ASTM D3711-95(2009)

(Test Method)Standard Test Method for Deposition Tendencies of Liquids in Thin Films and Vapors (Withdrawn 2016)

Standard Test Method for Deposition Tendencies of Liquids in Thin Films and Vapors (Withdrawn 2016)

SIGNIFICANCE AND USE

The test method shall measure the deposit formation tendencies of liquids on steel surfaces in air at 101.3 KPa (1-atm) pressure. Other surfaces and other atmospheric media may be substituted for steel and air at 1 atm provided that the substitution is noted in the test report.

SCOPE

1.1 This test method covers the determination of the tendency of liquids in thin films and of vapors to form deposits on metal surfaces. The test method applies to both petroleum-based and synthetic lubricants, hydraulic fluids, heat-transfer fluids, and related materials.

1.2 The values stated in SI units are to be regarded as the standard. In cases where materials, products, or equipment are available in inch-pound units only, SI units are omitted.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 7 and Annex A2.

WITHDRAWN RATIONALE

This test method covers the determination of the tendency of liquids in thin films and of vapors to form deposits on metal surfaces. The test method applies to both petroleum-based and synthetic lubricants, hydraulic fluids, heat-transfer fluids, and related materials.

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in July 2016 due to lack of interest in maintaining the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3711 − 95(Reapproved 2009)

Standard Test Method for

Deposition Tendencies of Liquids in Thin Films and Vapors

This standard is issued under the fixed designation D3711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E230 Specification and Temperature-Electromotive Force

(EMF) Tables for Standardized Thermocouples

1.1 This test method covers the determination of the ten-

2.2 ANSI Standard:

dency of liquids in thin films and of vapors to form deposits on

C96.1 Temperature Measurement Thermocouples.

metal surfaces. The test method applies to both petroleum-

based and synthetic lubricants, hydraulic fluids, heat-transfer

3. Terminology

fluids, and related materials.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as the

3.1.1 deposit tendency, n—deposition tendency of a thin

standard. In cases where materials, products, or equipment are

film or vapor is an index of the propensity of a material to form

available in inch-pound units only, SI units are omitted.

carbonaceous residues on hot surfaces in contact with the

1.3 This standard does not purport to address all of the

liquid or vapor phase of the sample.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 The test specimen is allowed to flow slowly in a thin

bility of regulatory limitations prior to use. For specific

film over a steel test specimen in a constant-temperature

warning statements, see Section 7 and Annex A2.

chamber (furnace liner). Circulation of the sample from the

sump to the heated surface and back to the sump is accom-

2. Referenced Documents

plished by means of a peristaltic pump. After the prescribed

2.1 ASTM Standards:

test period, the steel test specimen is removed from the

D216 Method of Test for Distillation of Natural Gasoline

apparatus and evaluated. The masses of deposits remaining

(Withdrawn 1988)

afterwashingwithpentane,afterwashingwithchloroform,and

D323 TestMethodforVaporPressureofPetroleumProducts

after wiping with a paper tissue are reported.

(Reid Method)

4.2 An optional procedure (see Annex A1) provides a

D4057 Practice for Manual Sampling of Petroleum and

method for the determination of the tendency of sample vapors

Petroleum Products

to form deposits on heated surfaces.Asecond test specimen is

D4177 Practice for Automatic Sampling of Petroleum and

placed in the vapor space over a thin flowing film of the liquid

Petroleum Products

in a constant-temperature chamber (furnace liner).After circu-

1 lation of the test liquid for a specified time the deposits on the

This test method is under the jurisdiction of ASTM Committee D02 on

test specimen exposed to the liquid and the vapor phases are

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.07 on Engineering Sciences of High Performance Fluids and

measured in the manner described in 4.1.

Solids (Formally D02.1100).

Current edition approved Oct. 1, 2009. Published November 2009. Originally

5. Significance and Use

approvedin1978.Lastpreviouseditionapprovedin2005asD3711–95(2005).DOI:

10.1520/D3711-95R09.

5.1 The test method shall measure the deposit formation

United States Patent 2,669,865. Joseph Cole and John Krawetz.

tendencies of liquids on steel surfaces in air at 101.3 KPa

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(1-atm) pressure. Other surfaces and other atmospheric media

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4 5

The last approved version of this historical standard is referenced on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

www.astm.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3711 − 95 (2009)

in. mm

12 304.8

16 406.4

A—Inlet end cap H—Sample outlet tube

B—Sample delivery tube I—Sample sump

C—Gas atmosphere outlet J—Peristaltic pump

D—Metal test piece for thin liquid films K—Insulated terminals of furnace heater element

E—Furnace liner (with standard taper male end joints) L—Tube furnace

F—Outlet end cap TC1—Control thermocouple for furnace controller

G—Gas atmosphere inlet TC2—Thermocouple for test temperature read out

FIG. 1 Tube Furnace

may be substituted for steel and air at 1 atm provided that the

substitution is noted in the test report.

6. Apparatus

6.1 Tube Furnace, with heating chamber 305 mm (12 in.)

6,7

long by 35 mm (1 ⁄8 in.) in diameter (see Fig. 1).

6.2 Furnace Liner (constant-temperature chamber)—See

Fig. 2.

7,8

6.3 Temperature Controller.

7,9

6.4 Potentiometer, direct-temperature readout.

6.5 Thermocouples, for temperature control and read-out in

accordance with ANSI C96.1 (see Specification E230).

The sole source of supply of the apparatus known to the committee at this time

is the Type FD303A combustion furnace, Hoskins Manufacturing Co., Detroit, MI

48232. 3

1 ⁄16 in. = 30.1 mm

If you are aware of alternative suppliers, please provide this information to

D—Metal test piece for thin liquid films

ASTM International Headquarters. Your comments will receive careful consider-

E—Furnace liner (with standard tape male end joints)

ation at a meeting of the responsible technical committee, which you may attend. M—Longitudinal aligning rods

The sole source of supply of the apparatus known to the committee at this time

is a Model 520 Solid State Controller, Barber Colman Co., Rockford, IL. FIG. 2 Furnace Liner

The sole source of supply of the apparatus known to the committee at this time

is a Model 400A digital temperature indicator, Doric Scientific, San Diego, CA.

D3711 − 95 (2009)

10. Procedure

10.1 Prepare a test specimen in accordance with the follow-

ing procedure:

10.1.1 Buff both sides of a piece of mild steel shim stock

with jewelers rouge on a cloth wheel. The direction of

polishingshouldbethesameasthatoftheintendedliquidflow.

10.1.2 Clean the shim stock thoroughly by washing with

pentane and chloroform. Allow the specimen to dry at room

temperature.

10.1.3 Cut a test specimen of the proper size from the

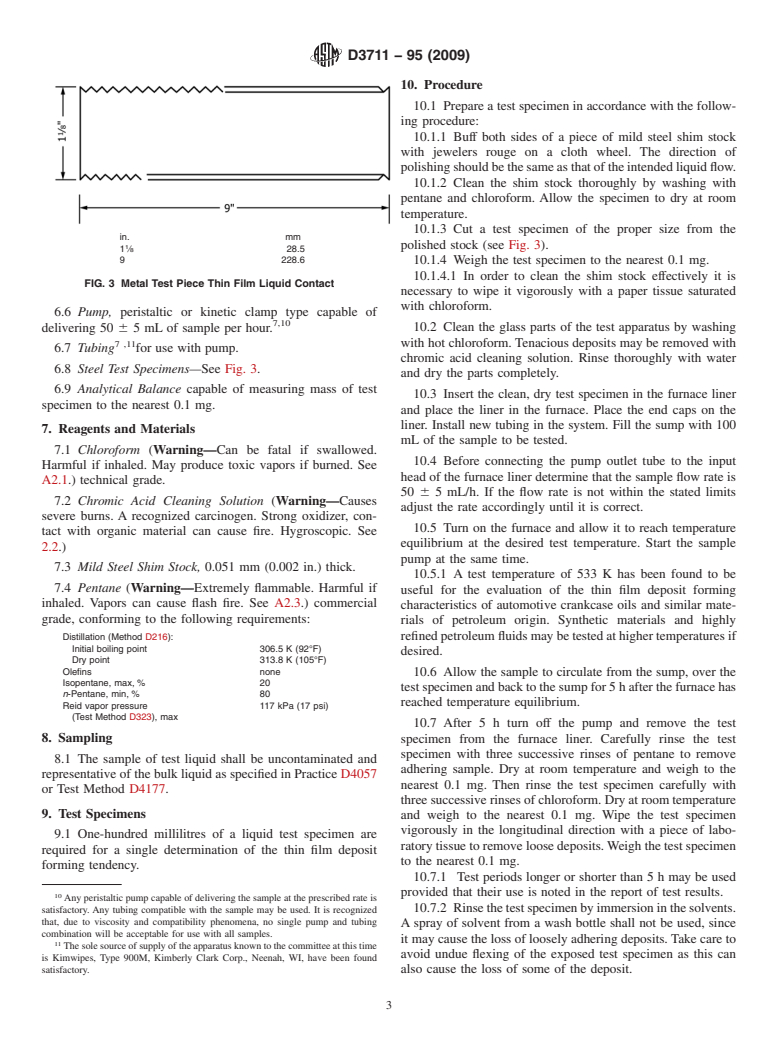

in. mm

polished stock (see Fig. 3).

1 ⁄8 28.5

9 228.6

10.1.4 Weigh the test specimen to the nearest 0.1 mg.

10.1.4.1 In order to clean the shim stock effectively it is

FIG. 3 Metal Test Piece Thin Film Liquid Contact

necessary to wipe it vigorously with a paper tissue saturated

with chloroform.

6.6 Pump, peristaltic or kinetic clamp type capable of

7,10

delivering 50 6 5 mL of sample per hour. 10.2 Clean the glass parts of the test apparatus by washing

7,11 with hot chloroform. Tenacious deposits may be removed with

6.7 Tubing for use with pump.

chromic acid cleaning solution. Rinse thoroughly with water

6.8 Steel Test Specimens—See Fig. 3.

and dry the parts completely.

6.9 Analytical Balance capable of measuring mass of test

10.3 Insert the clean, dry test specimen in the furnace liner

specimen to the nearest 0.1 mg.

and place the liner in the furnace. Place the end caps on the

liner. Install new tubing in the system. Fill the sump with 100

7. Reagents and Materials

mL of the sample to be tested.

7.1 Chloroform (Warning—Can be fatal if swallowed.

10.4 Before connecting the pump outlet tube to the input

Harmful if inhaled. May produce toxic vapors if burned. See

head of the furnace liner determine that the sample flow rate is

A2.1.) technical grade.

50 6 5 mL/h. If the flow rate is not within the stated limits

7.2 Chromic Acid Cleaning Solution (Warning—Causes

adjust the rate accordingly until it is correct.

severe burns. A recognized carcinogen. Strong oxidizer, con-

10.5 Turn on the furnace and allow it to reach temperature

tact with organic material can cause fire. Hygroscopic. See

equilibrium at the desired test temperature. Start the sample

2.2.)

pump at the same time.

7.3 Mild Steel Shim Stock, 0.051 mm (0.002 in.) thick.

10.5.1 A test temperature of 533 K has been found to be

7.4 Pentane (Warning—Extremely flammable. Harmful if

useful for the evaluation of the thin film deposit forming

inhaled. Vapors can cause flash fire. See A2.3.) commercial

characteristics of automotive crankcase oils and similar mate-

grade, conforming to the following requirements:

rials of petroleum origin. Synthetic materials and highly

Distillation (Method D216): refinedpetroleumfluidsmaybetestedathighertemperaturesif

Initial boiling point 306.5 K (92°F)

desired.

Dry point 313.8 K (105°F)

Olefins none

10.6 Allow the sample to circulate from the sump, over the

Isopentane, max, % 20

testspecimenandbacktothesumpfor5hafterthefurnacehas

n-Pentane, min, % 80

reached temperature equilibrium.

Reid vapor pressure 117 kPa (17 psi)

(Test Method D323), max

10.7 After 5 h turn off the pump and remove the test

8. Sampling specimen from the furnace liner. Carefully rinse the test

specimen with three successive rinses of pentane to rem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.