ASTM C633-01(2008)

(Test Method)Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings

Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings

SIGNIFICANCE AND USE

This test method is recommended for quality control, acceptance testing; or it may help to develop or qualify a thermal spray operator's equipment and procedure or to aid in developing thermal spray coatings with improved adhesion and integrity.

This test method is useful for comparing adhesion or cohesion strengths of coatings of similar types of thermal spray materials. The test should not be considered to provide an intrinsic value for direct use in making calculations, such as to determine if a coating will withstand specific environmental stresses. Because of residual stresses in thermal spray coatings, actual strength depends upon the shape of the particular coated part. Also, in use, a coating may be stressed in a more complex manner than is practical for a standard test.

SCOPE

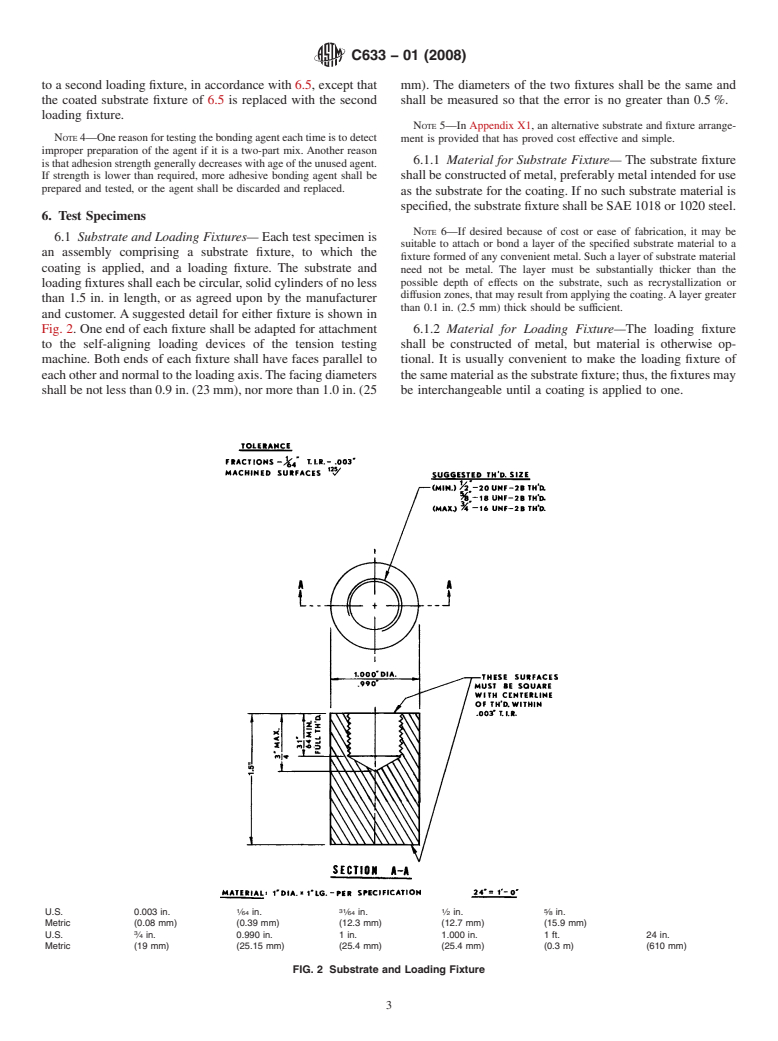

1.1 This test method covers the determination of the degree of adhesion (bonding strength) of a coating to a substrate or the cohesion strength of the coating in a tension normal to the surface. The test consists of coating one face of a substrate fixture, bonding this coating to the face of a loading fixture, and subjecting this assembly of coating and fixtures to a tensile load normal to the plane of the coating. It is adapted particularly for testing coatings applied by thermal spray, which is defined to include the combustion flame, plasma arc, two-wire arc, high-velocity oxygen fuel, and detonation processes for spraying feedstock, which may be in the form of, wire, rod, or powder.

Note 1—Thermal spray coating materials include ceramics, such as metal oxides or carbides, and metals. In some cases, a coating is formed of different spray materials, such as an oxide layer sprayed onto a sprayed metal-bonding layer. The substrate generally is a metal, but may be a ceramic, such as an oxide or graphite.

1.2 Usually this test method is performed at ambient temperature. Higher temperature testing is restricted by the need for a suitable adhesive bonding agent. For certain fundamental investigations, it is suggested that very low (cryogenic) temperature be used.

1.3 This test method is limited to testing thermal spray coatings that can be applied in thickness greater than 0.015 in. (0.38 mm). The limitation is imposed because an adhesive bonding agent is used in the test. Those bonding agents established so far for this method tend to penetrate thermal spray coatings and may invalidate results unless the coatings are thick enough to prevent penetration through the coating. Further development may establish that thin layers of certain types of especially dense coatings may be tested satisfactorily. Alternatively, new adhesive bonding agents that would allow reduction of the minimum thickness limitation may become available.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C633 − 01(Reapproved 2008)

Standard Test Method for

1

Adhesion or Cohesion Strength of Thermal Spray Coatings

This standard is issued under the fixed designation C633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of the degree

responsibility of the user of this standard to establish appro-

ofadhesion(bondingstrength)ofacoatingtoasubstrateorthe

priate safety and health limitations prior to use.

cohesion strength of the coating in a tension normal to the

surface. The test consists of coating one face of a substrate

2. Referenced Documents

fixture,bondingthiscoatingtothefaceofaloadingfixture,and

2

2.1 ASTM Standards:

subjecting this assembly of coating and fixtures to a tensile

E4Practices for Force Verification of Testing Machines

load normal to the plane of the coating. It is adapted particu-

larly for testing coatings applied by thermal spray, which is

3. Significance and Use

defined to include the combustion flame, plasma arc, two-wire

3.1 This test method is recommended for quality control,

arc, high-velocity oxygen fuel, and detonation processes for

acceptance testing; or it may help to develop or qualify a

spraying feedstock, which may be in the form of, wire, rod, or

thermal spray operator’s equipment and procedure or to aid in

powder.

developingthermalspraycoatingswithimprovedadhesionand

NOTE 1—Thermal spray coating materials include ceramics, such as

integrity.

metal oxides or carbides, and metals. In some cases, a coating is formed

ofdifferentspraymaterials,suchasanoxidelayersprayedontoasprayed

3.2 This test method is useful for comparing adhesion or

metal-bonding layer. The substrate generally is a metal, but may be a

cohesionstrengthsofcoatingsofsimilartypesofthermalspray

ceramic, such as an oxide or graphite.

materials. The test should not be considered to provide an

1.2 Usually this test method is performed at ambient tem-

intrinsic value for direct use in making calculations, such as to

perature. Higher temperature testing is restricted by the need

determine if a coating will withstand specific environmental

for a suitable adhesive bonding agent. For certain fundamental

stresses.Becauseofresidualstressesinthermalspraycoatings,

investigations, it is suggested that very low (cryogenic) tem-

actualstrengthdependsupontheshapeoftheparticularcoated

perature be used.

part.Also,inuse,acoatingmaybestressedinamorecomplex

manner than is practical for a standard test.

1.3 This test method is limited to testing thermal spray

coatings that can be applied in thickness greater than 0.015 in.

4. Apparatus

(0.38 mm). The limitation is imposed because an adhesive

bonding agent is used in the test. Those bonding agents 4.1 Atension testing machine shall conform to the require-

established so far for this method tend to penetrate thermal ments of Practices E4. The loads used in determining the

adhesionortensilestrengthshallbewithintheloadingrangeof

spray coatings and may invalidate results unless the coatings

are thick enough to prevent penetration through the coating. the testing machine, as defined in Practices E4. Permissible

variation shall be less than 1.0%. It shall be possible to apply

Further development may establish that thin layers of certain

types of especially dense coatings may be tested satisfactorily. increasing tensile load at a constant rate of cross-head travel

Alternatively, new adhesive bonding agents that would allow between 0.030 in./min (0.013 mm/s) and 0.050 in./min (0.021

reduction of the minimum thickness limitation may become mm/s).Themachineshallincludeaload-indicatingdevicethat

available. registers the maximum load applied before rupture occurs.

4.2 Self-aligningdevices,forapplyingthetensileloadtothe

assembly of the coating and fixtures, shall not permit eccentric

1

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

and Inorganic Coatingsand is the direct responsibility of Subcommittee B08.12 on

2

Materials for Porcelain Enamel and Ceramic-Metal Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2008. Published September 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2001 as C633–01. DOI: Standards volume information, refer to the standard’s Document Sum

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C633–79 (Reapproved 1999) Designation: C 633 – 01 (Reapproved 2008)

Standard Test Method for

Adhesion or Cohesive Strength of Flame-Sprayed

CoatingsAdhesion or Cohesion Strength of Thermal Spray

1

Coatings

This standard is issued under the fixed designation C 633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

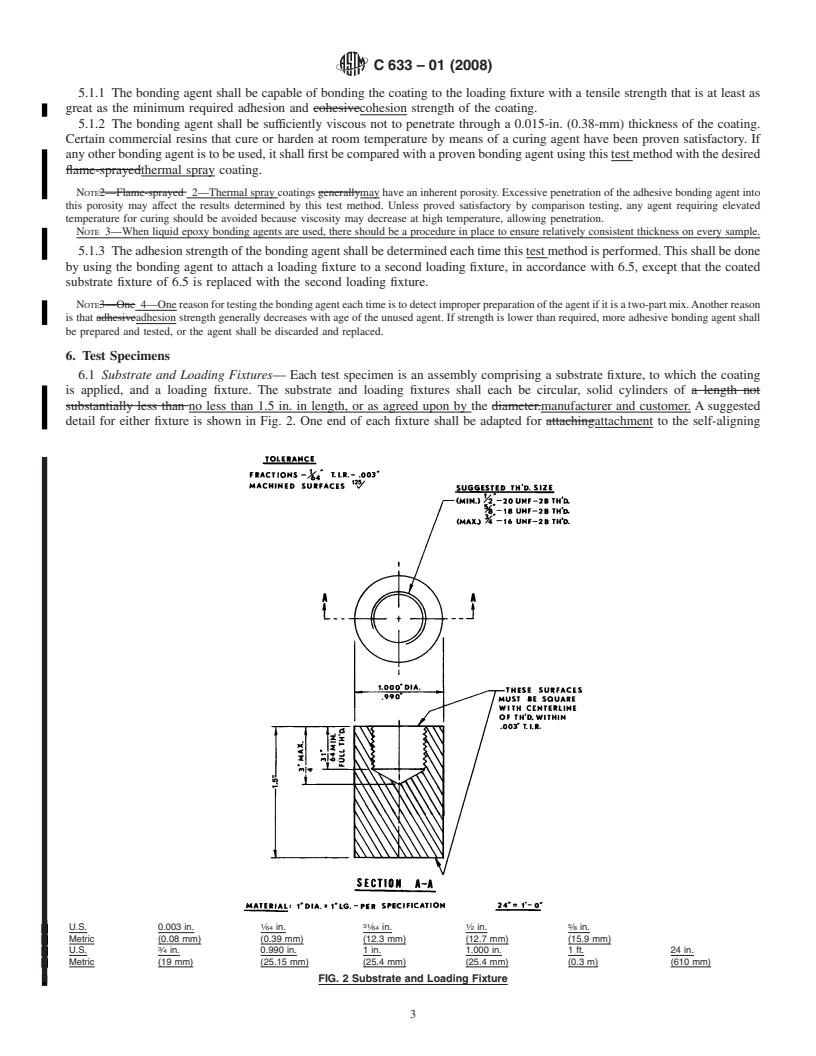

1.1 This test method covers the determination of the degree of adhesion (bonding strength) of a coating to a substrate, or the

cohesivecohesion strength of the coating in a tension normal to the surface. The test consists of coating one face of a substrate

fixture, bonding this coating to the face of a loading fixture, and subjecting this assembly of coating and fixtures to a tensile load

normal to the plane of the coating. It is particularly adapted particularly for testing coatings applied by flame spraying,thermal

spray, which is defined to include the combustion flame, plasma flame, arc gun, arc, two-wire arc, high-velocity oxygen fuel, and

detonation processes for spraying feedstock, which may be in the form of, wire, rod, or powder.

NOTE1—Flame-sprayed 1—Thermal spray coating materials include ceramics, such as metal oxides or carbides, and metals. In some cases, a coating

is formed of several layers of different flame-sprayedspray materials, such as an oxide layer sprayed onto a sprayed metal-bonding layer. The substrate

is generally is a metal, but may be a ceramic, such as an oxide or graphite.

1.2 Usually this test method is performed at ambient temperature. Higher temperature testing is restricted by the need for a

suitable adhesive bonding agent. For certain fundamental investigations, it is suggested that very low (cryogenic) temperature be

used.

1.3 This test method is limited to testing flame-sprayed thermal spray coatings that can be applied in thickness greater than

0.015 in. (0.38 mm). The limitation is imposed because an adhesive bonding agent is used in the test. Those bonding agents

established so far for this method tend to penetrate flame-sprayed thermal spray coatings and may invalidate results unless the

coatings are thick enough to prevent penetration through the coating. Further development may establish that thin layers of certain

types of especially dense coatings may be tested satisfactorily. Alternatively, new adhesive bonding agents that would allow

reduction of the minimum thickness limitation may be discovered or developed. become available.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E 4 Practices for Force Verification of Testing Machines

3. Significance and Use

3.1 This test method is recommended for quality- control, acceptance testing; or it may help to develop or qualify a flame-spray

thermal spray operator’s equipment and procedure or to aid in developing flame-sprayed thermal spray coatings with improved

adhesion and integrity.

3.2 This test method is useful for comparing adhesion or cohesivecohesion strengths of coatings of similar types of

flame-sprayed thermal spray materials. The test should not be considered to provide an intrinsic value for direct use in making

calculations, such as to determine if a coating will withstand specific environmental stresses. Because of residual stresses in

flame-sprayed thermal spray coatings, actual strength is dependent depends upon the shape of the particular coated part. Also, in

1

This test method is under the jurisdiction of ASTM Committee B-8B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

B08.13B08.12 on Test Methods Materials for Porcelain Enamel and Ceramic-Metal Systems.

CurrenteditionapprovedDec.28,1979.Aug.1,2008.PublishedFebruary1980.September2008.OriginallypublishedasC633–69.approvedin1969.Lastpreviousedition

C633–69 (1974).approved in 2001 as C 633 – 01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 03.01.volume information, refer to the standard’s Document Summary pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.