ASTM D6255/D6255M-99

(Specification)Standard Specification for Steel or Aluminum Slotted Angle Crates

Standard Specification for Steel or Aluminum Slotted Angle Crates

SCOPE

1.1 This specification covers the material and fabrication of new reusable metal (slotted angle) crates intended for use as containers for domestic and overseas shipment of lightweight airframe components and lightweight bulky items, not exceeding 3000 lb (1361 kg) for domestic or overseas air and surface shipments.

1.2 Slotted angle crate performance is dependent on its fabricated components; therefore, a variety of types, classes, and styles reflecting varied performance are specified. This specification, however, does not cover slotted angle crate performance under all atmosphere, handling, shipping, and storage conditions.

1.3 If the use of other construction methods or techniques are acceptable and permitted (see 5.1.12), the resulting packaging systems shall be of equal or better performance than would result from the use of these specified materials and procedures. The appropriate distribution cycle specified in Practice D4169 can be used to develop comparative procedures and criteria.

1.4 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. See IEEE/ASTM SI 10 for conversion units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6255/D 6255M – 99

Standard Specification for

Steel or Aluminum Slotted Angle Crates

This standard is issued under the fixed designation D 6255/D 6255M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope nized) Coatings on Iron and Steel Products

A 924/A 924M Specification for General Requirements for

1.1 This specification covers the material and fabrication of

Steel Sheet, Mettalic-Coated by the Hot-Dip Process

new reusable metal (slotted angle) crates intended for use as

B 209 Specification for Aluminum and Aluminum Alloy

containers for domestic and overseas shipment of lightweight

Sheet and Plate

airframe components and lightweight bulky items, not exceed-

B 633 Specification for Electrodeposited Coatings of Zinc

ing 3000 lb [1361 kg] for domestic or overseas air and surface

on Iron and Steel

shipments.

D 996 Terminology of Packaging and Distribution Environ-

1.2 Slotted angle crate performance is dependent on its

ments

fabricated components; therefore, a variety of types, classes,

D 1990 Practice for Establishing Allowable Properties for

and styles reflecting varied performance are specified. This

Visually-Graded Dimension, Lumber from In-Grade Test

specification, however, does not cover slotted angle crate

of Full-Size Specimens

performance under all atmosphere, handling, shipping, and

D 3951 Practice for Commercial Packaging

storage conditions.

D 3953 Specification for Strapping, Flat Steel and Seals

1.3 If the use of other construction methods or techniques

D 4169 Practice for Performance Testing of Shipping Con-

are acceptable and permitted (see 5.1.12), the resulting pack-

tainers and Systems

aging systems shall be of equal or better performance than

D 4727/D 4727M Specification for Corrugated and Solid

would result from the use of these specified materials and

Fiberboard Sheet Stock (Container Grade) and Cut

procedures. The appropriate distribution cycle specified in

Shapes

Practice D 4169 can be used to develop comparative proce-

D 6199 Practice for Quality of Wood Members of Contain-

dures and criteria.

ers and Pallets

1.4 The values stated in either inch-pound or SI units are to

F 1667 Specification for Driven Fasteners, Nails, Spikes,

be regarded separately as standard.Within the text, the SI units

and Staples

are shown in brackets.The values stated in each system are not

IEEE/ASTM SI 10 Standard for Use of the International

exact equivalents; therefore, each system must be used inde-

System of Units (SI): The Modern Metric System

pendentlyoftheother.Combiningvaluesfromthetwosystems

2.2 Federal Specifications:

may result in nonconformance with the standard. See IEEE/

TT-W-572 Wood Preservative: Water-Repellent

ASTM SI 10 for conversion of units.

2.3 APA—The Engineered Wood Association

1.5 This standard does not purport to address all of the

PS1-95 Construction and Industrial Plywood

safety concerns, if any, associated with its use. It is the

2.4 American Society of Mechanical Engineers (ASME)

responsibility of the user of the standard to establish appro-

Standards:

priate safety and health practices and determine the applica-

B18.2.1 Square and Hex Bolts and Screws (Inch Series)

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards: 3

Annual Book of ASTM Standards, Vol 01.06.

A 109/A 109M Specification for Steel, Strip, Carbon,

Annual Book of ASTM Standards, Vol 02.02.

Annual Book of ASTM Standards, Vol 02.05.

Cold-Rolled

Annual Book of ASTM Standards, Vol 15.09.

A 123/A 123M Specification for Zinc (Hot-Dip Galva-

Annual Book of ASTM Standards, Vol 04.10.

Annual Book of ASTM Standards, Vol 15.08.

Annual Book of ASTM Standards, Vol 14.02.

1 10

This specification is under the jurisdiction of ASTM Committee D-10 on Available from the Federal Supply Service Bureau, Specification Section,

Packaging and is the direct responsibility of Subcommittee D10.26 on Wooden Suite 8100, 480 L’Enfant Plaza, SW, Washington, DC 20408.

Crates, Pallets and Skids. Available fromAPA–The Engineered WoodAssociation, 7011 South 19th St.,

Current edition approved Oct. 10, 1999. Published December 1999. Originally P.O. Box 11700, Tacoma, WA 98411–0700.

published as D 6255/D 6255M – 98. Last previous edition D 6255/D 6255M – 98. Available from theAmerican Society of Mechanical Engineers, 345 East 47th

Annual Book of ASTM Standards, Vol 01.03. St., New York, NY 10017; American National Standard (ANSI) adopted.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6255/D 6255M

B18.2.2 Square and Hex Nuts (Inch Series) 5.1.12 Whether other construction methods or techniques

B18.2.3.5M Metric Hex Bolts are acceptable and permitted (see 1.3).

B18.2.4.1M Metric Hex Nuts, Style 1

5.1.12.1 Whether proof that other construction methods or

B18.2.4.2M Metric Hex Nuts, Style 2 techniques are acceptable (see 1.3) is required.

B18.5 Round Head Bolts (Inch Series)

B18.5.2.2M Metric Round Head Square Neck Bolts

6. Materials and Manufacture

2.5 Hardwood Plywood and Veneer Association:

6.1 Materials—It is encouraged that recycled material be

HPVA HP-1-1994 Hardwood and Decorative Plywood

used when practical. All recovered, recycled, or virgin mate-

2.6 National Motor Freight Traffıc Association:

rials used in crate manufacture shall meet the requirements of

National Motor Freight Classification

this specification and referenced documents. In addition, ma-

2.7 Uniform Classification Committee Standard:

terials shall not affect or be affected by the product being

Uniform Freight Classification

packed. Fiberboard panelboard shall have no more than 40 %

2.8 American Iron and Steel Institute (AISI) Standard:

post consumer recovered material.

Cold-Formed Steel Design Manual

6.1.1 Slotted Metal Angle—Slotted metal angle shall con-

form to the Supplemental Requirements of this specification.

3. Terminology

6.1.1.1 Slotted Angle Surface Finish—Steel for Class 1

3.1 Definitions— General definitions for packaging and

crates shall have a Class 3 surface finish (S4.7.1.3) applied.

distribution environments are found in Terminology D 996.

Steel for Class 2 crates shall have a Class 1 or 2 surface finish

(S4.7.1.1 or S4.7.1.2) applied. Aluminum slotted angle shall

4. Classification

require no additional finish.

4.1 Type: 6.1.2 Nuts and Bolts— Nuts and bolts used to assemble the

4.1.1 Type I—Open. slotted angle shall be of hardened steel and zinc plated after

4.1.2 Type II—Fully-enclosed or sheathed with solid mate- machining. All other bolts and nuts shall be zinc-coated and

rial. conform to ASME B18.5 (B18.5.2.2M) or B18.2.1

4.2 Class:

(B18.2.3.5M), for bolts; and, B18.2.2 (B18.2.4.1M), for nuts.

4.2.1 Class 1—Outside or indeterminate storage.

6.1.2.1 The slotted angle bolts shall be minimum ⁄16-in.

4.2.2 Class 2—Inside or protected storage.

[8-mm] shank diameter, ⁄8-in. [16-mm] length for Types I, II,

3 9

4.3 Style:

and IV, and ⁄4-in. for Type III and ⁄16-in. [14-mm] hexagon

4.3.1 Style A—Without skids or rubbing strips.

head. Bolts shall have an unthreaded load bearing shoulder to

4.3.2 Style B—With skid blocks or skids with rubbing strips

prevent shearing action on the threads. Bolts shall conform to

and provisions for forklift truck handling.

ASME B18.2.1 (B18.2.3.5M).

6.1.2.2 The slotted angle nuts shall be prevailing torque,

5. Ordering Information

hexagon, self-locking, to prevent loosening after extended

storage/handling and vibration during shipment. The ⁄16-in.

5.1 Purchasers should select the preferred permitted options

[8-mm] nuts shall be 0.551 to 0.564-in. [13.99 to 14.33-mm]

and include the following information in procurement docu-

across the flats (width). Other size nuts shall be ⁄16in. [14 mm]

ments:

across the hexagon flats. Nuts shall conform toASME B18.2.2

5.1.1 Specification title, number, and date.

(B18.2.4.2M).

5.1.2 Crate type, class, and style (see Section 4).

6.1.3 Strapping—Steel strapping used for banding or ten-

5.1.3 Box inside dimensions specified in order of length by

sion braces shall conform to Practice D 3953, Type I, zinc-

width by depth.

coated.

5.1.4 Whether sanded plywood is required (see 6.1.5).

6.1.4 Wood Members—Woodusedforskids,rubbingstrips,

5.1.5 Type sheathing required (see 7.6.1).

5.1.6 Whether full-length skids are required (see 7.7.3.2). load-bearing members, blocking and bracing, and all other

5.1.7 Special features (see 7.9). wooden components shall conform to the applicable Practice

5.1.8 Marking panel size (see 7.10.1). D 6199, Group II, III or IV woods structural class and shall

5.1.9 Whether crates are to be shipped assembled or disas- conform to commercial standards in accordance with Practice

sembled (see 8.1). D 1990.

5.1.10 Bolt and nut quantities required (see 6.1.2).

6.1.5 Plywood—Plywood for Class 1 crates shall conform

5.1.11 If self-locking nuts are required (see 6.1.2). to ANSI/HPVA HP-1-1994, Type I, Grade 3-4; APA PS1-95,

Interior with Exterior Glue; or, APA PS1-95, Exterior, Grade

C-C. Plywood for Class 2 crates shall conform toANSI/HPVA

HP-1-1994, Type II, Grade 3-4; or, APA PS1-95, Interior,

Available from Hardwood Plywood and Veneer Association, P.O. Box 2789,

Grade C-D. Plywood shall have no defects (knot holes, worm

Reston, VA 22090–0789; American National Standards Institute (ANSI) adopted.

holes, etc.) extending through the panel. Unless otherwise

Available from National Motor Freight Traffic Association, American Truck-

ing Associations, 2200 Mill Road, Alexandria, VA 22314.

specified, plywood shall be finished unsanded (see 5.1.4).

Available from the Uniform Classification Committee, Tariff Publishing

6.1.6 Wood Preservative—Wood or plywood components

Officer, 151 Ellis St., N.E., Suite 200, Atlanta, GA 30335.

shall be treated in accordance withTT-W-572, or a commercial

Available from the American Iron and Steel Institute, ATTN: Publication

Orders, P.O. Box 4327, Chestertown, MD 21690. equivalent.

D 6255/D 6255M

A

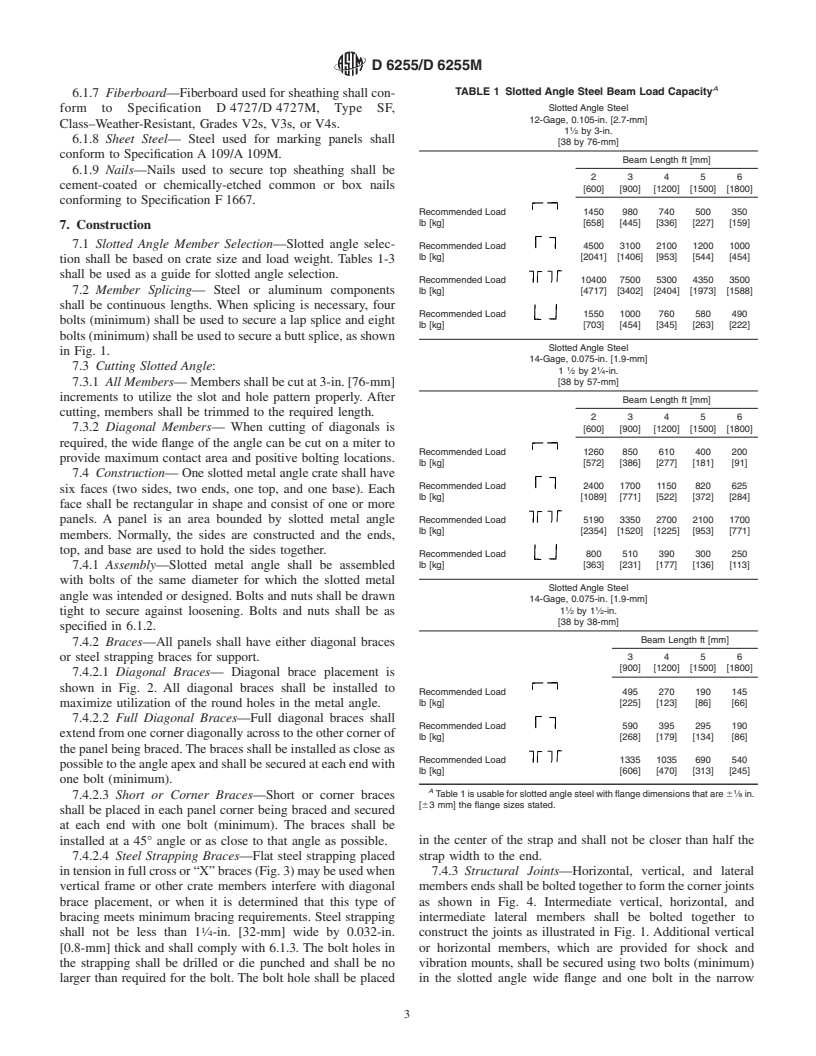

TABLE 1 Slotted Angle Steel Beam Load Capacity

6.1.7 Fiberboard—Fiberboard used for sheathing shall con-

Slotted Angle Steel

form to Specification D 4727/D 4727M, Type SF,

12-Gage, 0.105-in. [2.7-mm]

Class–Weather-Resistant, Grades V2s, V3s, or V4s.

1 ⁄2 by 3-in.

6.1.8 Sheet Steel— Steel used for marking panels shall

[38 by 76-mm]

conform to Specification A 109/A 109M.

Beam Length ft [mm]

6.1.9 Nails—Nails used to secure top sheathing shall be

cement-coated or chemically-etched common or box nails

[600] [900] [1200] [1500] [1800]

conforming to Specification F 1667.

Recommended Load 1450 980 740 500 350

lb [kg] [658] [445] [336] [227] [159]

7. Construction

7.1 Slotted Angle Member Selection—Slotted angle selec-

Recommended Load 4500 3100 2100 1200 1000

lb [kg] [2041] [1406] [953] [544] [454]

tion shall be based on crate size and load weight. Tables 1-3

shall be used as a guide for slotted angle selection.

Recommended Load 10400 7500 5300 4350 3500

7.2 Member Splicing— Steel or aluminum components lb [kg] [4717] [3402] [2404] [1973] [1588]

shall be continuous lengths. When splicing is necessary, four

Recommended Load 1550 1000 760 580 490

bolts (minimum) shall be used to secure a lap splice and eight

lb [kg] [703] [454] [345] [263] [222]

bolts (minimum) shall be used to secure a butt splice, as shown

Slotted Angle Steel

in Fig. 1.

14-Gage, 0.075-in. [1.9-mm]

7.3 Cutting Slotted Angle:

1 1

1 ⁄2 by 2 ⁄4-in.

[38 by 57-mm]

7.3.1 All Members— Members shall be cut at 3-in. [76-mm]

increments to utilize the slot and hole pattern properly. After

Beam Length ft [mm]

cutting, members shall be trimmed to the required length.

7.3.2 Diagonal Members— When cutting of diagonals is [600] [900] [1200] [1500] [1800]

required, the wide flange of the angle can be cut on a miter to

Recommended Load 1260 850 610 400 200

provide maximum contact area and positive bolting locations.

lb [kg] [572] [386] [277] [181] [91]

7.4 Construction— One slotted metal angle crate shall have

Recommended Load 2400 1700 1150 820 625

six faces (two sides, two ends, one top, and one base). Each

lb [kg] [1089] [771] [522] [372] [284]

face shall be rectangular in shape and consist of one or more

Recommended Load 5190 3350 2700 2100 1700

panels. A panel is an area bounded by slotted metal angle

lb [kg] [2354] [1520] [1225] [953] [771]

members. Normally, the sides are constructed and the ends,

top, and base are used to hold the sides together.

Recommended Load 800 510 390 300 250

lb [kg] [363] [231] [177] [136] [113]

7.4.1 Assembly—Slotted metal angle shall be assembled

with bolts of the same diameter for which the slotted metal

Slotted Angle Steel

angle was intended or designed. Bolts and nuts shall be drawn

14-Gage, 0.075-in. [1.9-mm]

1 1

1 ⁄2 by 1 ⁄2-in.

tight to secure against loosening. Bolts and nuts shall be as

[38 by 38-mm]

specified in 6.1.2.

Beam Length ft [mm]

7.4.2 Braces—All panels shall have either diagonal braces

or steel strapping braces for support. 3456

[900] [1200] [1500] [1800]

7.4.2.1 Diagonal Braces— Diagonal brace placement is

shown in Fig. 2. All diagonal braces shall be installed to

Recommended Load 495 270 190 145

lb [kg] [225] [123] [86] [66]

maximize utilization of the round holes in the metal angle.

7.4.2.2 Full Diagonal Braces—Full diagonal braces shall

Recommended Load 590 395 295 190

extend from one corner diagonally across to the other corner of

lb [kg] [268] [179] [134] [86]

the panel being braced.The braces shall be installed as close as

Recommended Load 1335 1035 690 540

possibletotheangleapexandshallbesecuredateachendwith

lb [kg] [606] [470] [313] [245]

one bolt (minimum).

A

Table1isusableforslottedanglesteelwithflangedimensionsthatare 6 ⁄8in.

7.4.2.3 Short or Corner Braces—Short or corner braces

[63 mm] the flange sizes stated.

shall be placed in each panel corner being braced and secured

at each end with one bolt (minimum). The braces shall be

installed at a 45° angle or as close to that angle as possible. in the center of the strap and shall not be closer than half the

7.4.2.4 Steel Strapping Braces—Flat steel strapping placed strap width to the end.

intensioninfullcrossor“X”braces(Fig.3)maybeusedwhen 7.4.3 Structural Joints—Horizontal, vertical, and lateral

vertical frame or other crate members interfere with diagonal members ends shall be bolted together to form the corner joints

brace placement, or when it is determined that this type of as shown in F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.