through the window test specimen from

1.2.4 Type D—A window assembly which incorporates one

or more fixed panes (lites) or stationary sash that are designed the exterior.

not to open.

5. Significance and Use

1.3 The values stated in SI units are to be regarded as the

5.1 These test methods are intended to establish a measure

standard. The values given in parentheses are for information

of resistance for window assemblies subjected to attacks (other

only.

than impacting glazing materials) by unskilled or opportunistic

1.4 This standard does not purport to address all of the

burglars. Resistance to higher levels of force generated by

safety concerns, if any, associated with its use. It is the

skilled burglary attack requires methods, such as alarms,

responsibility of the user of this standard to establish appro-

communication, or apprehension systems, or special security

priate safety and health practices and determine the applica-

glazing materials more sophisticated than those evaluated by

bility of regulatory limitations prior to use. For a specific

these test methods.

hazard statement, see Section 8.

5.2 Acceptance criteria for performance levels are a matter

2. Referenced Documents

for authorities having specific jurisdiction to establish. Sug-

2.1 ASTM Standards: gested guidelines are found in the Annex.Annex A1

E 631 Terminology of Building Constructions

6. Test Criteria

6.1 Window Test Specimen—The same window assembly

These test methods are under the jurisdiction of ASTM Committee E06 on

shall be used for all testing and shall contain sash having the

Performance of Buildings and are the direct responsibility of Subcommittee E06.51

greatest height and width for which approval is sought.

on Component Performance of Windows, Curtain Walls, and Doors.

Current edition approved April 10, 1997. Published June 1997. Originally

published as F 588 – 79. Last previous edition F 588 – 85 (1994).

Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F588–97

FIG. 1 Typical Window Types (viewed from the exterior)

6.1.1 The construction of the window test specimen, includ- 6.4 Test Sequence—Perform the tests for each window test

ing all hardware, components, and arrangement of sash shall be specimen in the sequence as outlined in Section 10. The

sequence for testing multiple sash shall be at the discretion of

representative of that for which acceptance is desired.

the testing agency.

6.1.2 The window test specimen shall consist of the entire

6.5 Loading—Apply test loads and forces at a rate not to

assembled unit, including frame, glazing, and anchorage as

exceed 4.5 kg/s (10 lb/s). Maintain performance level loads for

supplied by the manufacturer for installation in the building.

a period of 60 6 5s.

6.1.3 Unless otherwise specified, the window test specimen

6.6 Load Removal—At the conclusion of each test, remove

shall contain annealed glass for testing and shall be single

all loads before starting the next test.

glazed if designed for either single or double glazing, or double

glazed if designed exclusively for multiple glazing. Products

7. Apparatus

tested with glazing materials other than annealed glass shall

7.1 Instrumentation—Load and time-measuring devices

qualify only the specific glazing material tested.

with an accuracy of 6 2 % of the full scale shall be incorpo-

6.1.4 Windows tested with more than one locking device

rated in the test setups. The scale ranges used shall assure that

shall not qualify windows with fewer locking devices, regard-

the performance levels are within an accuracy of 6 5%.

less of size.

7.2 Load Attachments—Brackets, fasteners, or other de-

6.2 Performance Criteria—The performance level is at-

vices used in performing these tests shall be designed and

tained if all locking devices remain engaged and entry cannot

attached so as to minimize their influence on the test results.

be gained during the test or upon removal of loads. If during

7.3 Test Frame—The test frame shall be designed and

testing, any component, including the glazing material, fails,

constructed to accept and rigidly secure the window specimen

allowing entry, this shall be considered a failure to attain the and to provide rigid points of anchor for all test loads described

performance level. Glazing which breaks, but which does not

in Section 10. The load bearing members of the test frame shall

allow entry, shall not be considered a failure to attain the be constructed to limit deflection of such members to a

performance level. maximum of 3 mm ( ⁄8 in.) under full prescribed load.

6.3 Multiple Sash—Window assemblies with a combination

8. Hazards

of operable sash and fixed panes (lites) shall be classified and

tested separately for each type. If multiple sash within a 8.1 Glass breakage may occur during the application of

window assembly are identical in construction and locking

loads or forces required by these test methods. Take adequate

condition, only one sash need be tested. precautions to protect personnel from broken glass.

F588–97

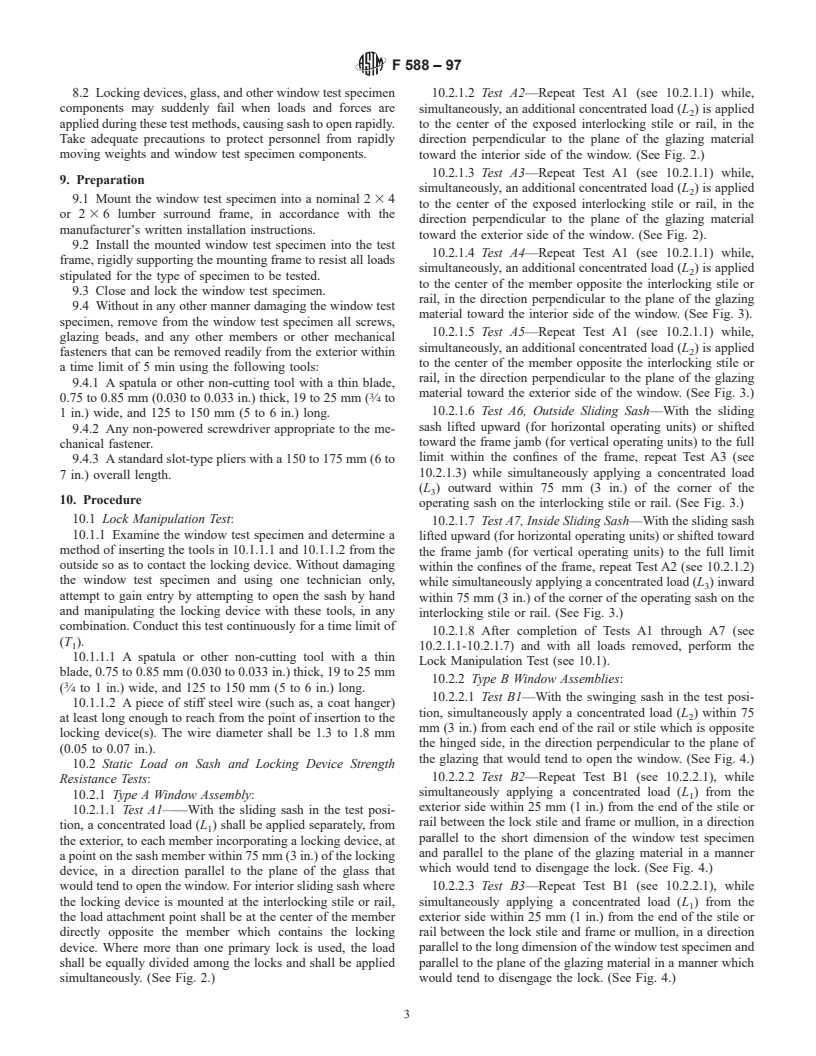

8.2 Locking devices, glass, and other window test specimen 10.2.1.2 Test A2—Repeat Test A1 (see 10.2.1.1) while,

components may suddenly fail when loads and forces are simultaneously, an additional concentrated load (L ) is applied

applied during these test methods, causing sash to open rapidly. to the center of the exposed interlocking stile or rail, in the

Take adequate precautions to protect personnel from rapidly direction perpendicular to the plane of the glazing material

moving weights and window test specimen components.

toward the interior side of the window. (See Fig. 2.)

10.2.1.3 Test A3—Repeat Test A1 (see 10.2.1.1) while,

9. Preparation

simultaneously, an additional concentrated load (L ) is applied

9.1 Mount the window test specimen into a nominal 2 3 4

to the center of the exposed interlocking stile or rail, in the

or 2 3 6 lumber surround frame, in accordance with the

direction perpendicular to the plane of the glazing material

manufacturer’s written installation instructions.

toward the exterior side of the window. (See Fig. 2).

9.2 Install the mounted window test specimen into the test

10.2.1.4 Test A4—Repeat Test A1 (see 10.2.1.1) while,

frame, rigidly supporting the mounting frame to resist all loads

simultaneously, an additional concentrated load (L ) is applied

stipulated for the type of specimen to be tested.

to the center of the member opposite the interlocking stile or

9.3 Close and lock the window test specimen.

rail, in the direction perpendicular to the plane of the glazing

9.4 Without in any other manner damaging the window test

material toward the interior side of the window. (See Fig. 3).

specimen, remove from the window test specimen all screws,

10.2.1.5 Test A5—Repeat Test A1 (see 10.2.1.1) while,

glazing beads, and any other members or other mechanical

simultaneously, an additional concentrated load (L ) is applied

fasteners that can be removed readily from the exterior within

to the center of the member opposite the interlocking stile or

a time limit of 5 min using the following tools:

rail, in the direction perpendicular to the plane of the glazing

9.4.1 A spatula or other non-cutting tool with a thin blade,

3 material toward the exterior side of the window. (See Fig. 3.)

0.75 to 0.85 mm (0.030 to 0.033 in.) thick, 19 to 25 mm ( ⁄4 to

10.2.1.6 Test A6, Outside Sliding Sash—With the sliding

1 in.) wide, and 125 to 150 mm (5 to 6 in.) long.

sash lifted upward (for horizontal operating units) or shifted

9.4.2 Any non-powered screwdriver appropriate to the me-

toward the frame jamb (for vertical operating units) to the full

chanical fastener.

limit within the confines of the frame, repeat Test A3 (see

9.4.3 A standard slot-type pliers with a 150 to 175 mm (6 to

10.2.1.3) while simultaneously applying a concentrated load

7 in.) overall length.

(L ) outward within 75 mm (3 in.) of the corner of the

10. Procedure

operating sash on the interlocking stile or rail. (See Fig. 3.)

10.1 Lock Manipulation Test:

10.2.1.7 Test A7, Inside Sliding Sash—With the sliding sash

10.1.1 Examine the window test specimen and determine a

lifted upwar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.