ASTM D6905-20

(Practice)Standard Practice for Impact Flexibility of Organic Coatings

Standard Practice for Impact Flexibility of Organic Coatings

SIGNIFICANCE AND USE

5.1 Coatings attached to substrates are subjected to damaging impacts during the manufacture of articles and their use in service. This impact resistance practice has been found to be useful in predicting the performance of organic coatings for their ability to resist cracking caused by impacts.

SCOPE

1.1 This practice covers a procedure for determining the ability of a coating film and its substrate to resist shattering, cracking, or chipping when the film and substrate are distended beyond their original form by impact.

1.2 This practice does not measure impact resistance but uses rapid impact to improve Test Methods D522, a test method for flexibility. Since the impact of the coating is almost instantaneous, all of the problems associated with time variables in the mandrel tests are eliminated.

1.3 This practice is similar in content but not technically equivalent to Test Method D2794.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6905 − 20

Standard Practice for

1

Impact Flexibility of Organic Coatings

This standard is issued under the fixed designation D6905; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Related Coating Products

D823 Practices for Producing Films of Uniform Thickness

1.1 This practice covers a procedure for determining the

of Paint, Coatings and Related Products on Test Panels

ability of a coating film and its substrate to resist shattering,

D2240 Test Method for Rubber Property—Durometer Hard-

cracking,orchippingwhenthefilmandsubstratearedistended

ness

beyond their original form by impact.

D2794 Test Method for Resistance of Organic Coatings to

1.2 This practice does not measure impact resistance but

the Effects of Rapid Deformation (Impact)

uses rapid impact to improve Test Methods D522, a test

D7091 Practice for Nondestructive Measurement of Dry

method for flexibility. Since the impact of the coating is almost

Film Thickness of Nonmagnetic Coatings Applied to

instantaneous, all of the problems associated with time vari-

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

ables in the mandrel tests are eliminated.

ings Applied to Non-Ferrous Metals

1.3 This practice is similar in content but not technically

3. Terminology

equivalent to Test Method D2794.

3.1 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as the

3.1.1 impact flexibility, n—of a coating, the percent area

standard. The values given in parentheses are for information

increase required to produce cracking in the deformed coating.

only.

1.5 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 The organic coating under test is applied to suitable thin

responsibility of the user of this standard to establish appro-

metal panels (see Practice D609). After the coating has cured,

priate safety, health, and environmental practices and deter-

a standard weight/indenter is dropped from a measured dis-

mine the applicability of regulatory limitations prior to use.

tance so as to strike the substrate which deforms the coating

1.6 This international standard was developed in accor-

and the substrate. The percent elongation is the highest area of

dance with internationally recognized principles on standard-

distensibility in which there is no film breaks that the film can

ization established in the Decision on Principles for the

stand.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 Coatings attached to substrates are subjected to damag-

2. Referenced Documents

ing impacts during the manufacture of articles and their use in

2

service. This impact resistance practice has been found to be

2.1 ASTM Standards:

useful in predicting the performance of organic coatings for

D522 Test Methods for Mandrel Bend Test of Attached

their ability to resist cracking caused by impacts.

Organic Coatings

D609 Practice for Preparation of Cold-Rolled Steel Panels

6. Apparatus

for Testing Paint, Varnish, Conversion Coatings, and

3

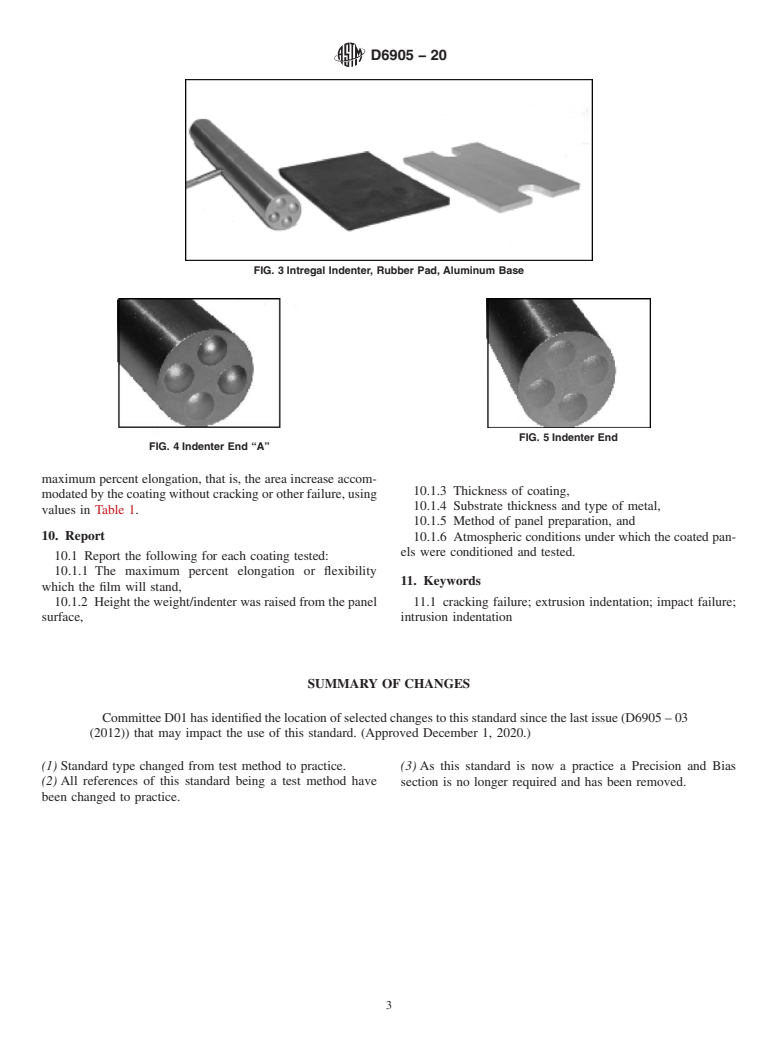

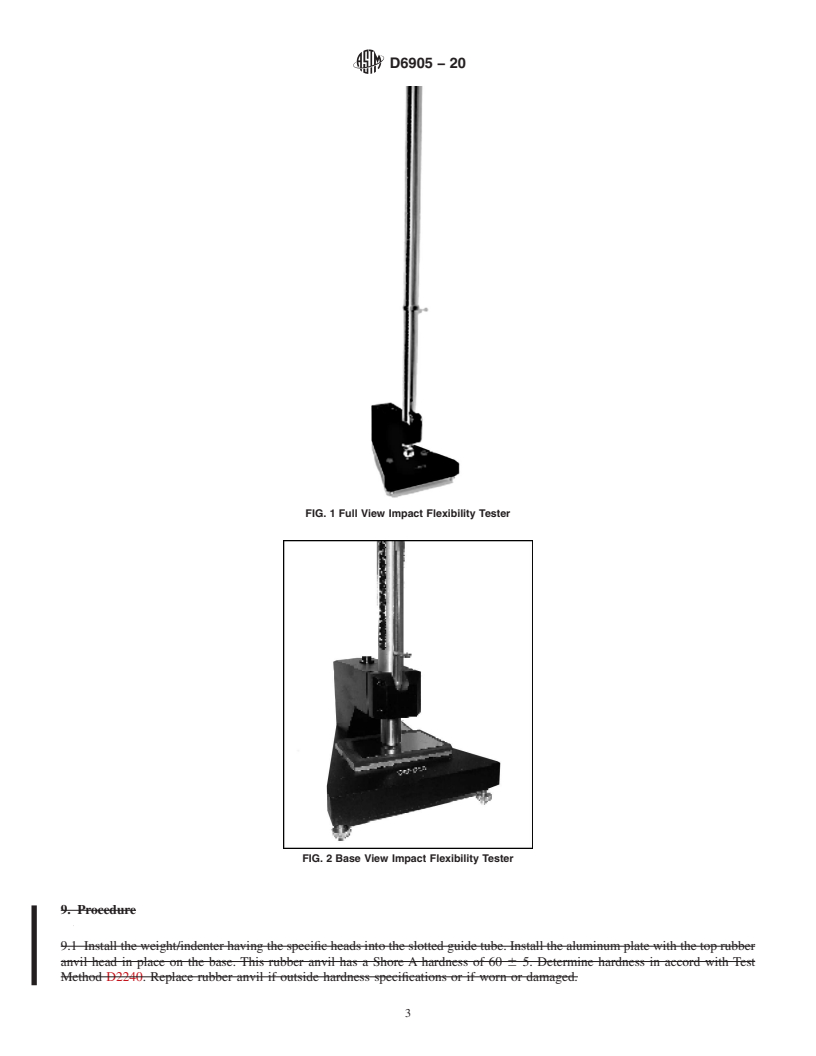

6.1 Impact Flexibility Tester ,assemblyillustratedinFigs.1

and 2. The instrument contains a 1.63 kg (3.6 lb) weight/

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

indenter, a rubber pad and an aluminum pad, Fig. 3. The round

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Dec. 1, 2020. Published December 2020. Originally

3

approved in 2003. Last previous edition approved in 2012 as D6905 – 03 (2012). The sole source of supply of the apparatus known to the committee at this time

DOI: 10.1520/D6905-20. is the IM-172-GE ImpactTester, available from the Paul N. Gardner Company, Inc.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 316 N.E. First Street, Pompano Beach, FL 33060. If you are aware of alternative

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM suppliers, please provide this information to ASTM International Headquarters.

Standards volume information, refer to the standard’s Document Summary page on Your comments will receive careful consideration at a meeting of the responsible

1

the ASTM website.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6905 − 03 (Reapproved 2012) D6905 − 20

Standard Test Method Practice for

1

Impact Flexibility of Organic Coatings

This standard is issued under the fixed designation D6905; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determining the ability of a coating film and its substrate to resist shattering, cracking,

or chipping when the film and substrate are distended beyond their original form by impact.

1.2 This test method does not measure impact resistance but uses rapid impact to improve Test Methods D522, another test method

for flexibility. Since the impact of the coating is almost instantaneous, all of the problems associated with time variables in the

mandrel tests are eliminated.

1.3 This test method is similar in content but not technically equivalent to Test Method D2794.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D522 Test Methods for Mandrel Bend Test of Attached Organic Coatings

D609 Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint, Varnish, Conversion Coatings, and Related Coating

Products

D823 Practices for Producing Films of Uniform Thickness of Paint, Coatings and Related Products on Test Panels

D1186 Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous

3

Base (Withdrawn 2006)

D1400 Test Method for Nondestructive Measurement of Dry Film Thickness of Nonconductive Coatings Applied to a

3

Nonferrous Metal Base (Withdrawn 2006)

D2240 Test Method for Rubber Property—Durometer Hardness

D2794 Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1

This test method practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility

of Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Nov. 1, 2012Dec. 1, 2020. Published November 2012December 2020. Originally approved in 2003. Last previous edition approved in 20082012

as D6905 – 03 (2008).(2012). DOI: 10.1520/D6905-03R12.10.1520/D6905-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6905 − 20

3.1.1 impact flexibility, n—of a coating, the percent area increase required to produce cracking in the deformed coating.

4. Summary of Test Method

4.1 The organic coating under test is applied to suitable thin metal panels. After the coating has cured, a standard weight/indenter

is dropped from a measured distance so as to strike the substrate which deforms the coating and the substrate. The percent

elongation is the highest area of distensibility in which there is no film breaks that the film can stand.

5. Significance and Use

5.1 Coatings attached to substrates are subjected to damaging impacts during the manufacture of articles and their use in service.

This impact resistance test method has been found to be useful in predicting the performance of organic coatings for their ability

to resist cracking caused by impacts.

6. Apparatus

4

6.1 Impact Flexibility Tester ,assembly illustrated in Figs. 1 and 2. The instrument contains a 1.63 kg (3.6 lb) weight/indenter, a

rubber pad and an aluminum pad, Fig. 3. The round rod weight/indenter’s two spherical ends (Marked “A” and “B”) are shown

in Figs. 4 and 5. The dimensions for the Spherical weight/indenter are shown in Table 1. The rod slides in a vertical, slotted guide

and serves as a falling

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.