ASTM B521-22

(Specification)Standard Specification for Tantalum and Tantalum Alloy Seamless and Welded Tubes

Standard Specification for Tantalum and Tantalum Alloy Seamless and Welded Tubes

ABSTRACT

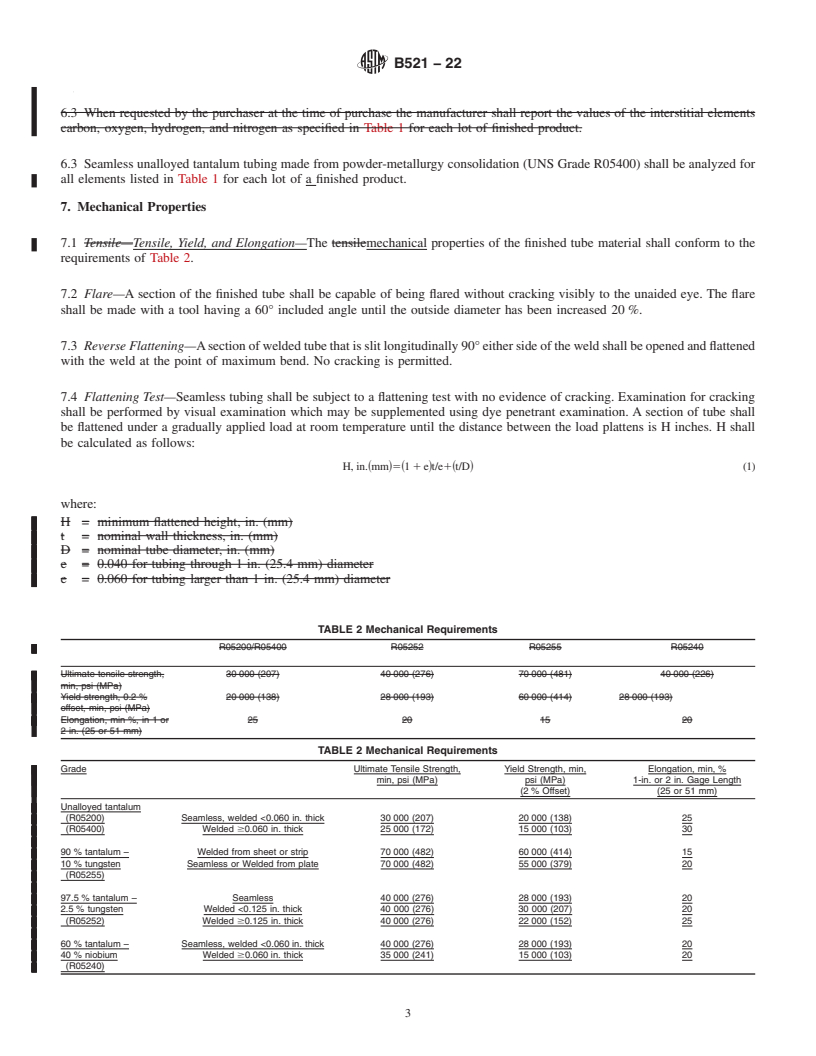

This specification covers tantalum and tantalum alloy seamless and welded tubes of the following grades: UNS Grade R05400 which is unalloyed tantalum, powder-metallurgy consolidation, UNS Grade R05200 which is unalloyed tantalum, vacuum melted, UNS Grade R05252 which is tantalum with 2.5% tungsten alloy, vacuum melted, UNS Grade R05255 which is tantalum with 10% tungsten alloy, vacuum melted, and UNS Grade R05240 which is tantalum alloy with 60% tantalum, 40% columbium, electron-beam furnace or vacuum arc melted, or both. Seamless tube shall be made by any seamless method and the welded tube shall be made from flat-rolled product by an automatic or semiautomatic fusion welding process with no addition of filler metal. Mechanical properties such as ultimate tensile strength, yield strength, and elongation shall be determined by tensile, flare, and reverse flattening tests. Nondestructive tests such as hydrostatic test, pneumatic test, helium leak test, and ultrasonic test shall be done as well.

SIGNIFICANCE AND USE

12.1 For the purpose of determining compliance with the specified limits of property requirements, an observed value or a calculated value shall be rounded in accordance with the rounding method of Practice E29.

SCOPE

1.1 This specification covers tantalum and tantalum alloy seamless and welded tubes of the following grades:

1.1.1 UNS Grade R05400—Unalloyed tantalum, powder-metallurgy consolidation,

1.1.2 UNS Grade R05200—Unalloyed tantalum, vacuum melted,

1.1.3 UNS Grade R05252—Tantalum + 2.5 % tungsten alloy, vacuum melted.

1.1.4 UNS Grade R05255—Tantalum + 10 % tungsten alloy, vacuum melted.

1.1.5 UNS Grade R05240—Tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace, vacuum arc melt, or both.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B521 −22

Standard Specification for

1

Tantalum and Tantalum Alloy Seamless and Welded Tubes

This standard is issued under the fixed designation B521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Austenitic Stainless Steel and Similar Alloys

E499Practice for Leaks Using the Mass Spectrometer Leak

1.1 This specification covers tantalum and tantalum alloy

Detector in the Detector Probe Mode

seamless and welded tubes of the following grades:

2.2 Other Documents:

1.1.1 UNS Grade R05400—Unalloyed tantalum, powder-

ASNT Document SNT-TC-1APersonnel Qualification and

metallurgy consolidation,

3

Certification in Nondestructive Testing

1.1.2 UNS Grade R05200—Unalloyed tantalum, vacuum

melted,

3. Terminology

1.1.3 UNS Grade R05252—Tantalum + 2.5 % tungsten

3.1 Definitions of Terms Specific to This Standard:

alloy, vacuum melted.

3.1.1 lot—all material produced from the same ingot or

1.1.4 UNS Grade R05255—Tantalum + 10 % tungsten

single powder blend, of the same size and last annealed in the

alloy, vacuum melted.

same furnace charge.

1.1.5 UNS Grade R05240—Tantalum alloy, 60% tantalum,

3.1.2 process length—the one-piece length of each tube that

40% niobium, electron-beam furnace, vacuum arc melt, or

results from the production operation that first yields the

both.

tubular form. Sampling and testing should in general be based

1.2 The values stated in inch-pound units are to be regarded

on process lengths unless specifically stated otherwise.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Ordering Information

and are not considered standard.

4.1 Ordersformaterialunderthisspecificationshallinclude

1.3 This international standard was developed in accor-

the following information:

dance with internationally recognized principles on standard-

4.1.1 Quantity,

ization established in the Decision on Principles for the

4.1.2 UNS grade,

Development of International Standards, Guides and Recom-

4.1.3 Type (welded or seamless),

mendations issued by the World Trade Organization Technical

4.1.4 Dimensions,

Barriers to Trade (TBT) Committee.

4.1.5 Nondestructive test requirements, designation of in-

spection and testing options if the purchaser has a preference,

2. Referenced Documents

and

2

4.1.6 Additions to the specification and supplementary

2.1 ASTM Standards:

E29Practice for Using Significant Digits in Test Data to requirements, if any.

Determine Conformance with Specifications

5. Materials and Manufacture

E213Practice for Ultrasonic Testing of Metal Pipe and

Tubing 5.1 Seamless tube shall be made by any seamless method

E426PracticeforElectromagnetic(EddyCurrent)Examina- that will yield a product meeting the requirements of this

tion of Seamless and Welded Tubular Products, Titanium, specification. Intermediate and/or final annealing (if required)

shall be accomplished in a manner to prevent contamination

and absorption of hydrogen, nitrogen, oxygen, or carbon

1

This specification is under the jurisdiction of ASTM Committee B10 on during the annealing process.

Reactive and Refractory Metals and Alloys and is the direct responsibility of

5.2 Welded tube shall be made from flat-rolled product by

Subcommittee B10.03 on Niobium and Tantalum.

an automatic or semiautomatic fusion welding process with no

Current edition approved April 1, 2022. Published April 2022. Originally

approved in 1970. Last previous edition approved in 2019 as B521–19. DOI:

addition of filler metal.

10.1520/B0521-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from the American Society for Nondestructive Testing International

Standards volume information, refer to the standard’s Document Summary page on Service Center, 1711 Arlingate Lane, Columbus, OH 43228-0518, https://

the ASTM website. www.asnt.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B521−22

6. Chemical Composition 7.5 One set of these mechanical tests shall be made on each

lot of tubes and for each fifty process length tubes of each lot

6.1 The material shall conform to the requirements of

or fraction thereof.

chemical composition prescribed

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B521 − 19 B521 − 22

Standard Specification for

1

Tantalum and Tantalum Alloy Seamless and Welded Tubes

This standard is issued under the fixed designation B521; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers tantalum and tantalum alloy seamless and welded tubes of the following grades:

1.1.1 UNS Grade R05400—Unalloyed tantalum, powder-metallurgy consolidation,

1.1.2 UNS Grade R05200—Unalloyed tantalum, vacuum melted,

1.1.3 UNS Grade R05252—Tantalum + 2.5 % tungsten alloy, vacuum melted.

1.1.4 UNS Grade R05255—Tantalum + 10 % tungsten alloy, vacuum melted.

1.1.5 UNS Grade R05240—Tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or furnace, vacuum arc melt,

or both.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E426 Practice for Electromagnetic (Eddy Current) Examination of Seamless and Welded Tubular Products, Titanium, Austenitic

Stainless Steel and Similar Alloys

E499 Practice for Leaks Using the Mass Spectrometer Leak Detector in the Detector Probe Mode

2.2 Other Documents:

3

ASNT Document SNT-TC-1A Personnel Qualification and Certification in Nondestructive Testing

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.03 on Niobium and Tantalum.

Current edition approved Nov. 1, 2019April 1, 2022. Published December 2019April 2022. Originally approved in 1970. Last previous edition approved in 20122019 as

B521 – 12.B521 – 19. DOI: 10.1520/B0521-19.10.1520/B0521-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the American Society for Nondestructive Testing International Service Center, 1711 Arlingate Lane, Columbus, OH 43228-0518, https://www.asnt.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B521 − 22

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot—all material produced from the same ingot or single powder blend, of the same size and last annealed in the same furnace

charge.

3.1.2 process length—the one-piece length of each tube that results from the production operation that first yields the tubular form.

Sampling and testing should in general be based on process lengths unless specifically stated otherwise.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity,

4.1.2 UNS grade,

4.1.3 Type (welded or seamless),

4.1.4 Dimensions,

4.1.5 Nondestructive test requirements, designation of inspection and testing options if the purchaser has a preference, and

4.1.6 Additions to the specification and supplementary requirements, if any.

5. Materials and Manufacture

5.1 Seamless tube shall be made by any seamless method that will yield a product meeting the requirements of this specification.

Intermediate and/or final annealing (if required) shall be accomplished in a manner to prevent contamination and absorption of

hydrogen, nitrogen, oxygen, or carbon during the annealing process.

5.2 Welded tube shall be made from flat-rolled product by an automatic or semiautomatic fusion welding process with no addition

of filler metal.

6. Chemical Composition

6.1 The m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.