ASTM D4636-99

(Test Method)Standard Test Method for Corrosiveness and Oxidation Stability of Hydraulic Oils, Aircraft Turbine Engine Lubricants, and Other Highly Refined Oils

Standard Test Method for Corrosiveness and Oxidation Stability of Hydraulic Oils, Aircraft Turbine Engine Lubricants, and Other Highly Refined Oils

SCOPE

1.1 This test method is used to test hydraulic oils, aircraft turbrine engine lubricants, and other highly refined oils to determine their resistance to oxidation and corrosion degradation and their tendency to corrode various metals. Petroleum and synthetic fluids may be evaluated using moist or dry air with or without metal test specimens.

1.2 This test method consists of a standard test procedure, an alternative Procedure 1 and an alternative Procedure 2. As there are variations possible with this test method, it will be up to the particular specification to establish the conditions required. In addition to temperature, the variables to specify if other than those of the standard procedure or alternative Procedure 1 or 2 are: test time, air flow and humidity, sample frequency, test fluid quantity, and metal specimen(s).

1.3 The values stated in acceptable SI units are to be regarded as standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4636 – 99

Standard Test Method for

Corrosiveness and Oxidation Stability of Hydraulic Oils,

Aircraft Turbine Engine Lubricants, and Other Highly

Refined Oils

This standard is issued under the fixed designation D 4636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

This test method is the result of combining Federal Test Methods, 5307.2 and 5308.7. Features and

details of both these test methods are included, but the new test method is basically Method 5307.2

expanded to include Method 5308.7.

1. Scope D 91 Test Method for Precipitation Number of Lubricating

Oils

1.1 This test method is used to test hydraulic oils, aircraft

D 445 Test Method for Kinematic Viscosity of Transparent

turbine engine lubricants, and other highly refined oils to

and Opaque Liquids (and the Calculation of Dynamic

determine their resistance to oxidation and corrosion degrada-

Viscosity)

tion and their tendency to corrode various metals. Petroleum

D 664 Test Method for Acid Number of Petroleum Products

and synthetic fluids may be evaluated using moist or dry air

by Potentiometric Titration

with or without metal test specimens.

D 1193 Specification for Reagent Water

1.2 This test method consists of a standard test procedure,

D 3339 Test Method for Acid Number of Petroleum Prod-

an alternative Procedure 1 and an alternative Procedure 2. As

ucts by Semi-Micro Color Indicator Titration

there are variations possible with this test method, it will be up

2.2 U.S. Federal Test Method Standards:

to the particular specification to establish the conditions

Method 5307.2, Corrosiveness and Oxidation Stability of

required. In addition to temperature, the variables to specify if

Aircraft Turbine Engine Lubricants

other than those of the standard procedure or alternative

Method 5308.7 Corrosiveness and Oxidation Stability of

Procedure 1 or 2 are: test time, air flow and humidity, sample

Light Oils (Metal Squares)

frequency, test fluid quantity, and metal specimen(s).

MIL-S-13282 Refined Silver (99.95) (P07015)

1.3 The values stated in acceptable SI units are to be

2.3 Other Standards:

regarded as standard. The values in parentheses are for

AMS 4616 Silicon Iron Bronze (C65900)

information only.

AMS 4908 Titanium Alloy—(8 % Mn) Annealed (R56080)

1.4 This standard does not purport to address all of the

AMS 6490 Steel (M50) (T11350)

safety concerns, if any, associated with its use. It is the

QQ-A-671 Cadmium Anod (L01900)

responsibility of the user of this standard to establish appro-

QQ-C-576 Copper Electrolytic Tough Pitch (ETP)

priate safety and health practices and determine the applica-

(C11000)

bility of regulatory limitations prior to use.

QQ-M-44 Magnesium Alloy AZ31B Condition H24 or H26

2. Referenced Documents (M11311)

2.1 ASTM Standards:

1 2

This test method is under the jurisdiction of ASTM Committee D-2 on Annual Book of ASTM Standards, Vol 05.01.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 11.01.

D02.09 on Oxidation. Annual Book of ASTM Standards, Vol 05.02.

Current edition approved June 10, 1999. Published August 1999. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as D 4636–86. Withdrawn 1994 and reinstated January 1997. Last Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

previous edition D 4636–98. See ASTM DS 56, Metal and Alloys in the Unified Numbering System.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4636

QQ-S-698 Low-Carbon Steel 1010, CR Temper No. 4 or 5 ated conditions likely will cause one or more of the following

(G10100) measurable effects: mass change and corroded appearance of

QQ-A-250/4 Aluminum Alloy 2024 T-3 or T-4 (A92024) some metals; change of viscosity; increase in acid number;

measurable reaction products in the form of sludge; and mass

3. Summary of Test Method

loss of oil due to evaporation.

4.3 This test method is most suitable for oils containing

3.1 This test method consists of a standard test procedure

oxidation and corrosion inhibitors. Without such ingredient(s)

(see 10.1), an alternative Procedure 1 (see 10.2), and an

the severe test conditions will yield rather drastic changes to

alternative Procedure 2 (see 10.3). The standard test procedure

the oil.

uses washer-shaped metal specimens stacked on the air tube,

200 mL of test oil, 10 L/h air flow rate, and periodic test oil

5. Apparatus

withdrawal and evaluation. Alternative Procedure 1 uses

5.1 The main apparatus consists of the following items of

washer-shaped metal specimens, 165 mL of test oil, 10 L/h air

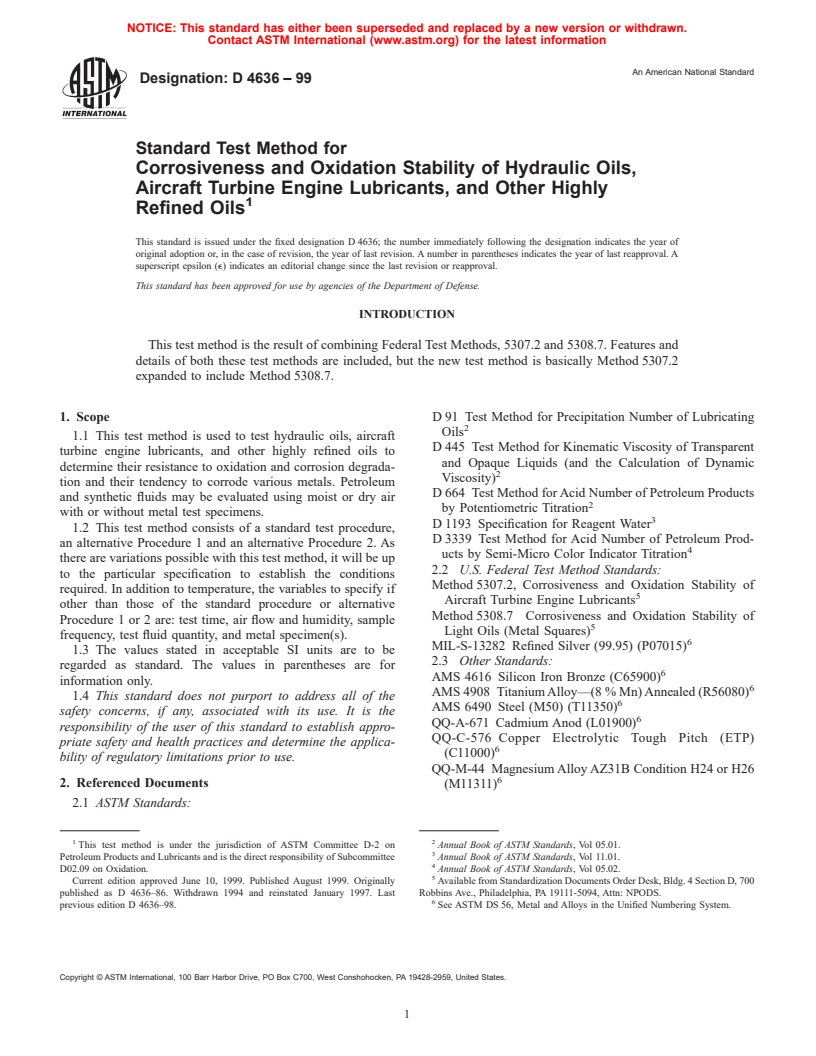

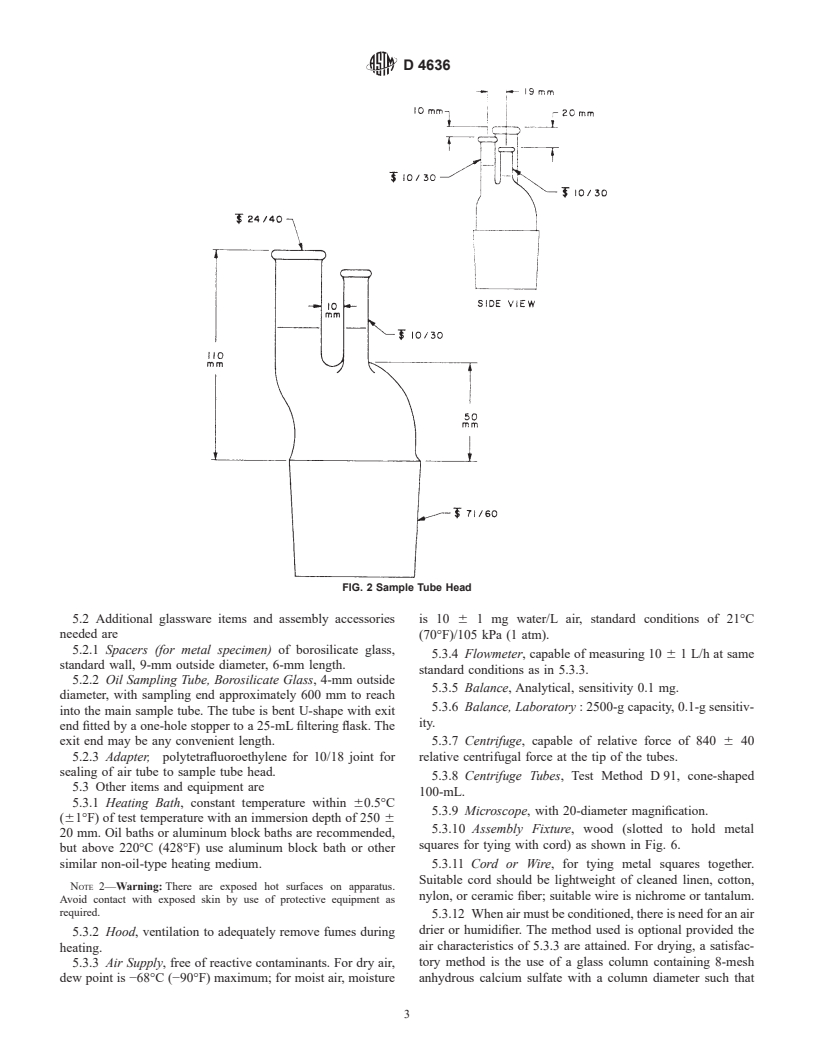

standard wall borosilicate glassware as shown in Figs. 1-5:

flow rate, and no periodic test oil sampling. Alternative

5.1.1 Main Sample Tube (Fig. 1).

Procedure 2 uses square metal specimens tied together resting

5.1.2 Sample Tube Head (Fig. 2).

vertically in the large glass tube, 100 mL of test oil, 5 L/h air

5.1.3 Air Tube (Fig. 3).

flow rate, and no periodic test oil sampling.

5.1.4 Condenser, Allihn Type (Fig. 4).

NOTE 1—Flow rates other than those listed in this test method may be

5.1.5 Condenser, Allihn Type, Fig. 4 with 71/60 joint.

required by various specifications; if they are so used, the modification to

5.1.6 Assembled Apparatus (Fig. 5).

the test method should be stated in the test report.

3.2 A large glass tube containing a sample of oil and metal

specimens is placed in a constant temperature bath and heated

An 800-mm air tube may be used for alternate Procedure 1 or 2 when using the

for the specified number of hours while air is passed through

condenser as opposed to the sample tube head in the standard procedure.

the oil to provide agitation and a source of oxygen. Typically,

temperatures of the bath used are from 100°C (212°F) to 360°C

(680°F). Weighed metal specimens are placed in the tube

during the test. Corrosiveness of the oil is determined by loss

in metal mass, and microscopic examination of the sample

metal surface(s). Oil samples are withdrawn from the test oil

and checked for changes in viscosity and acid number as a

result of the oxidation reactions.

3.3 Metals used in the basic test and alternative test Proce-

dure 1 are titanium, magnesium, steel (two types), bronze,

silver, and aluminum. Metals used in alternative test Procedure

2 are copper, steel, aluminum, magnesium, and cadmium.

Other metals may be specified.

3.4 Sampling of the oil for analysis is done periodically

throughout the test. Alternatively no periodic samples are taken

and a final viscosity and acid number are determined for

comparison with those of the original untested oil.

3.5 At the end of the test the amount of sludge present in the

oil remaining in the same tube is determined by centrifugation.

Also the quantity of oil lost during the test is determined

gravimetrically.

3.6 Air is used dry in the standard test. A humidifier may be

used to provide controlled moist air, if required.

4. Significance and Use

4.1 This test method simulates the environment encountered

by fully formulated lubricating fluids in actual service and uses

an accelerated oxidation rate to permit measurable results to be

obtained in a reasonable time. The use of metals provides

catalytic reactive surfaces of those materials commonly found

in real systems. The high temperature and air agitation help

accelerate the oxidation reactions that are expected to occur.

Moisture in the air adds another realistic condition that

encourages oil breakdown by facilitating acid formation.

4.2 Interpretation of results should be done by comparison

with data from oils of known field performance. The acceler- FIG. 1 Sample Tube

D 4636

FIG. 2 Sample Tube Head

5.2 Additional glassware items and assembly accessories is 10 6 1 mg water/L air, standard conditions of 21°C

needed are

(70°F)/105 kPa (1 atm).

5.2.1 Spacers (for metal specimen) of borosilicate glass,

5.3.4 Flowmeter, capable of measuring 10 6 1 L/h at same

standard wall, 9-mm outside diameter, 6-mm length.

standard conditions as in 5.3.3.

5.2.2 Oil Sampling Tube, Borosilicate Glass, 4-mm outside

5.3.5 Balance, Analytical, sensitivity 0.1 mg.

diameter, with sampling end approximately 600 mm to reach

5.3.6 Balance, Laboratory : 2500-g capacity, 0.1-g sensitiv-

into the main sample tube. The tube is bent U-shape with exit

ity.

end fitted by a one-hole stopper to a 25-mL filtering flask. The

exit end may be any convenient length. 5.3.7 Centrifuge, capable of relative force of 840 6 40

5.2.3 Adapter, polytetrafluoroethylene for 10/18 joint for

relative centrifugal force at the tip of the tubes.

sealing of air tube to sample tube head.

5.3.8 Centrifuge Tubes, Test Method D 91, cone-shaped

5.3 Other items and equipment are

100-mL.

5.3.1 Heating Bath, constant temperature within 60.5°C

5.3.9 Microscope, with 20-diameter magnification.

(61°F) of test temperature with an immersion depth of 250 6

5.3.10 Assembly Fixture, wood (slotted to hold metal

20 mm. Oil baths or aluminum block baths are recommended,

squares for tying with cord) as shown in Fig. 6.

but above 220°C (428°F) use aluminum block bath or other

similar non-oil-type heating medium. 5.3.11 Cord or Wire, for tying metal squares together.

Suitable cord should be lightweight of cleaned linen, cotton,

NOTE 2—Warning: There are exposed hot surfaces on apparatus.

nylon, or ceramic fiber; suitable wire is nichrome or tantalum.

Avoid contact with exposed skin by use of protective equipment as

required.

5.3.12 When air must be conditioned, there is need for an air

drier or humidifier. The method used is optional provided the

5.3.2 Hood, ventilation to adequately remove fumes during

air characteristics of 5.3.3 are attained. For drying, a satisfac-

heating.

tory method is the use of a glass column containing 8-mesh

5.3.3 Air Supply, free of reactive contaminants. For dry air,

dew point is −68°C (−90°F) maximum; for moist air, moisture anhydrous calcium sulfate with a column diameter such that

D 4636

FIG. 4 Condenser, Allihn Type

6.2 Purity of Water— Unless otherwise indicated, refer-

FIG. 3 Air Tube

ences to water shall be understood to mean reagent water as

defined by Specification D 1193. Referee situations require

velocity of air does not exceed 1.2 m/min. For humidifying, a

Type II distilled water defined by Specification D 1193.

satisfactory device is included in Appendix X1 to provide the

6.3 Metal Specimens:

required moist air.

6.3.1 Washer-Shaped Metal Specimens, 6.35-mm ( ⁄4-in.)

5.3.13 Oven, optional, to dry glassware at elevated tempera-

inside diameter by 19.05-mm ( ⁄4-in.) outside diameter by 0.81

ture.

mm (0.032 in.) thick in the following metals:

5.3.14 Forceps, stainless steel.

R56080 Titanium 8 % Mn

5.3.15 Thermocouple , 70 cm (27.6 in.) sheathed.

M11311 Magnesium AZ31B

5.3.16 Brush, short-bristled, stiff (typewriter cleaning brush

T11350 Steel M50

G10100 Steel grade 1010

or equivalent).

C65900 Silicon-iron-bronze

P07015 Silver 99.95

6. Reagents and Materials

A92024 Aluminum Alloy 2024 T-3 or T-4

6.1 Purity of Reagents—Reagent grade chemicals shall be

6.3.2 Square-Shaped Metal Specimens (as shown in Fig. 6),

used in all tests. Unless otherwise indicated it is intended that

0.81-mm (0.032-in.) by 25.4-mm (1-in.) square in the follow-

all reagents conform to the specifications of the Committee on

ing metals:

Analytical Reagents of the American Chemical Society where

C11000 Copper (ETP)

such specifications are available. Other grades may be used

G10100 Steel Grade 1010

A92024 Aluminum Alloy 2024 T-3 or T-4

provided it is first ascertained that the reagent is of sufficiently

M11311 Magnesium AZ31B

high purity to permit its use without lessening the accuracy of

L01900 Cadmium Anod

the determination.

6.4 Abrasive Paper, silicon carbide, various grades, includ-

ing 240 and 400 grit. Many papers, including “wet or dry,”

“waterproof,” or iron-containing abrasives, such as natural

A resistance temperature device (RTD) is also acceptable.

Reagent Chemicals, American Chemical Society Specifications, American

emery are not satisfactory.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, Satisfactory metal specimens may be obtained from: Metaspec Co., P.O. Box

MD. 27702, San Antonio, TX 78227-0707.

D 4636

6.8 Nitric Acid, concentrated.

NOTE 5—Warning: Poison. Corrosive. Strong oxidizer.

6.9 Degreasing Solvents: n-Heptane or toluene.

6.10 Carbon Remover for Glassware (Warning—See

Note 7)—Mix 35 mL of saturated sodium dichromate (aque-

ous) solution and 1000 mL of concentrated sulfuric acid.

NOTE 6—Warning: Corrosive.

6.11 Glassware Cleaning Solution (Warning—See Note

7)—Mix 35 mL of MICRO in water or 35 mL of NOCHRO-

MIX and 1000 mL of concentrated sulfuric acid.

NOTE 7—Warning: Causes severe burns.

6.12 Metal Cleaning Solution—Mix equal parts of 15 g

NaOH per litre of water and 15 g of Na PO per litre of water.

3 4

NOTE 8—Warning: Corrosive.

7. Hazards

7.1 As this test method investigates the corrosive effect of

oil on metal in an artificial environment, precautions must be

taken to prevent premature oxidation of metal specimens by

stray chemicals during test preparations. The cleaned speci-

mens shall be touched only by surfaces known to be free of

interfering contaminants. Do not touch cleaned specimen(s)

with hands. Maintain clean glassware (see Appendix X2) in a

dust-free cabinet; rinse again and dry if clean glass has been

FIG. 5 Assembled Apparatus

stored unused for more than a week.

7.2 Heating Bath, n-heptane, toluene, acetone, carbon re-

mover, nitric and sulfuric acids, and sodium hydroxide all

require caution in handling as detailed in Notes 2-8.

8. Sampling

8.1 As this test method is performed on uniform, finished

oils, no special sampling procedure is needed for this oil.

8.2 Preparation of Metal Specimens.

8.2.1 Collect the required number and types of specimens to

be used in the test method. Measure the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.