ASTM D7030-04(2022)

(Test Method)Standard Test Method for Short Term Creep Performance of Corrugated Fiberboard Containers Under Constant Load Using a Compression Test Machine

Standard Test Method for Short Term Creep Performance of Corrugated Fiberboard Containers Under Constant Load Using a Compression Test Machine

SIGNIFICANCE AND USE

4.1 In the distribution system, the packaged product may be stored for a period of time in a manner such that one or more containers are stacked on one another. The bottom package is thus continually subjected to a constant compression load.

4.2 This test method subjects an empty container to a predetermined static load and to specified atmospheric conditions, if required, over a short period of time using fixed platen compression testing equipment. Deflection is measured over time.

4.3 Deflection versus time data can be used to predict time to failure of corrugated shipping containers under constant load.

SCOPE

1.1 This test method covers determining the resistance of an empty paper corrugated shipping container to a vertically applied constant compression load for a specified time. The test method may also include palletized or unitized loads made of such containers. The boxes are tested in the orientation that they are most likely to be stacked in a unitized or palletized load.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7030 − 04 (Reapproved 2022)

Standard Test Method for

Short Term Creep Performance of Corrugated Fiberboard

Containers Under Constant Load Using a Compression Test

Machine

This standard is issued under the fixed designation D7030; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Paperboard by Oven Drying (Withdrawn 2010)

D685 Practice for Conditioning Paper and Paper Products

1.1 This test method covers determining the resistance of an

for Testing

empty paper corrugated shipping container to a vertically

D996 Terminology of Packaging and Distribution Environ-

appliedconstantcompressionloadforaspecifiedtime.Thetest

ments

method may also include palletized or unitized loads made of

D4332 Practice for Conditioning Containers, Packages, or

such containers. The boxes are tested in the orientation that

Packaging Components for Testing

they are most likely to be stacked in a unitized or palletized

D4577 Test Method for Compression Resistance of a Con-

load.

tainer Under Constant Load

1.2 The values stated in inch-pound units are to be regarded E4 Practices for Force Calibration and Verification of Test-

as standard. The values given in parentheses are mathematical ing Machines

conversions to SI units that are provided for information only E122 Practice for Calculating Sample Size to Estimate,With

and are not considered standard. Specified Precision, the Average for a Characteristic of a

Lot or Process

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions—General definitions for the packaging and

priate safety and health practices and determine the applica-

distribution environments are found in Terminology D996.

bility of regulatory limitations prior to use.

1.4 This international standard was developed in accor- 3.2 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard- 3.2.1 constant load—aloadthatisinvariableorunchanging.

ization established in the Decision on Principles for the

3.2.2 creep—continued deformation over time while under

Development of International Standards, Guides and Recom-

constant load.

mendations issued by the World Trade Organization Technical

3.2.3 load—the force applied to a body.

Barriers to Trade (TBT) Committee.

3.2.4 static load—an imposed stationary force, constant in

magnitude and direction.

2. Referenced Documents

2.1 ASTM Standards:

4. Significance and Use

D642 Test Method for Determining Compressive Resistance

4.1 In the distribution system, the packaged product may be

of Shipping Containers, Components, and Unit Loads

stored for a period of time in a manner such that one or more

D644 Test Method for Moisture Content of Paper and

containers are stacked on one another. The bottom package is

thus continually subjected to a constant compression load.

4.2 This test method subjects an empty container to a

This test method is under the jurisdiction of ASTM Committee D10 on

predetermined static load and to specified atmospheric

Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping

conditions, if required, over a short period of time using fixed

Containers and Systems - Application of Performance Test Methods.

Current edition approved May 1, 2022. Published May 2022. Originally

platen compression testing equipment. Deflection is measured

approved in 2004. Last previous edition approved in 2017 as D7030 – 04 (2017).

over time.

DOI: 10.1520/D7030-04R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7030 − 04 (2022)

4.3 Deflection versus time data can be used to predict time 5.3 Conditioning Apparatus—Adequate facilities shall be

to failure of corrugated shipping containers under constant provided to maintain a conditioned atmosphere of temperature

load.

and humidity as required for the purpose of the test.

5. Apparatus 5.4 Miscellaneous Equipment—Drying oven, scales, knife,

saws, and the like, for use in determination of the moisture

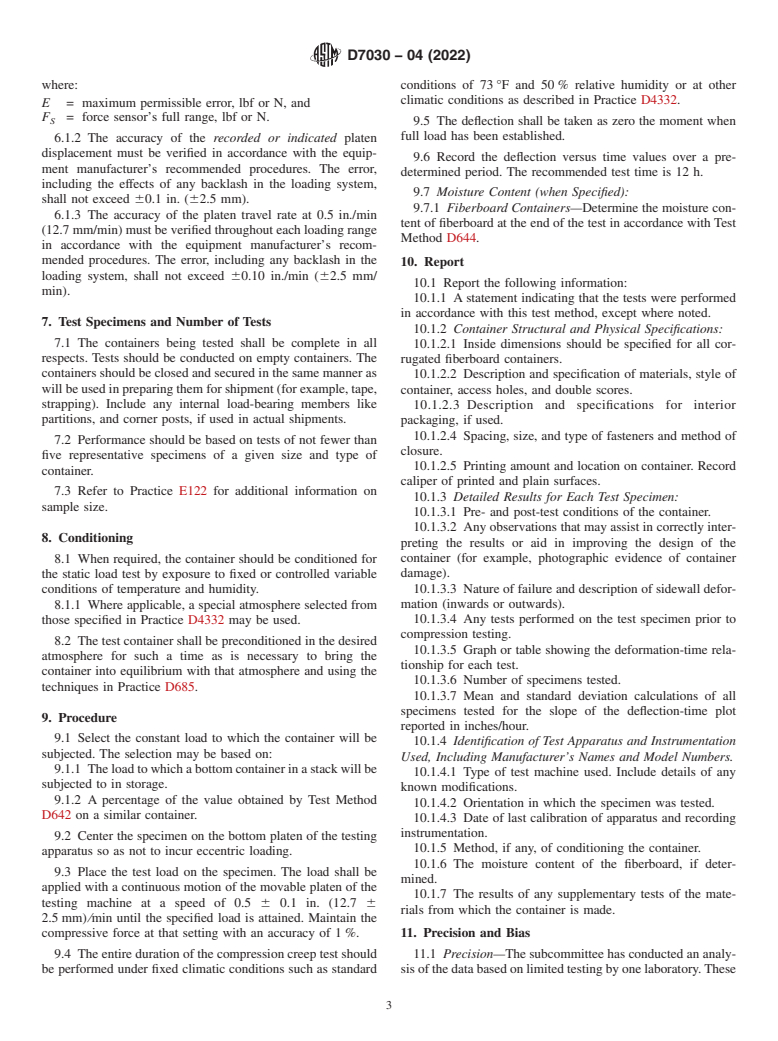

5.1 Fixed-Platen Testing Machine—Two platens, flat to

content or for making other supplementary tests of the mate-

within 0.01 in. (0.25 mm) for each 12 in. (304.8 mm) in length,

rials from which the containers are made.

one of which is movable in the vertical direction so as to

compress the container between the platens. One is the load

6. Calibration

measuring platen, and both should be of sufficient size so that

the test container does not extend beyond the edges of the

6.1 The accuracy of the test equipment must be verified to

platens. Both platens are fixed in the horizontal directions so

ensure reliable test data.

that the lateral movement is not greater than 0.05 in. (1.3 mm),

6.1.1 The overall system accuracy of the recorded or indi-

and are held parallel throughout the test to within 0.04 in.

cated applied load (force) shall be verified in accordance with

(1 mm) for each 12 in. (304.8 mm) in the length and width

Practice E4. The verified loading range shall be specified, and

dimensions. See Fig. 1. The testing machine should be capable

errors within the loading range shall not exceed 61.0 % of the

to maintain load within 1 % of the required level for the

reading (as calculated in Practice E4). If testing below the

duration of the test.

Practice E4 verified loading range is desired, then the maxi-

5.2 Closing Equipment for Fiberboard Boxes—Suitable ma-

mum permissible error shall not exceed 60.2 % of the full

terials and application equipment for closing boxes should be

range of the force sensor, calculated as follows:

used. If adhesives are used, sealing boards described in Test

Method D642 may be needed. E 5 F 30.002

S

FIG. 1 Corrugated Container Under Creep Test in Compression Test Machine

D7030 − 04 (2022)

where: conditions of 73 °F and 50 % relative humidity or at other

climatic conditions as described in Practice D4332.

E = maximum permissible error, lbf or N, and

F = force sensor’s full range, lbf or N.

S 9.5 The deflection shall be taken as zero the moment when

full load has been established.

6.1.2 The accuracy of the recorded or indicated platen

displacement must be verified in accordance with the equip-

9.6 Record the deflection versus time values over a pre-

ment manufacturer’s recommended procedures. The error,

determined period. The recommended test time is 12 h.

including the effects of any backlash in the loading system,

9.7 Moisture Content (when Specified):

shall not exceed 60.1 in. (62.5 mm).

9.7.1 Fiberboard Containers—Determine the moisture con-

6.1.3 The accuracy of the platen travel rate at 0.5 in./min

tent of fiberboard at the end of the test in accordance with Test

(12.7 mm/min) must be verified throughout each loading range

Method D644.

in accordance with the equipment manufacturer’s recom-

mended procedures. The error, including any backlash in the

10. Report

loading system, shall not exceed 60.10 in./min (62.5 mm/

10.1 R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.