ASTM D3363-22

(Test Method)Standard Test Method for Film Hardness by Pencil Test

Standard Test Method for Film Hardness by Pencil Test

SIGNIFICANCE AND USE

5.1 Pencil hardness measurements have been used by the coatings industry for many years to determine the hardness of clear and pigmented organic coating films. This test method has also been used to determine the cure of these coatings, especially when using forced dried heat.

5.2 This test method is convenient in developmental work and in production control testing in a single laboratory. It should be recognized that the results obtained may vary between different laboratories when different manufacturer’s pencils as well as when different substrates are used. To improve test result reproducibility for a specific group of tests, it is recommended to utilize drawing leads or pencils made by the same manufacturer and from the same batch. If drawing leads or pencils from the same manufacturer and from the same batch are not available at the time of subsequent evaluations, it shall be noted on the test report.

Note 3: Using leads or pencils made by different manufacturers or from the same manufacturer but different production batches, may result in significant variation for leads within the same pencil hardness scale.

5.3 This test method has been found to be useful in providing relative rankings for a series of coatings that exhibit significant differences in film hardness. Caution should be used when attempting to compare coatings of similar film hardness.

5.4 This test method may not be appropriate for coatings applied to a wood or other softer substrate in which results may be more a function of substrate deformation than coating hardness.

5.5 If this test method is used as a basis for purchase agreement, maximum precision will be achieved if a given set of referee pencils be agreed upon between the interested parties.

SCOPE

1.1 This test method covers a procedure for rapid, inexpensive determination of the film hardness of an organic coating on a metal or similarly hard substrate in terms of drawing leads or pencil leads of known hardness.

1.2 This test method is similar in content (but not technically equivalent) to ISO 15184.

Note 1: Other procedures are available to measure permanent deformation of organic coatings under the action of a single point (stylus tip) including but not limited to Test Methods D2197, D5178, and G171.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3363 − 22

Standard Test Method for

1

Film Hardness by Pencil Test

This standard is issued under the fixed designation D3363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2.2 Other Standards:

3

ISO 15184 Determination of film hardness by pencil test

1.1 This test method covers a procedure for rapid, inexpen-

sive determination of the film hardness of an organic coating

3. Terminology

on a metal or similarly hard substrate in terms of drawing leads

3.1 Definitions of Terms Specific to This Standard:

or pencil leads of known hardness.

3.1.1 gouge hardness, n—the hardest pencil lead that will

1.2 This test method is similar in content (but not techni-

1

leavethefilmuncutforastrokelengthofatleast3mm( ⁄8 in.);

cally equivalent) to ISO 15184.

also referred to as pencil hardness.

NOTE 1—Other procedures are available to measure permanent defor-

3.1.2 scratch hardness, n—the hardest pencil lead that will

mation of organic coatings under the action of a single point (stylus tip)

not rupture or scratch the film.

including but not limited to Test Methods D2197, D5178, and G171.

1.3 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The values given in parentheses are for information

4.1 A coated panel is placed on a firm horizontal surface.

only.

The pencil is held firmly against the film at a 45° angle (point

1.4 This standard does not purport to address all of the

awayfromtheoperator)andpushedawayfromtheoperatorfor

safety concerns, if any, associated with its use. It is the

1

a minimum of 6.5 mm ( ⁄4-in.) stroke. The process is started

responsibility of the user of this standard to establish appro-

with the hardest pencil and continued down the scale of

priate safety, health, and environmental practices and deter-

hardness to either of two end points: one, the pencil that will

mine the applicability of regulatory limitations prior to use.

not cut into or gouge the film (pencil hardness), or two, the

1.5 This international standard was developed in accor-

pencil that will not scratch the film (scratch hardness).

dance with internationally recognized principles on standard-

NOTE 2—A result in which the film coating is removed, revealing the

ization established in the Decision on Principles for the

substrate or previous coating layer if two or more coatings are present is

Development of International Standards, Guides and Recom-

considered a cut or gouge. A result in which the lead leaves a blemish or

mendations issued by the World Trade Organization Technical

defacement of the film coating, but does not reveal the substrate is

Barriers to Trade (TBT) Committee.

considered a scratch. A result in which the lead is transferred to the film

coating, but does not result in any damage is a pencil mark. See Fig. 1 and

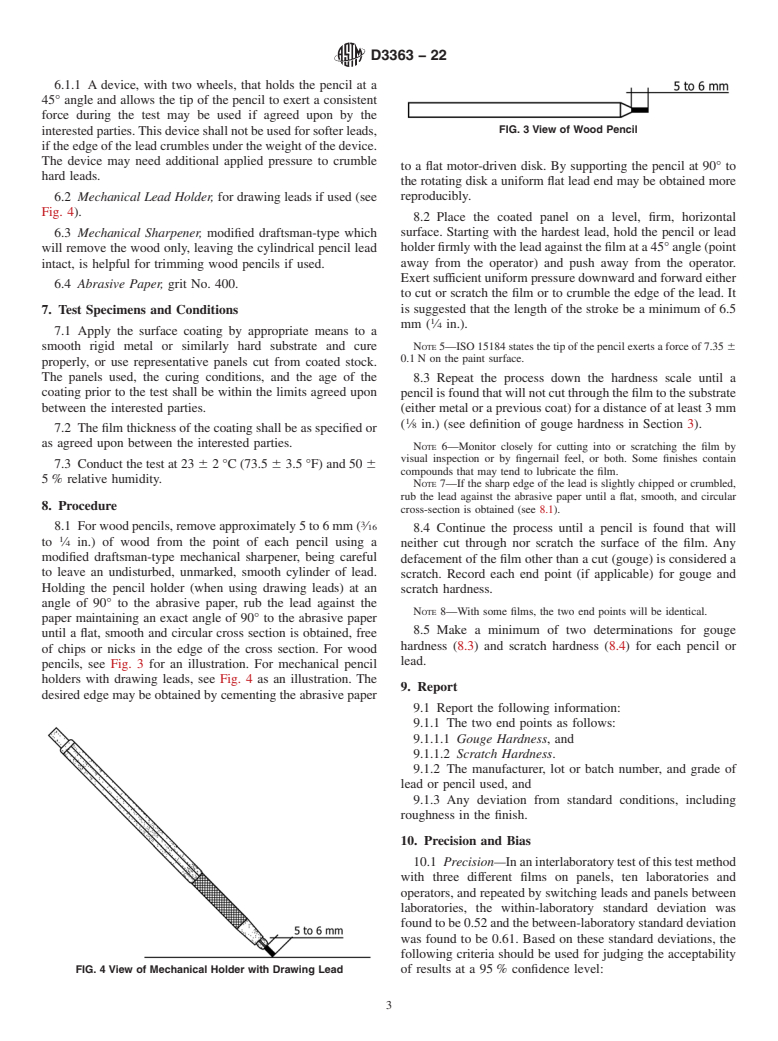

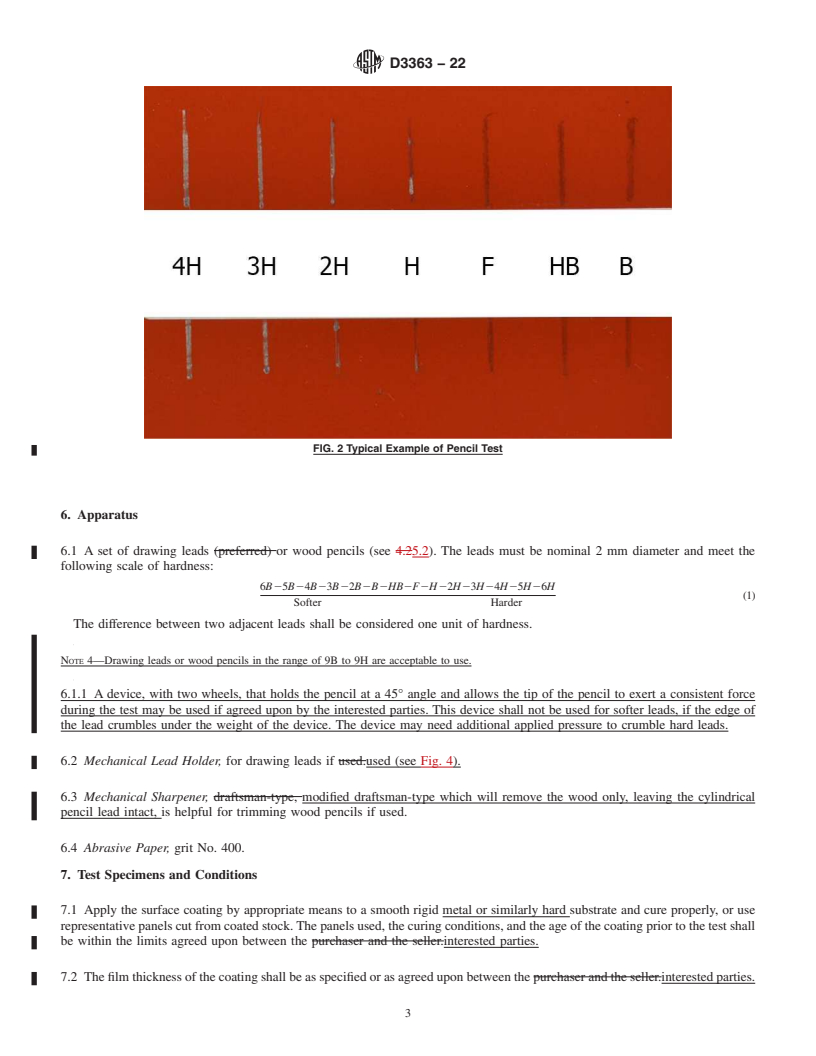

2. Referenced Documents Fig. 2.

2

2.1 ASTM Standards:

5. Significance and Use

D2197 Test Method for Adhesion of Organic Coatings by

5.1 Pencil hardness measurements have been used by the

Scrape Adhesion

coatings industry for many years to determine the hardness of

D5178 Test Method for Mar Resistance of Organic Coatings

clear and pigmented organic coating films. This test method

G171 Test Method for Scratch Hardness of Materials Using

has also been used to determine the cure of these coatings,

a Diamond Stylus

especially when using forced dried heat.

5.2 This test method is convenient in developmental work

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and in production control testing in a single laboratory. It

and Related Coatings, Materials, andApplications and is the direct responsibility of

should be recognized that the results obtained may vary

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved

between different laboratories when different manufacturer’s

in 1974. Last previous edition approved in 2020 as D3363 – 20. DOI: 10.1520/

pencils as well as when different substrates are used. To

D3363-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3363 − 20 D3363 − 22

Standard Test Method for

1

Film Hardness by Pencil Test

This standard is issued under the fixed designation D3363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers a procedure for rapid, inexpensive determination of the film hardness of an organic coating on a metal

or similarly hard substrate in terms of drawing leads or pencil leads of known hardness.

1.2 This test method is similar in content (but not technically equivalent) to ISO 15184.

NOTE 1—Other procedures are available to measure permanent deformation of organic coatings under the action of a single point (stylus tip) including

but not limited to Test Methods D2197, D5178, and G171.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2197 Test Method for Adhesion of Organic Coatings by Scrape Adhesion

D5178 Test Method for Mar Resistance of Organic Coatings

G171 Test Method for Scratch Hardness of Materials Using a Diamond Stylus

2.2 Other Standards:

3

ISO 15184 Determination of film hardness by pencil test.test

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Sept. 1, 2020June 1, 2022. Published September 2020July 2022. Originally approved in 1974. Last previous edition approved in 20112020 as

ɛ2

D3363 – 05 (2011)D3363 – 20. which was withdrawn in May 2020 and reinstated in September 2020. DOI: 10.1520/D3363-20.DOI: 10.1520/D3363-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3363 − 22

1

3.1.1 gouge hardness, n—the hardest pencil lead that will leave the film uncut for a stroke length of at least 3 mm ( ⁄8 in.); also

referred to as pencil hardness.

3.1.2 scratch hardness, n—the hardest pencil lead that will not rupture or scratch the film.

4. Summary of Test Method

4.1 A coated panel is placed on a firm horizontal surface. The pencil is held firmly against the film at a 45° angle (point away from

1

the operator) and pushed away from the operator in a 6.5-mm for a minimum of 6.5 mm ( ⁄4-in.) stroke. The process is started with

the hardest pencil and continued down the scale of hardness to either of two end points: one, the pencil that will not cut into or

gouge the film (pencil hardness), or two, the pencil that will not scratch the film (scratch hardness).

NOTE 2—A result in which the film coating is removed, revealing the substrate or previous coating layer if two or more coatings are present is considered

a cut or gouge. A result in which the lead leaves a blemish or defacement of the film coating, but does not reveal the substrate is considered a scratch.

A result in which the lead is transferred to the film coating, but does not result in any damage is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.