ASTM D5187-10(2015)e1

(Test Method)Standard Test Method for Determination of Crystallite Size (Lc) of Calcined Petroleum Coke by X-Ray Diffraction

Standard Test Method for Determination of Crystallite Size (L<inf>c</inf>) of Calcined Petroleum Coke by X-Ray Diffraction

SIGNIFICANCE AND USE

5.1 The crystallinity of petroleum coke, as reflected by the Lc value, is a general measure of quality affecting suitability for end use and is a function of the heat treatment.

5.2 The crystallite thickness is used to determine the extent of such heat treatment, for example, during calcination. The value of the Lc determined is not affected by coke microporosity or the presence of foreign, non-crystalline materials such as dedust oil.

SCOPE

1.1 This test method covers the determination of the mean crystallite thickness of a representative, pulverized sample of calcined petroleum coke by interpretation of a X-ray diffraction pattern produced through conventional X-ray scanning techniques.

1.2 Calcined petroleum coke contains crystallites of different thicknesses. This test method covers the determination of the average thickness of all crystallites in the sample by empirical interpretation of the X-ray diffraction pattern. The crystallite diameter (La) is not determined by this test method.

1.3 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound units given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5187 − 10 (Reapproved 2015)

Standard Test Method for

Determination of Crystallite Size (L ) of Calcined Petroleum

c

Coke by X-Ray Diffraction

This standard is issued under the fixed designation D5187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in December 2015.

1. Scope Determine the Precision of a Test Method

1.1 This test method covers the determination of the mean

3. Terminology

crystallite thickness of a representative, pulverized sample of

3.1 Definitions of Terms Specific to This Standard:

calcinedpetroleumcokebyinterpretationofaX-raydiffraction

3.1.1 crystallites, n—stacks of graphitic carbon platelets

pattern produced through conventional X-ray scanning tech-

located parallel to one another.

niques.

3.1.2 L,n—the mean or average thickness of crystallites in

1.2 Calcined petroleum coke contains crystallites of differ- c

a sample. It is expressed as a linear dimension in angstrom

ent thicknesses. This test method covers the determination of

−1

˚

units, A (10 nm).

the average thickness of all crystallites in the sample by

empirical interpretation of the X-ray diffraction pattern. The

3.1.3 hkl(002), n—the Miller indices of the crystalline

crystallite diameter (L ) is not determined by this test method. planes of graphite corresponding to a lattice spacing (d)of

a

3.35Å.

1.3 The values stated in SI (metric) units are to be regarded

as the standard. The inch-pound units given in parentheses are 3.1.4 Theta angle,Θ, n—the glancing angle produced when

provided for information purposes only.

a parallel beam of uniform X-rays impinges upon a crystalline

lattice. This angle is measured by the X-ray goniometer and is

1.4 This standard does not purport to address all of the

usually expressed in degrees TwoTheta ° (2Θ).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

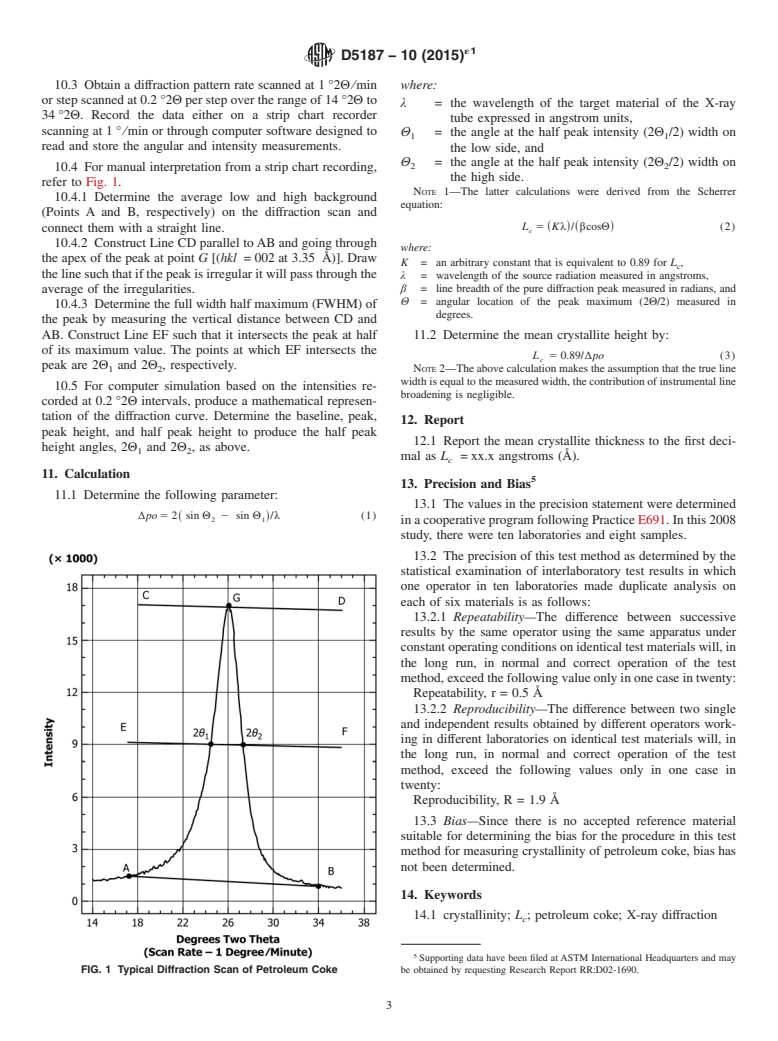

4.1 A packed sample pulverized to less than 75µm is

subjected to a monochromatic X-ray beam and rotated to

2. Referenced Documents

produce a diffraction pattern under specific conditions. The

˚

locationandshapeofthepeakwith hkl =(002)at d =3.35 A

2.1 ASTM Standards:

is used to calculate the L by manual interpretation of the peak

D346Practice for Collection and Preparation of Coke

c

or by computer simulation.

Samples for Laboratory Analysis

D2013Practice for Preparing Coal Samples for Analysis

5. Significance and Use

D2234/D2234MPractice for Collection of a Gross Sample

of Coal

5.1 The crystallinity of petroleum coke, as reflected by the

D4057Practice for Manual Sampling of Petroleum and

L value,isageneralmeasureofqualityaffectingsuitabilityfor

c

Petroleum Products

end use and is a function of the heat treatment.

E691Practice for Conducting an Interlaboratory Study to

5.2 The crystallite thickness is used to determine the extent

of such heat treatment, for example, during calcination. The

1 value of the L determined is not affected by coke microporo-

This test method is under the jurisdiction of ASTM Committee D02 on c

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of sity or the presence of foreign, non-crystalline materials such

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

as dedust oil.

Current edition approved Oct. 1, 2015. Published December 2015. Originally

published in 1991. Last previous edition approved in 2010 as D5187–10. DOI:

6. Apparatus

10.1520/D5187-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 X-Ray Powder Diffractometer, equipped with an X-ray

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

source, a monochromator or filter for restricting the wave-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. length range, a sample holder, a radiation detector, a signal

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5187 − 10 (2015)

processor, and readout (chart or computer memory). The (Slide 2) on top of the sample and secure with tape. Remove

diffractometer must be capable of rate scanning at 1°2Θ⁄min Slide1toexposeaflat,smoothsurfacebeforeinsertingintothe

or incrementally step scanning at 0.2°2Θ steps. diffractometer for analysis.

8.5.2 Front Fill Technique—Place a confining ring over the

6.2 Sample Holders, as specified by the manufacturer of the

round sample holder and fill the holder cavity and ring with

diffractometer that enables packing of a pulverized sample of

sample.The ring will initially overfill the sample holder.Work

sufficient thickness to expose a level, smooth surface to the

thesampleintotheentirecavityandring.Scrapetheexcessoff

X-ray beam.

withaglassplateorspatula.Pressdownusingaflatglassslide.

6.3 Briquetting Press, capable of generating pressures up to

Remove any excess material on the front face of the holder.

69MPa (10000psi).

Repressthesamplewiththeglassslidewhileturningclockwise

and anti-clockwise. Continue until the sample is level with the

6.4 Compressible Aluminum Caps, used as a support for

producing a briquetted sample. holder face. Place the sample in diffractometer holder.

8.5.3 Side Loading Technique—Pack the sample following

6.5 Silicon or Quartz Sample, available from National

the procedure used by the National Institute of Standards and

Institute of Standards and Technology (NIST).

Technology and the Joint Committee on Powder Diffraction

Standards to prepare standard powder diffraction patterns.

7. Reagents and Materials

Clamp a glass slide over the top face to form a temporary

7.1 Purity of Reagents—Reagent grade chemicals shall be

cavity wall. With the holder in a vertical position, drift the

usedinalltests.Itisintendedthatallreagentsshallconformto

powdered sample into the end opening. If necessary, use a

the specifications of the Committee onAnalytical Reagents of

cardboard pusher cut to fit the cavity to lightly compress the

the American Chemical Society where such specifications are

sample so it will remain in the cavity. Return the holder to a

available. Other grades may be used, provided it is first

horizontal position and carefully remove the glass slide. Place

ascertained that the reagent is of sufficiently high purity to

the sample in diffractometer holder.

permit its use without lessening the accuracy of the determi-

8.5.4 Briquetting Technique—Weighout4.0gofthesample

nation.

onto a watch glass and pipette exactly 3mL of the binding

7.2 Acetone.

agentontothesampleandmixthoroughlywithaspatula.Place

the sample under an infrared heat lamp and allow the acetone

7.3 Polyethylene Glycol, (approximate molecular weight of

to evaporate. Typically, between 1min and 2min will be

200 AU).

required to eliminate the acetone odor from sample. Break up

7.4 Binding Agent—Prepare a 15% by mass solution of

the caked sample with a spatula and transfer to an aluminum

polyethylene glycol and acetone by adding 15g of polyethyl-

capwhosediameteriscompatiblewiththesampleholderofthe

ene glycol to 85g of acetone.

diffractometer. Place the cap in a briquetting press and press at

48MPa (7000psi). Transfer the pelletized sample to the

8. S

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D5187 − 10 D5187 − 10 (Reapproved 2015)

Standard Test Method for

Determination of Crystallite Size (L ) of Calcined Petroleum

c

Coke by X-Ray Diffraction

This standard is issued under the fixed designation D5187; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made throughout in December 2015.

1. Scope*Scope

1.1 This test method covers the determination of the mean crystallite thickness of a representative, pulverized sample of

calcined petroleum coke by interpretation of a X-ray diffraction pattern produced through conventional X-ray scanning techniques.

1.2 Calcined petroleum coke contains crystallites of different thicknesses. This test method covers the determination of the

average thickness of all crystallites in the sample by empirical interpretation of the X-ray diffraction pattern. The crystallite

diameter (L ) is not determined by this test method.

a

1.3 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound units given in parentheses are

provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

D2013 Practice for Preparing Coal Samples for Analysis

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 crystallites—crystallites, n—stacks of graphitic carbon platelets located parallel to one another.

3.1.2 L —, n—the mean or average thickness of crystallites in a sample. It is expressed as a linear dimension in angstrom units,

c

−1

A˚ (10 nm).

3.1.3 hkl(002)—hkl(002), n—the Miller indices of the crystalline planes of graphite corresponding to a lattice spacing (d) of 3.35

Å.3.35 Å.

3.1.4 Θ—the Theta angle, Θ, n—the glancing angle produced when a parallel beam of uniform X-rays impinges upon a

crystalline lattice. This angle is measured by the X-ray goniometer and is usually expressed in degrees TwoTheta ° 2Θ.(2Θ).

4. Summary of Test Method

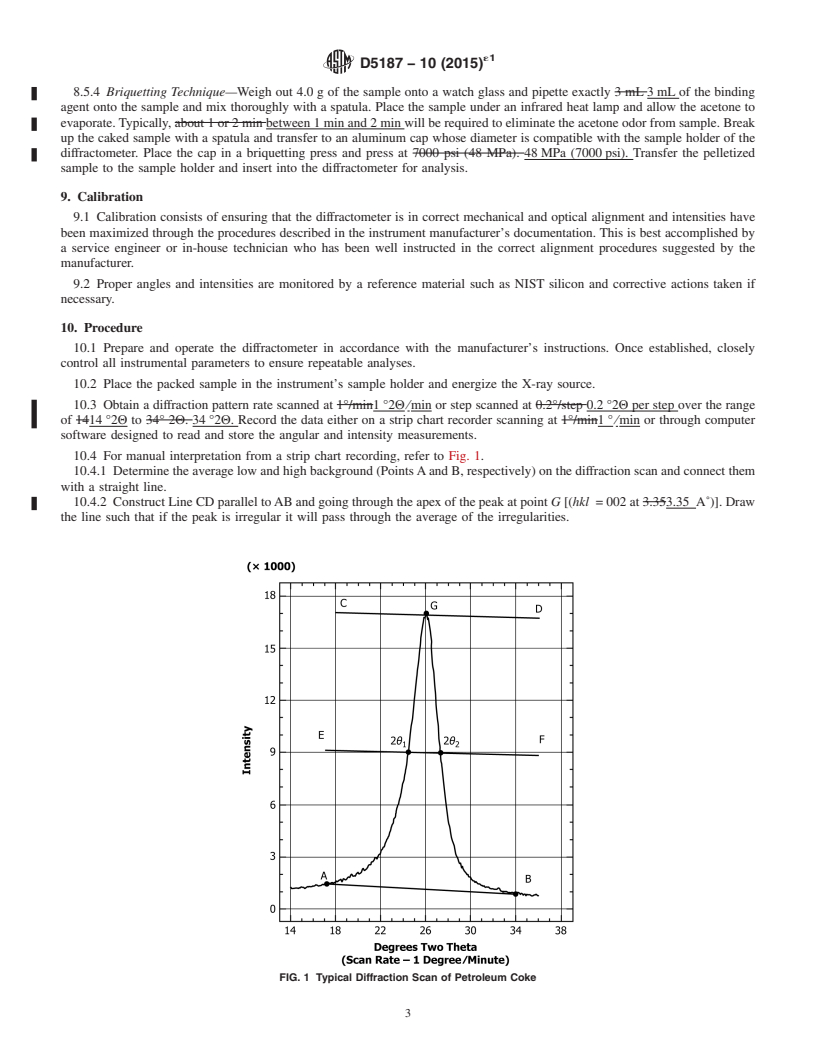

4.1 A packed sample pulverized to less than 75 μm 75 μm is subjected to a monochromatic X-ray beam and rotated to produce

a diffraction pattern under specific conditions. The location and shape of the peak with hkl = (002) at d = 3.35; = 3.35 A˚ is used

to calculate the L by manual interpretation of the peak or by computer simulation.

c

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved May 1, 2010Oct. 1, 2015. Published July 2010December 2015. Originally published in 1991. Last previous edition approved in 20072010 as

D5187–91(2007).D5187 – 10. DOI: 10.1520/D5187-10.10.1520/D5187-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5187 − 10 (2015)

5. Significance and Use

5.1 The crystallinity of petroleum coke, as reflected by the L value, is a general measure of quality affecting suitability for end

c

use and is a function of the heat treatment.

5.2 The crystallite thickness is used to determine the extent of such heat treatment, for example, during calcination. The value

of the L determined is not affected by coke microporosity or the presence of foreign, non-crystalline materials such as dedust oil.

c

6. Apparatus

6.1 X-Ray Powder Diffractometer , Diffractometer, equipped with an X-ray source, a monochromator or filter for restricting the

wavelength range, a sample holder, a radiation detector, a signal processor, and readout (chart or computer memory). The

diffractometer must be capable of rate scanning at 1°1 °2Θ ⁄ per minute min or incrementally step scanning at 0.2° per step.0.2 °2Θ

steps.

6.2 Sample Holders, as specified by the manufacturer of the diffractometer that enables packing of a pulverized sample of

sufficient thickness to expose a level, smooth surface to the X-ray beam.

6.3 Briquetting Press, capable of generating pressures up to 10 000 psi (69 MPa).69 MPa (10 000 psi).

6.4 Compressible Aluminum Caps, used as a support for producing a briquetted sample.

6.5 Silicon or Quartz Sample, available from National Institute of Standards and Technology (NIST).

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. It is intended that all reagents shall conform to the

specifications of the Committee on Analytical Reagents of the American Chemical Society where such specifications are available.

Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without

lessening the accuracy of the determination.

7.2 Acetone.

7.3 Polyethylene Glycol, (approximate molecular weight of 200).200 AU).

7.4 Binding Agent—Prepare a 15 15 % by mass % solution of polyethylene glycol and acetone by adding 15 g 15 g of

polyethylene glycol to 85 g 85 g of acetone.

8. Sample Preparation

8.1 For recommended practices for obtaining, handling and preparing coke samples, refer to Test Methods D2013 and

D2234/D2234M and Practices D346 and D4057. The equipment and procedures for crushing and dividing are also described in

these test methods.

8.2 Reduce and divide the gross sample to obtain a laboratory analysis sample.

8.3 Divide, by riffling, a minimum of 100 g 100 g from the laboratory analysis sample.

8.4 Crush 100 g 100 g of the test sample such that 98 % will pass through a 75 μm 75 μm (No. 200) sieve.

8.5 Techniques—Any of the following techniques can be used for packing the sample into the X-ray diffractometer specimen

holder:

8.5.1 Back Fill Technique—Put the window on a glass slide (Slide 1) and transfer sufficient quantities of sample into the

window. Work the sample towards the corners of the holder by use of a glass slide or spatula. Press down using a flat glass slide

and scrape off any excess material. Place a glass slide (Slide 2) on top of the sample and secure with tape. Remove Slide 1 to expose

a flat, smooth surface before inserting into the diffractometer for analysis.

8.5.2 Front Fill Technique—Place a confining ring over the round sample holder and fill the holder cavity and ring with sample.

The ring will initially overfill the sample holder. Work the sample into the entire cavity and ring. Scrape the excess off with a glass

plate or spatula. Press down using a flat glass slide. Remove any excess material on the front face of the holder. Repress the sample

with the glass slide while turning clockwise and anti-clockwise. Continue until the sample is level with the holder face. Place the

sample in diffractometer holder.

8.5.3 Side Loading Technique—Pack the sample following the procedure used by the National Institute of Standards and

Technology and the Joint Committee on Powder Diffraction Standards to prepare standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.