ASTM D2876-00(2016)

(Test Method)Standard Test Method for Water-Soluble Matter of Vegetable-Tanned Leather

Standard Test Method for Water-Soluble Matter of Vegetable-Tanned Leather

SIGNIFICANCE AND USE

4.1 The test method is useful for determining the water-soluble materials in vegetable-tanned leathers.

4.2 The water-soluble matter includes the soluble nontanning components of the tanning materials used, sugars and materials of a similar nature, and inorganic compounds such as Epsom salts, Glauber's salts, borax, and other soluble salts added during curing and tannery processing.

SCOPE

1.1 This test method covers the determination of the water-soluble materials in all types of vegetable-tanned leathers. This test method does not apply to wet blue.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2876 − 00 (Reapproved 2016)

Standard Test Method for

1

Water-Soluble Matter of Vegetable-Tanned Leather

This standard is issued under the fixed designation D2876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus

1.1 This test method covers the determination of the water- 5.1 Crystallizing Dish, borosilicate glass, 50 mm tall, 70

soluble materials in all types of vegetable-tanned leathers.This mm in outside diameter, and weighing between 30 and 39 g.

test method does not apply to wet blue. 3

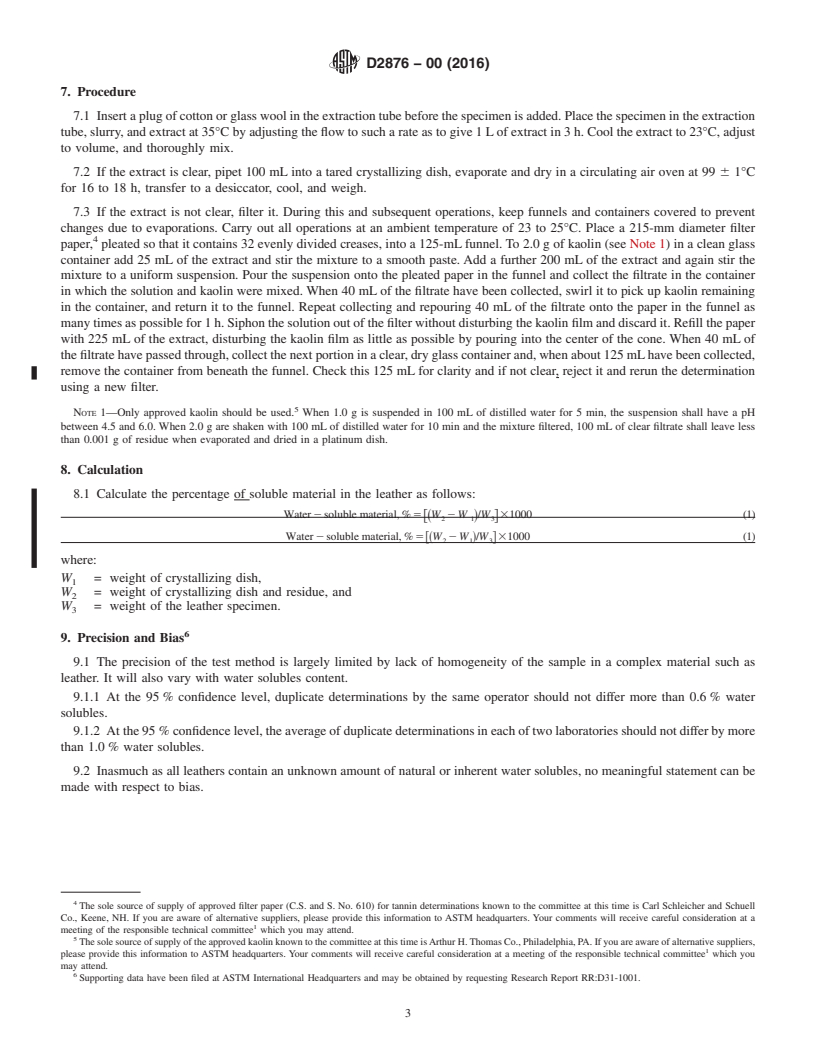

5.2 Extractor, Reed-Churchill Type —The extraction tube

1.2 The values stated in SI units are to be regarded as shall have an internal diameter of 45 6 2 mm and a length of

standard. No other units of measurement are included in this 233 6 10 mm. See Fig. 1.

standard.

5.3 WaterBath, equipped to control the temperature at 35 6

1.3 This standard does not purport to address all of the

0.5°C.

safety concerns, if any, associated with its use. It is the

5.4 CirculatingAirOven,capableofmaintainingatempera-

responsibility of the user of this standard to establish appro-

ture of 99 6 1°C.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Test Specimen

6.1 Thespecimenshallconsistofthe5-gleathersamplethat

2. Referenced Documents

has been extracted with hexane as directed in Test Method

2

2.1 ASTM Standards:

D3495.Anydeviationfromthissamplesizeshouldbeincluded

D3495 Test Method for Hexane Extraction of Leather

with the analytical results.

3. Summary of Test Method

7. Procedure

3.1 The test method gives the amount of water-soluble

7.1 Insert a plug of cotton or glass wool in the extraction

matter extracted from the leather at 35°C by 1 L of water in 3

tube before the specimen is added. Place the specimen in the

h. The leather is first freed of hexane-extractable material by

extraction tube, slurry, and extract at 35°C by adjusting the

extraction with hexane and leaving at ambient temperature in

flow to such a rate as to give 1 L of extract in 3 h. Cool the

an exhaust hood to remove the hexane.

extract to 23°C, adjust to volume, and thoroughly mix.

7.2 If the extract is clear, pipet 100 mL into a tared

4. Significance and Use

crystallizing dish, evaporate and dry in a circulating air oven at

4.1 The test method is useful for determining the water-

99 6 1°C for 16 to 18 h, transfer to a desiccator, cool, and

soluble materials in vegetable-tanned leathers.

weigh.

4.2 The water-soluble matter includes the soluble nontan-

7.3 If the extract is not clear, filter it. During this and

ning components of the tanning materials used, sugars and

subsequent operations, keep funnels and containers covered to

materials of a similar nature, and inorganic compounds such as

prevent changes due to evaporations. Carry out all operations

Epsom salts, Glauber’s salts, borax, and other soluble salts

at an ambient temperature of 23 to 25°C. Place a 215-mm

added during curing and tannery processing.

4

diameter filter paper, pleated so that it contains 32 evenly

divided creases, into a 125-mL funnel. To 2.0 g of kaolin (see

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

and is the direct responsibility of Subcommittee D31.01 on Vegetable Leather. This

3

test method was developed in cooperation with the American Leather Chemists Reed, H. C. and Churchill, J. B., “An Extractor for Water Soluble in Leather,”

Assn. (Standard Method B8–1954). Journal of the American Leather Chemists Association, JALCA, Vol 14, 1919, p.

Current edition approved Sept. 1, 2016. Published September 2016. Originally 137.

4

approved in 1970. Last previous edition approved in 2010 as D2876–00 (2010). The sole source of supply of approved filter paper (C.S. and S. No. 610) for

DOI: 10.1520/D2876-00R16. tannin determinations known to the committee at this time is Carl Schleicher and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Schuell Co., Keene, NH. If you are aware of alternative suppliers, please provide

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM this information to ASTM headquarters. Your comments will receive careful

1

Standards volume information, refer to the standard’s Document Summary page on consideration at a meeting of the responsible technical committee which you may

the ASTM website. attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2876 − 00 (2016)

FIG. 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2876 − 00 (Reapproved 2010) D2876 − 00 (Reapproved 2016)

Standard Test Method for

1

Water-Soluble Matter of Vegetable-Tanned Leather

This standard is issued under the fixed designation D2876; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the water-soluble materials in all types of vegetable-tanned leathers. This test

method does not apply to wet blue.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D3495 Test Method for Hexane Extraction of Leather

3. Summary of Test Method

3.1 The test method gives the amount of water-soluble matter extracted from the leather at 35°C by 1 L of water in 3 h. The

leather is first freed of hexane-extractable material by extraction with hexane and leaving at ambient temperature in an exhaust

hood to remove the hexane.

4. Significance and Use

4.1 The test method is useful for determining the water-soluble materials in vegetable-tanned leathers.

4.2 The water-soluble matter includes the soluble nontanning components of the tanning materials used, sugars and materials

of a similar nature, and inorganic compounds such as Epsom salts, Glauber’s salts, borax, and other soluble salts added during

curing and tannery processing.

5. Apparatus

5.1 Crystallizing Dish, borosilicate glass, 50 mm tall, 70 mm in outside diameter, and weighing between 30 and 39 g.

3

5.2 Extractor, Reed-Churchill Type —The extraction tube shall have an internal diameter of 45 6 2 mm and a length of 233

6 10 mm. See Fig. 1.

5.3 Water Bath, equipped to control the temperature at 35 6 0.5°C.

5.4 Circulating Air Oven, capable of maintaining a temperature of 99 6 1°C.

6. Test Specimen

6.1 The specimen shall consist of the 5-g leather sample that has been extracted with hexane as directed in Test Method D3495.

Any deviation from this sample size should be included with the analytical results.

1

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.01 on Vegetable Leather. This test

method was developed in cooperation with the American Leather Chemists Assn. (Standard Method B8–1954).

Current edition approved April 1, 2010Sept. 1, 2016. Published May 2010September 2016. Originally approved in 1970. Last previous edition approved in 20052010 as

D2876–00 (2005).(2010). DOI: 10.1520/D2876-00R10.10.1520/D2876-00R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Reed, H. C. and Churchill, J. B., “An Extractor for Water Soluble in Leather,” Journal of the American Leather Chemists Association, JALCA, Vol 14, 1919, p. 137.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2876 − 00 (2016)

FIG. 1 Reed-Churchill Type Extractor

2

---------------------- Page: 2 ----------------------

D2876 − 00 (2016)

7. Procedure

7.1 Insert a plug of cotton or glass wool in the extraction tube before the specimen is added. Place the specimen in the extraction

tube, slurry, and extract at 35°C by adjusting the flow to such a rate as to give 1 L of extract in 3 h. Cool the extract to 23°C, adjust

to volume, and thoroughly mix.

7.2 If the extract is clear, pipet 100 mL into a tared crystallizing dish, evaporate and dry in a circulating air oven at 99 6 1°C

for 16 to 18 h, transfer to a desiccator, cool, and weigh.

7.3 If the extract is not clear, filter it. During this and subsequent operations, keep funnels and containers covered to prevent

changes due to evaporations. Carry out all operations at an ambient temperature of 23 to 25°C. Place a 215-mm diameter filter

4

paper, pleated so that it c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.