ASTM D6230-98(2005)

(Test Method)Standard Test Method for Monitoring Ground Movement Using Probe-Type Inclinometers

Standard Test Method for Monitoring Ground Movement Using Probe-Type Inclinometers

SIGNIFICANCE AND USE

An inclinometer is a device for measuring deformation normal to the axis of a pipe by passing a probe along the pipe and measuring the inclination of the probe with respect to the line of gravity. Measurements are converted to distances using trigonometric functions. Distances are summed to find the position of the pipe. Successive measurements give differences in position of the pipe and indicate deformation normal to the axis of the pipe. In most cases the pipe is installed in a near-vertical hole. Measurements indicate subsurface horizontal deformation. In some cases the pipe is installed horizontally and the measurements indicate vertical deformation.

Inclinometers are also called slope inclinometers or slope indicators. Typical applications include measuring the rate of landslide movement and locating the zone of shearing, monitoring the magnitude and rate of horizontal movements for embankments and excavations, monitoring the settlement and lateral spread beneath tanks and embankments, and monitoring the deflection of bulkheads, piles or structural walls.

SCOPE

1.1 This test method covers the use of inclinometers to monitor the internal movement of ground. The test method covers types of instruments, installation procedures, operating procedures and maintenance requirements. It also provides formulae for data reduction.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate health and safety practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6230 − 98(Reapproved 2005)

Standard Test Method for

Monitoring Ground Movement Using Probe-Type

Inclinometers

This standard is issued under the fixed designation D6230; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope axis of the pipe. In most cases the pipe is installed in a

near-vertical hole. Measurements indicate subsurface horizon-

1.1 This test method covers the use of inclinometers to

tal deformation. In some cases the pipe is installed horizontally

monitor the internal movement of ground. The test method

and the measurements indicate vertical deformation.

covers types of instruments, installation procedures, operating

procedures and maintenance requirements. It also provides 3.2 Inclinometers are also called slope inclinometers or

formulae for data reduction. slope indicators. Typical applications include measuring the

rate of landslide movement and locating the zone of shearing,

1.2 The values stated in SI units are to be regarded as the

monitoring the magnitude and rate of horizontal movements

standard. The inch-pound units given in parentheses are for

for embankments and excavations, monitoring the settlement

information only.

and lateral spread beneath tanks and embankments, and moni-

1.3 This standard does not purport to address all of the

toring the deflection of bulkheads, piles or structural walls.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Apparatus

priate health and safety practices and determine the applica-

4.1 The probe type inclinometer uses sensors inside a probe

bility of regulatory limitations prior to use.

to indicate the orientation of the probe relative to the pull of

gravity. The complete system consists of:

2. Referenced Documents

4.1.1 A permanently installed pipe, called casing, with test

2.1 ASTM Standards:

method grooves. The casing is made of plastic, aluminum

D653 Terminology Relating to Soil, Rock, and Contained

alloy, or fiberglass.

Fluids

4.1.2 The Probe—Most probes use force balance acceler-

D4622 Test Method for Rock Mass Monitoring Using Incli-

ometers which give a voltage output that is proportional to

nometers (Discontinued 2000) (Withdrawn 2000)

inclination of the probe. Biaxial probes contain two sensors

oriented 90° apart to permit readings in orthogonal directions

3. Significance and Use

at the same time.

3.1 An inclinometer is a device for measuring deformation

4.1.3 A portable readout unit with power supply for the

normal to the axis of a pipe by passing a probe along the pipe

sensors and display to indicate probe inclination. The readout

and measuring the inclination of the probe with respect to the

unit may have internal memory to record data.

line of gravity. Measurements are converted to distances using

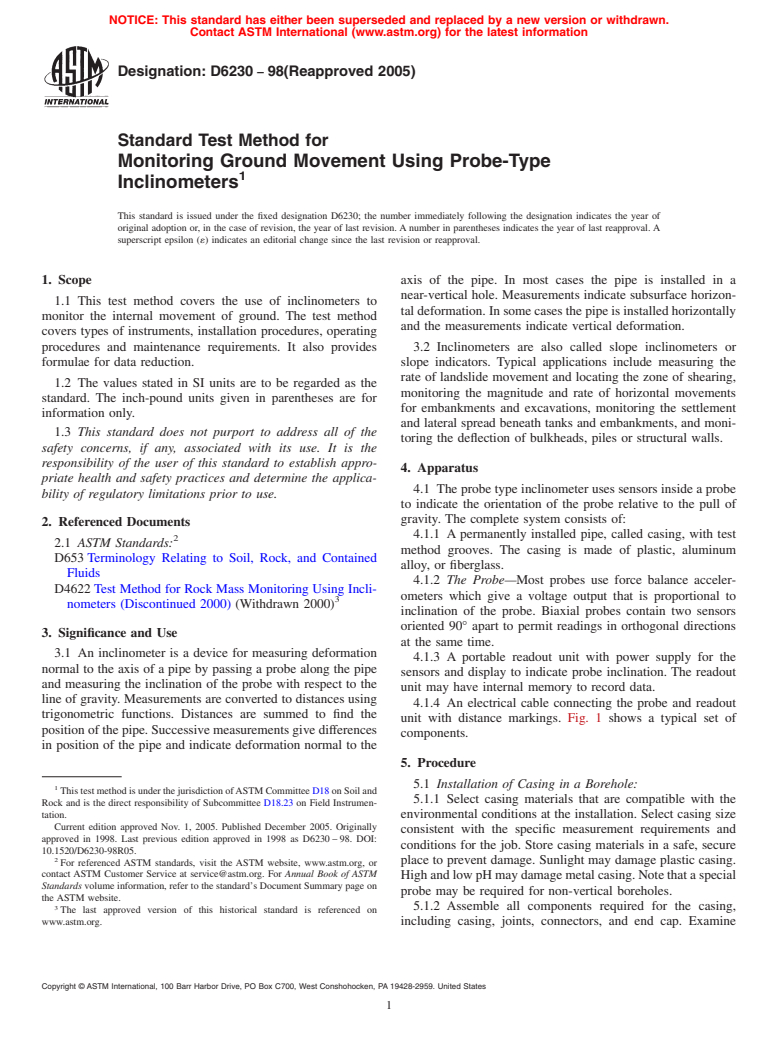

4.1.4 An electrical cable connecting the probe and readout

trigonometric functions. Distances are summed to find the

unit with distance markings. Fig. 1 shows a typical set of

position of the pipe. Successive measurements give differences

components.

in position of the pipe and indicate deformation normal to the

5. Procedure

5.1 Installation of Casing in a Borehole:

This test method is under the jurisdiction ofASTM Committee D18 on Soil and

5.1.1 Select casing materials that are compatible with the

Rock and is the direct responsibility of Subcommittee D18.23 on Field Instrumen-

tation.

environmental conditions at the installation. Select casing size

Current edition approved Nov. 1, 2005. Published December 2005. Originally

consistent with the specific measurement requirements and

approved in 1998. Last previous edition approved in 1998 as D6230 – 98. DOI:

conditions for the job. Store casing materials in a safe, secure

10.1520/D6230-98R05.

place to prevent damage. Sunlight may damage plastic casing.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

HighandlowpHmaydamagemetalcasing.Notethataspecial

Standards volume information, refer to the standard’s Document Summary page on

probe may be required for non-vertical boreholes.

the ASTM website.

5.1.2 Assemble all components required for the casing,

The last approved version of this historical standard is referenced on

www.astm.org. including casing, joints, connectors, and end cap. Examine

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6230 − 98 (2005)

backfill is preferable unless the surrounding ground is too

pervioustoholdthegrout.Placegroutwithatremie.Buoyancy

must be overcome with grout backfills. Add a weight to the

bottom of the inclinometer casing, temporarily place clean drill

pipe inside the casing, or place the first 3 m (10 ft) of grout

aroundthebottomofthecasingandletitset,thencompletethe

grouting. Place sand and gravel backfills slowly and with

techniques to prevent leaving large voids in the backfill. Such

voids can later lead to erratic readings. Place backfill and

withdraw drill casing or augers in sequence to prevent any

squeezing off of the borehole. Withdraw drill casing and

hollow-stem augers without rotation to prevent damage to the

inclinometer casing. Use measures to prevent backfill from

spilling into the inclinometer casing.

5.2 Installation on The Ground Surface of Horizontal Cas-

ing:

NOTE 1—A practical limit for installing horizontal casing is about 100

m. Beyond 100 m cable friction makes it difficult to pull the inclinometer

FIG. 1 Typical Components of Inclinometer System

probe through the casing. Special TFE-fluorocarbon inserts on the cable

alleviate the problem to some degree.

5.2.1 Select casing materials that are compatible with the

each component for defects. Do not use defective components

environmental conditions at the installation. Select casing size

since they may later cause problems with readings that are

consistent with the specific measurement requirements and

difficult to diagnose and impossible to correct. Keep all

conditions for the job. Store casing materials in a safe, secure

components clean and free of foreign matter during assembly.

place to prevent damage. Sunlight may damage plastic casing.

Follow the manufacturer’s instructions for assembly of the

HighandlowpHmaydamagemetalcasing.Notethataspecial

casing. If required, use sealing mastic and tape to seal all

probe is required for horizontal casing. If one end of the casing

couplings to prevent later flow of soil particles into the casing.

istobeburiedthentheendcapcontainsapulleytocarryawire

Thisisespeciallyimportantwhenusinggrouttosealthecasing

that is used to pull the probe into the inclinometer casing.

in the hole. Exercise care to keep the casing grooves free of

Special care must be taken to insure that the pulley is correctly

obstructions. When assembling couplings, use procedures to

assembled, free to turn and has the wire in place. Take

prevent spiraling of the casing grooves. Twist adjacent cou-

precautions at all times during installation to keep the wire

plings in alternate directions before fixing to minimize spiral-

clean.

ing. Examine the casing during assembly to confirm that

5.2.2 Create a near-level surface over the length where the

spiraling is not occurring. Place a cap on the bottom end and

casing is to be installed. Cover with a bed of at least 50-mm

seal it to prevent inflow.

(2-in.) deep and 300-mm (12-in.) wide of clean sand, pea

5.1.3 Create the borehole using procedures to keep it

gravel or a lean grout.

aligned within the range of the readout equipment. Extend the

5.2.3 Assemble all components required for the casing,

borehole at least 5 m (16 ft) beyond the zone of expected

including casing joints, connectors, and end cap. Examine each

movement. It may be necessary to use casing, hollow-stem

component for defects. Do not use defective components since

augers, or drilling mud to keep the hole open and stable. Flush

theymaylatercauseproblemswithreadingsthataredifficultto

the hole until clear of drilling cuttings.

5.1.4 Insert the casing into the borehole. Establish the diagnose and impossible to correct. Keep all components clean

and free of foreign matter during assembly. Follow the manu-

reference orientation for the casing and align one set of groves

with this reference.This orientation is commonly referred to as facturer’s instructions for assembly of the casing. If required

usesealingmasticandtapetosealallcouplingstopreventlater

the A direction. It should align with the direction of greatest

anticipated movement. Add clean water to the casing if flow of soil particles into the casing. This is especially

important when using grout to seal the casing in the borehole.

necessary to overcome buoyancy. Use care to minimize any

twistofthecasingduringinstallation.Careshouldbeexercised Exercise care to keep the casing grooves free of obstructions.

When assembling couplings, use procedures to prevent spiral-

to maintain orientation without twisting from the first piece of

casing to the last. Twisting the top of the casing may cause ing of the casing grooves.Twist adjacent couplings in alternate

directions before fixing to minimize spiraling. Examine the

spiraling of casing at depth.

5.1.5 Backfill the annular space between the borehole wall casing during assembly to confirm that spiraling is not occur-

ring.

and the inclinometer casing with a suitable filling material.

Borehole can be pre-grouted or post-grouted. If post-grouted, 5.2.4 Place the casing onto the bed and adjust its position

grouting can be through a tremie placed in the annulus of the until it is within the tolerances required by the readout device.

inclinometer casing and the borehole’s walls or via an internal Establish the reference orientation for the casing and align one

tremie connected to a one-way bottom grout valve. Options set of groves with this reference. This orientation is commonly

includecementgrout,sandandpeagravel.Aleancementgrout referred to as the A direction. It aligns with the direction of

D6230 − 98 (2005)

greatest anticipated movement. Visually check for and remove readings. Repeat the procedure to the top of the casing to

any spiraling. Determine that the pull cable is in position and complete the traverse. Remove the probe from the casing,

moves freely through the inclinometer casing. rotate it 180°, and lower it to the bottom of the casing. Start

5.2.5 Use hand tools or light construction equipment to readings for this traverse from exactly the same depth as the

place clean sand, pea gravel or lean grout evenly, at least first traverse and make each reading at exactly the same depth

150-mm (6-in.) wide, on both sides of the casing. Cover the as the first traverse. For biaxial probes, two traverses complete

inclinometer casing with at least 50 mm (2 in.) of clean sand, the set of readings. For uniaxial probes, two more traverses

pea gravel or lean grout. Place fill over casing in 150-mm must be made for the B direction the same way as for the A

(6-in.) lifts. Fill for the first lift should not contain any particles direction.

larger than 25 mm (1 in.). If compaction is required, use hand

5.4.2 Check the set of readings by summing the readings for

compactors for the first two lifts.

the A and A' directions at each depth and the readings for the

B and B' direction. These sums are called check-sums and

5.3 Calibration:

should equal a constant value that is a characteristic of the

5.3.1 Inclinometers are factory calibrated and supplied with

probe. Refer to the manufacturer’s literature for information on

a calibration factor, K, that is specific to the probe and the

allowable variation in the check-sum. A single deviation in a

readout unit. Some manufacturers provide standardized read-

check-sum probably indicates a bad reading. Erratic behavior

out units that can be used with multiple probes. However it

of the check-sums generally indicates a poor electrical connec-

should be noted that electronic variations in the readout

tion or a malfunctioning probe or readout.

equipment may cause conditions where different probes will

give different readings. It is recommended that a calibration

5.5 Initial Readings:

check be performed any time a probe and readout unit

5.5.1 Makeinitialobservationsafterallowingsufficienttime

combination is changed. For applications involving small but

for the grout around the casing to set or for the backfill to

important changes over several years, recalibrate the instru-

stabilize. Since computation of all displacements is based on

ment to the precision of the device at least once per year.

theinitialreadings,itisimportanttohaveavalidset.Verifythe

5.3.2 Perform a calibration check before each set of incli-

initial set of readings with at least two sets of readings, taken

nometer readings. Field checks can be made using a test stand,

on the same day. Check these readings for stability of the

a test casing, or a section of field casing in material that does

check-sums and for displacement within the accuracy of the

not move. Test stands are available from most manufacturers.

equipment. Repeat observations until satisfactory agreement is

They employ a short piece of inclinometer casing preset at a

obtained. From all initial readings taken, one set should be

fixed angle. The test stand must be set on a stable base and

selected for use as the reference set for all subsequent readings.

properly aligned by the manufacturer’s instructions. A test

Take readings on any spiral with a spiral sensor if corrections

casing is a short piece of casing installed in a fixed position

for twist are desired, or if there is potential for twist in the

with the grooves at angles of 0 to 10° from the vertical. A

casing of sufficient magnitude to affect the computed displace-

section of field casing that is placed in fixed material can be

ments of the casing.

used to check calibrations. This last method is the least

5.5.2 Thetopposition(x,yandz)oftheinclinometercasing

preferable since most field casings are near-vertical (or near-

must be located by survey at the same time initial readings are

horizontal). Calibration checks on vertical casing can indicate

made by survey to the accuracy of the inclinometer readings.

malfunctioning equipment but cannot provide an accurate

Later changes in the top position of the casing can be used to

calibration.

check the inclinometer readings or to correct for movement of

5.3.3 Perform a calibration c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.